Solar cell and solar cell unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

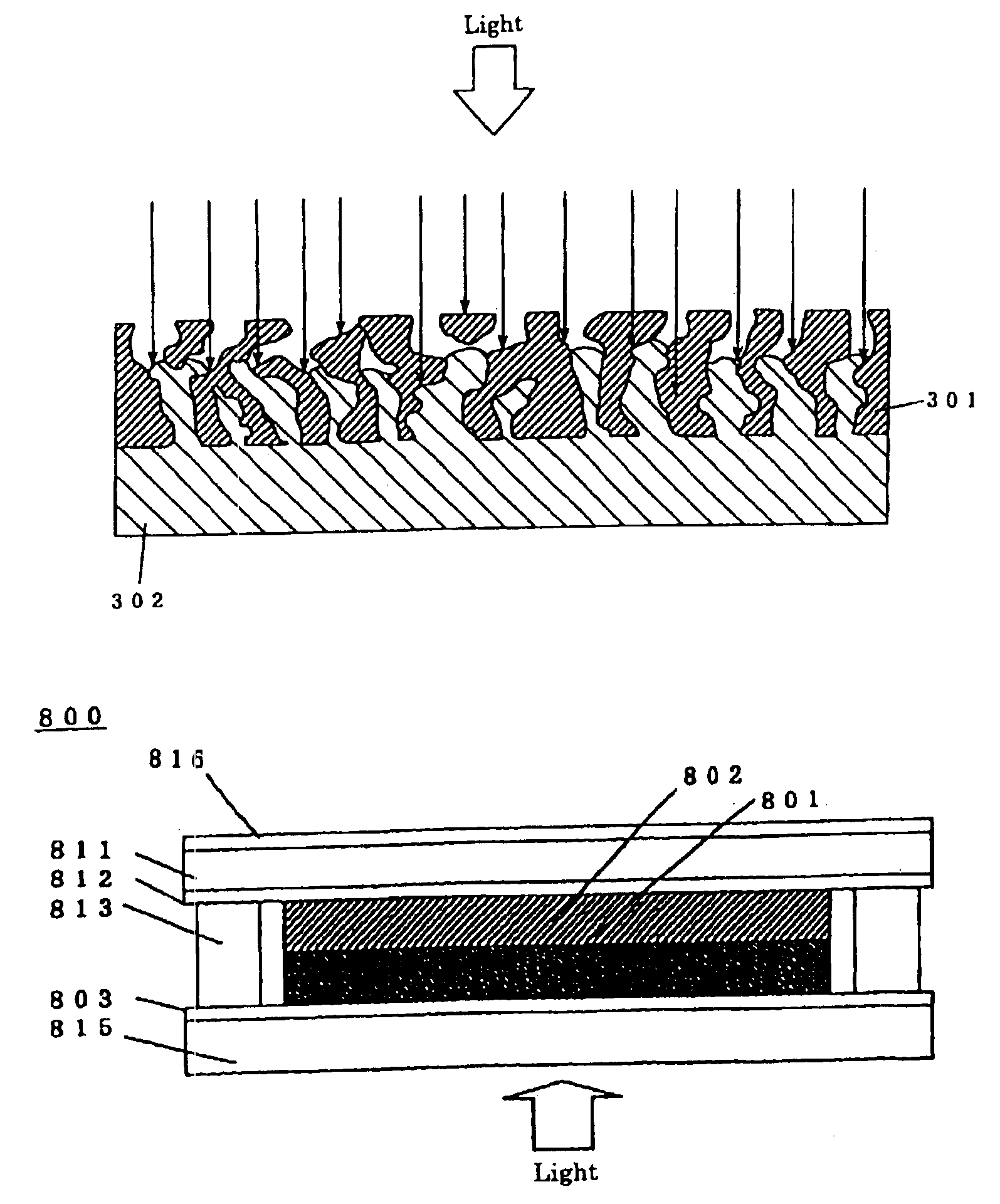

[0052]FIG. 1 is an illustration which schematically shows the structure of a solar cell (solar cell unit) 100, which is an embodiment of a solar cell employing a semiconductor according to the present invention.

[0053]The solar cell 100 includes a first substrate 104, such as a glass substrate or a metal substrate, and a first electrode 103 formed on the first substrate 104. The first electrode 103 is formed from a transparent electrode mask of ITO or the like or a metallic electrode (which is made of a metal selected from the group consisting of Al, Ni, Cr, Pt, Ag, Au, Cu, Mo, Ti and Ta, an alloy containing any one or more of these metals, or a compound containing any one of these metals).

[0054]An anatase type titanium dioxide (TiO2) semiconductor 101 is formed on the first electrode 103. The titanium dioxide (TiO2) semiconductor is an n-type semiconductor.

[0055]A comb-shaped (stripe-like) second electrode 102 is formed on the anatase type titanium dioxide (TiO2) semiconductor 101. ...

second embodiment

[0085]While the normal titania semiconductor reacts with only the ultraviolet rays in solar rays as described above, the titania semiconductor of the present invention is subjected to the processing for sensitizing to absorption wavelength of rays, such as solar rays, so as to be able to react with the rays up to the visible ray region.

[0086]Specifically, examples of such processing include (1) a method in which dye is adsorbed on the porous surface of the titania semiconductor (the dye adsorption method), (2) a method in which oxygen defects are formed in the titania to reduce the band gap in order to sensitize to the visible rays (the oxygen defect method), and (3) a method in which the titania is doped with a very small quantity of impurities (the impurity doping method), and so forth, and one kind of, or two or more kinds of, these methods can be used alone or in combination with other method.

[0087]First, the first method (the dye adsorption method) will hereinbelow be described...

third embodiment

[0102]Next, the method of forming the titania semiconductor films 101, 201 of the present invention will hereinbelow be described in detail.

1 Powder Molding Method

[0103]The titania semiconductor employed in the present invention is formed by utilizing what is referred to as Powder Injection Molding method (in general, it is called the PIM Method), or what is referred to as Metal Injection Molding Method (in general, it is called the MIM method).

[0104]In these methods, a resin binder of 99 to 50% in the volume ratio is added to titanium fine powder, having the particle size of about 20 to 2,000 nm, and then they are kneaded to form a source compound, having the low viscosity (in the range of 1,000 to 3,000 P) with which the injection molding can be carried out.

[0105]At this time, Cr or V is added thereto in order to increase the absorption wavelength width of rays. This may be added to the source compound, either in the state of the oxide of Cr (CrO3), or in the state of the oxide of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com