Etchants containing filterable surfactant

a technology of surfactant and etching rate, which is applied in the direction of basic electric elements, electrical equipment, chemistry apparatus and processes, etc., can solve the problems of physical wetting by etchant solution on a substrate becoming more difficult, and achieve the effects of excellent surface active properties, superior wetting, and desirable etching ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparatory example

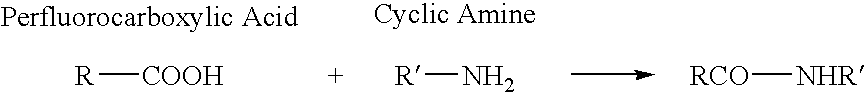

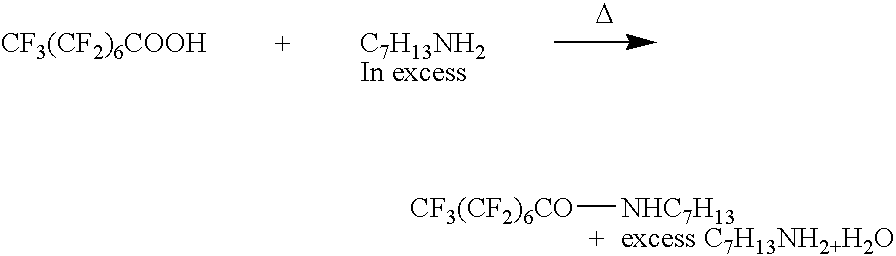

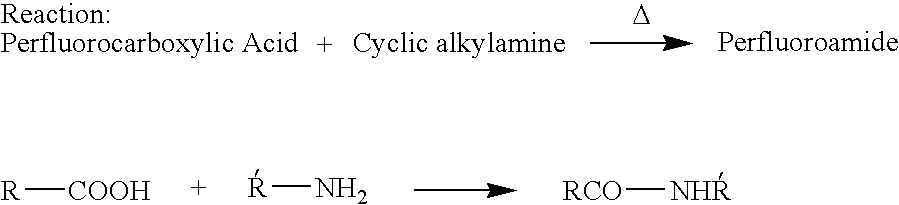

[0051]An aqueous solution of 10% of surfactant in 50% 2-propanol (by weight)[0052]i.e., refer to the reaction above of perfluorooctanoic acid and cycloheptyl amine.[0053]Composition of 100 g of 10% surfactant include:[0054]5 g Acid (approx. 99% purity)[0055]5 g amine (approx. 99% purity)[0056]45 g 2-propanol (approx. 99% purity)[0057]45 g deionized H2O

[0058]Various runs were conducted to demonstrate that the surfactant(s) met the desired criteria. Generally the experimental runs were carried out in pilot scale (1 lb. to 100 lbs. batches).

General Run

[0059]A preliminary testing was conducted prior to filtration to evaluate whether individual components of the claimed surfactant(s), would work individually, need modification, or require combining to give a basic understanding which would lead to synthesis of the surfactant(s) of the invention. Potential surfactant candidates were prepared and evaluated in an aqueous mixture comprised of about 35% by weight of ammonium fluoride, NH4F, a...

example 1

[0061]80 lbs. of an aqueous mixture comprised of 40% by weight of ammonium fluoride and 0.5% by weight of hydrofluoric acid (defined as BOE 100-1) was mixed with 500-ppm of surfactant “H” (a selected member of the claimed surfactant group as listed in Table I), by weight of the mixed etchant, and filtered through two 0.2-micron polyethersulfone (PES) filters. The surfactant mixture was not aggressively agitated, but circulated through filters runs for three days with interval samplings of approximately every four hours. The mean results are given in Table II below:

[0062]

TABLE IIBeforeAfterMeet SuccessProperties / CriteriaFiltrationFiltrationCriteria (Yes / No)Surface Tension1838Encouraged(dynes / cm2)Particulates (cts / ml)≧1.0 micron >3,00010Yes≧0.5 micron>10,00033YesFoamingInsignificantInsignificantYes[0063]The surface tension was found to increase following filtration. Data indicates the surfactants were removed during filtration, and failed to meet one of the success criteria. Another e...

example 2

[0064]200 ppm of surfactant “H” (Table I) were added into an aqueous mixture comprising of about 35% by weight of ammonium fluoride and about 6.3% by weight of hydrofluoric acid (defined as BOE 7-1), and without agitation, the mixture was circulated through two −0.2 μm filters (PES and Teflon or otherwise known as polytetrefluoroethylene or PTFE) and the results are given in Table III below:

[0065]

TABLE IIIBeforeAfterMeet SuccessProperties / CriteriaFiltrationFiltrationCriteria (Yes / No)ST (dynes / cm2)2036EncouragedPC:≧1.0 μm—6Yes≧0.5 μm—82YesFoamInsignificantInsignificantYes

[0066]Results similar to those of Example 1 were seen, despite different blends, concentrations of ammonium fluoride and hydrofluoric acid and different sets of filters (1 PES+1 Teflon instead of 2 PES). At this point, it was unknown whether the surfactant(s) filtered out or was not fully solubilized within the etching solution. A mechanical rotating blade mixer was introduced into the small pilot scale reactor to en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com