Botulinum toxin compositions

a technology of botulinum toxin and composition, which is applied in the field of improved botulinum toxin pharmaceutical composition, can solve the problems of loss of active ingredient, loss of protein activity, etc., and achieve the effect of enhancing potency or stability, enhancing potency, and enhancing potency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

High Potency Botulinum Toxin Formulations (Research Method) with Various Ratios of Sodium Chloride to Albumin

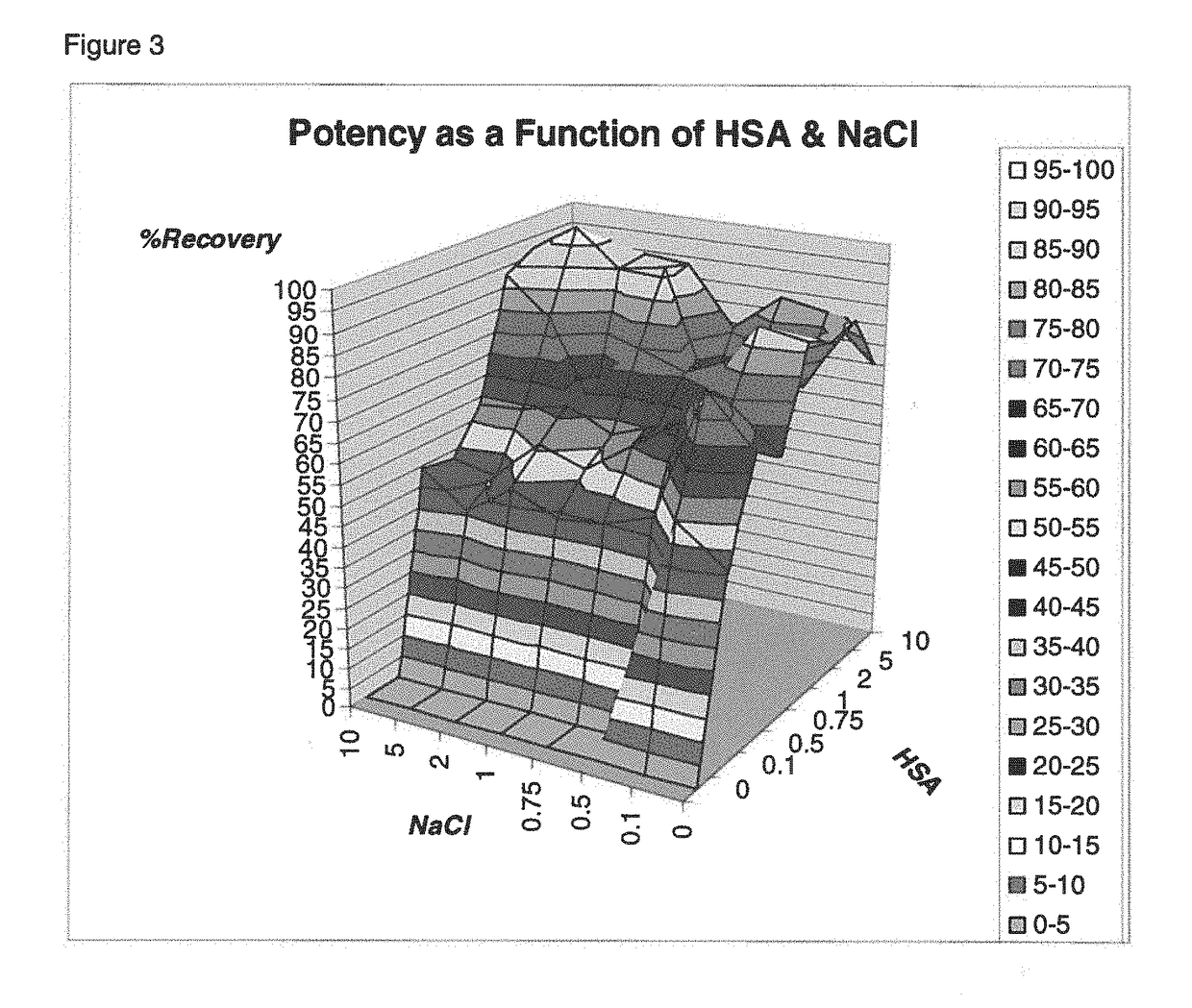

[0141]An experiment was carried out to assess the recovered potency of numerous botulinum toxin research vial formulations with the same amount of botulinum toxin type A complex in each formulation, but with different amounts of HSA and NaCl present in the each formulation. Thus, while 2.5 ng of the botulinum toxin was used consistently per vial, each formulation vial contained from 0N (0 μg) of HSA to 10N (5000 μg) of HSA, and from 0N (0 μg) of NaCl to 10N (9000 μg) of NaCl.

[0142]The data in Table 1 was obtained using research lot preparation procedures. Thus, the Table 1 data was obtained by mixing one of the specified seven different amounts of sodium chloride (NaCl) (from a 0.1N amount of 90 μg per vial to a 10N amount of 9000 μg per vial) with one of the specified three different amounts of human serum albumin (HSA) (Bayer) (from a 0.5N amount of 250 μg per vial to a 1N ...

example 2

High Potency Botulinum Toxin Formulations (Commercial Method) with Particular Ratio of Sodium Chloride to Albumin

[0148]A further experiment was carried out in which botulinum toxin pharmaceutical compositions were made (compounded) using botulinum toxin type A complex, sodium chloride and human serum albumin. Botulinum toxin pharmaceutical compositions containing differing ratios of sodium chloride to the HSA were compounded using commercial manufacturing lot procedures. The compositions were then either lyophilized and vacuum dried to a solid, powder) state, followed by reconstitution with saline and mouse LD50 recovered potency evaluation.

[0149]Results obtained are set forth in Table 3. The Table 3 data was obtained as follows: for the BOTOX data (last row in Table 3) 100 units vials of Botox® were reconstituted with normal saline followed by use of the mouse LD50 assay to measure potency. The 1N HSA, 2N HSA, 5N HSA and 10N HSA represent formulations compounded in the same way use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com