Catadioptric reduction projection optical system and exposure apparatus having the same

a technology of reduction projection and optical system, applied in the field of catadioptric reduction projection optical system and exposure apparatus, can solve the problems of insufficient abbe constant of synthetic quartz and fluorite, and shortwavelength, etc., to achieve excellent imaging performance and easy adjustment of optical system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

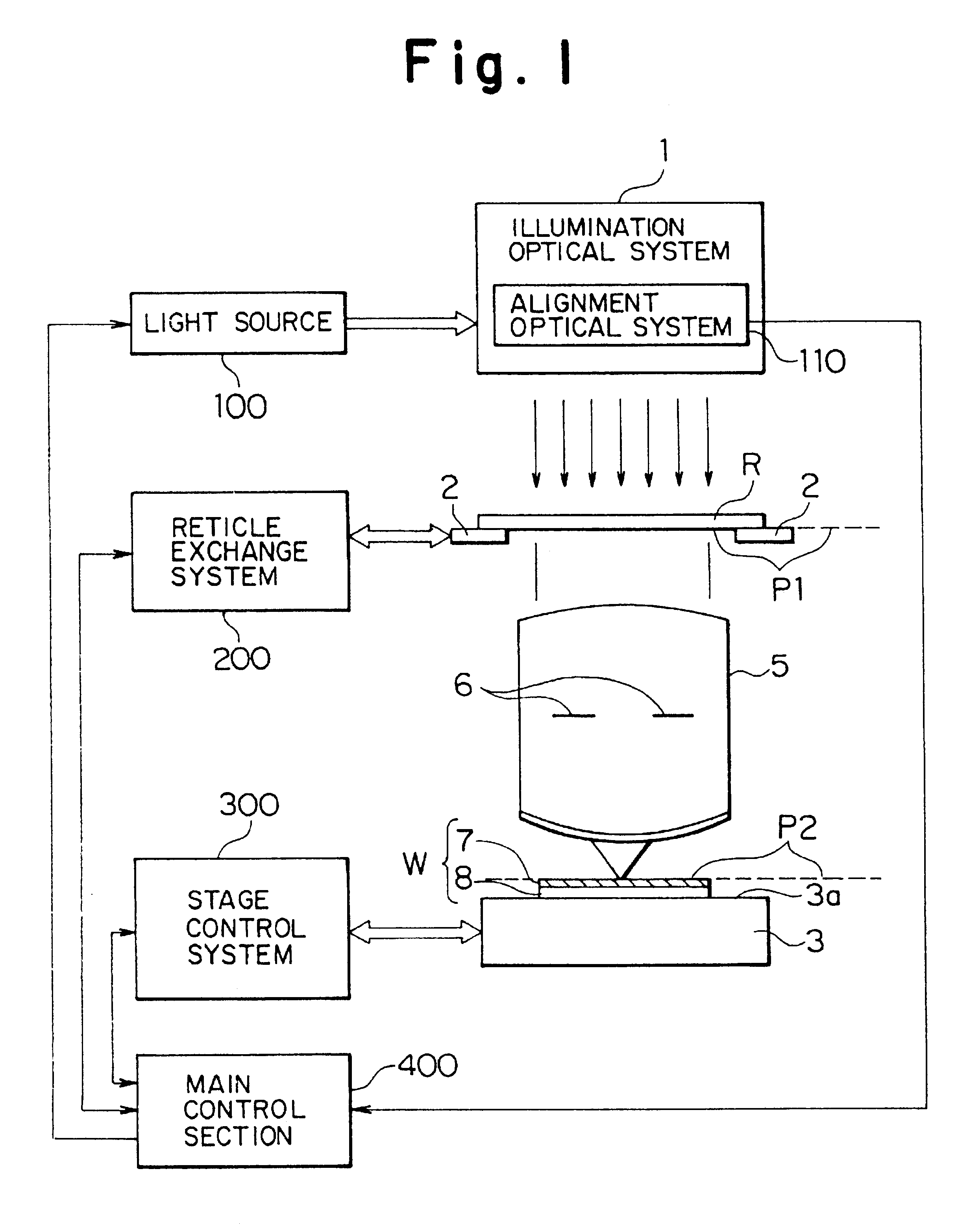

The first embodiment is a projection optical system suitable for a projection optical apparatus (e.g., a stepper) of a one-shot exposure method and having a magnification of 1 / 4.times..

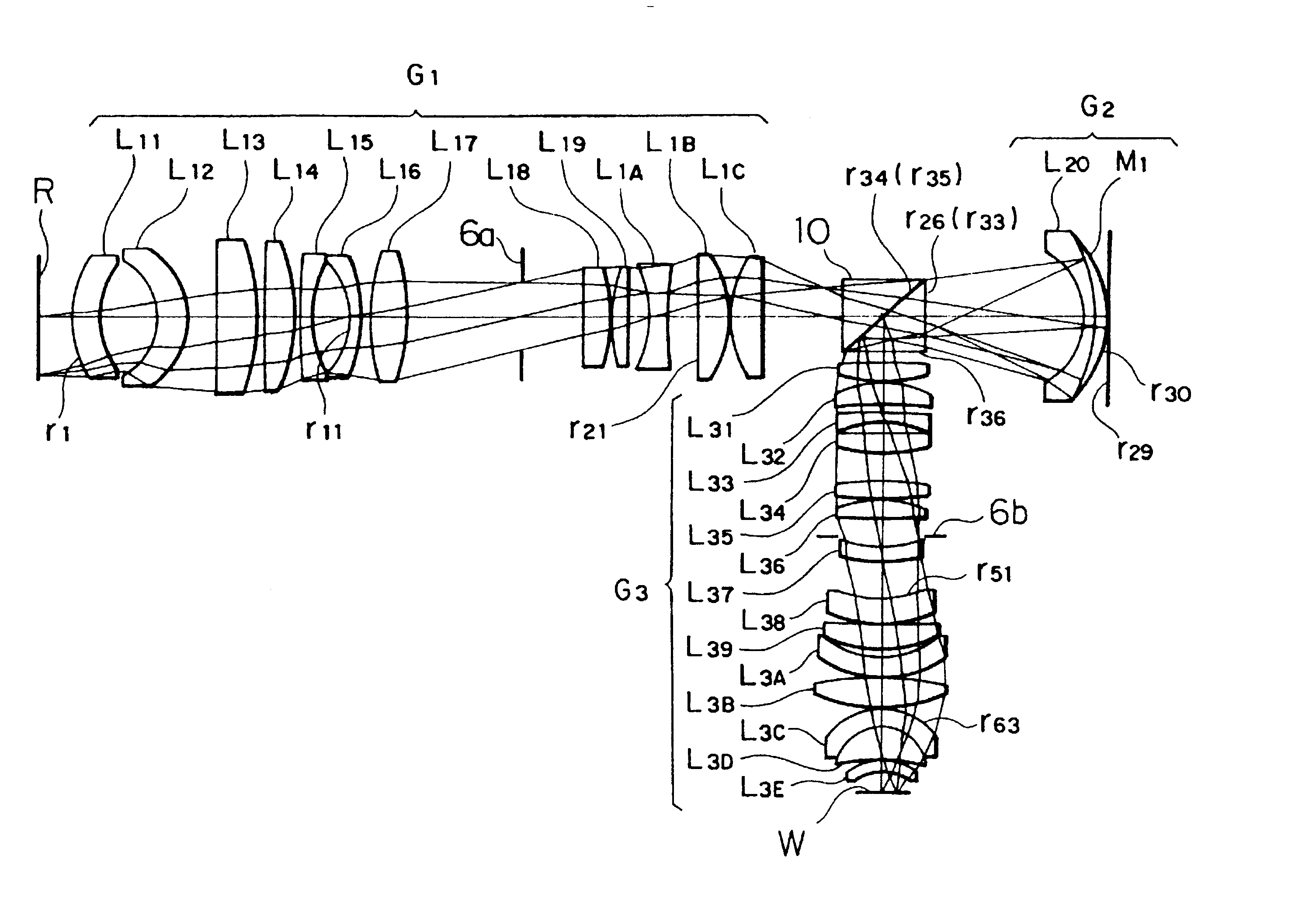

FIGS. 3 and 4 show the overall arrangement of the first embodiment. Referring to FIGS. 3 and 4, a reticle R (see FIG. 11) on which a pattern to be transferred is drawn is placed on an object plane P1, and a wafer W (see FIG. 11) coated with a photoresist is placed on an image plane P2. The reticle R on the object plane P1 is illuminated with exposure illumination light from the light source 100 of the illumination optical system 1, and a light beam passing through the reticle R forms a first intermediate image 9 via a refracting lens group G.sub.1 as a focusing lens group having a focal length f.sub.1. A light beam from the first intermediate image 9 is incident on a polarizing beam splitter (PBS) 10. A p-polarized light beam transmitted through a polarizing / reflecting surface 10a of the polarizing be...

second embodiment

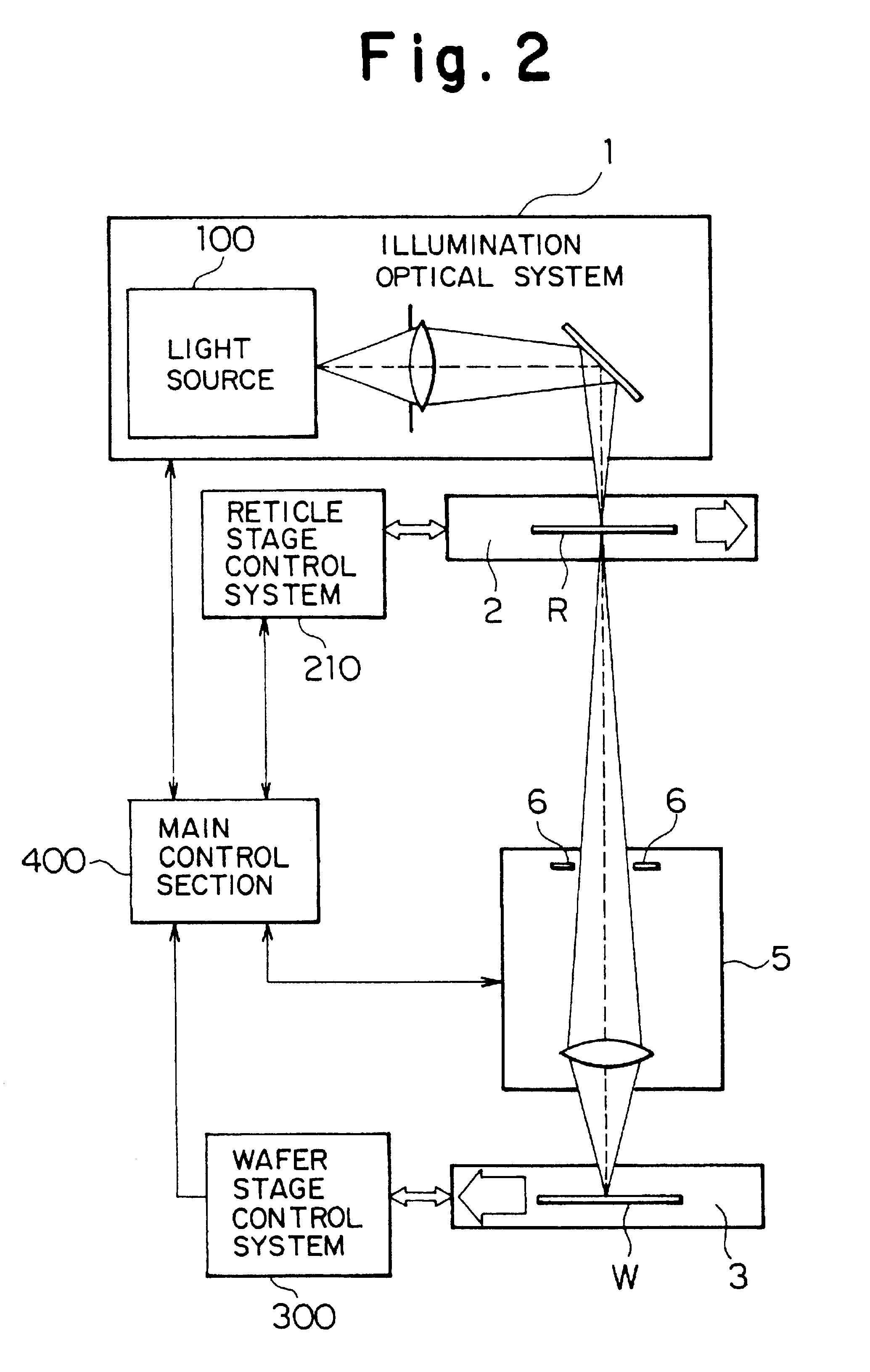

The second embodiment is a projection optical system suitable for a projection optical apparatus based on the scanning exposure scheme and having a magnification of 1 / 4.times..

FIG. 5 shows the overall arrangement of the second embodiment. Referring to FIG. 5, a reticle R is placed on an object plane P1, and a wafer W is placed on an image plane P2. FIG. 6 is a plane view showing the reticle R when viewed in the direction of a refracting lens group G.sub.1 (f.sub.1) in FIG. 5. In this case, a bar-shaped illumination region 22, on the reticle R, which is slightly offset from the optical axis of the projection optical system is illuminated with illumination light from the light source 100 of the illumination optical system 1.

Referring to FIG. 5, a light beam passing through the illumination region 22 forms a first intermediate image 9 via the refracting lens group G.sub.1, and a light beam from the first intermediate image 9 passes through a side surface of a mirror (to be referred to ...

third embodiment

The third embodiment is a projection optical system suitable for a projection exposure apparatus of a scanning exposure method and having a magnification of 1 / 4.times.. A partial mirror is used in the third embodiment like in the second embodiment. However, an off-axis light ray further offset from the optical axis than in the second embodiment is used in the third embodiment.

FIG. 8 shows the overall arrangement of the second embodiment. Referring to FIG. 8 which indicates similar or same parts with the same reference numerals as in FIG. 5, a reticle 21 is placed on an object plane P1, and a wafer W is placed on an image plane P2. FIG. 9 is a plane view showing the reticle R when viewed in the direction of a refracting lens group G.sub.1 (f.sub.1). As shown in FIG. 9, an arcuated illumination region 22A, on the reticle R, which is slightly offset from the optical axis of the projection optical system is illuminated.

Referring to FIG. 8, a light beam passing through the illumination r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| maximum field angle | aaaaa | aaaaa |

| field angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com