Microscopic imaging apparatus with flat-top distribution of light

a microscopic imaging and intensity distribution technology, applied in the field of global imaging apparatus, can solve the problems of limiting the development of global imaging methods, difficult manufacture of powell lenses, and misreading sample concentration, and achieve the effect of fast measured speed and realistic imag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

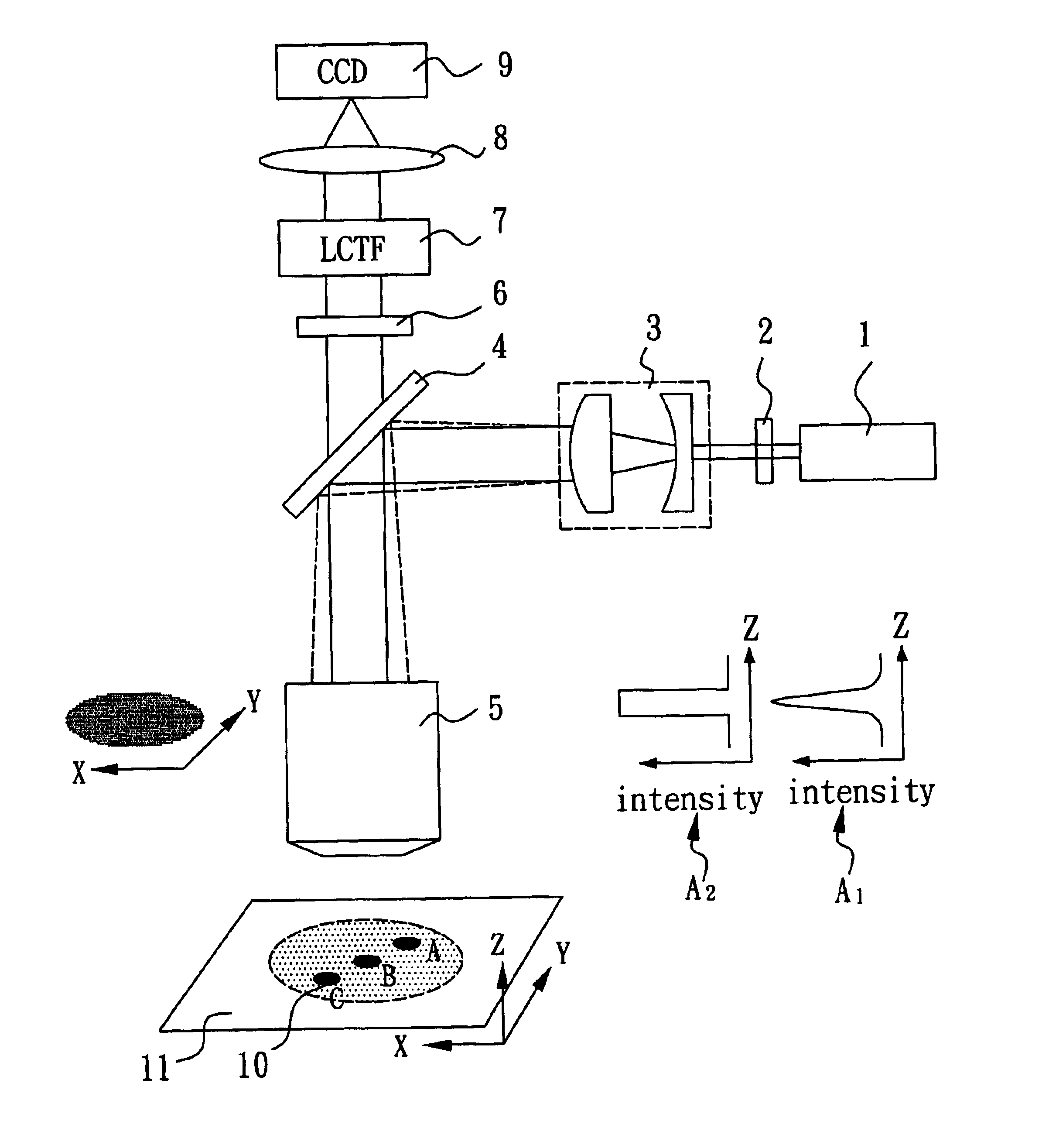

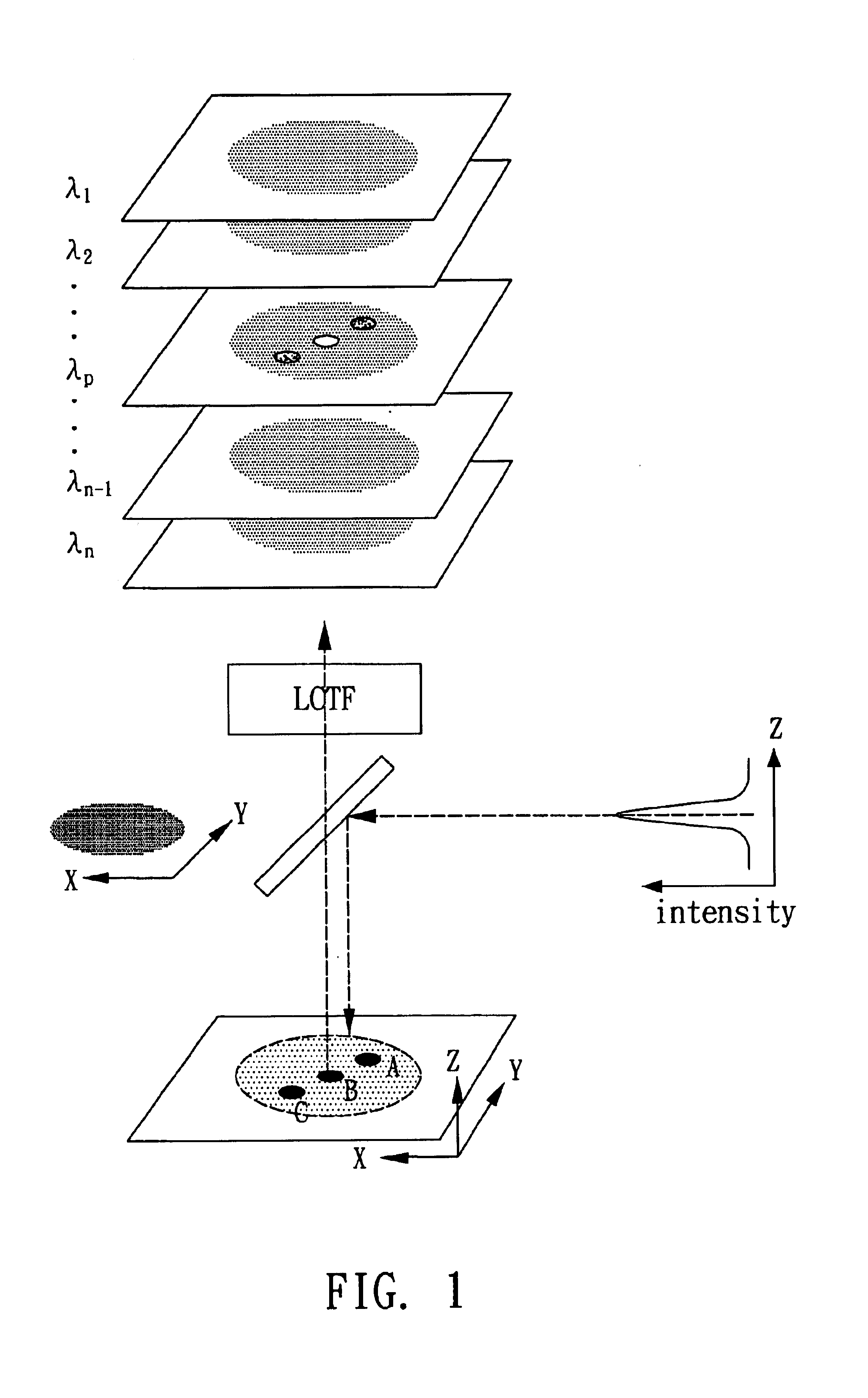

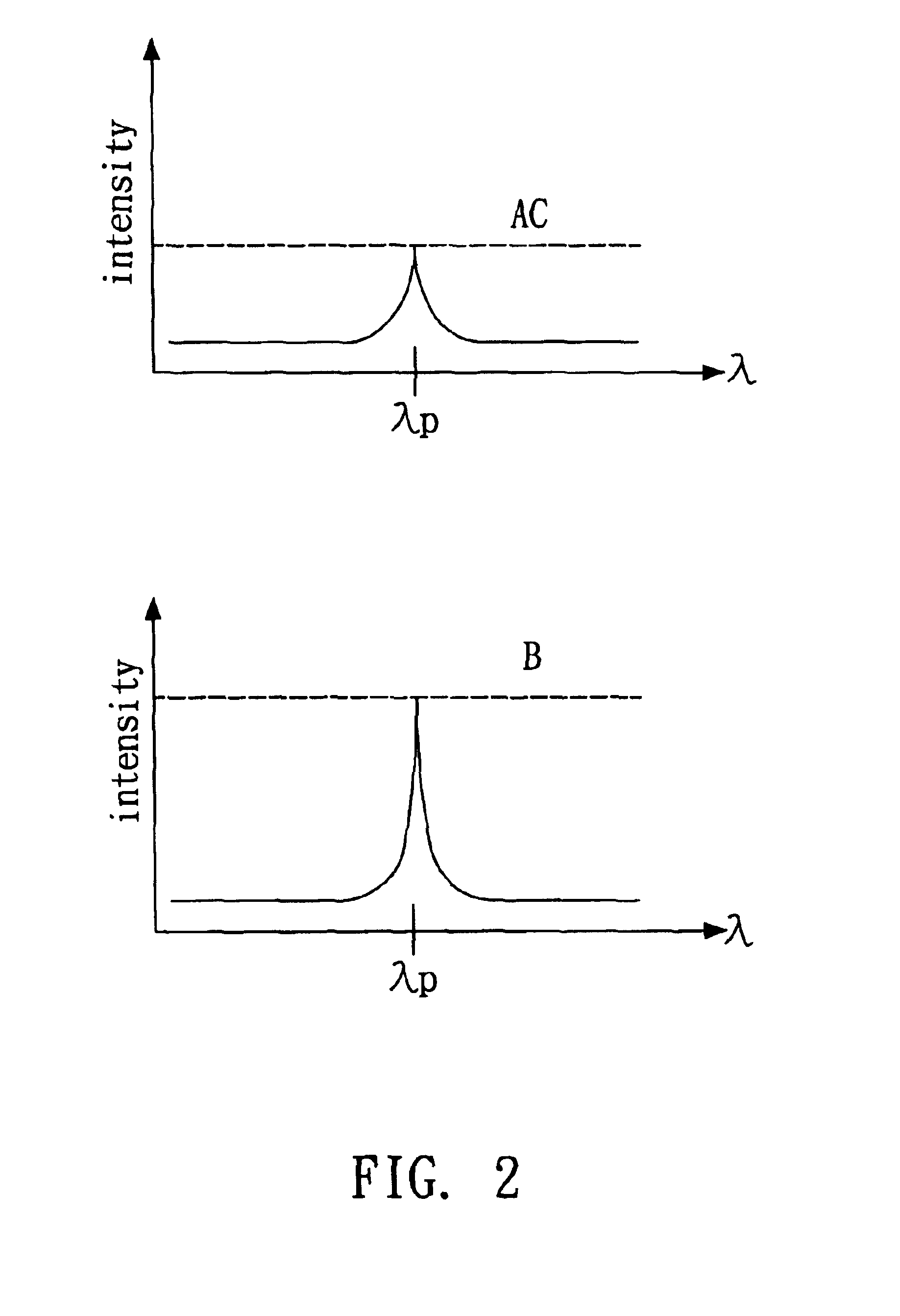

[0021]The preferred example illustrates the microscopic imaging apparatus of the present invention with the detection of polystyrene micro-spheres. With reference to FIG. 3, there is shown a microscopic imaging apparatus composed of an incident light source 1, a diffractive optical element 2, a beam expander 3, a beam-splitter 4, an objective lens 5, an optical filter 6, a tunable filter 7, an imaging lens 8, an image sensor 9, a sample 10, and a holder 11.

[0022]The incident light source 1 of the present example can be any kind of light source. Preferably, it is a light emitting diode or a laser diode, and most preferably, it is a laser. The diffractive optical element 2 is made of visible light or infrared rays passable materials. Preferably, the diffractive optical element 2 is made of quartz, polymethyl methacrylate (PMMA), or silicon according to the Scalar Diffraction Theory. The sample 10 is polystyrene micro-spheres. Preferably, the beam-splitter 4 is a dichroic mirror, the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com