Production method for hematite for iron production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

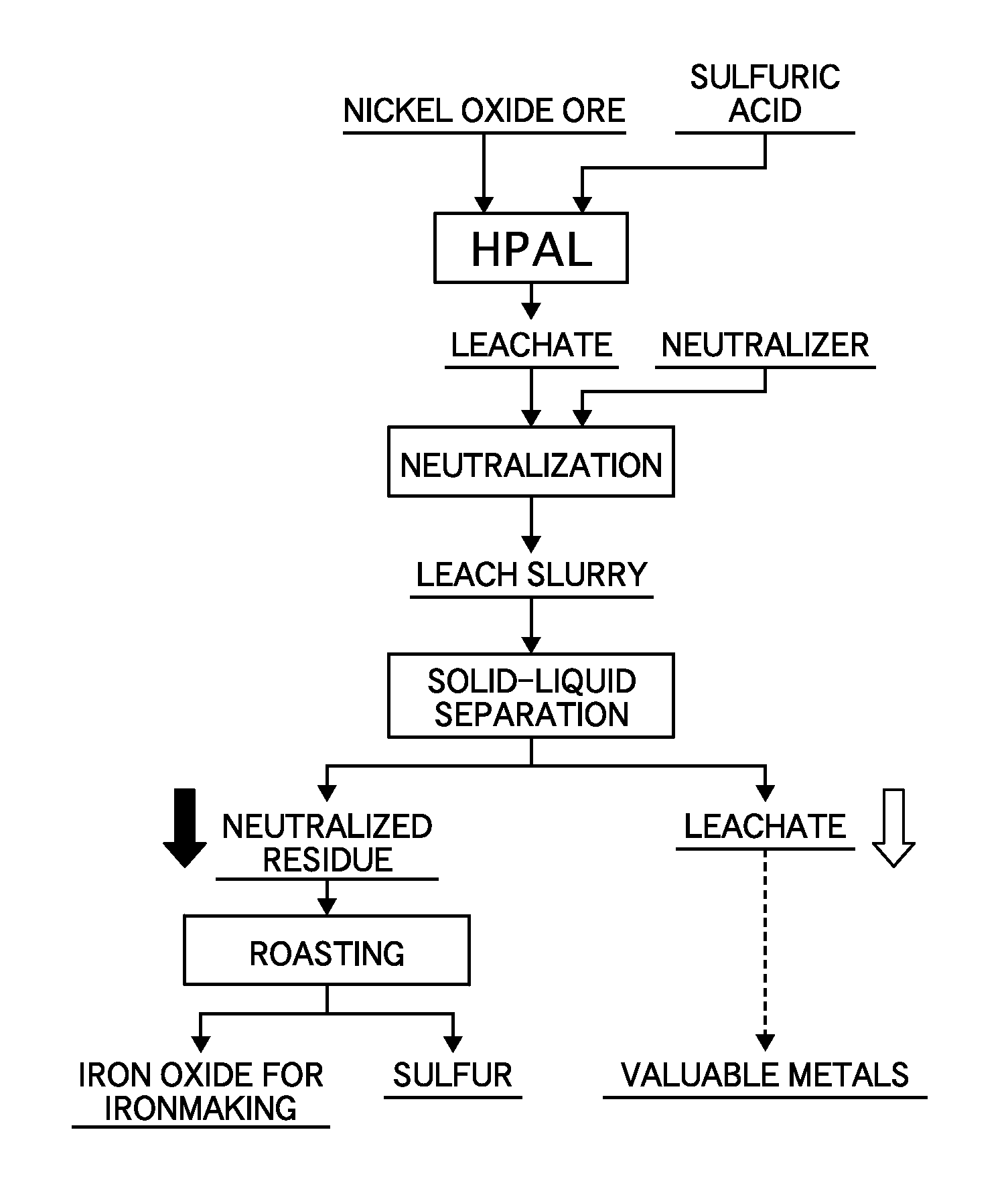

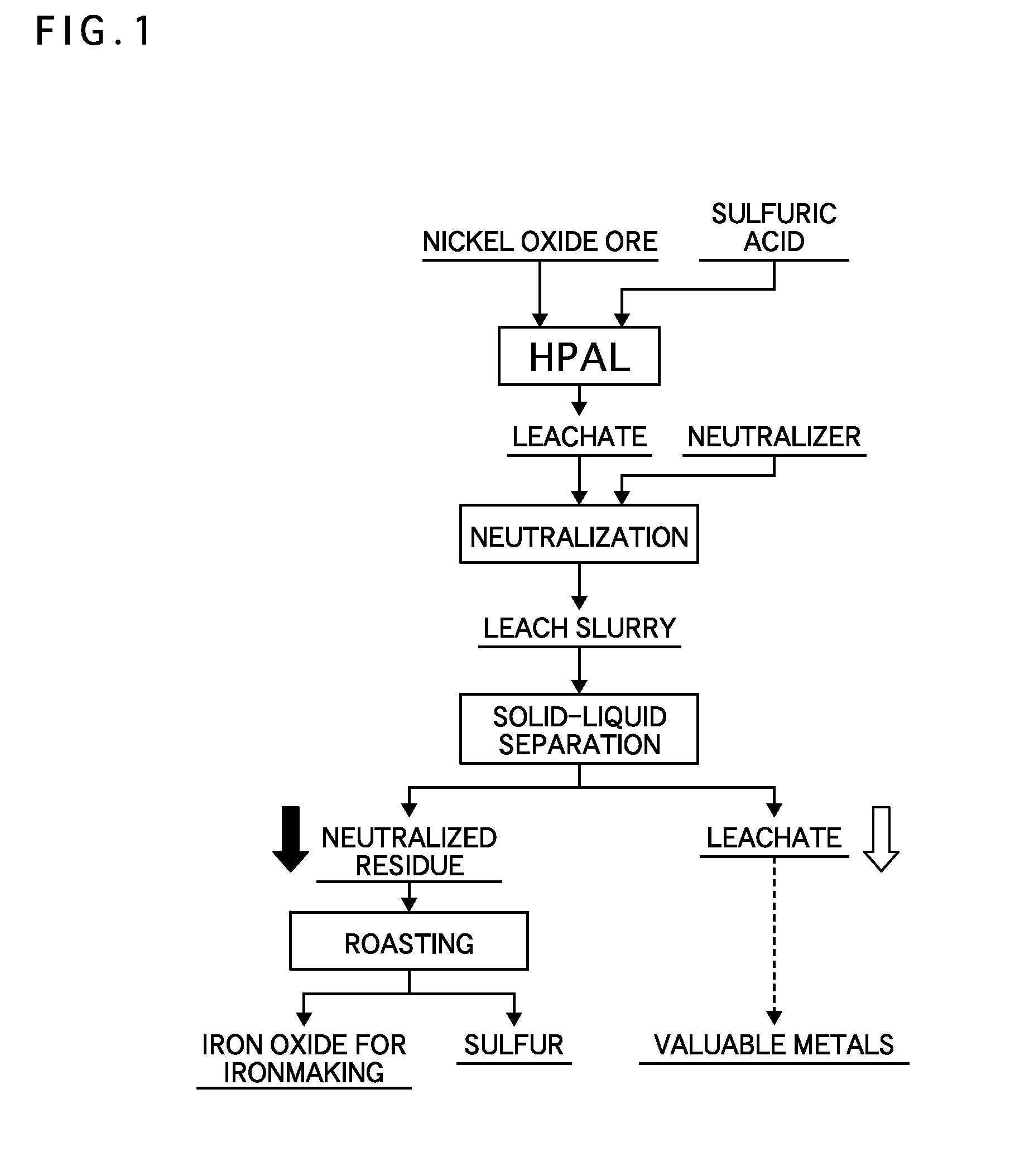

Problems solved by technology

Method used

Image

Examples

example 1

[0042]Nickel oxide ore having 1% nickel grade and 46 to 48% iron grade was adjusted to be a slurry of 30 to 40% by weight, and then was mixed with sulfuric acid of 64% by weight. Subsequently, the slurry was charged into a pressure device, heated to 240 to 250° C., and maintained for one hour, and a leachate was obtained by leaching nickel in the ore (HPAL).

[0043]After the leaching, the leachate was cooled to about 70° C., and then slaked lime was added to neutralize a surplus acid (neutralization). The slurry containing a leach residue after the surplus acid was neutralized (hereinafter the leach residue after the neutralization is referred to as “neutralized residue’) was subjected to solid-liquid separation using Nutsche and a filtering bottle, and was separated into the leachate and the neutralized residue (solid-liquid separation).

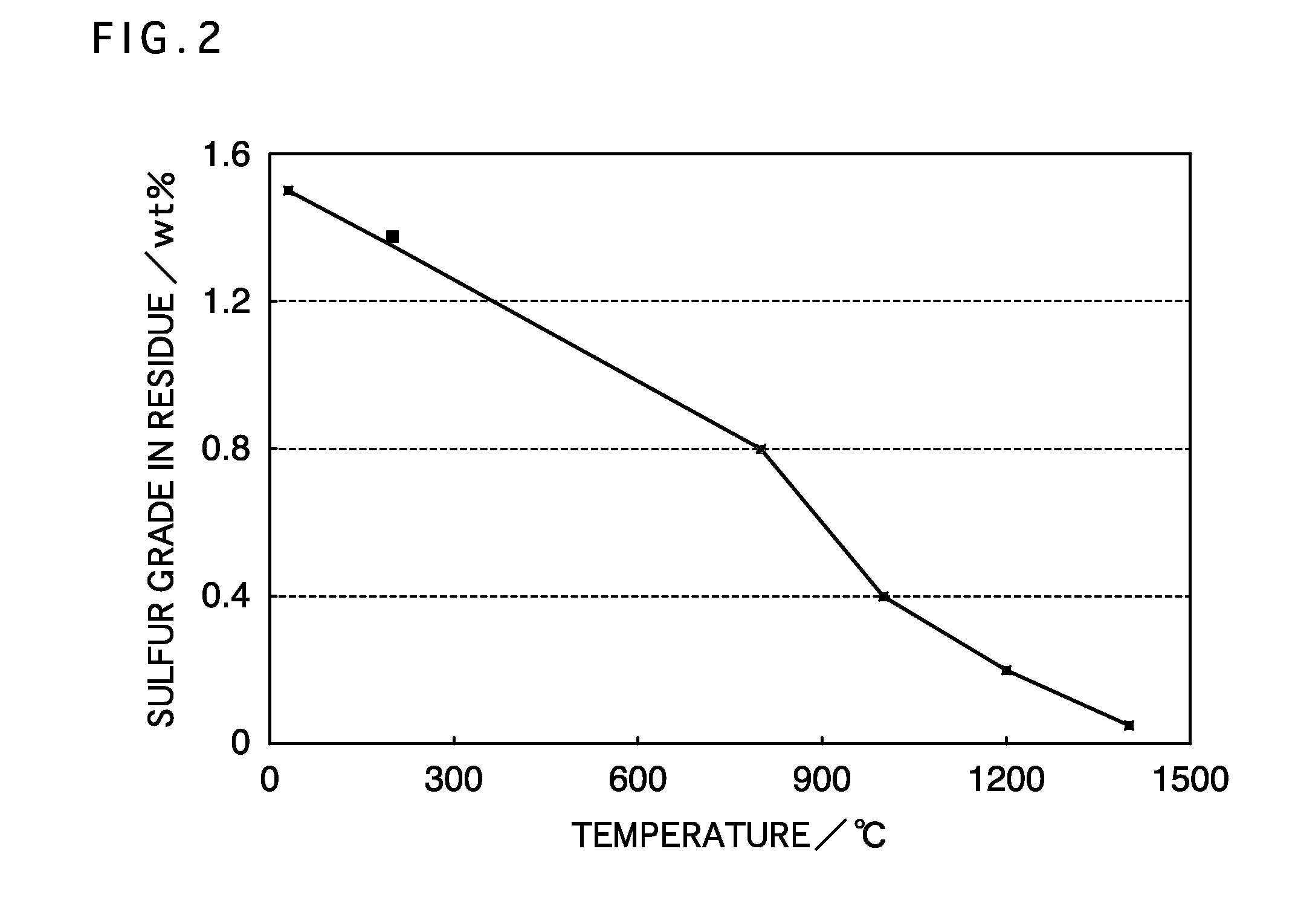

[0044]In the neutralized residue, an iron grade was 49.9%, and a sulfur grade was 1.5%.

[0045]Next, the neutralized residue was equally divided into s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com