Electromechanical drive for track-laying vehicles

a technology of electric motors and tracklaying vehicles, applied in electric propulsion mounting, transportation and packaging, gearing, etc., can solve the problems of limited arrangement of motors in vehicles, a lot of construction space for motors, etc., and achieve the effect of high integration and compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

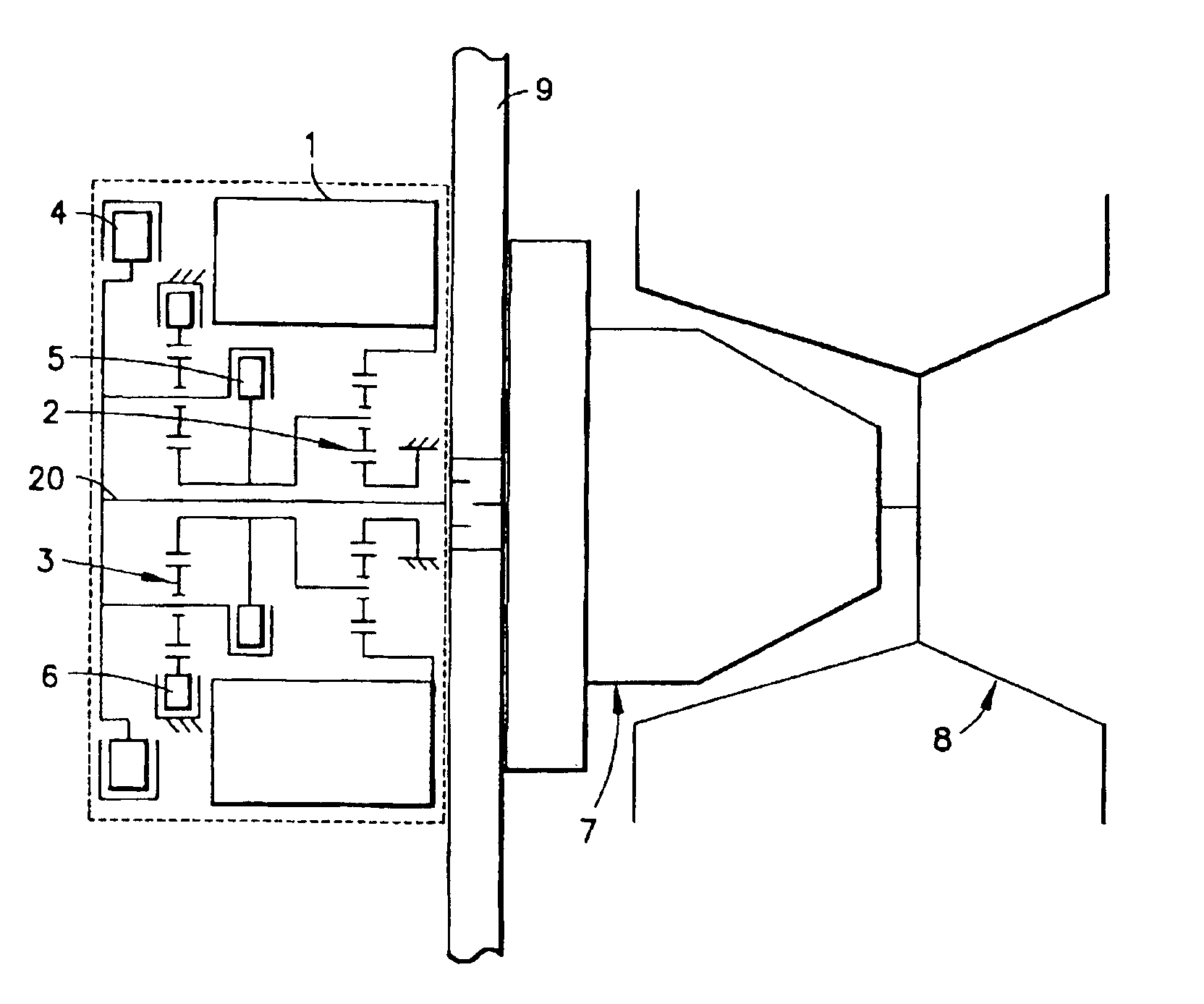

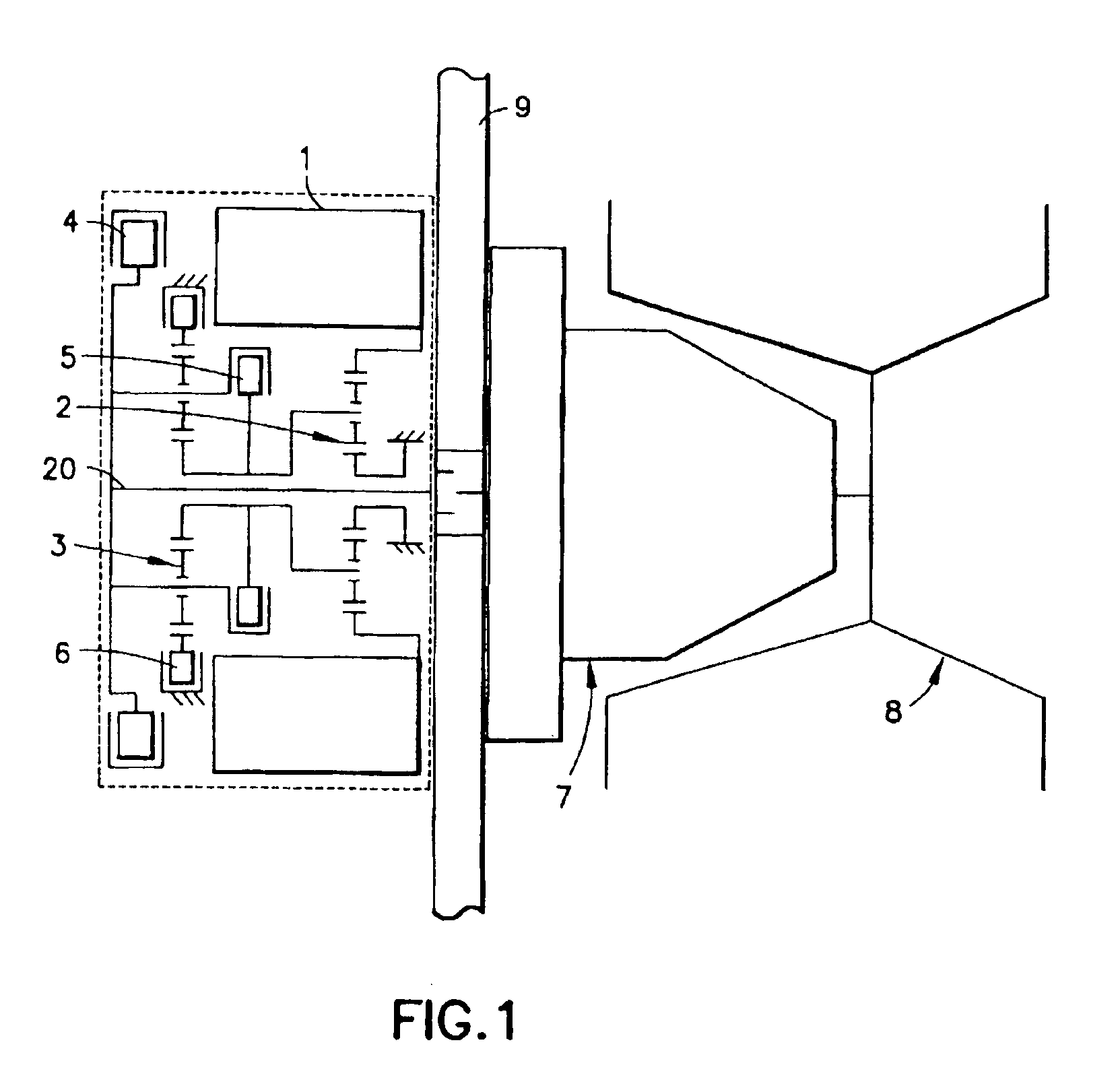

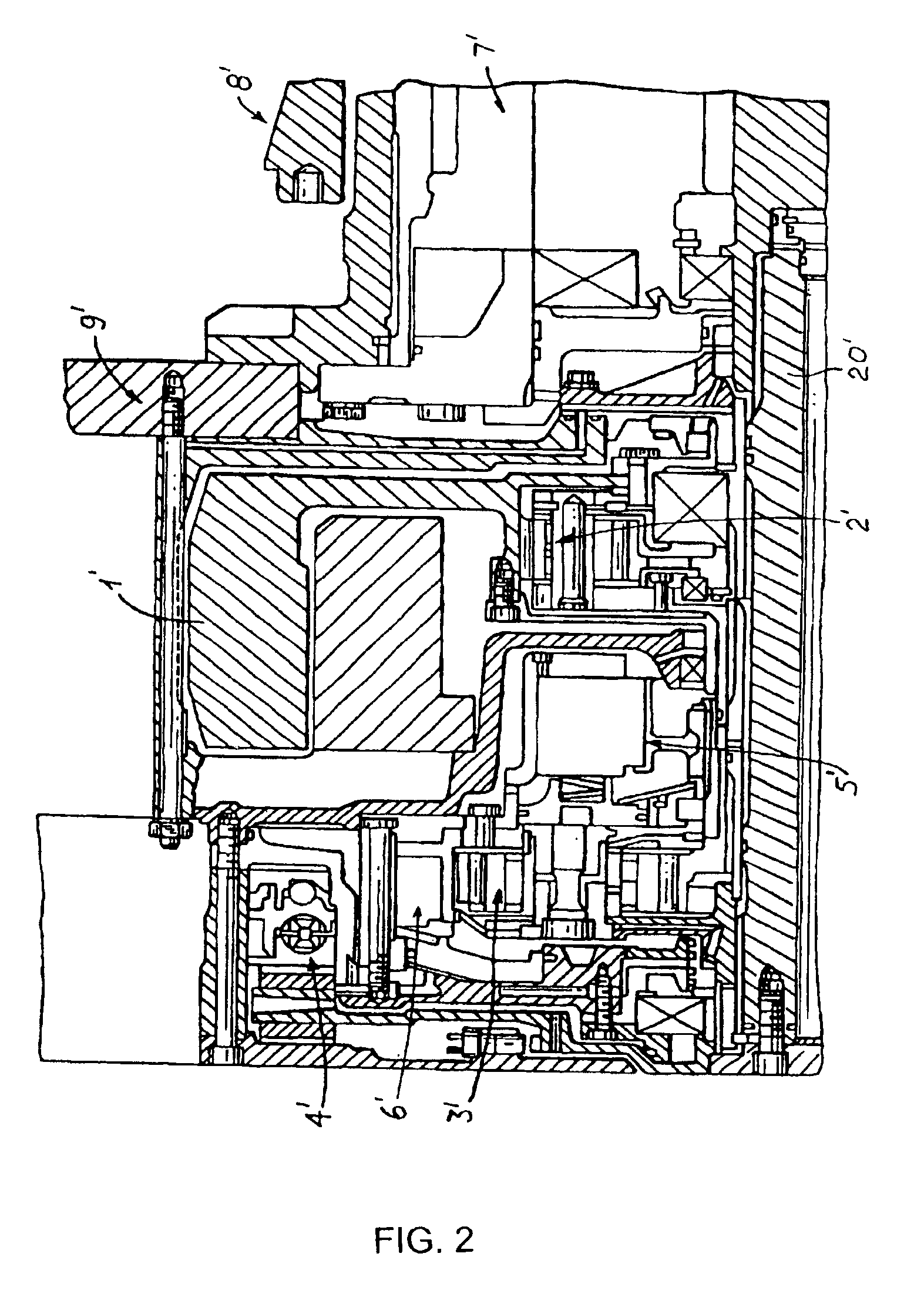

[0016]The basic construction of an exemplary embodiment of a drive according to the invention is shown in FIG. 1. An electric motor 1 drives the ring gear of an epicyclic gear unit 2, which is provided as a reducing fixed stage. The electric motor may be of a type operable to allow brief operation close to a motor cut-off output. The output of epicyclic gear unit 2 is effected via its revolving web, which, with clutch 5 closed and at the same time clutch 6 open, directly drives the output shaft 20 of the drive. By controlled and thus matched opening of the clutch 5 and closing of the clutch 6, the epicyclic gear unit 2 drives the sun gear of an epicyclic gear unit 3. Since this epicyclic gear unit 3, in this set-up, drives the output shaft 20 via its web. A further gear stage is thus connected in which the revolving planet gears are rotatably mounted. Accordingly, the epicyclic gear units 2, 3 and the clutches 5, 6 comprise a shiftable transmission.

[0017]The brake 4 is firmly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com