Fluorescent non-metallic particles encapsulated in a metallic coating

a non-metallic particle, fluorescence technology, applied in the field of optical elements, can solve the problems of dramatic increase of losses, failure to fabricate microcavities with sizes below one micron, etc., and achieve the effect of enhancing the total radiative power of such nanocavities, reducing the number of cavity modes, and reducing the number of cavities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiments

[0139]Excitation of Optical Cavity Modes in a Surface-Adsorbed Fluorescent Non-Metallic Particle Encapsulated into a Metallic Coating

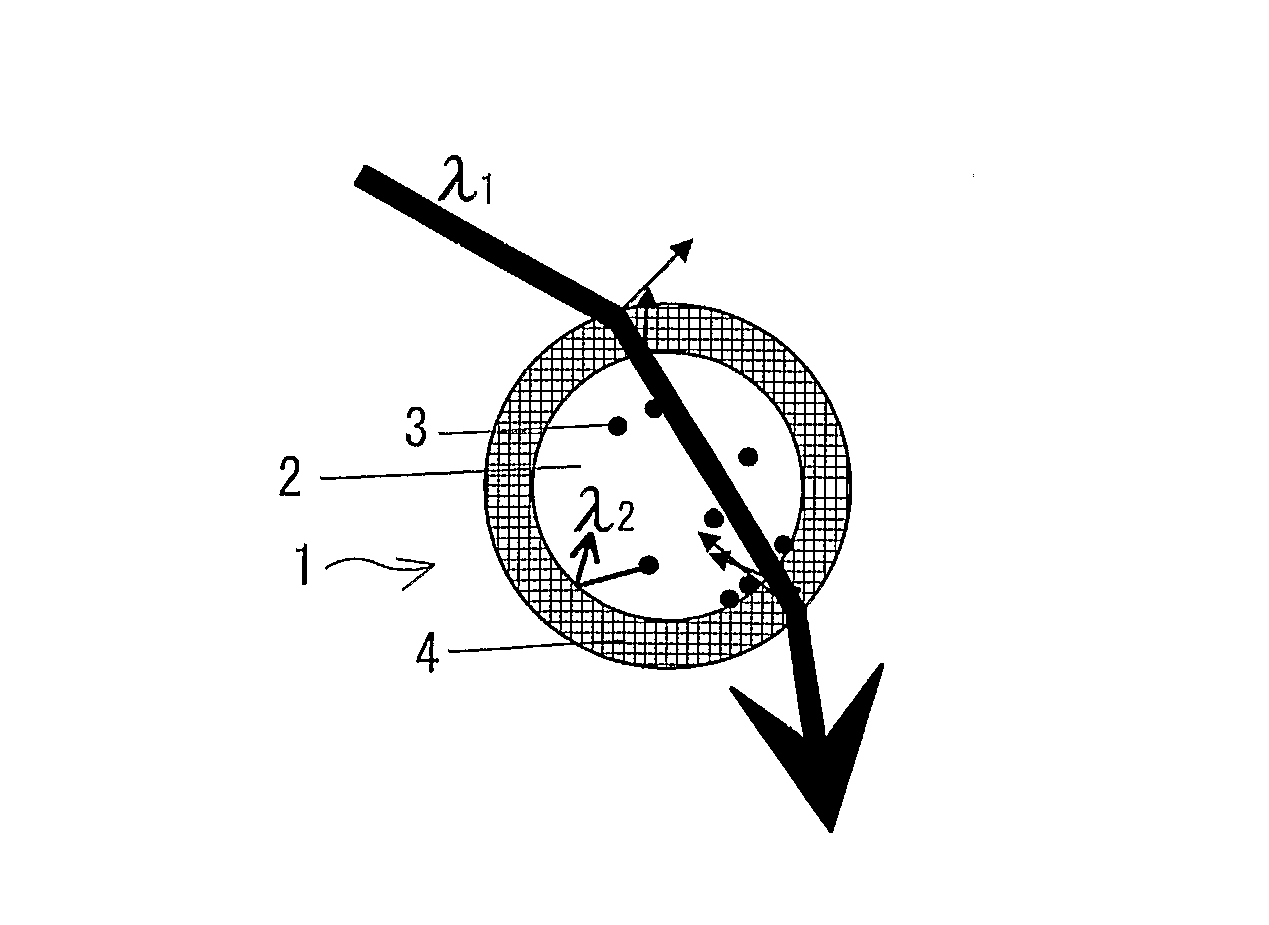

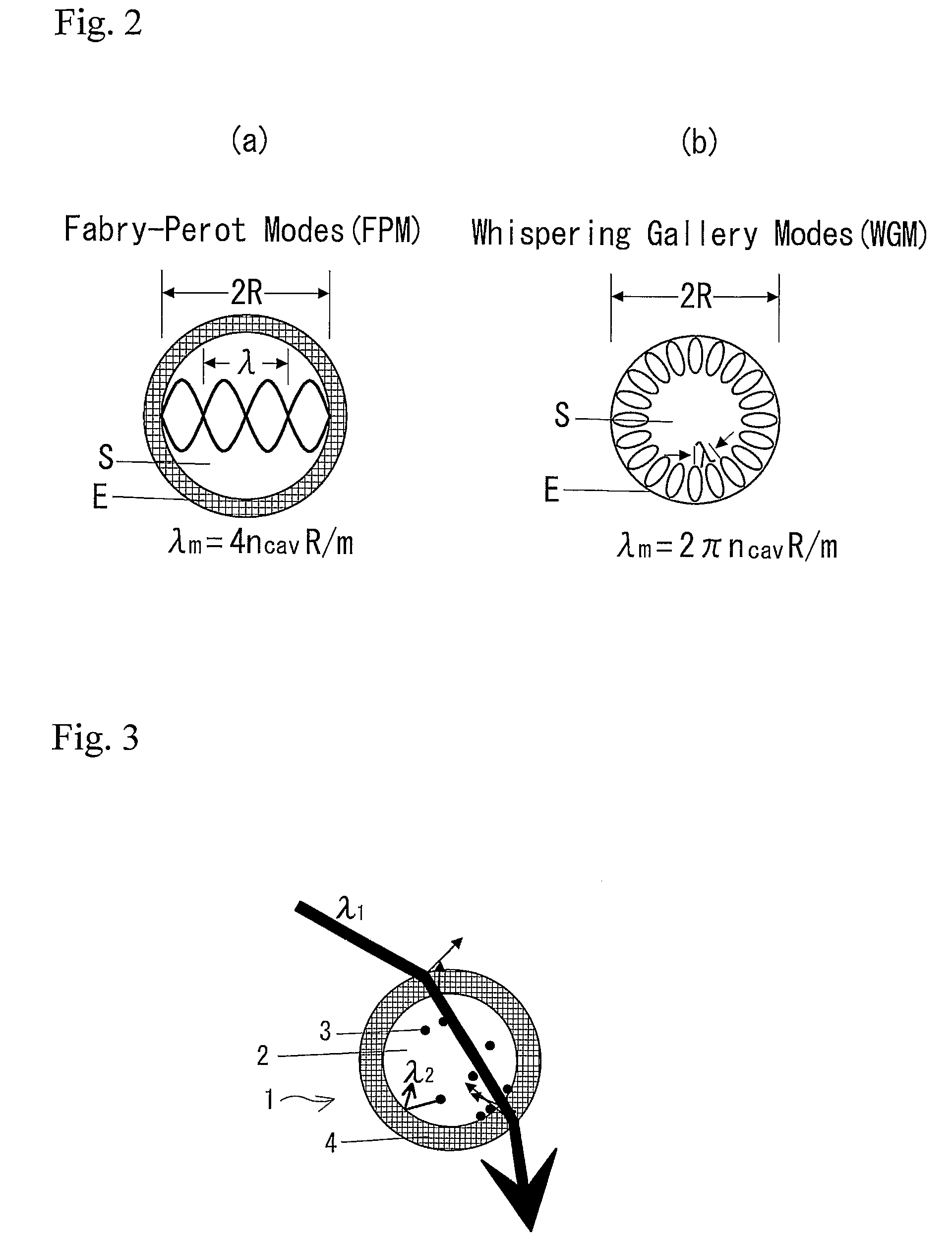

[0140]Optical cavity modes can be excited and detected in a simple manner according to the schemes shown in FIG. 4.

[0141]In the case of scheme (I), the particle 1, consisting of a non-metallic core 2 material containing a fluorescent material 3 and encapsulated into a metallic coating 4 is entirely coated with the metal 4 and adsorbed with the metallic coating 4 in contact with the surface. A light beam 20 used for excitation of the fluorescent material 3 inside of the metallic coating 4 is directed onto the surface, where it is reflected and / or transmitted, depending on the optical properties of the substrate 5. Due to leakage of the cavity, i.e. its finite quality factor, some light 21 of the excited cavity modes is emergent from the particle 1 into its outer environment, where it is collected by suitable optics, e.g. a convex lens 22, and guided to ...

example 1

Sensitivity Estimate for Spherical Cavities Based on Quantum Interference Effects

[0175]This example gives an estimate on the expected sensitivity of a single cavity with respect to biomolecular adsorption, if the cavity volume is chosen as small as possible for the wavelength, at which the cavity is operated (according to eq. 5a). We chose realistic materials, which can be purchased, e.g. from Polysciences, Inc. 400 Valley Road, Warrington, Pa. 18976.

[0176]Given:

[0177]1. Polystyrene beads with a refractive index of ncav=1.60 and doped with dye molecules, which emit light at an emission wavelength λem=420 nm

[0178]2. Antibody with a volume of (10 nm)3

[0179]Further assumptions: For calculating a sensitivity estimate, we further assume that

[0180]1. The refractive index of the antibody is larger than that of the surrounding of the cavity, in fact, we assume that it is the same as that of the cavity material. Then, the adsorption of a biomolecule on the outer surface of the cavity causes...

example 2

Estimated Radiative Power of a Single Nanocavity Due to Purcell Enhancement

[0187]Example 1 shows that the sensitivity of a nanocavity with a diameter of 205 nm and operated at a wavelength of 420 nm (emission wavelength of the dye incorporated inside of the cavity) should be high enough for single antibody detection. However, high sensitivity alone does not help for construction of a nano-biosensor if the signal, the sensor radiates, is too weak. Therefore, in this example we give an estimate on the expected radiative power of the system discussed in example 1.

[0188]Further Assumptions:

[0189]1. Dye molecules inside of the cavity have a density of 0.1 / nm3 and a dipole moment typical for organic dyes, d=2×10−29 C×m

[0190]2. Further, we assume a Q-factor of Q=100, which in the case of a metal-coated cavity would correspond to a reflectivity of the metallic shell coating 4 of Rsh=97% according to eq. 19 and with all other parameters as given above.

[0191]Estimate:

[0192]Under these assumpt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thicknesses | aaaaa | aaaaa |

| thicknesses | aaaaa | aaaaa |

| thicknesses | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com