A method of treating oily solid particles

a technology of oily solid particles and oil, applied in solvent extraction, separation processes, dewatering/demulsification with chemical means, etc., to achieve the effect of enhancing the efficiency of the disclosed method, reducing the oil content, and reducing the pressur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

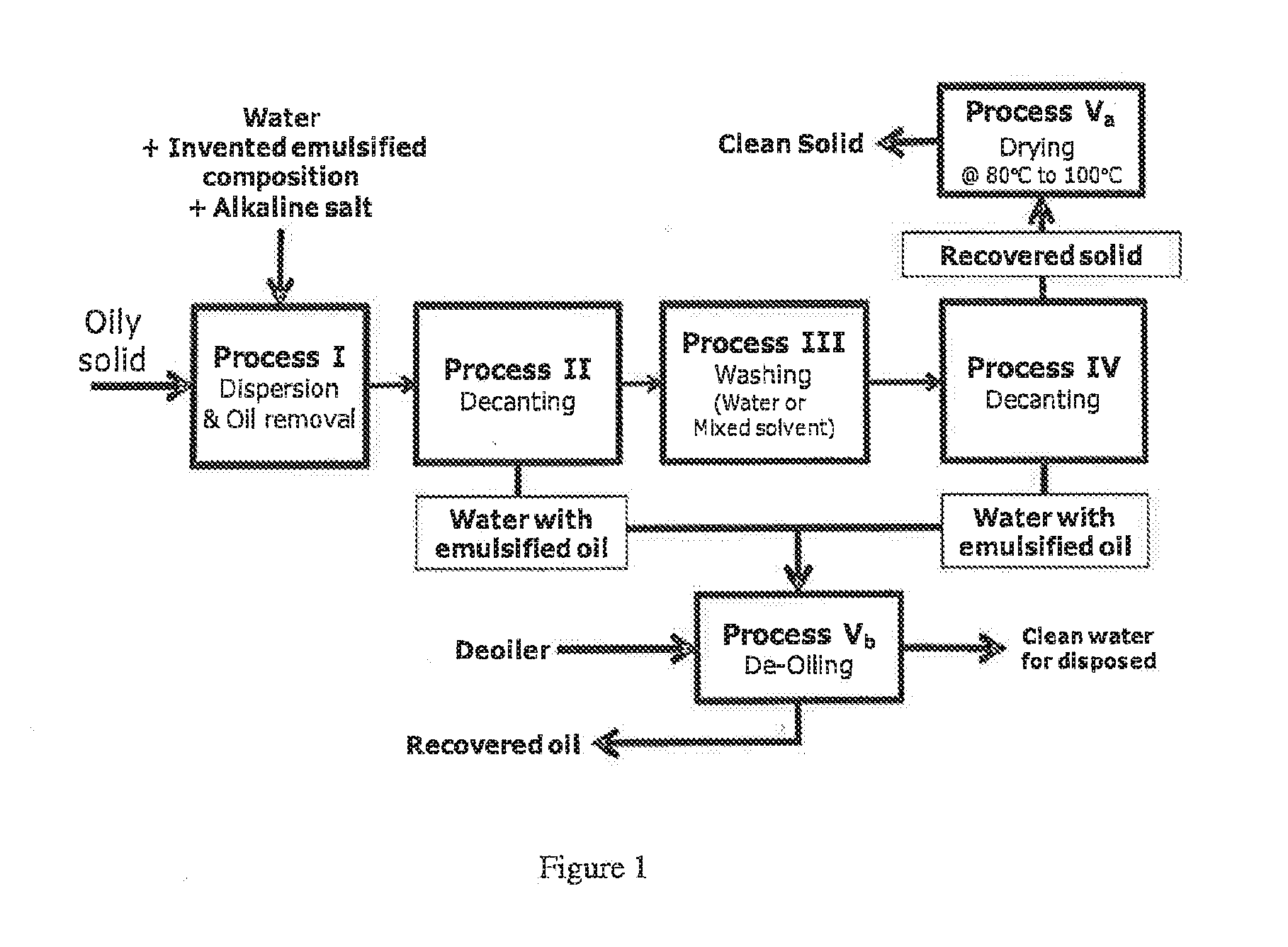

Image

Examples

example 1

[0034]The invented emulsified composition presented in following examples are water-in-oil nanoemulsion with oil-water interfacial tension lower than 0.01 mN / m (measured at 25° C. by KRUSS spinning drop tensiometer; model SITE100). The mean particle size of the nanoemulsion is smaller than 100 nm (measured at 25° C. by particle size analyzer; Malvern Zetasizer Nano ZS). The oily solid samples listed in TABLE 1 are the samples used in testing various embodiments of the present invention. The properties of each oily solid sample were determined by using the retort analysis. All samples are actual specimens from Oil & Gas industrial processes. Treatment on these oily solid samples aims to reduce the oil content in the disposed solid to <1 w / w %. The evaluation of the effectiveness of the invented emulsified composition, treatment process and other related cleaning chemicals are demonstrated in the next EXAMPLEs.

TABLE 1Composition of oily solid samples from retort analysis% Total% Wax (...

example 2

[0035]The efficiency of the invented oily solid treatment method and cleaning chemical composition was evaluated with different process steps and cleaning chemicals used. The efficiency of the process was referred to the total oil content in the solid after final treatment. Oil content was determined by the retort analysis and / or Soxhlet solvent extraction (if the oil content was expected to be <1 w / w %). The typical target of the oil content in the solid after treatment is <1 w / w %. Sample A, which is drill cuttings had been used for the experiment in this EXAMPLE. Sodium carbonate, sodium tripolyphosphate and potassium hydroxide had been used as the alkaline salt to adjust the pH of the cleaning solution to 8-12. The cleaning solution / sample ratio is 1 / 1 by weight. The washing solvent was water or water mixed with co-solvent (ethylene glycol, isopropanol, or butoxyethanol). Water was the solvent of cleaning solution for the first process step. The % concentration of cleaning solut...

example 3

[0048]The treatment of different kinds of oily solid samples was evaluated in this example. There are 4 kinds of samples shown in TABLE 1 which are drill cuttings (experiment A8), sand produced from oil production well (experiment B1), solid sediment from the used oil-based drilling fluid (experiment C1), and crude oil sludge solid sediment (experiment D1, D2 & 0.15 D3). The cleaning solution in the first process step contains 1 w / w % of the invented emulsified composition and 5 w / w % sodium carbonate in water. Water was used as the washing agent in the washing step. All experiments used drying process as the final treatment step. It was indicated that the oil could be efficiently removed from the solid for sample A, B and C (experiment A6, B1 and C1, respectively) effectively, reducing the oil content in the solid samples from 12-13 w / w % to <1 w / w %.

[0049]However, the same cleaning solution composition used to treat these 3 samples was not very effective for sample D (experiment D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| particle size analyzer | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com