Integrated circuit for driving semiconductor device and power converter

a technology of integrated circuits and semiconductor devices, which is applied in the direction of substation/switching arrangement details, power conversion systems, semiconductor/solid-state device details, etc., can solve the problems of reducing the chip size, affecting and affecting so as to improve the reliability of noise immunity, the chip area is increased, and the development period and cost of semiconductor chips are reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 2

[0070]A second embodiment of the present invention will be described with reference to FIGS. 8 through 13. FIGS. 8 through 11 show the construction of a driver IC of this embodiment. FIG. 12 shows parasitic capacitance in a level shift circuit of the driver IC of this embodiment. FIG. 13 shows the circuit arrangement of the driver IC of this embodiment. In the following, only the construction differing from that of the above-mentioned embodiment will be described and a description of the remaining similar construction is omitted.

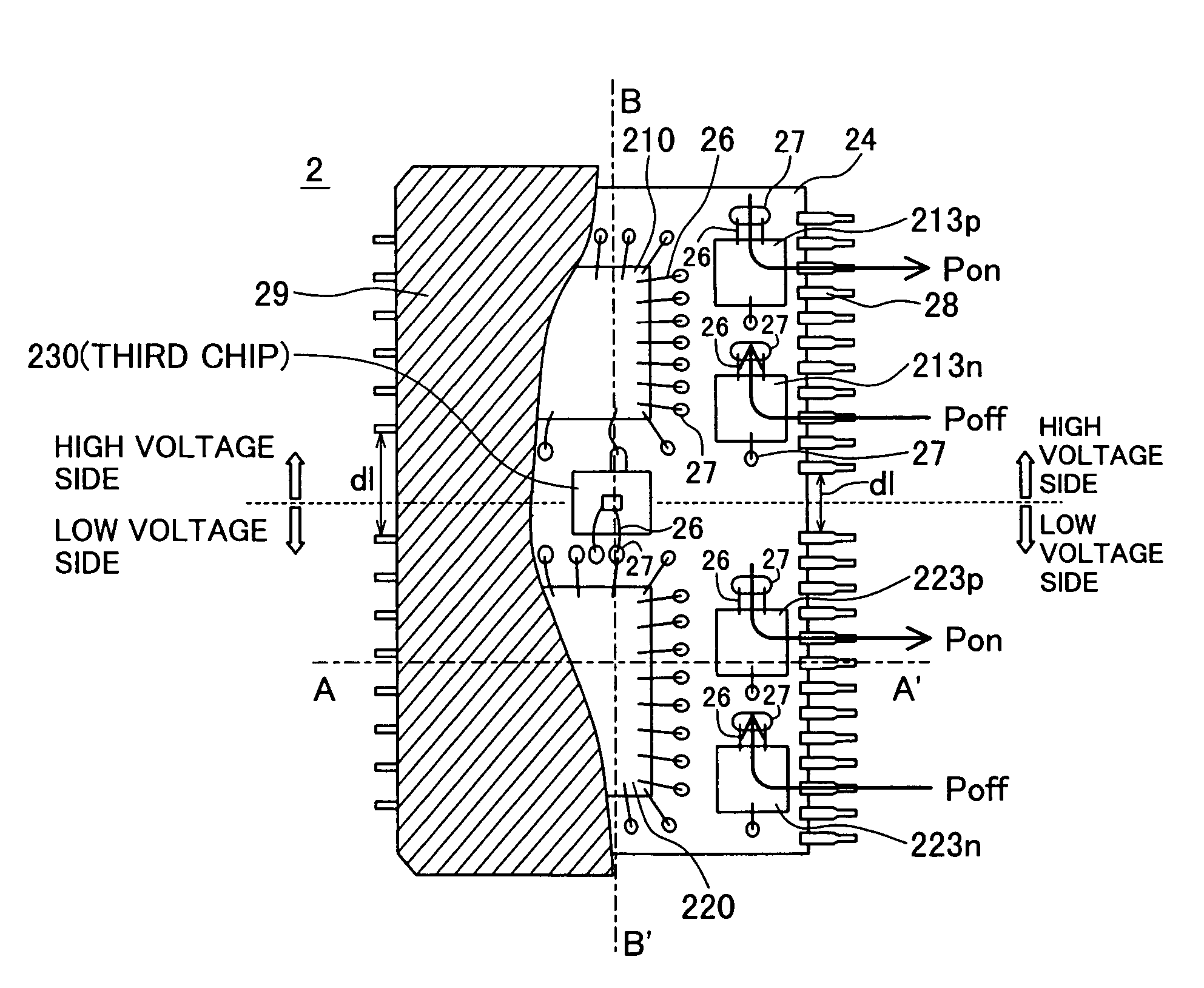

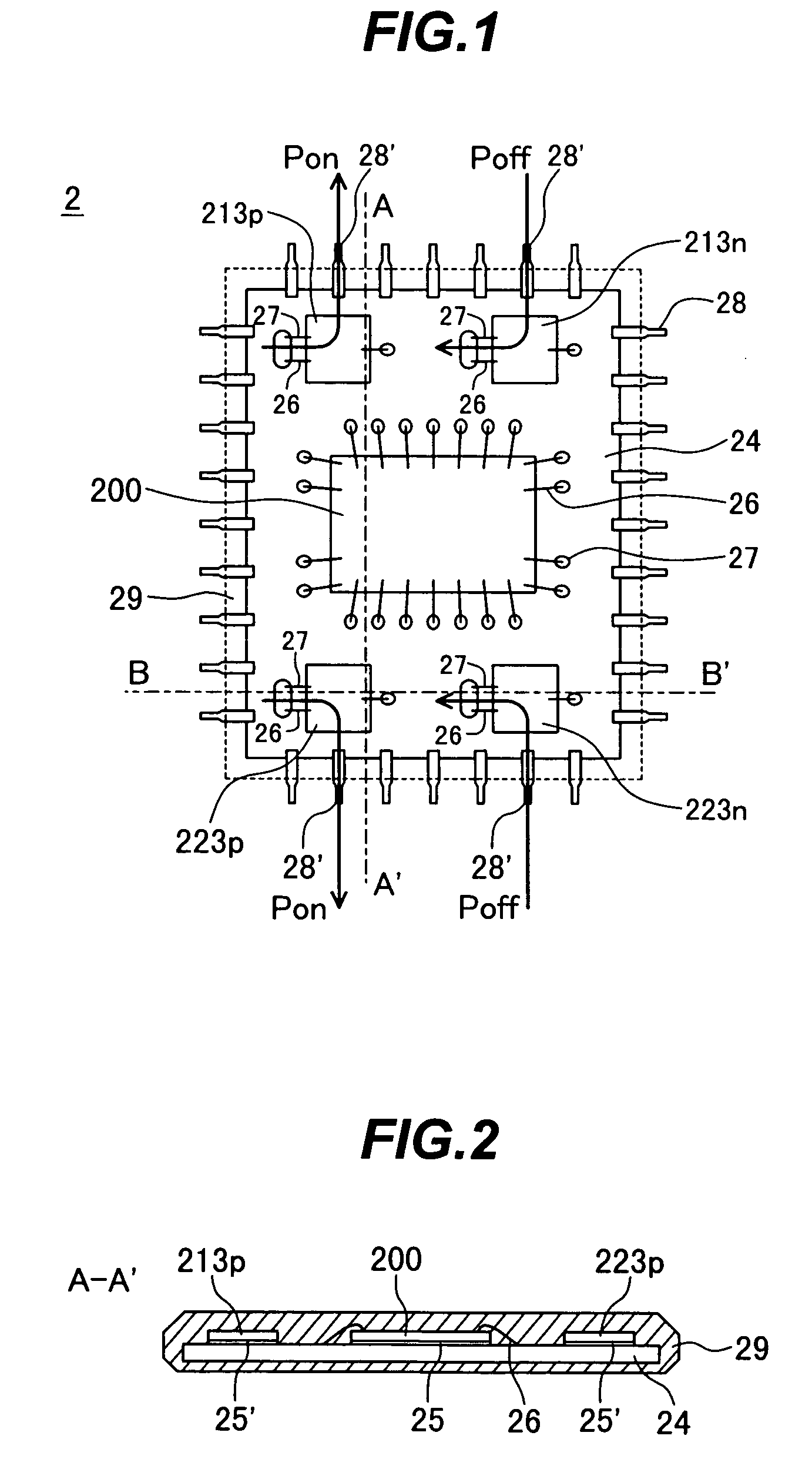

[0071]This embodiment is a modification of the first embodiment. In addition to the final output stage buffer sections 213, 223 being built in separate chips, the circuit elements constituting the level shift circuit 20 are also built in separate chips. Further, the high withstand voltage IC chip 200 is separated into a high voltage section and a low voltage section, which are built in separate chips. More specifically, in this embodiment, circuit elements c...

embodiment 3

[0083]A third embodiment of the present invention will be described with reference to FIGS. 14 through 18. FIGS. 14 through 16 show the construction of a driver IC of this embodiment. FIGS. 17 and 18 show the construction of an inverter of this embodiment. In the following, only the construction differing from that of the above-mentioned embodiments will be described and a description of the remaining similar construction is omitted.

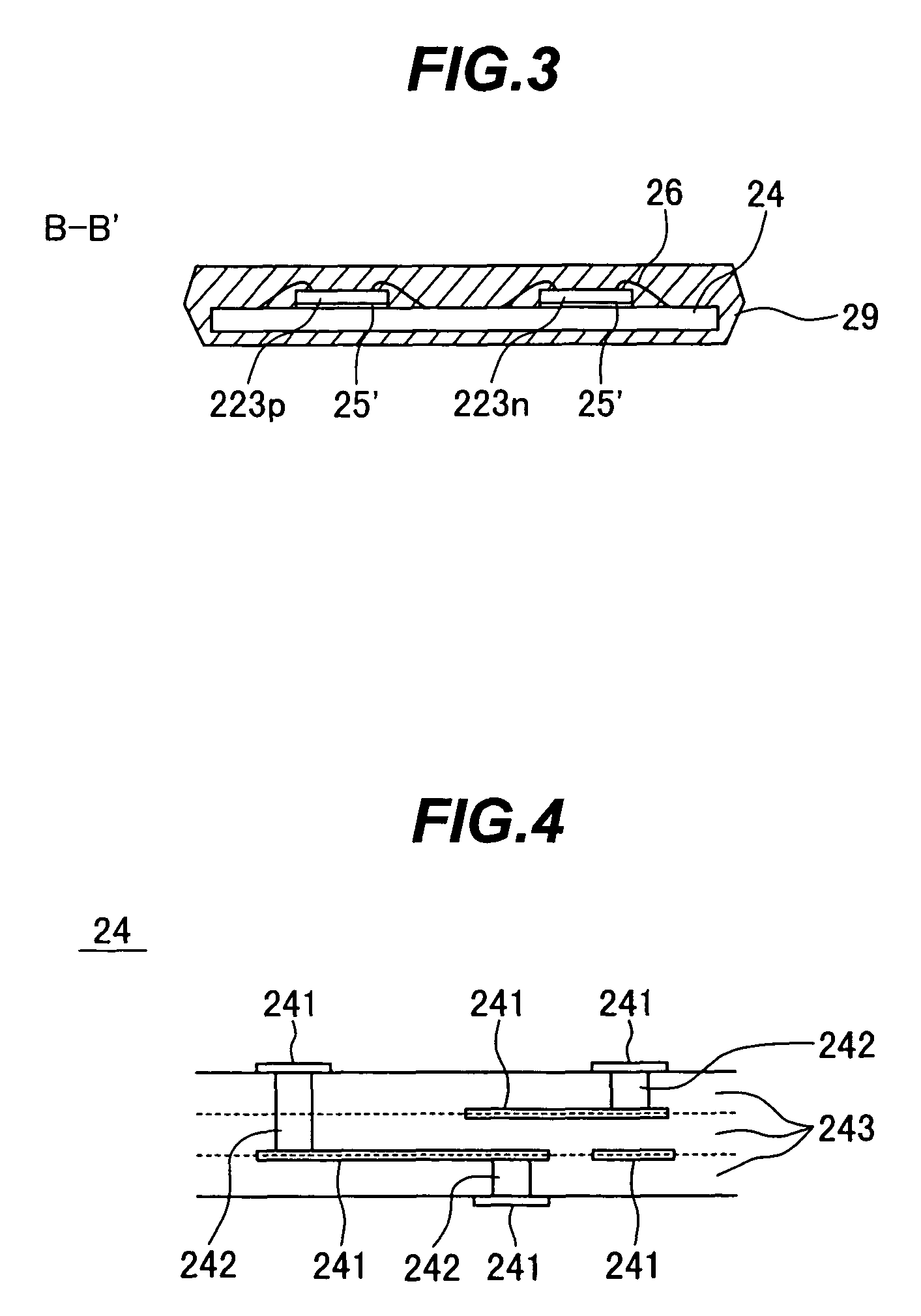

[0084]This embodiment is an improved version of the second embodiment. The upper arm IC chip 210 and the lower arm IC chip 220 are each connected onto the isolation wiring board 24 by facedown (flip-chip) bonding with solder balls 261 (in BGA (Ball Grid Array)). With this embodiment thus constructed, since the wires and the bonding pads are omitted, the occupancy area of the upper arm IC chip 210 and the lower arm IC chip 220 is reduced. Also, with this embodiment, such a reduction of the occupancy area enables the passive parts 5 for filtering, which ar...

embodiment 4

[0091]A drive system of this embodiment, shown in FIG. 19, comprises a drive circuit 402, a drive circuit 403, resistances 404 and 405 for connecting the drive circuit 402 and the drive circuit 403 to the gate of the IGBT 32H (32L), a gate power supply V, a control circuit 406 for controlling the operations of the drive circuits, a slope detecting circuit 407, and a timer circuit 410 for transferring an output of the slope detecting circuit 407 to a later stage after the lapse of a preset time.

[0092]The slope detecting circuit 407 comprises a change rate detecting circuit 408 for detecting a time change rate of the gate voltage of the IGBT 32H (32L), and a waveform shaping circuit 409 for shaping an output waveform from the change rate detecting circuit 408.

[0093]If an output signal of the change rate detecting circuit 408 is at a level sufficient for being transferred to the stage downstream of the slope detecting circuit 407, the waveform shaping circuit 409 may be dispensed with....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com