Low-Stringiness Thickener and Cosmetic Material Admixed with Said Thickner

a technology of low stringiness and thickener, which is applied in the direction of pharmaceutical active ingredients, medical preparations, toilet preparations, etc., can solve the problems of poor spreadability, inability to separate properties, and high demand for synthetic polymer compounds, so as to improve the stringiness, sliminess, and stickiness. , the effect of improving the stringiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Precision Synthesis of Sodium Polyacrylate and Sodium PAMPS

[0035]By the RAFT polymerization method, which is a living radical polymerization, six kinds of sodium polyacrylate with different weight-average molecular weights and four kinds of sodium PAMPS with different weight-average molecular weights were precision-synthesized. Detailed procedures are shown below. In the below-described synthesis reactions, 4,4′-azobis-(4-cyanovaleric acid) (V-501, manufactured by Wako Pure Chemical Industries, Ltd.) was used as the polymerization initiator, and 4-cyanopentanoic acid dithiobenzoate (synthesized according to NPL 1, hereinafter abbreviated as CPD) was used as the chain transfer agent. As the chain transfer agent, α-(methyltrithiocarbonate)-S-phenylacetic acid (synthesized according to NPL 2, normally abbreviated as MTPA) may also be used.

[0036]Acrylic acid (2511 mg) and V-501 (0.17 mg) were dissolved in ion-exchanged water (9 mL), a methanol solution (1 mL) in which CPD (0.17 mg) had ...

example 2

Molecular Weight Distribution of Precision-Synthesized Sodium Polyacrylate and Sodium PAMPS

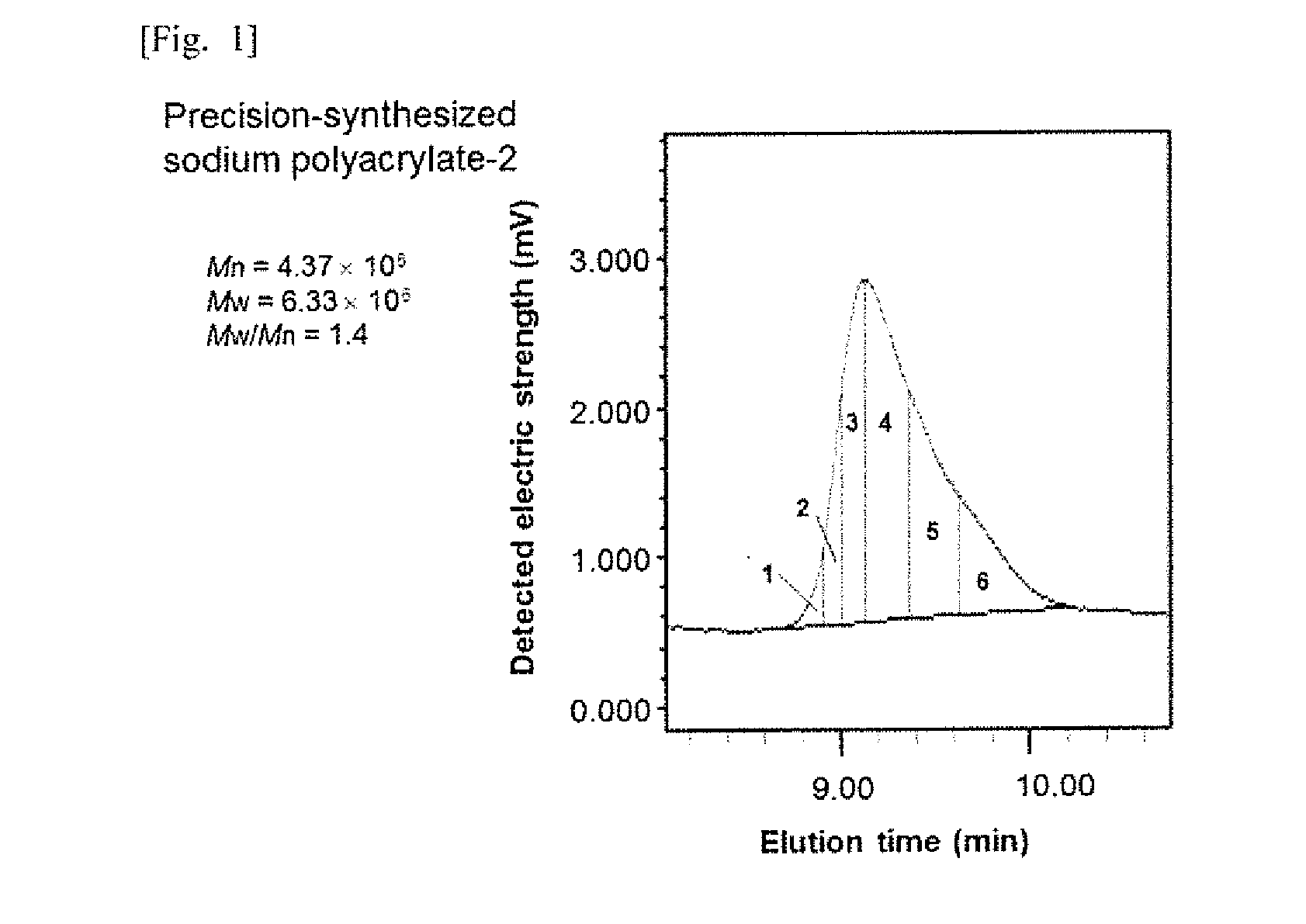

[0048]The elution peak obtained in the GPC analysis of the above-described precision-synthesized sodium polyacrylate-2 (GPC analysis chart) is shown in FIG. 1. The weight-average molecular weight is 6.33×106, and the number-average molecular weight is 4.376×106; therefore, the molecular weight distribution (weight-average molecular weight / number-average molecular weight) is 1.4. Accordingly, the precision-synthesized sodium polyacrylate-2 synthesized by the method of the present invention is seen to be a uniform molecular weight compound.

[0049]In the following, the above-described GPC analysis chart was divided into six regions for the respective compounds having the below-described molecular weights (FIG. 1), and the area percentages of the respective regions were determined. The results are shown in Table 1.

Region 1: compound whose molecular weight is three times or higher of the weight-aver...

example 3

Evaluation of Stringiness Property and Usability

[0061]In the following, the stringiness property and usability are evaluated, for the above-described polymer compounds, according to the methods explained below.

[0062]One mass % solution of each polymer compound was prepared and placed in a container at room temperature. The container was set on a texture analyzer (TA.XT Plus, manufactured by Stable Micro Systems), a round disk with the diameter of about 1 cm was uniformly and lightly contacted on the surface of the above-described solution, and the stringiness behavior of the solution was observed by letting down the container at the velocity of 5 mm / sec. The distance that the container descended, until the cut of the stringiness solution, was measured as the “stringiness length”. This stringiness length is the indicator of the stringiness property of polymer compounds, and “the larger the value, the stronger the stringiness property” (PTL 5). In this application, when the stringines...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| polymerization time | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com