Liquid crystal device and liquid crystal apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

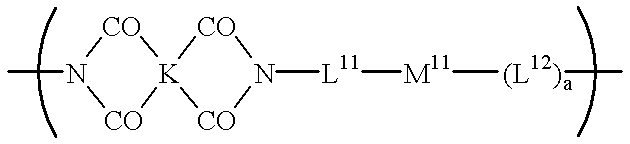

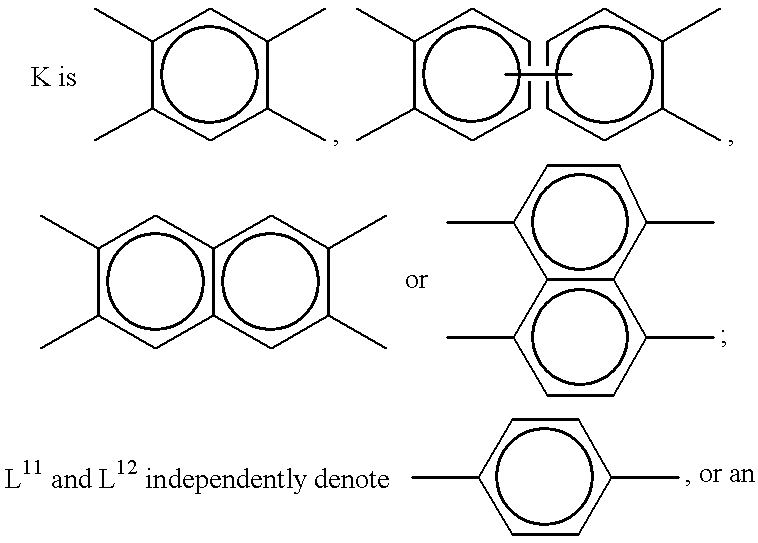

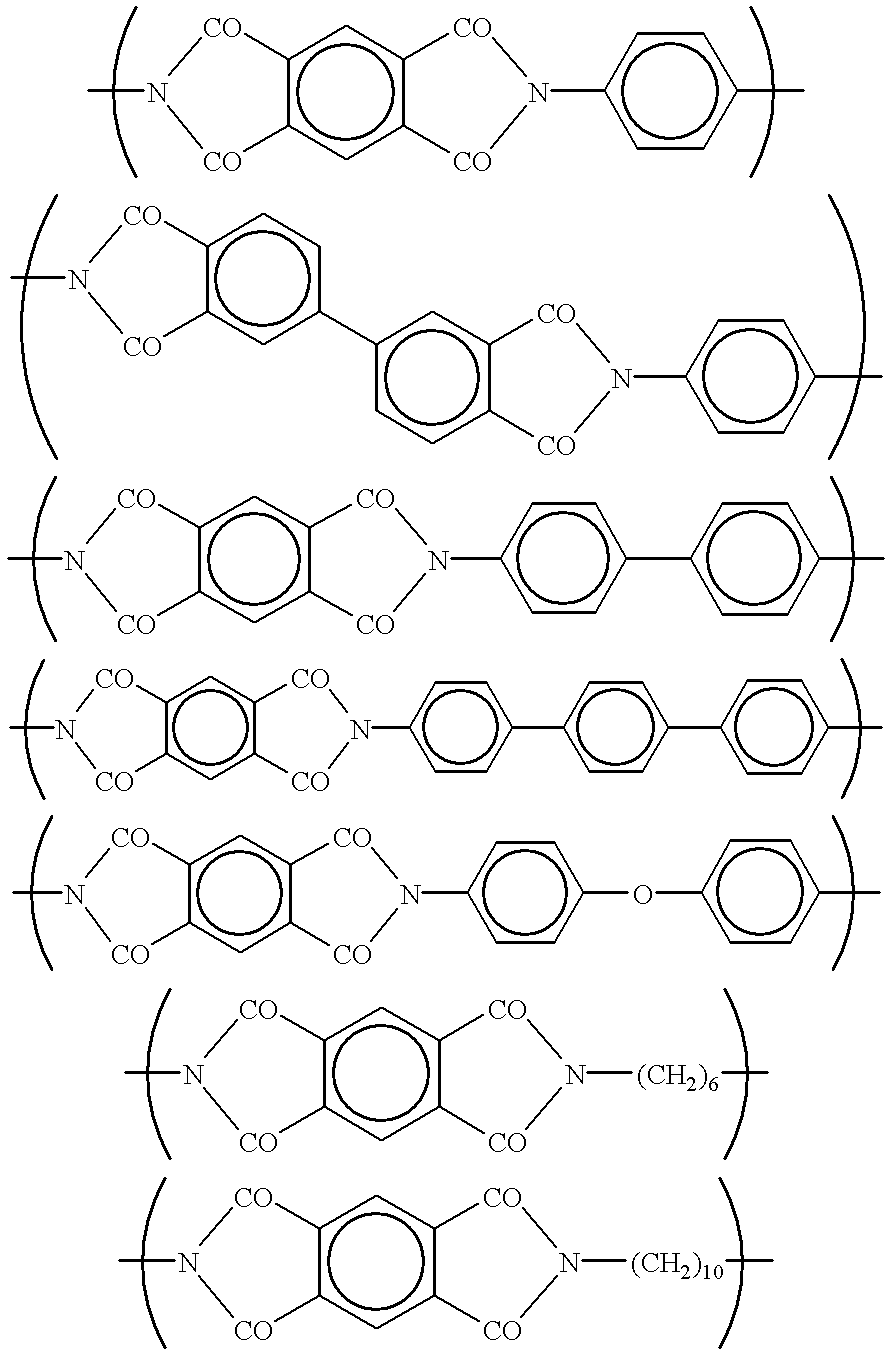

Method used

Image

Examples

example 2

A liquid crystal display device was prepared in the same manner as in Example 1 except that the liquid crystal composition A was changed to a liquid crystal composition B shown below.

In the above phase transition series, Sx denotes a smectic phase (unidentified); Sc denotes a smectic C phase; S.sub.A denotes a smectic A phase; and Iso denotes an isotropic phase.

The liquid crystal display device, similarly as in Example 1, provided a uniform alignment and could effect high quality display without malfunction at the time of high-speed switching. Further, the device provided a contrast of at least 100.

example 3

A liquid crystal display device was prepared in the following manner.

One electrical plate was prepared in the same manner as in the electrode plate including no masking member (as shown in FIGS. 2A-2E) in Example 1.

The other electrode plate as shown in FIG. 10 was prepared as follows.

On a double side-polished blue plate glass (300.times.310.times.1.1 mm), a 20 .mu.m-thick layer of Mo--Ta was formed by sputtering and patterned through a photolithographic-etching to form a glass substrate coated with a masking member including elongated portions each having a width of 18 .mu.m.

On the glass substrate, a photosensitive resin solution containing a green pigment dispersed therein was applied by spin coating and pre-dried at 80.degree. C., followed by spin coating and pre-dried at 80.degree. C., followed by exposure to light, development and hot backing at 250.degree. C. to form 1.3 .mu.m-thick stripe-shaped color filter segments of green in a width of 95 .mu.m. Similarly, a photosensitive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com