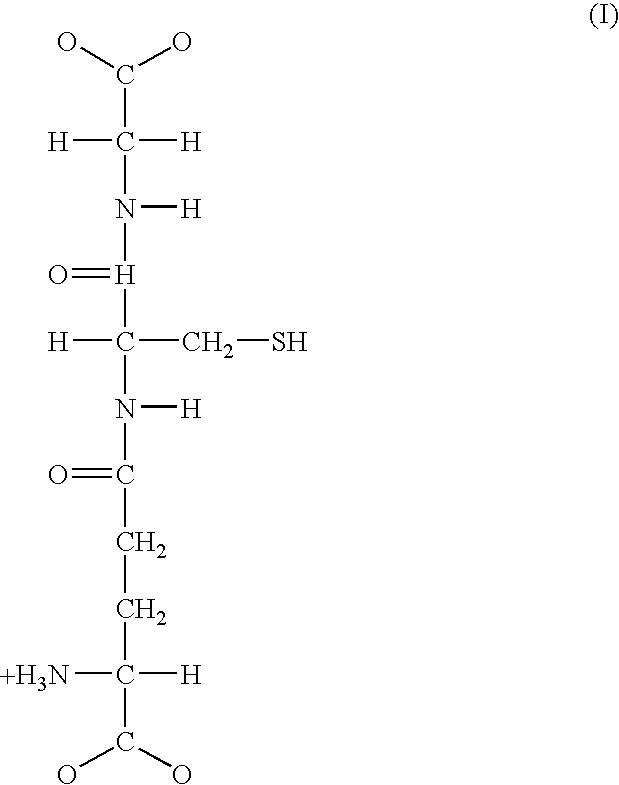

Method of treatment of glutathione deficient mammals

a glutathione deficiency and mammals technology, applied in the field of mammals with glutathione deficiency, can solve the problems of affecting the inability to use cysteine normally being the rate-limiting factor, and the inability to achieve sustained gsh depletion, etc., to achieve the effect of stimulating the natural production of glutathion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0053]A mixture of the following ingredients is prepared by hand mixing:

[0054]

IngredientQuantityN-acetylcysteine1,000 to 20,000mgvitamin C5,000 to 50,000mgalpha-lipoic acid100 to 2,500mgsylmarin100 to 2,500mgQuercetin100 to 2,500mgl-glutamine500 to 2,000mgN-acetyl-d-glucosamine500 to 2,000mgwhey protein concentrate1,000 to 20,000mgTwenty Million to One BillionCFU; Schiff Products, Inc.,Salt Lake City, Utah.orange essence flavorAdjust to taste

[0055]The mixture which constitutes the essential active ingredient of a preferred embodiment of the invention, together with a flavorant may be compounded into wafers, tablets or capsules containing 750 to 14,000 mg of active ingredient. In an uncompounded form, the powder dry mixture may be orally administered to a human (one teaspoonful, once or twice daily) as a dietary supplement or as recommended by a health care professional. Alternatively, the dry powder may be mixed with juice, water or food to facilitate administration.

example 2

[0056]Three dosage units in powder form, each containing 500 mg of essential active ingredient (e.g an amount of the mixture of Example 1, supra. were prepared from the following ingredients:

[0057]

essential active ingredient1500gstarch (Rx-1500)300gmagnesium stearate, USP39gcolloidal silicic acid19.5gAvicel ® pH 102. q.s. to3900g

[0058]The essential active ingredient was ground through a 0.25 mm sieve opening screen. The powdered active ingredient, with 50% of the total amount of magnesium stearate be used, colloidal silicic acid and Avicel® pH 10.2 were passed through a 40 mesh sieve, mixed for 20 minutes and then slugged. The slugs were broken down by forcing through a screen No. 11, and mixed with the remaining magnesium stearate.

[0059]One dosage given orally 1-4 times a day is useful in the relief of immuno-deficiency in adult humans provoked by infective disease, or other etiological causes.

example 3

[0060]Three thousand dosage units for oral use, each containing 750 mg of the essential active ingredient, were prepared from the following ingredients:

[0061]

essential active ingredient750gcolloidal silicic acid30gmagnesium stearate, USP30gmicrocrystalline cellulose150glactose90g

[0062]In accordance with the active ingredient potency, the amount of lactose was adjusted to achieve a weight of 900 mg for each dosage unit. The ingredients were passed through a 40 mesh sieve and mixed for 30 minutes. The powder may be mixed into a drink or inserted into hard gelatin capsules No. 0 and filled using Zanazi, model RV-59 equipment. The capsules should be preserved in airtight, light-resistant containers.

[0063]When administered to a human adult suffering from low levels of glutathione (GSH) 1 to 4 dosage units daily, the level is adjusted upward to a normal range.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pH | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| composition | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com