Patents

Literature

32results about How to "Shorten the measurement period" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Photovoltaic power station spiral steel pipe pile construction method

ActiveCN106193034AGuaranteed positioning accuracyEnsure personal safetyBulkheads/pilesGps measurementTotal station

The invention relates to the field of construction of photovoltaic power stations, and discloses a photovoltaic power station spiral steel pipe pile construction method. The construction method uses a total station for calibrating and adjusting pile positions on main axles after using GPS measuring equipment for quickly measuring and setting the pile positions, so that the positioning precision of the pile positions is guaranteed; a domestic general outdoor down-hole drill is refitted, so that the cost is low, the performance is reliable, and the safety is high; the propelling and rotating functions of the drill are used; and a self-made driving shaft is added at the front end of a revolving speed reducing box output shaft of the drill, so that a drill output shaft and a spiral steel pipe pile can be connected and disassembled more conveniently, the drilling construction requirements of the spiral steel pipe pile are satisfied, and the construction efficiency, reliability, safety and economy are greatly improved. The method is suitable for flat floors or mountains with slopes of not higher than 30 degrees, and is suitable for construction of the spiral steel pipe pile under the condition that the thickness of a remolded place soil layer is not smaller than a designed drilling depth.

Owner:SEPCO ELECTRIC POWER CONSTR CORP

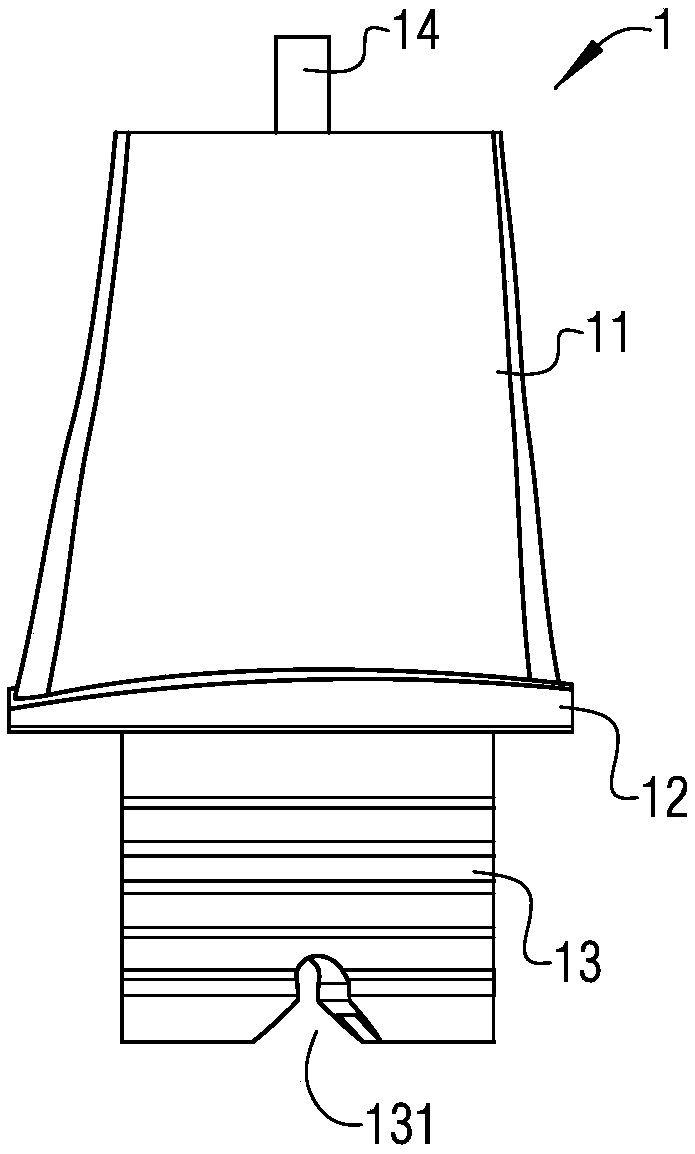

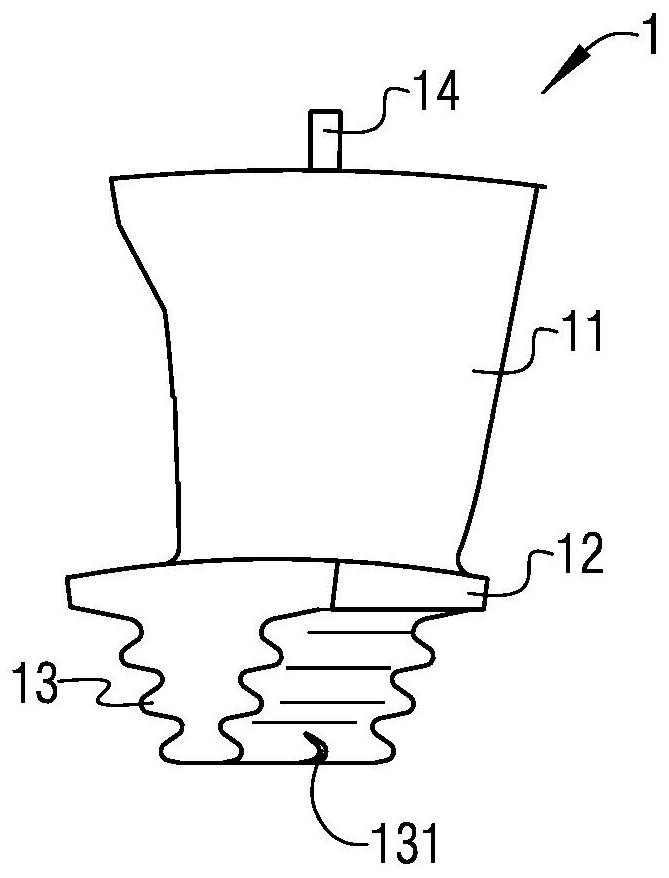

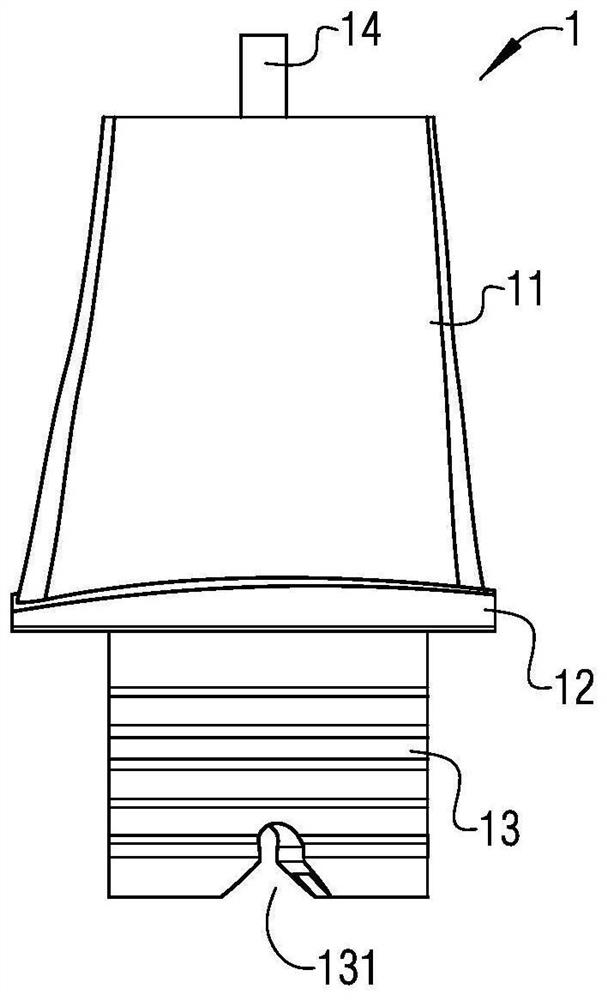

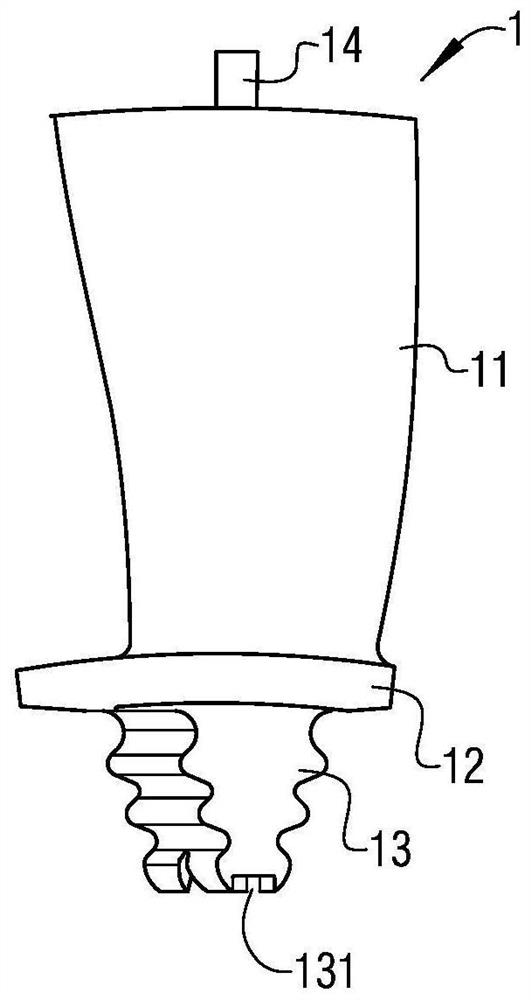

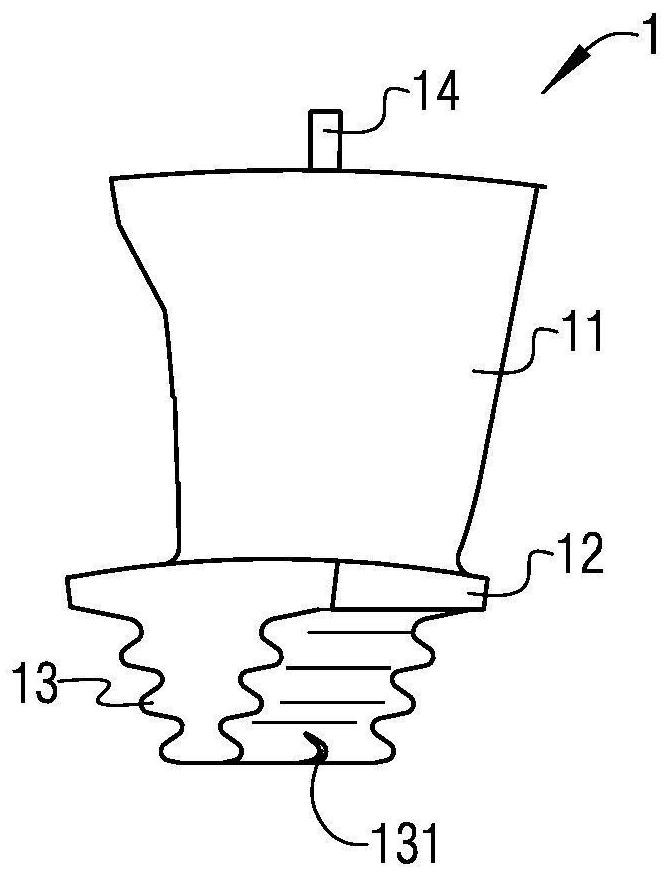

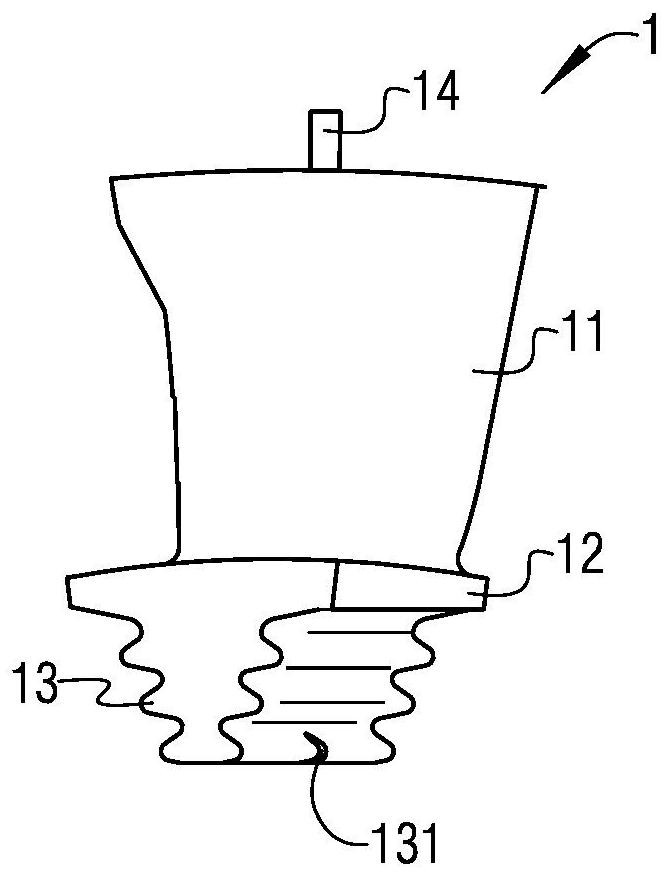

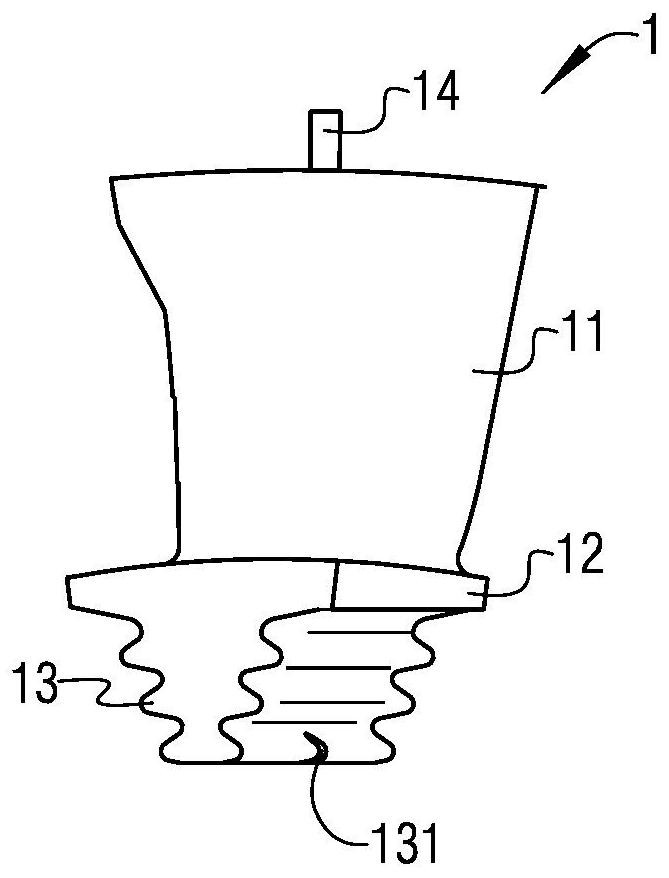

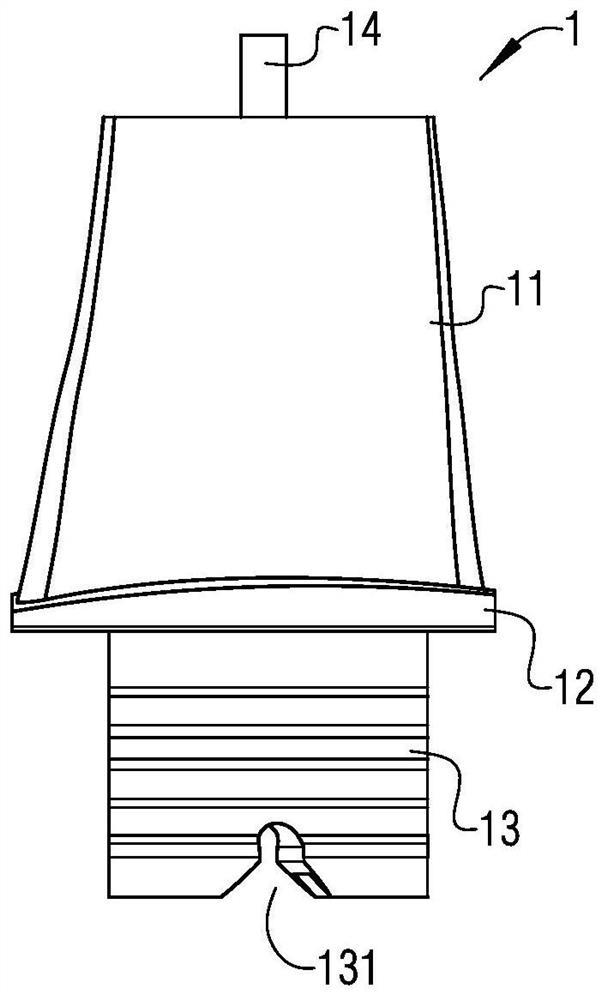

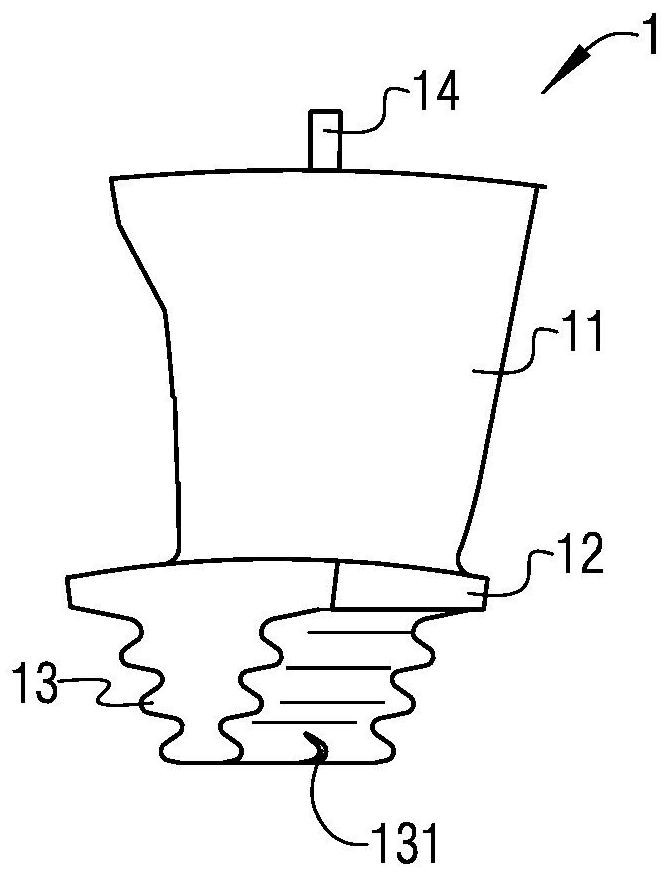

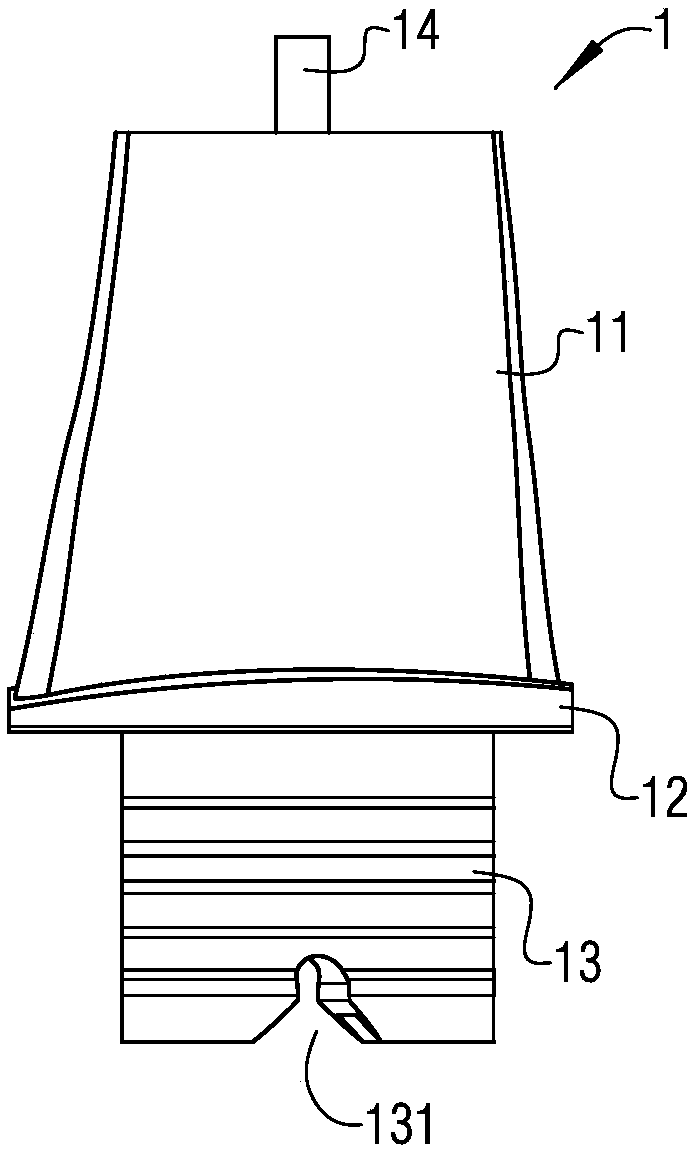

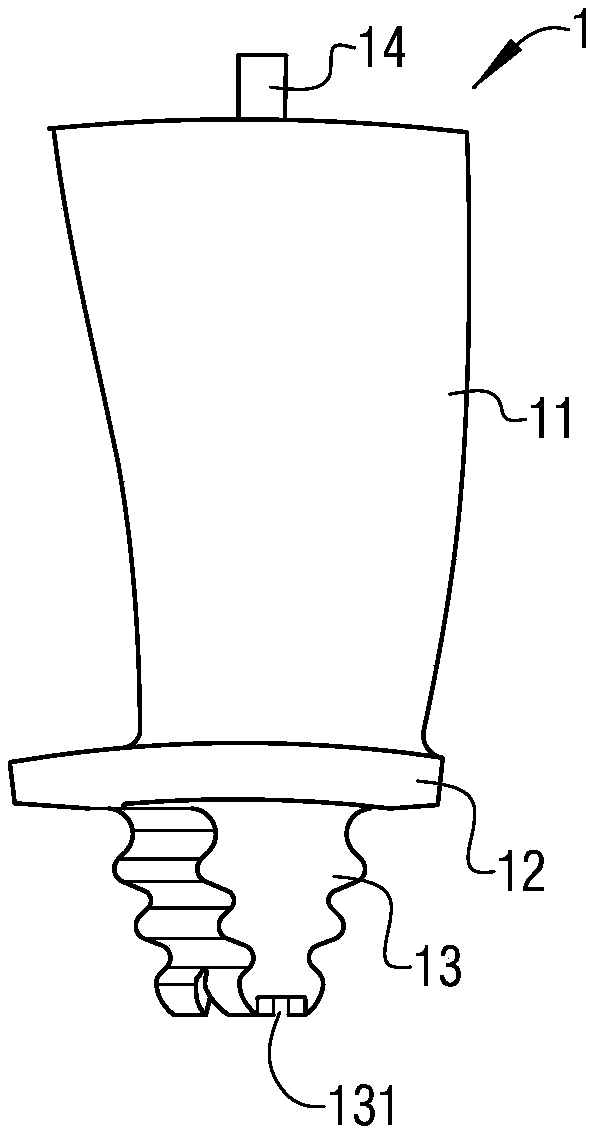

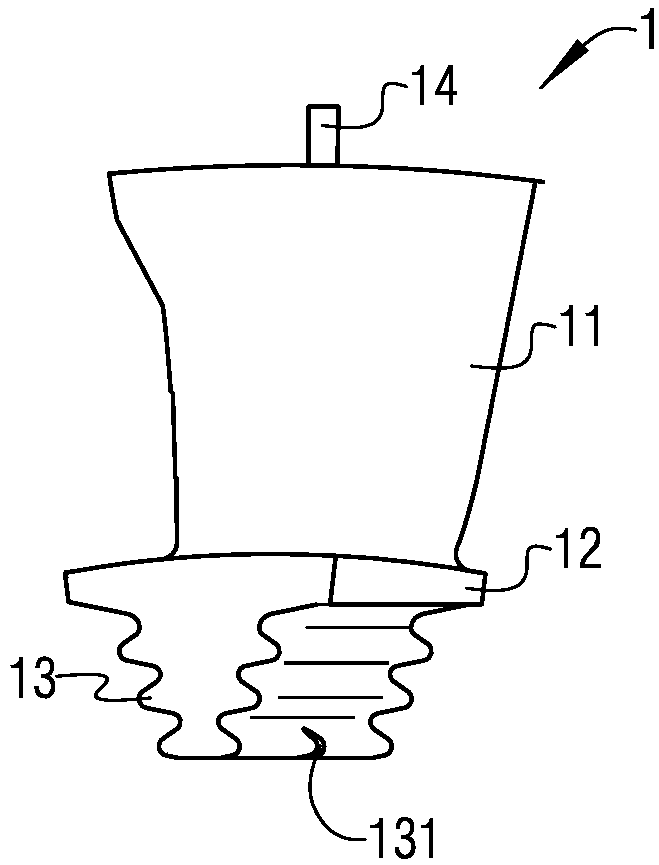

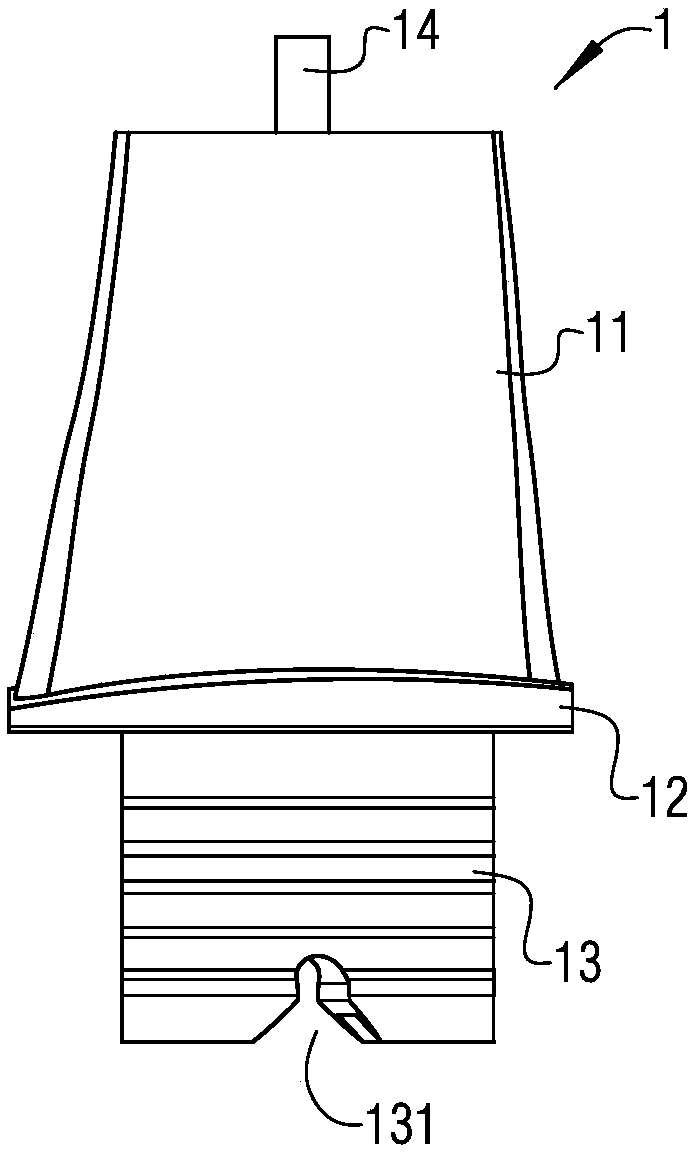

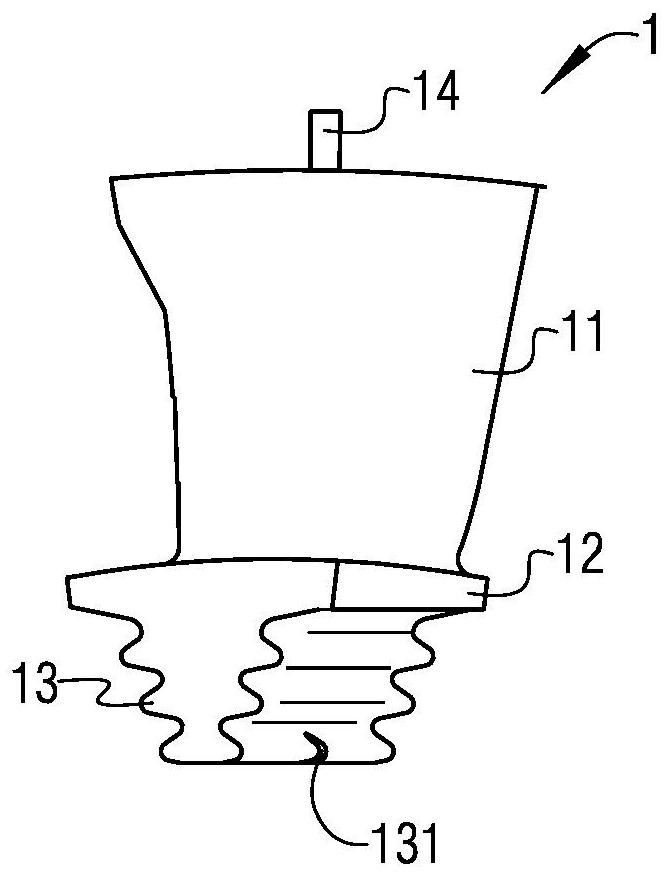

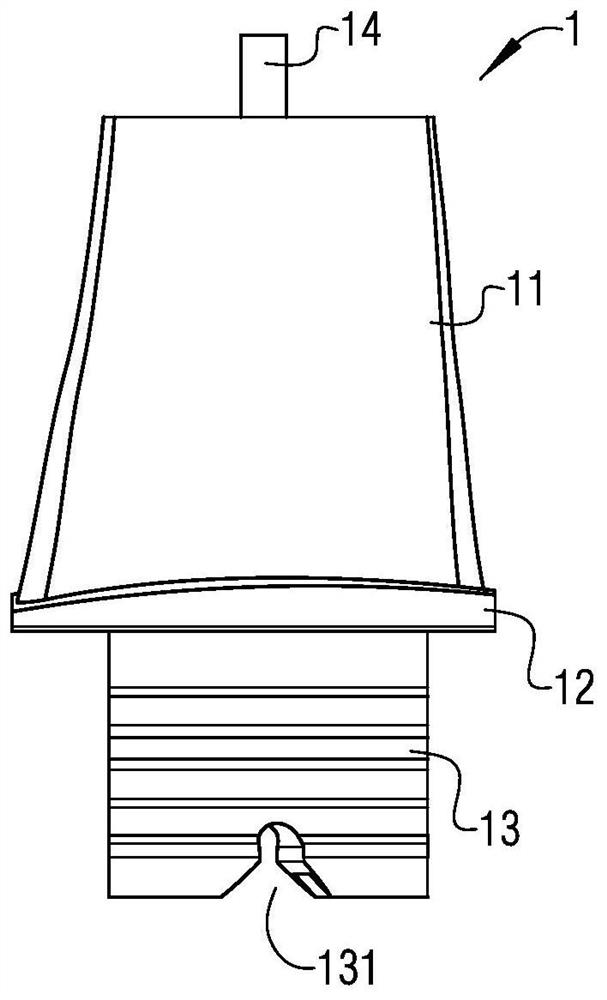

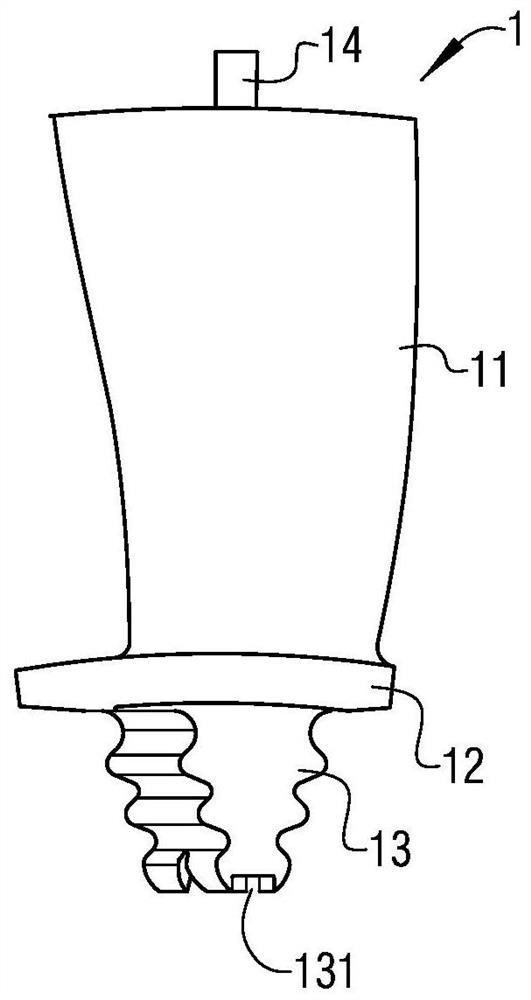

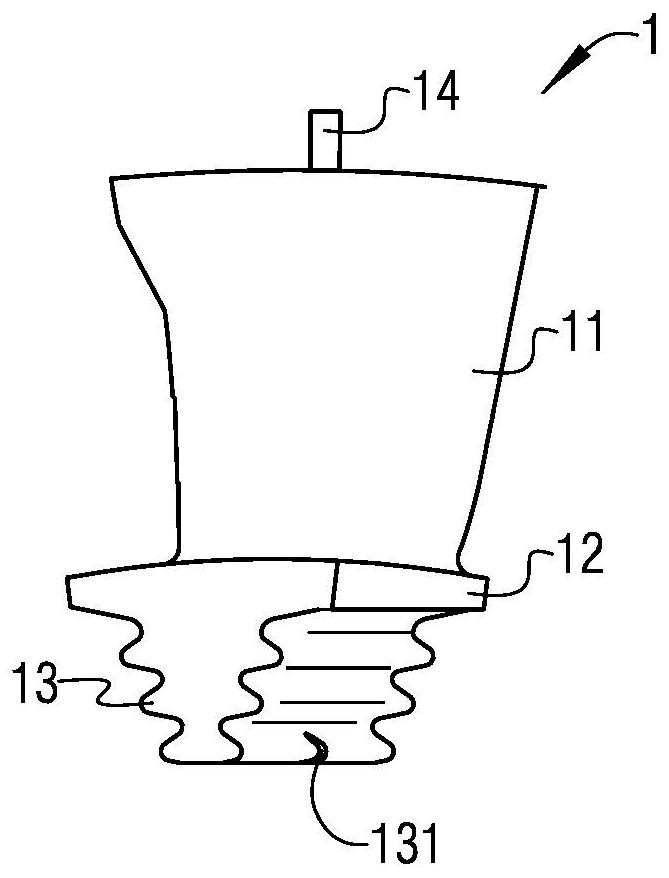

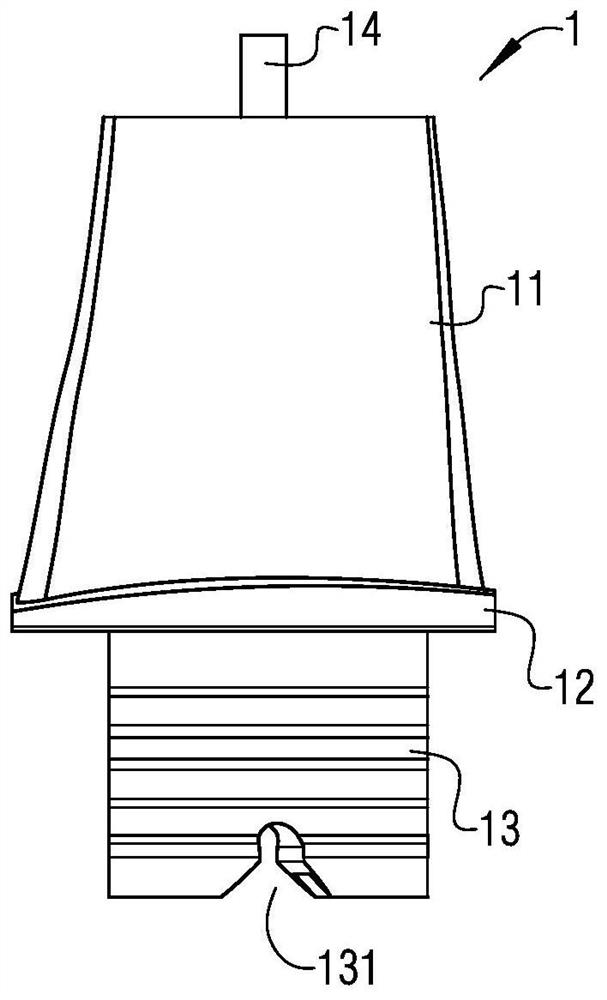

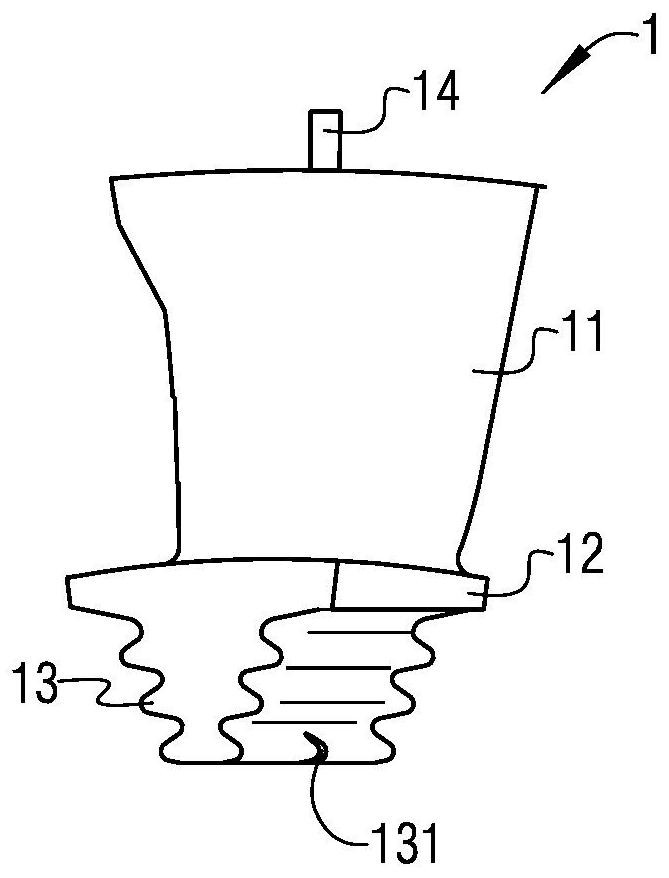

Impeller auxiliary measuring base manufacturing device

ActiveCN109458901AShorten the measurement periodReduce production and maintenance costsFoundry mouldsFoundry coresImpellerMaterials science

The invention discloses an impeller auxiliary measuring base manufacturing device. The device comprises a piece of casting equipment which is used for casting a blank of a rectangular block and a melting shaping equipment which is used for shaping the blank of the rectangular block. The casting equipment comprises a casting base, a positioning sampling plate and a casting cavity, the casting cavity is of a T-shaped cavity, the casting cavity is formed by the casting base and moving side walls which are movably connected with the casting base, two first reserving grooves are formed in the T-shaped face of the side wall, where a first suspending arm is located, of the casting base, second reserving grooves are formed in the parts, corresponding to the first reserving grooves, of the moving side walls, the moving side walls are provided with pressing blocks which are correspondingly and detachably connected with the second reserving grooves, and two strip-shaped positioning plates are arranged through the first reserving grooves and the second reserving grooves. The device has the advantages that the measuring working period of an impeller can be greatly shortened.

Owner:CHINA HANGFA SOUTH IND CO LTD

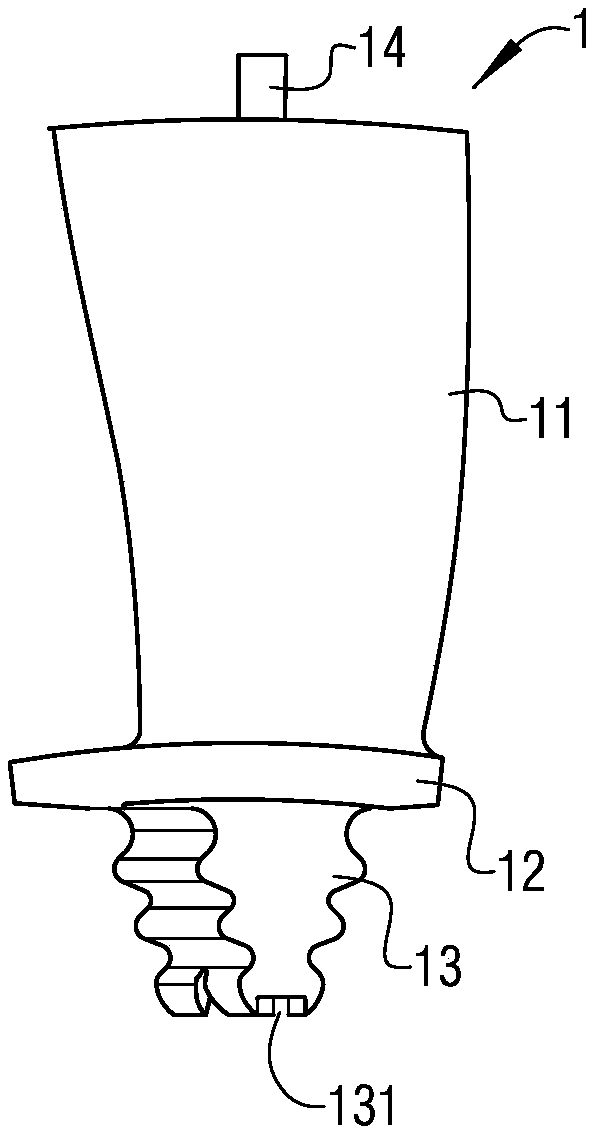

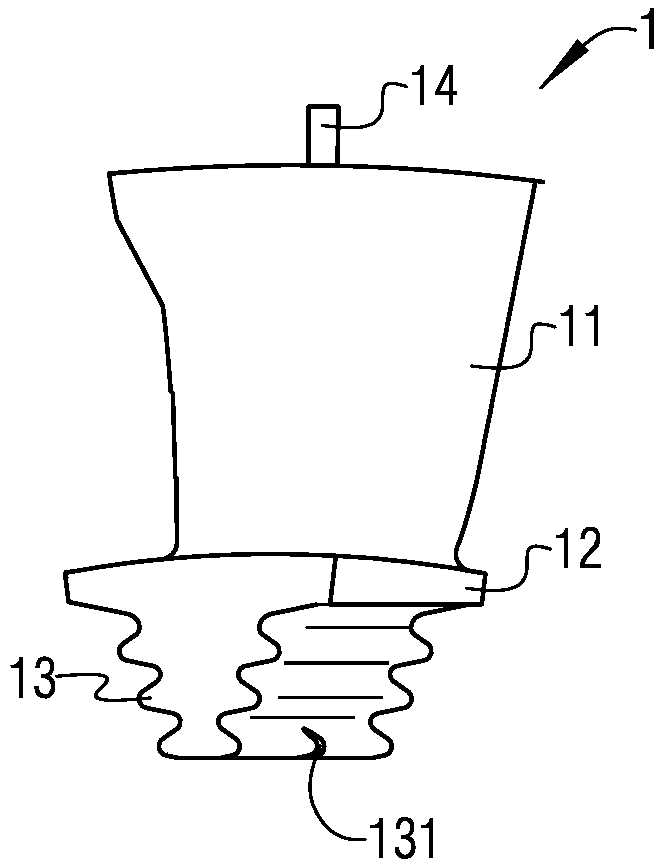

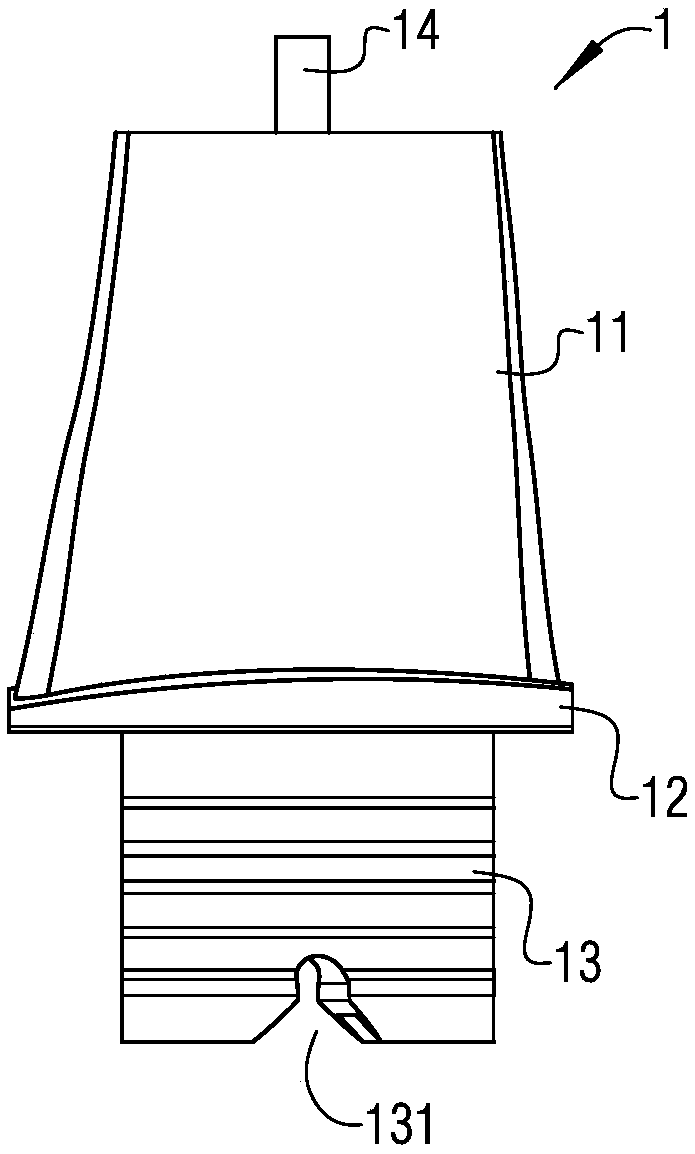

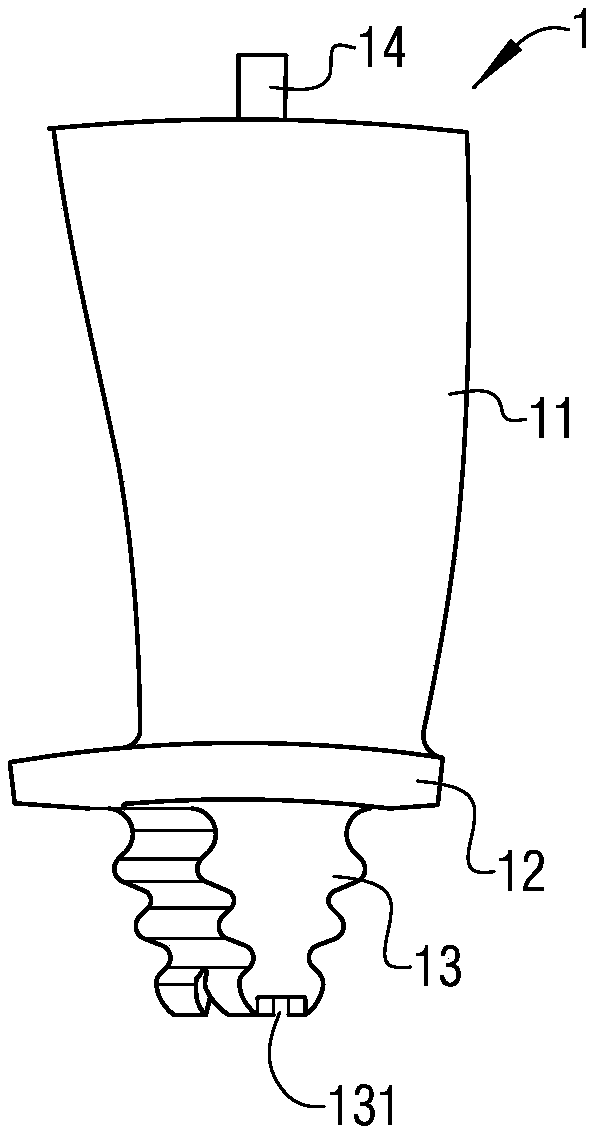

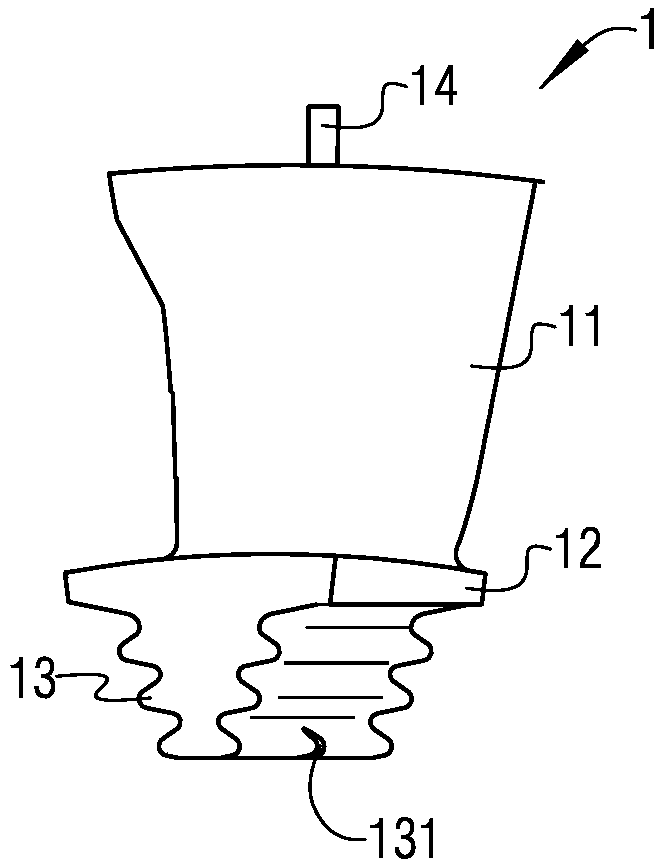

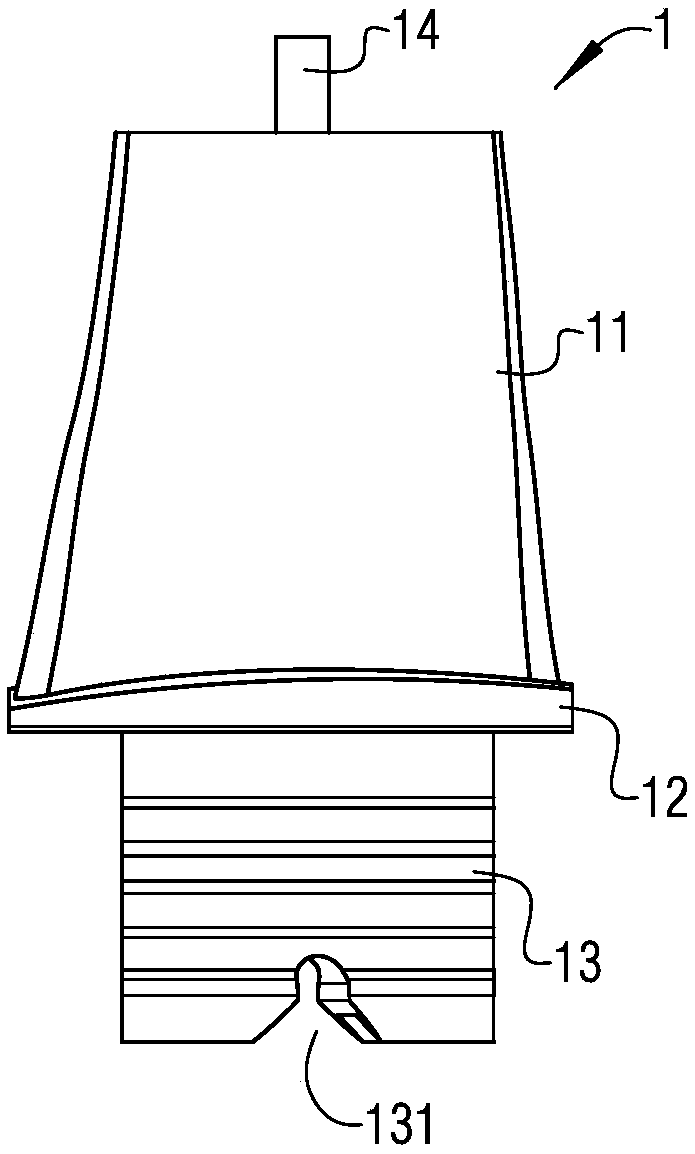

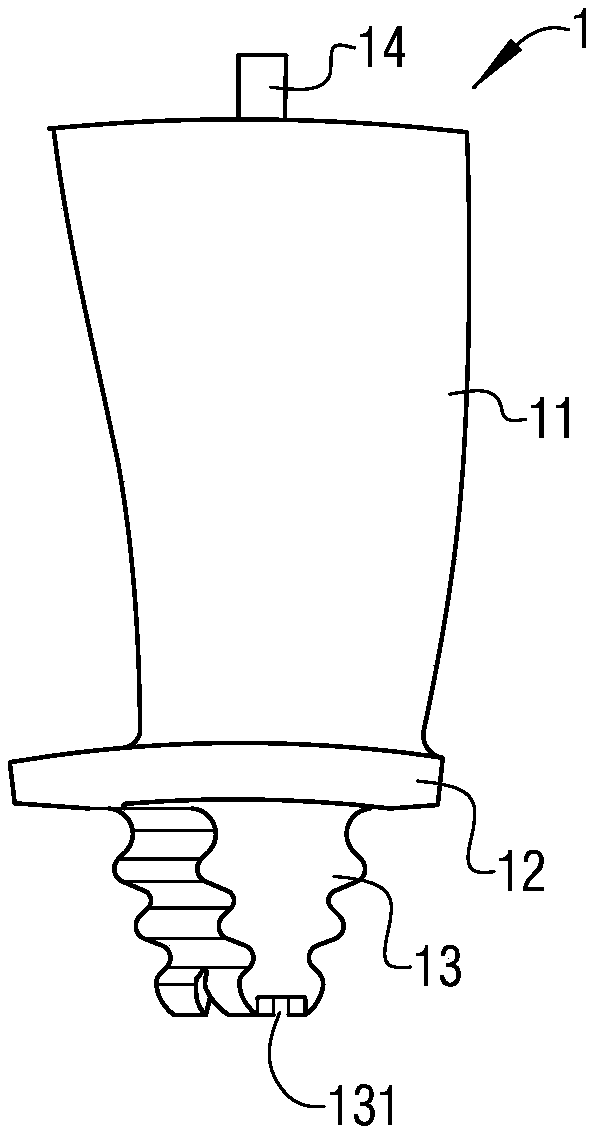

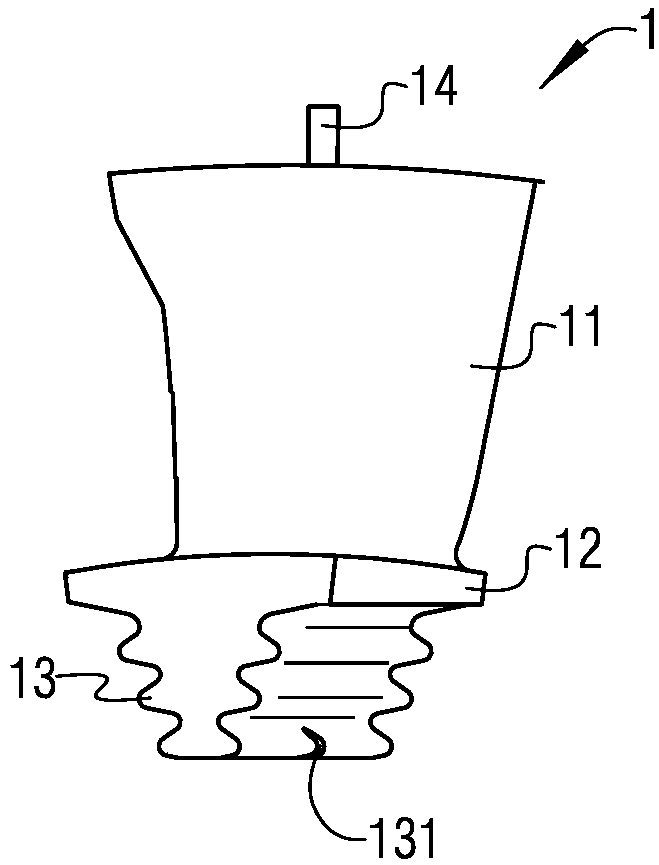

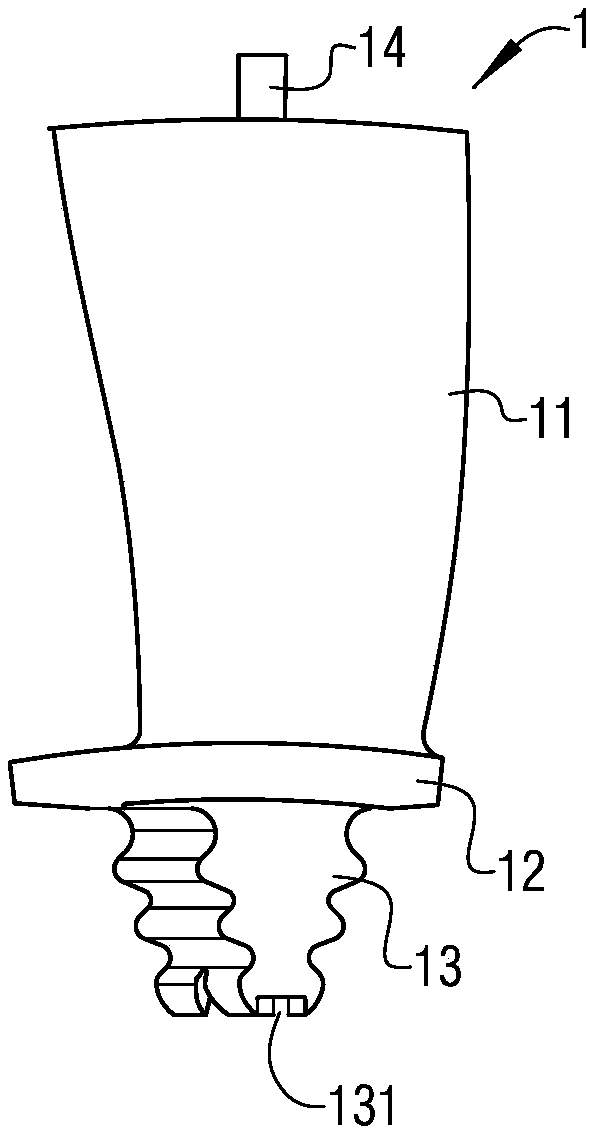

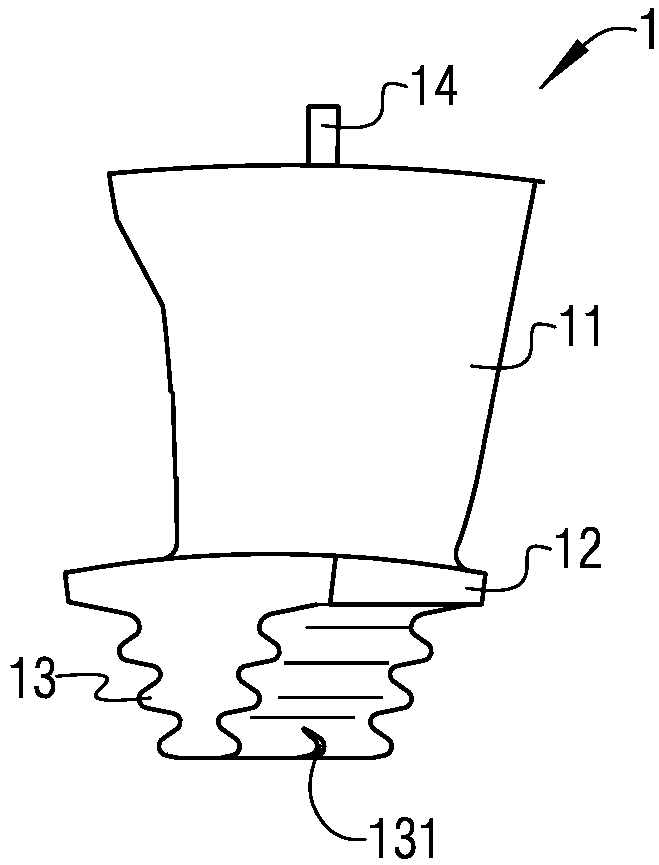

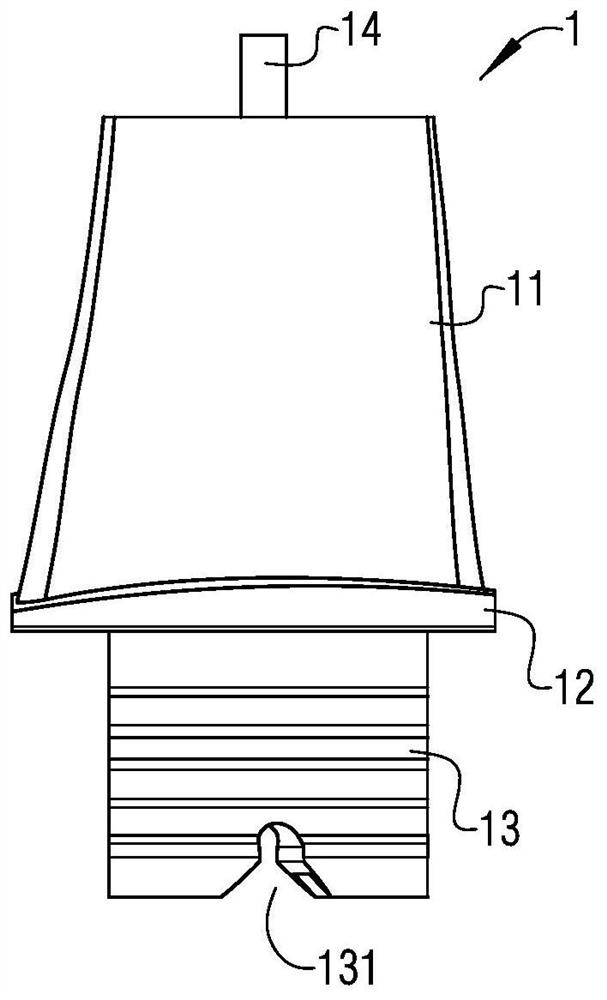

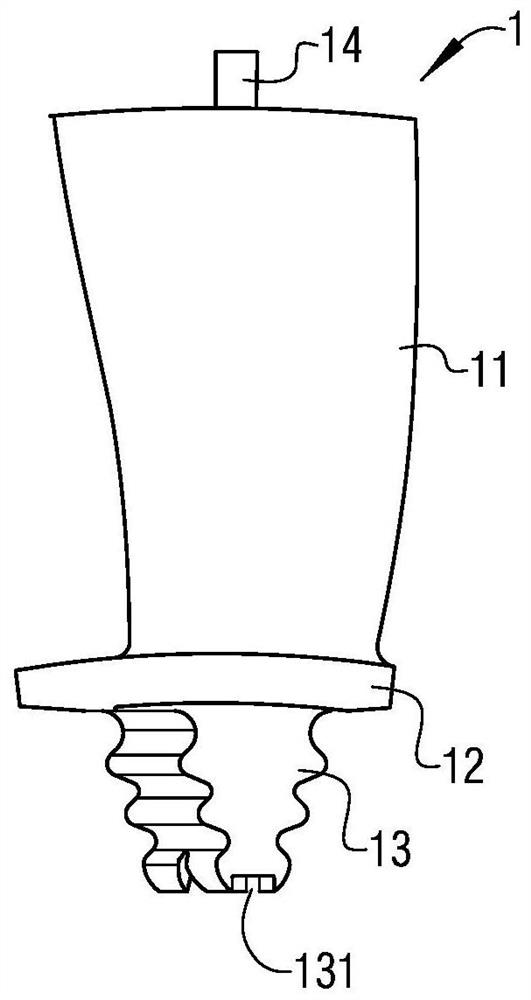

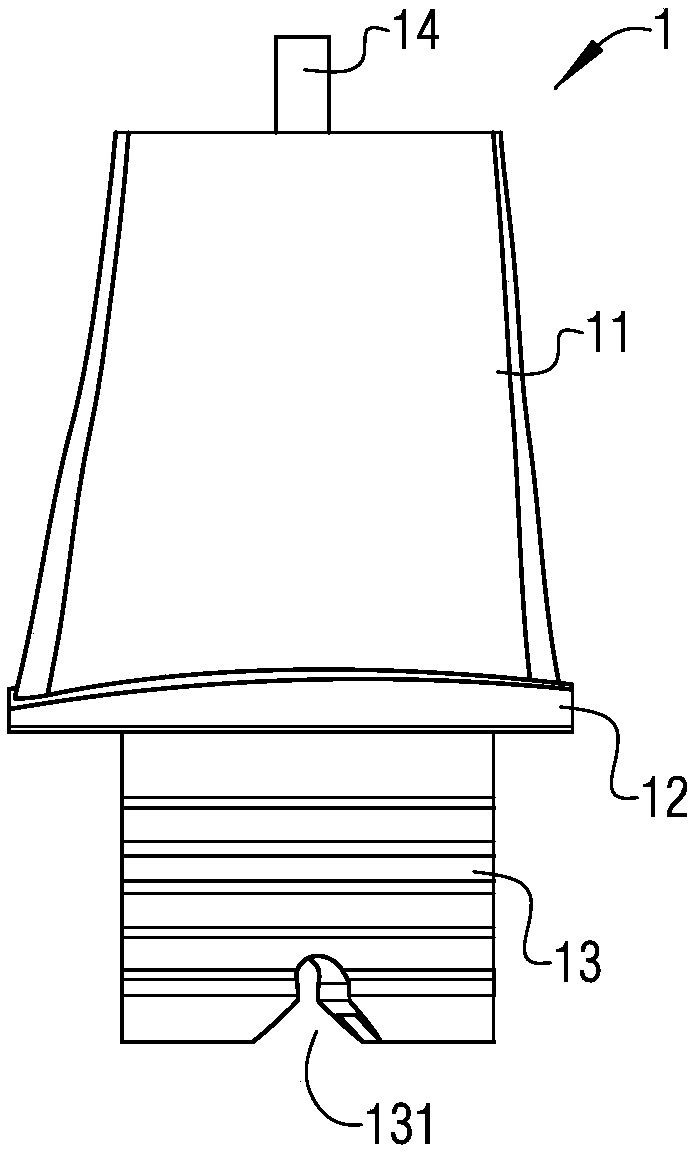

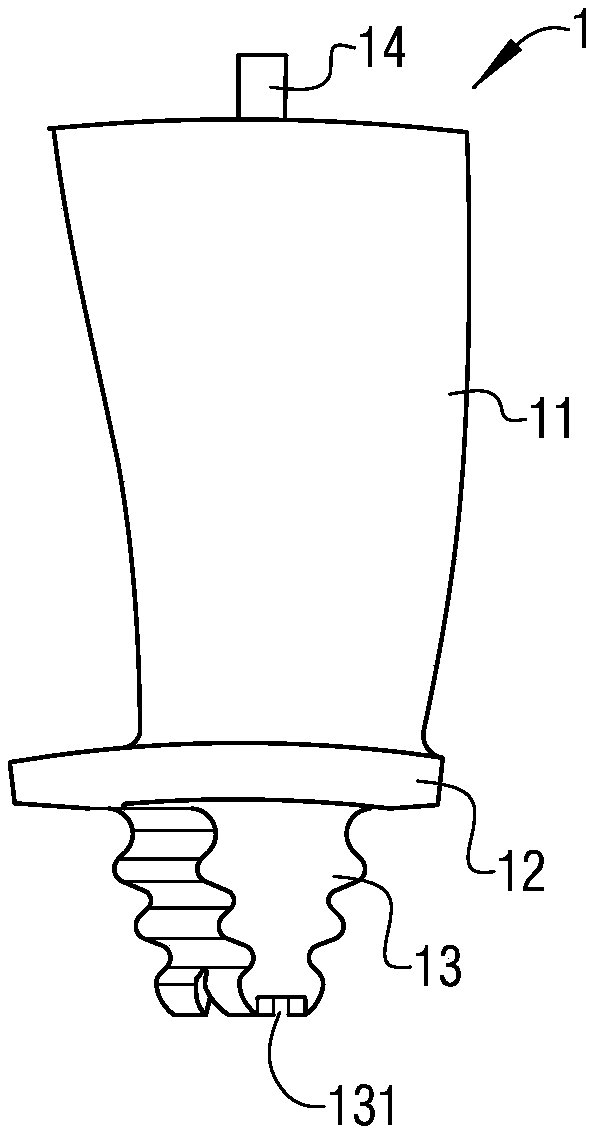

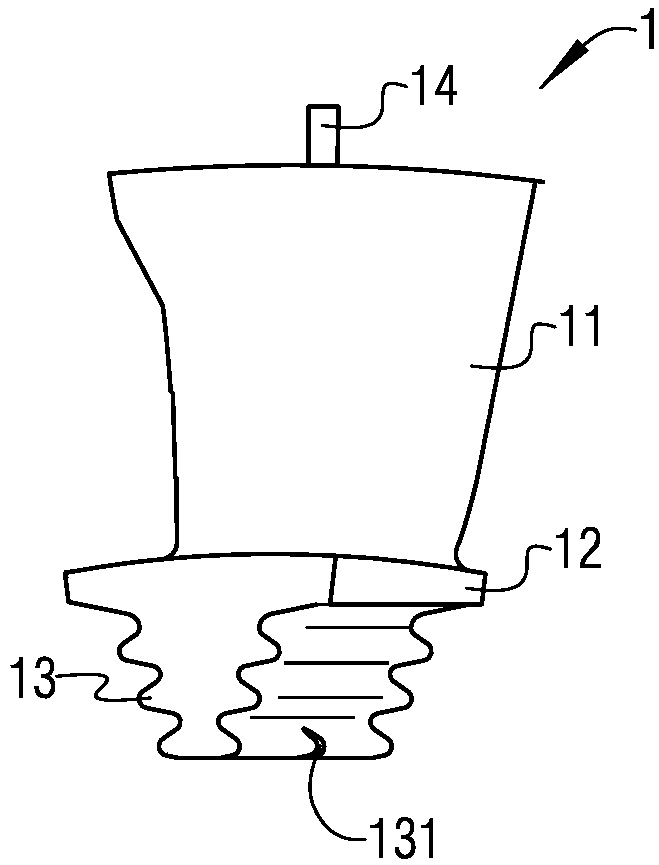

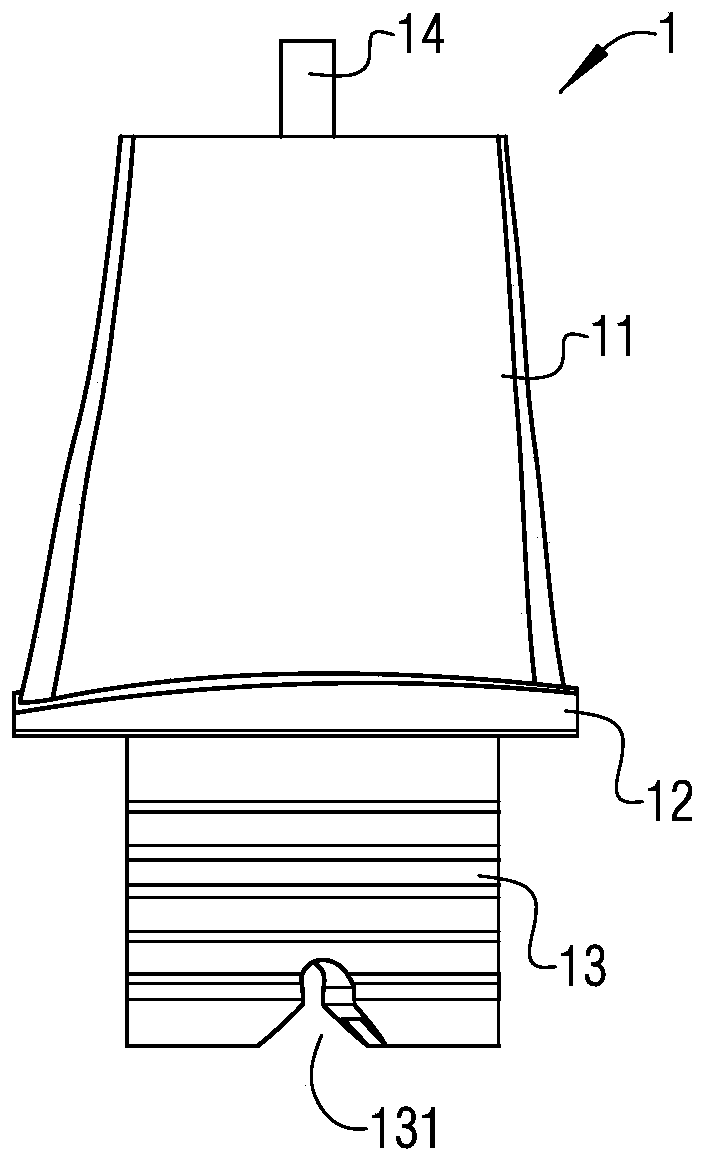

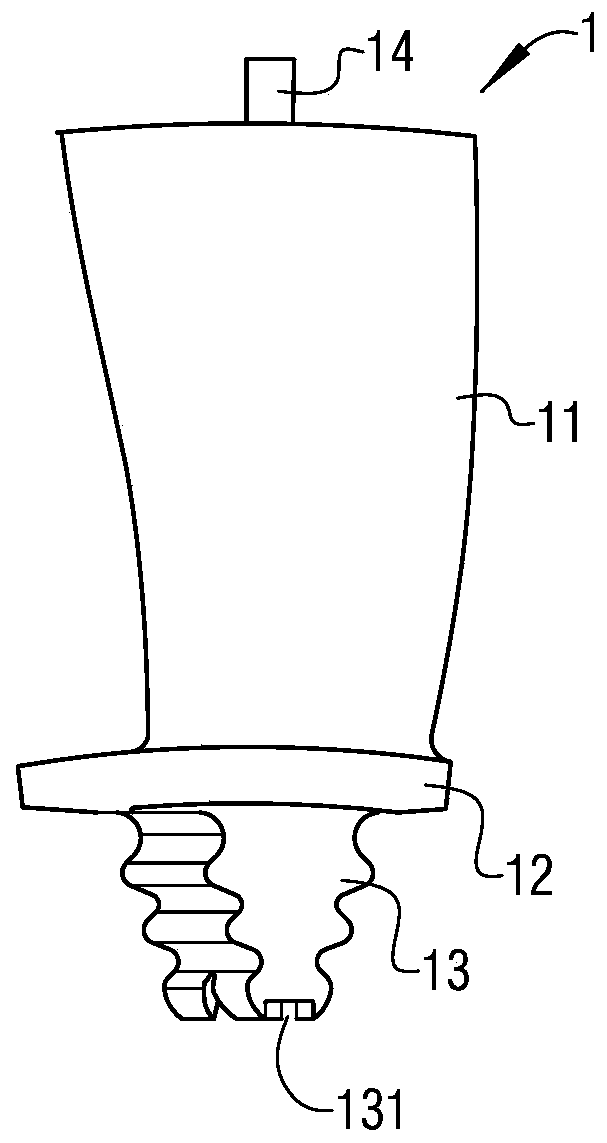

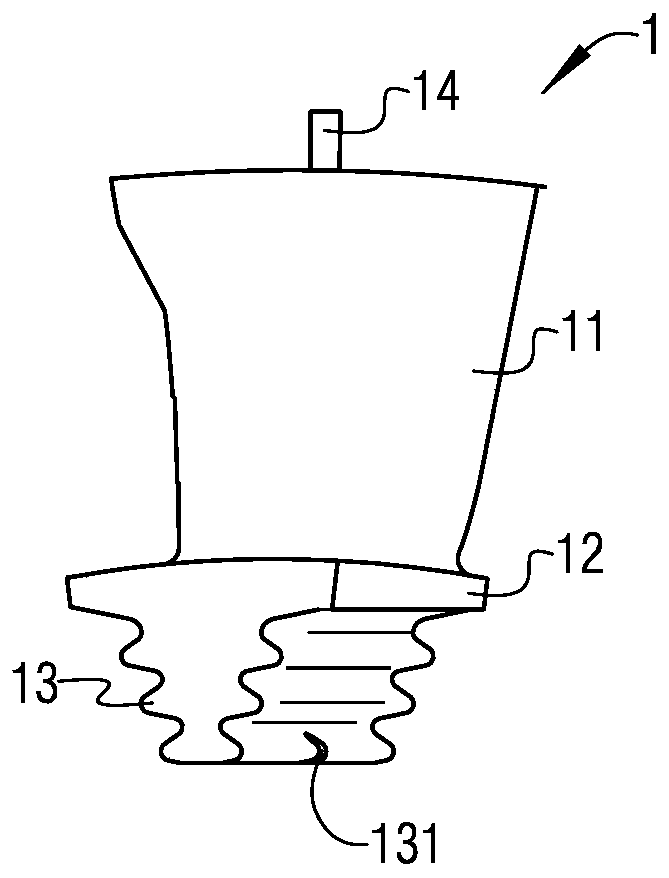

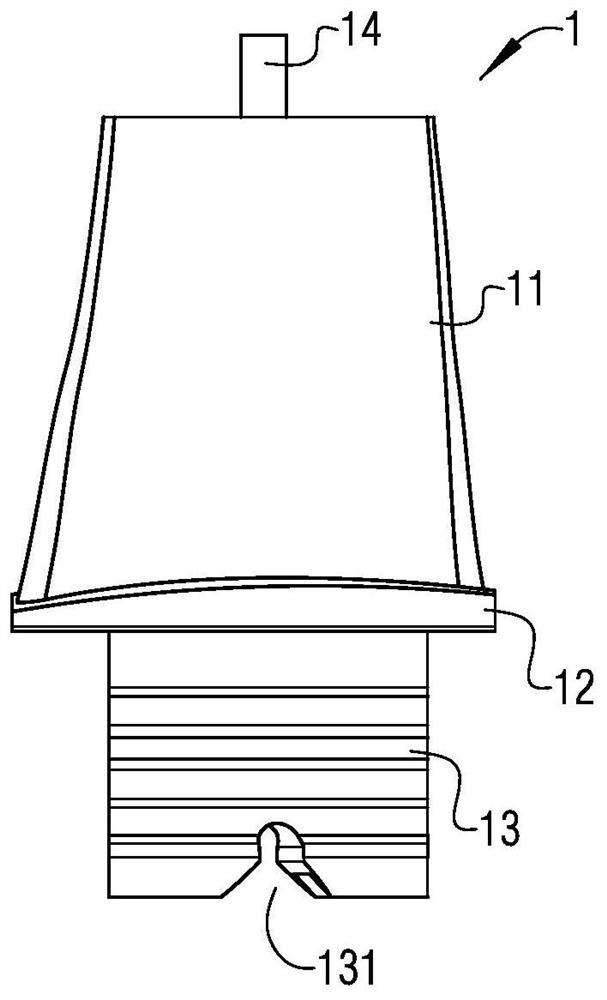

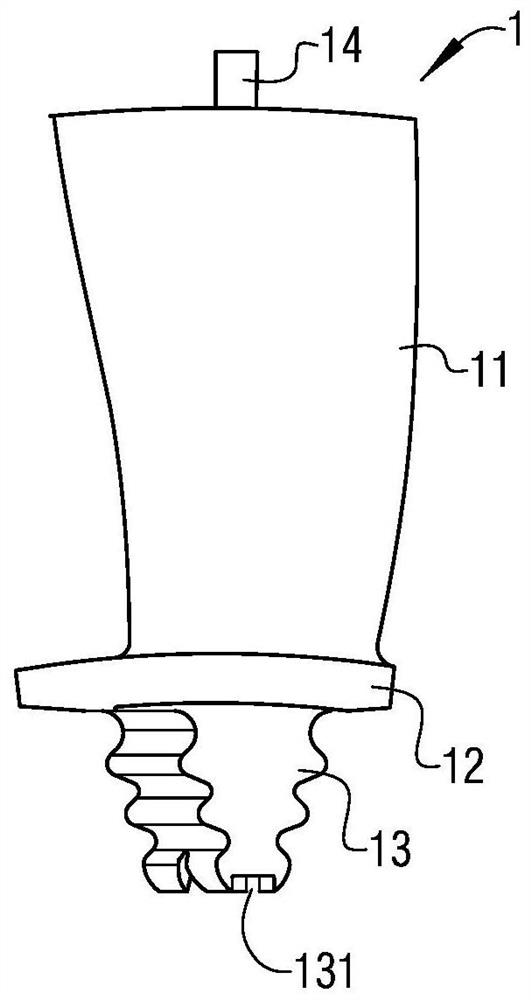

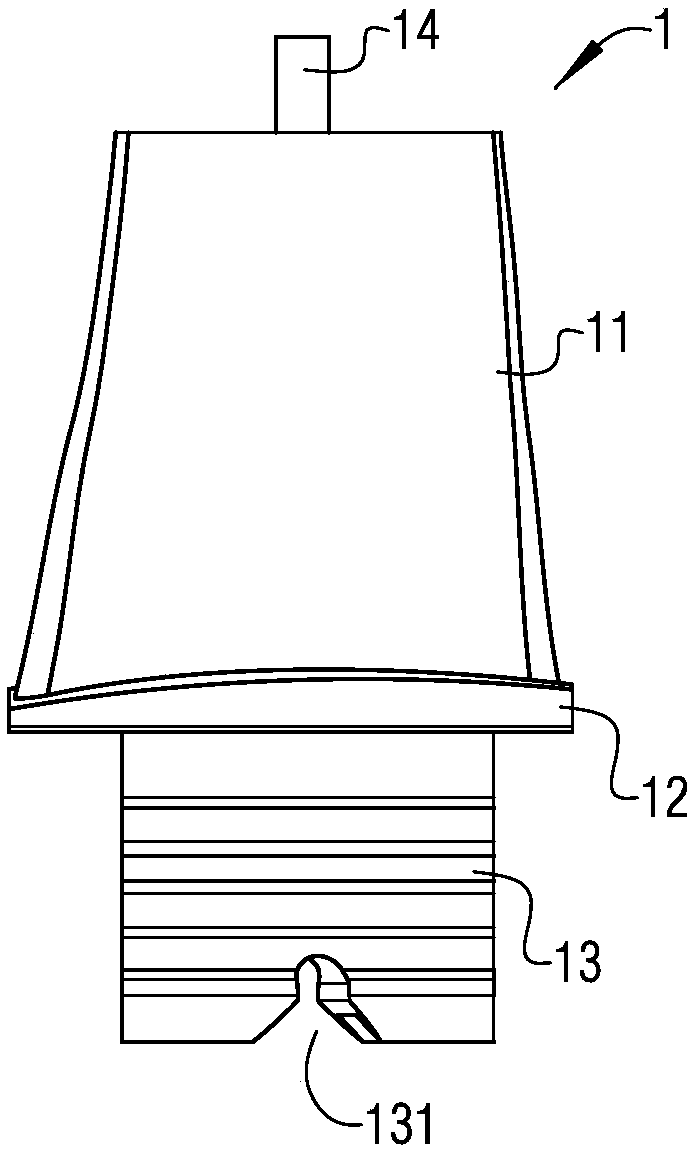

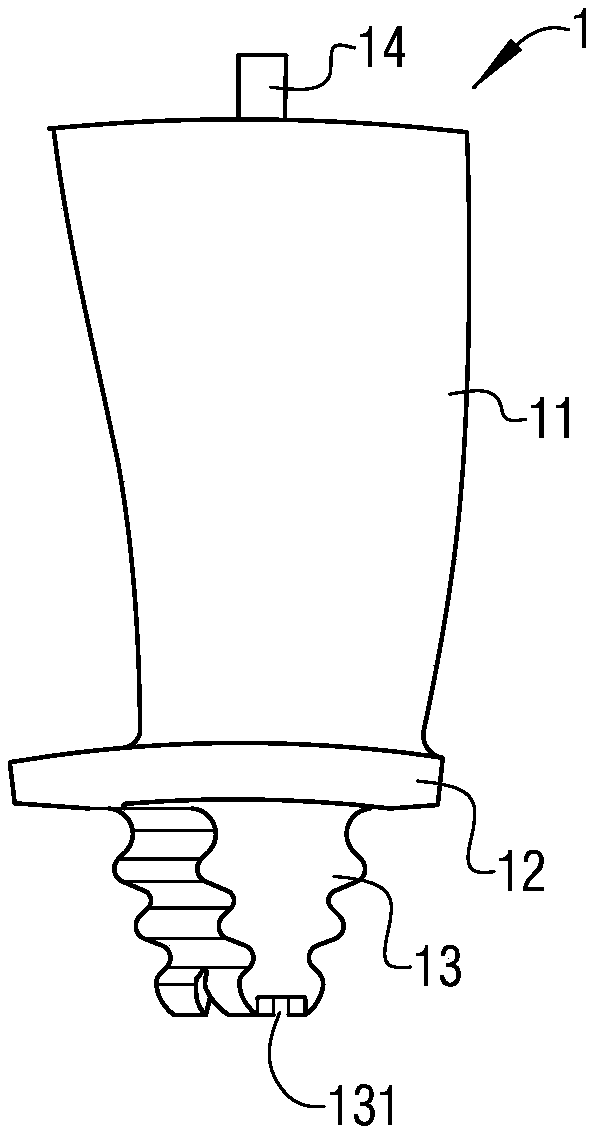

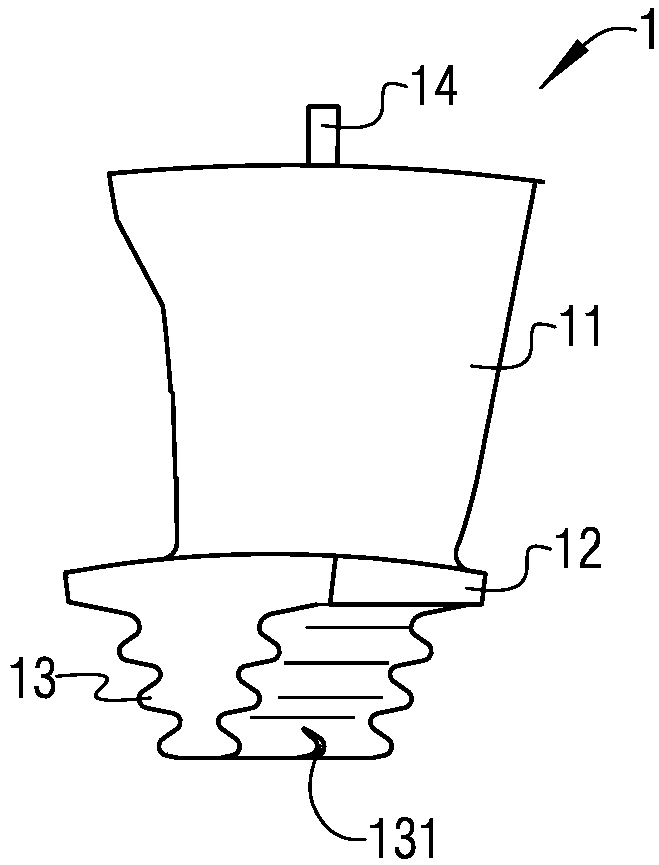

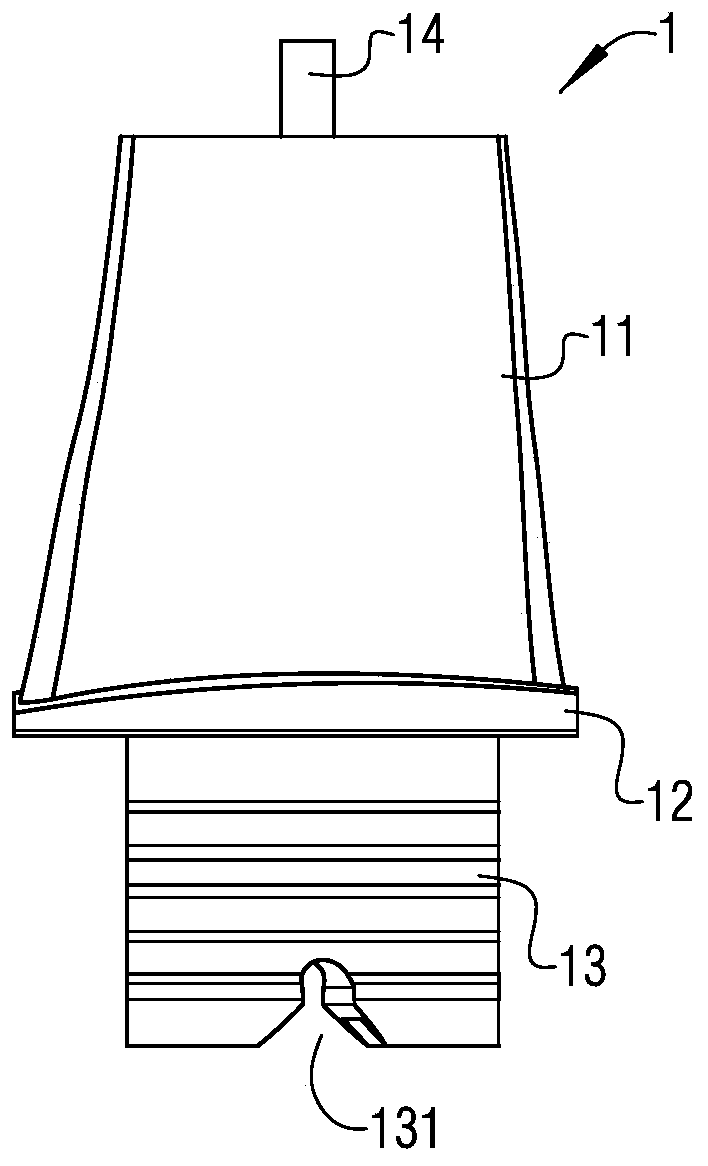

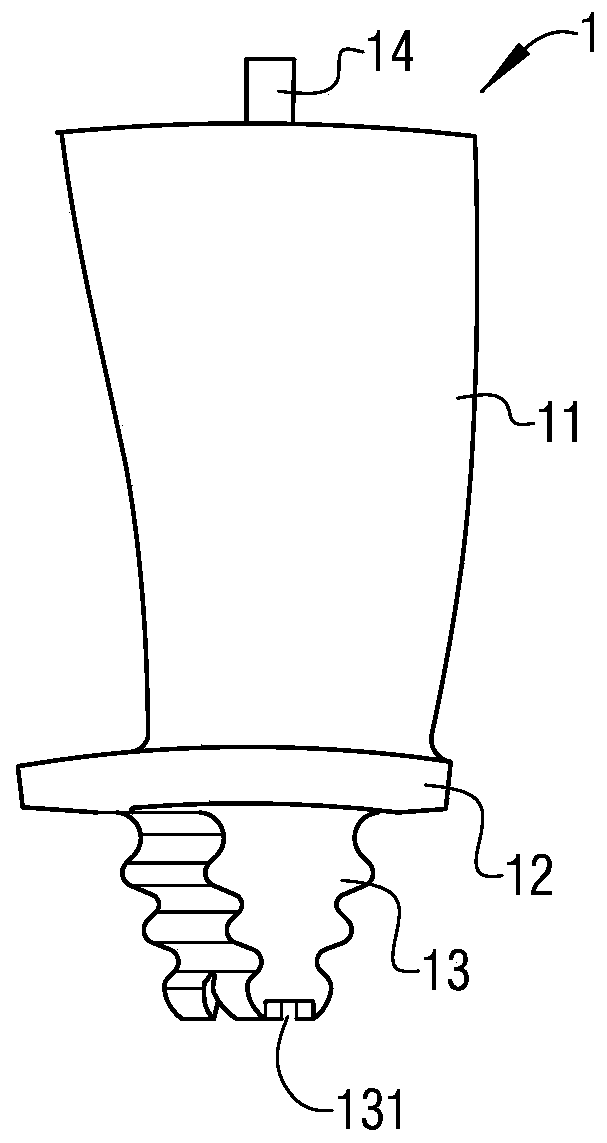

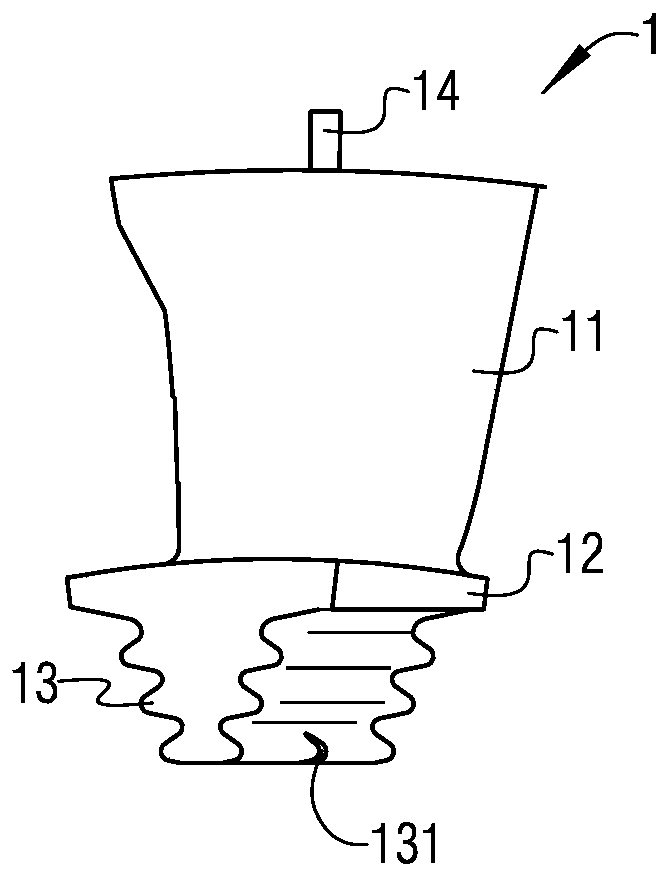

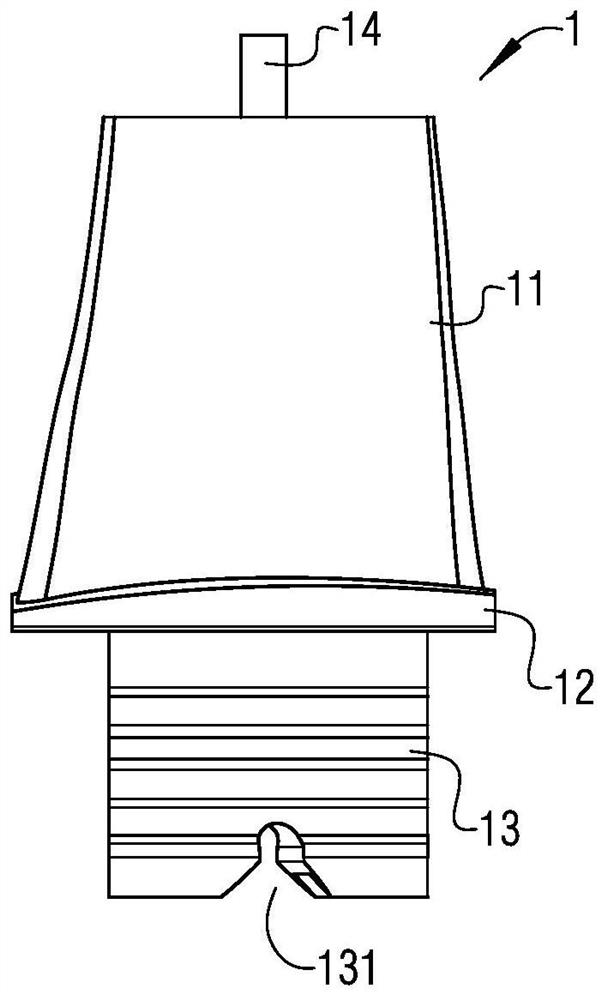

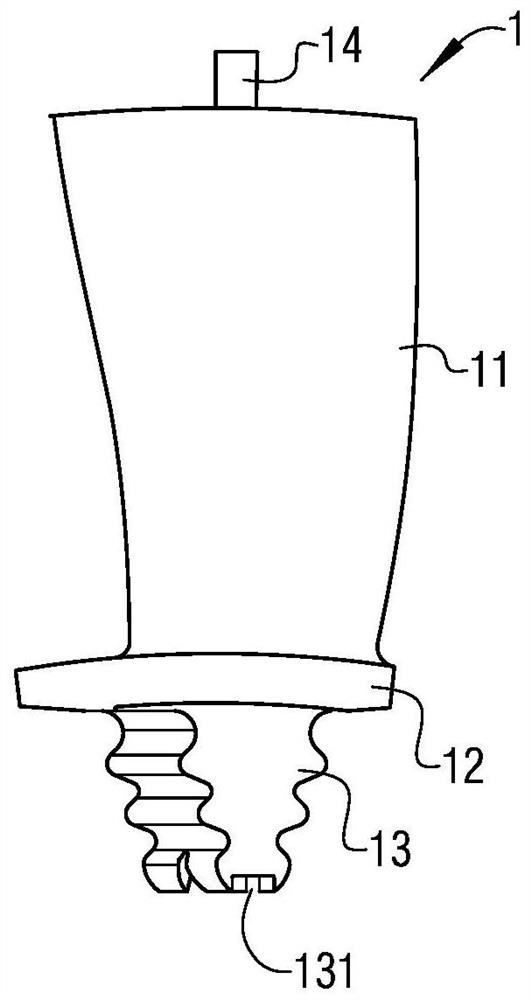

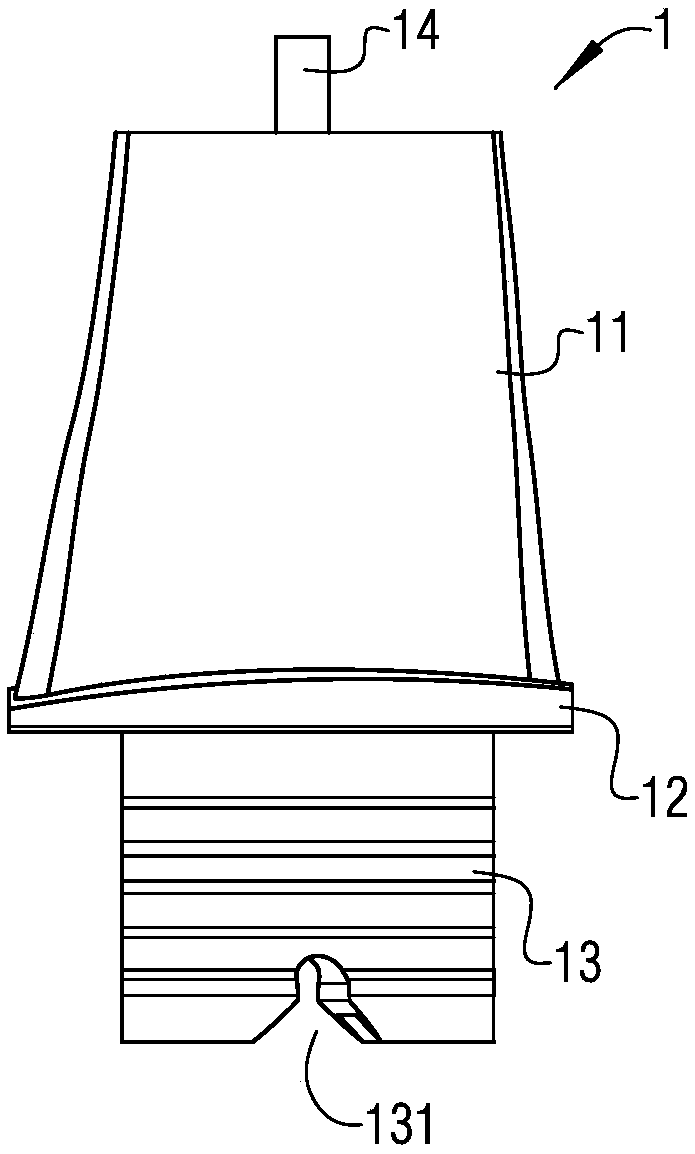

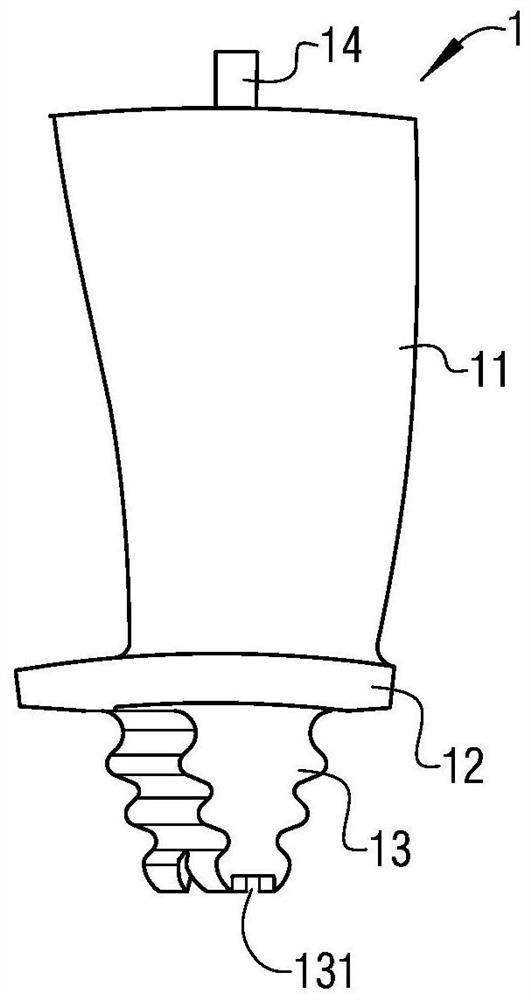

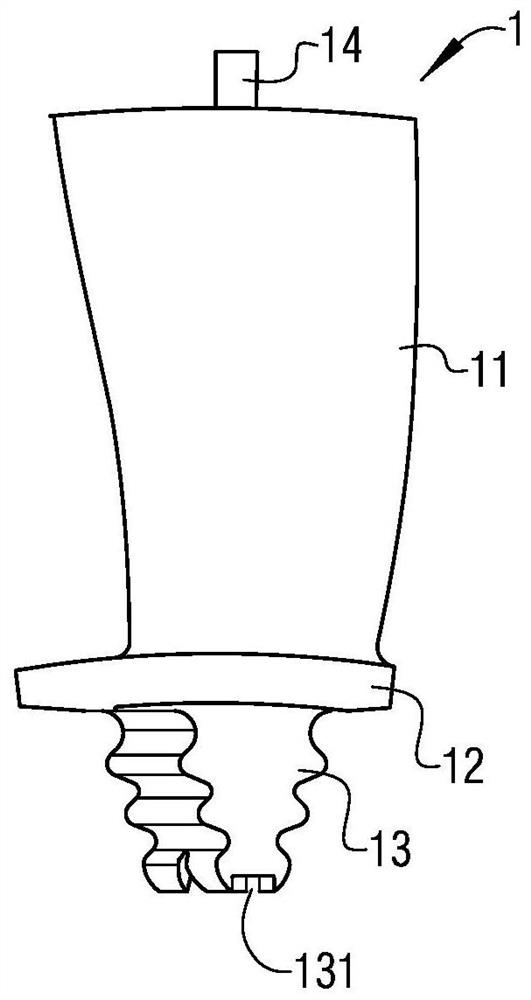

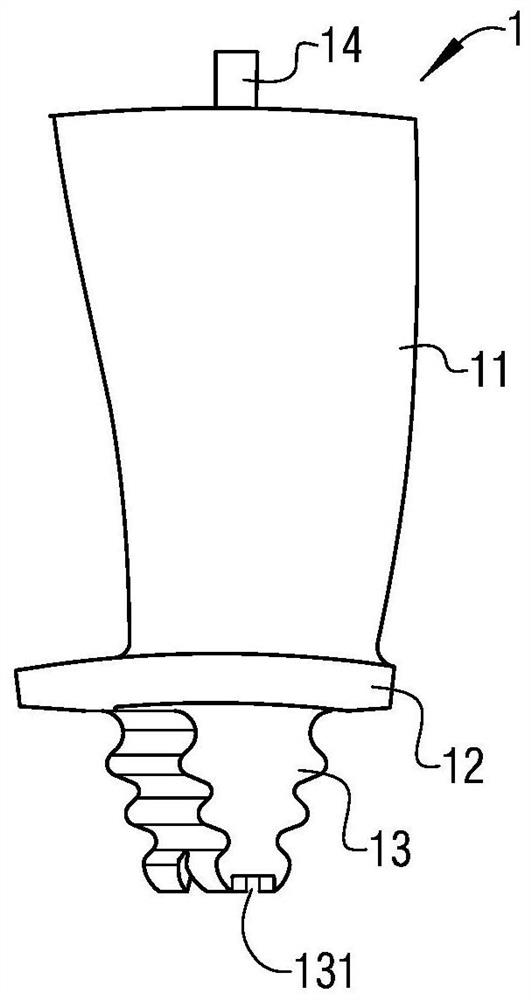

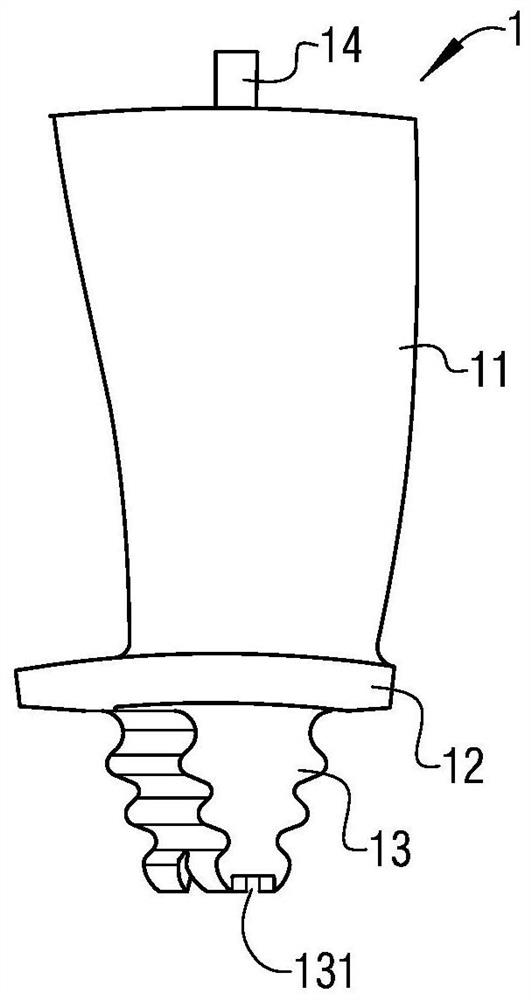

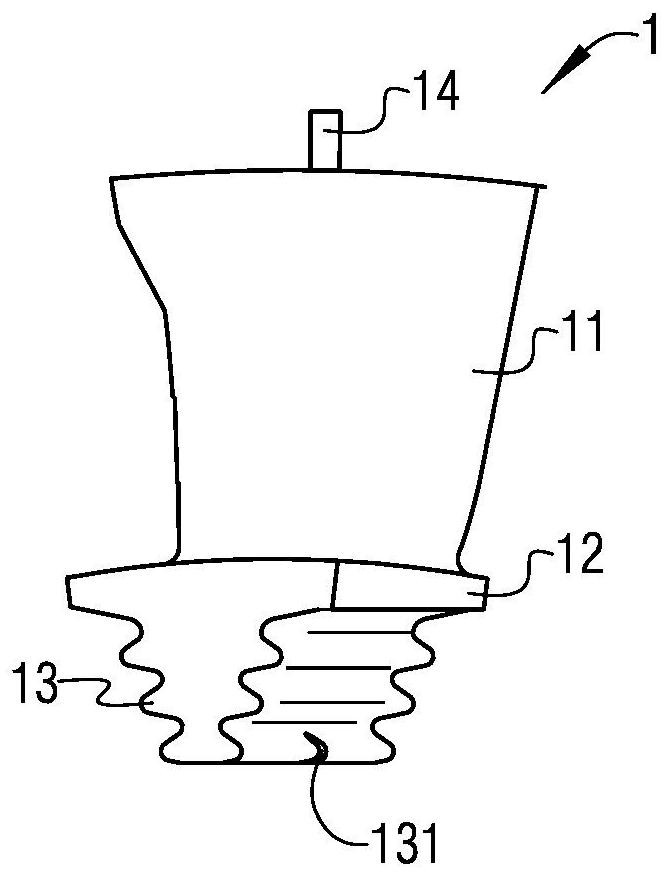

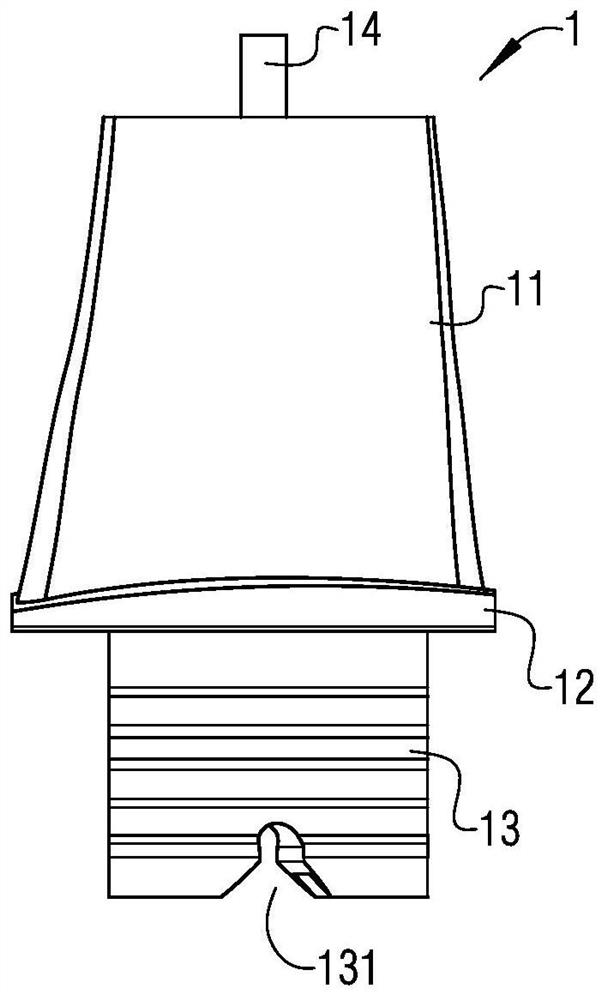

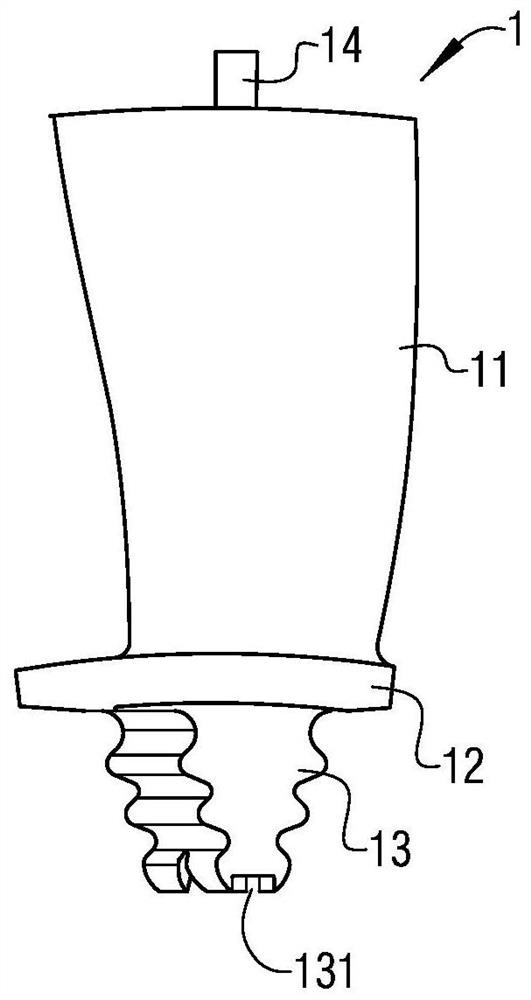

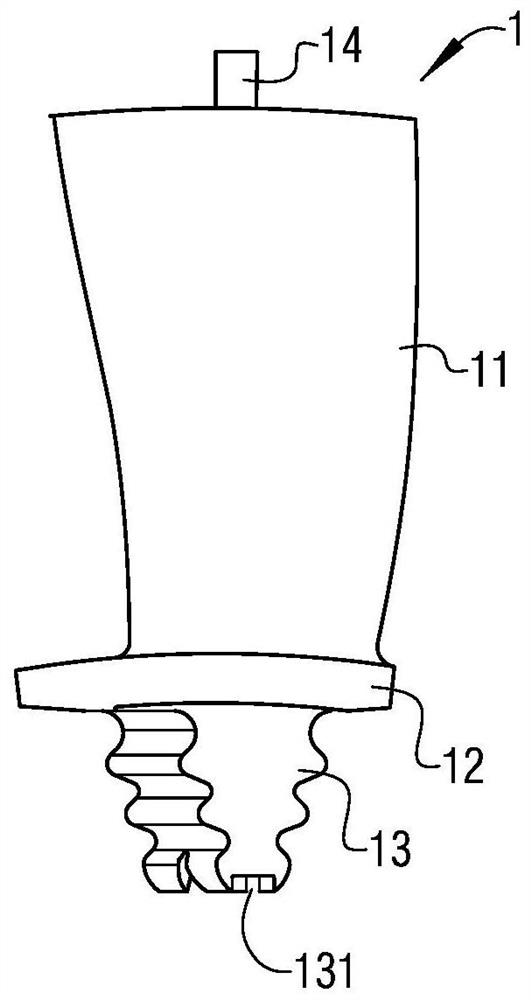

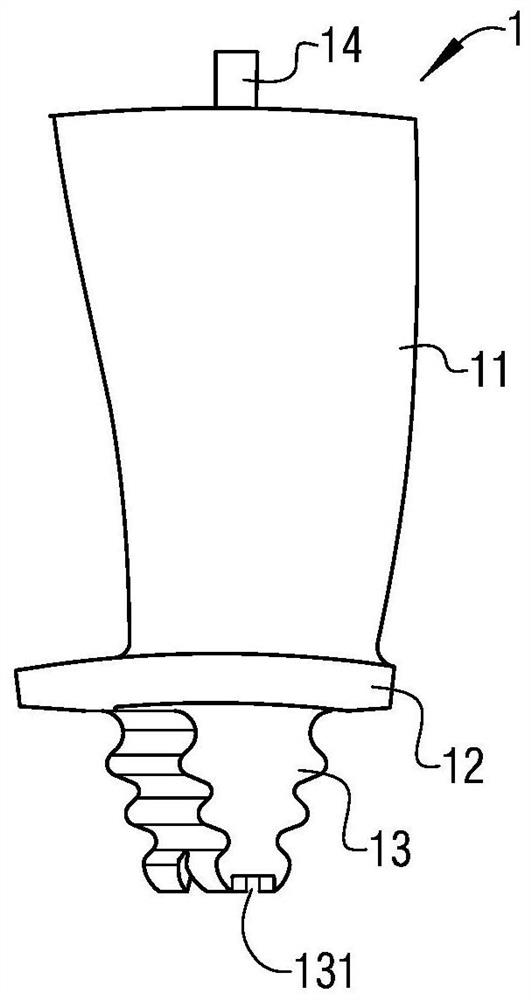

Turbine blade positioning base manufacturing method

ActiveCN109483172AShorten the measurement periodReduce manufacturing costWork holdersTurbine bladeAlloy

The invention discloses a turbine blade positioning base manufacturing method. The turbine blade positioning base manufacturing method comprises the following steps: (A) casting equipment is provided;the casting equipment comprises a casting base, a fixed positioning block and a movable positioning block; and a movable clamping part and a fixed clamping part fixedly clamp tenon teeth; (B) low-melting-point alloys are cast; and (C) alloy removing equipment is provided, and comprises a shaping base; the shaping base is provided with a rectangular working groove; horizontal oil spraying heads with the same heights are arranged on two opposite side walls in the working groove; and the horizontal oil spraying heads spray hot oil with a temperature of not lower than 180 DEG C to the connectingplace between two strip cavities until alloy blocks wrapped on top teeth of tenon heads under the strip cavities fall to finish preparation of rectangular blocks. In the turbine blade positioning basemanufacturing method, through preparation of standard positioning bases, the blade measuring period can be greatly shortened.

Owner:CHINA HANGFA SOUTH IND CO LTD

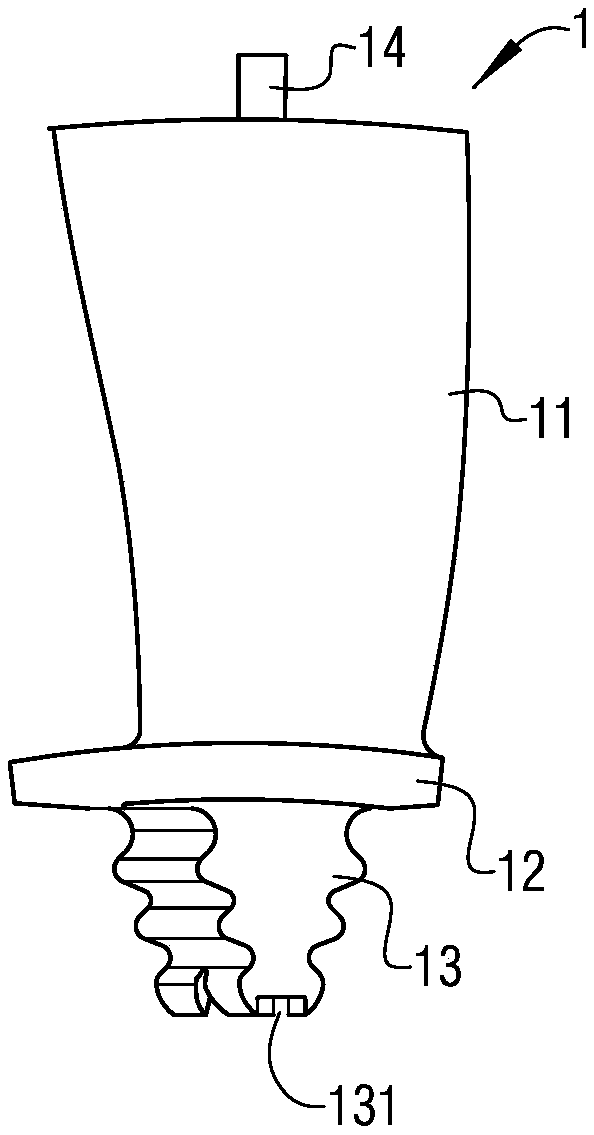

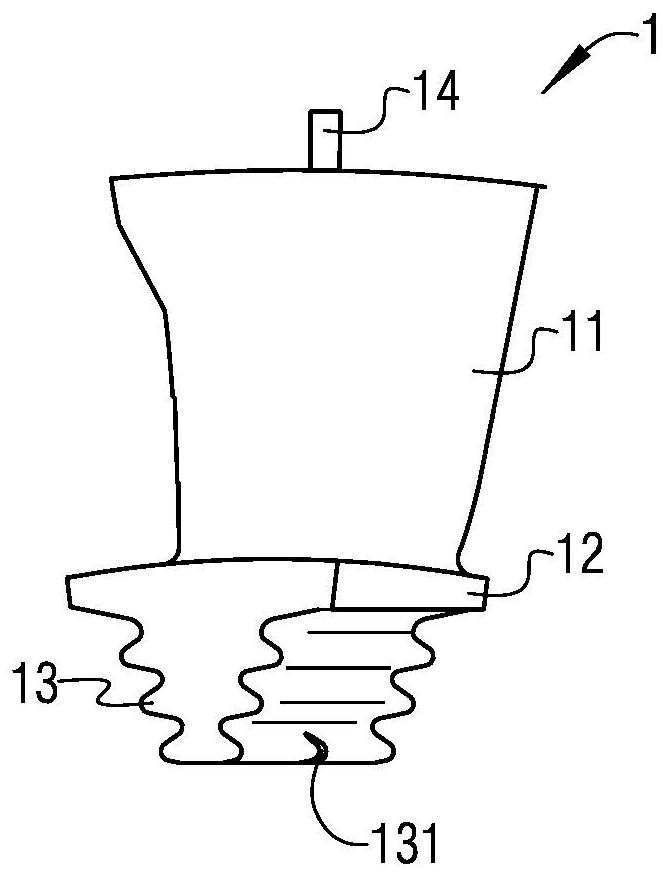

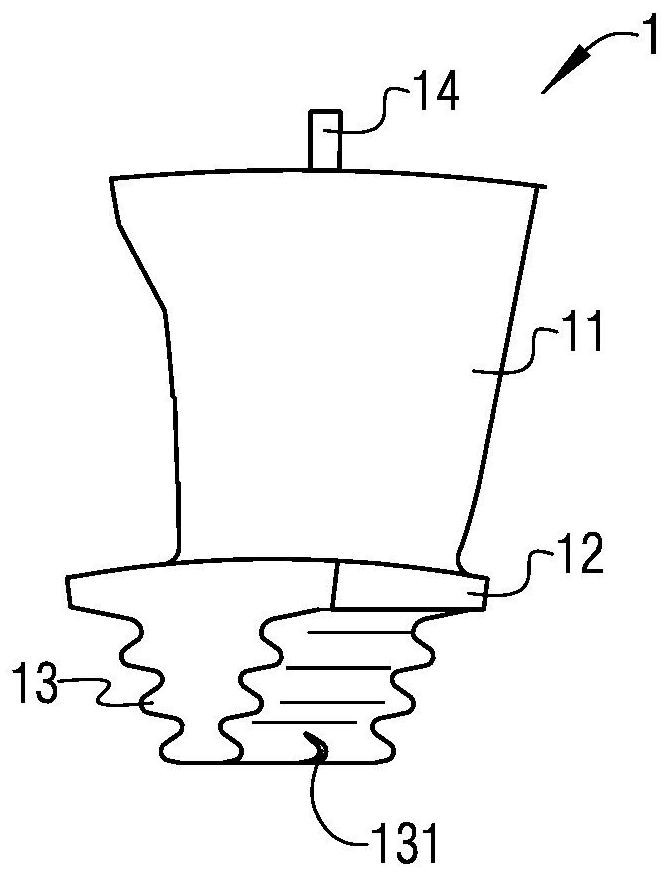

Blade measurement base preparation method

ActiveCN109317936AShorten the measurement periodReduce manufacturing costOther manufacturing equipments/toolsElectric heatingLocking plate

The invention provides a blade measurement base preparation method. The preparation method comprises the following steps of A, providing a casting device which comprises a casting base, a fixed locating block and a movable locating block; B, casting a low-melting-point alloy, cooling and solidifying the low-melting-point alloy and taking out a blade; and C, providing a cutting device and cutting an alloy part wrapping a locking plate groove at the bottom of tenon teeth through an electric heating wire to complete preparation of the rectangular block. Through the blade measurement base preparation method provided by the invention, a standard base is prepared, the measurement period of blades can be greatly shortened, and meanwhile, the production cost and the maintenance cost can be reduced.

Owner:CHINA HANGFA SOUTH IND CO LTD

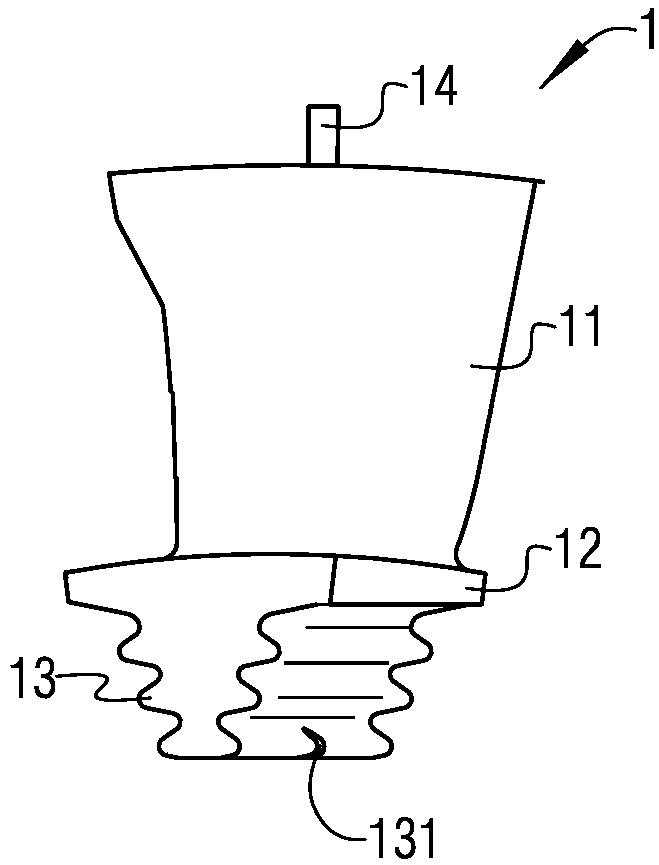

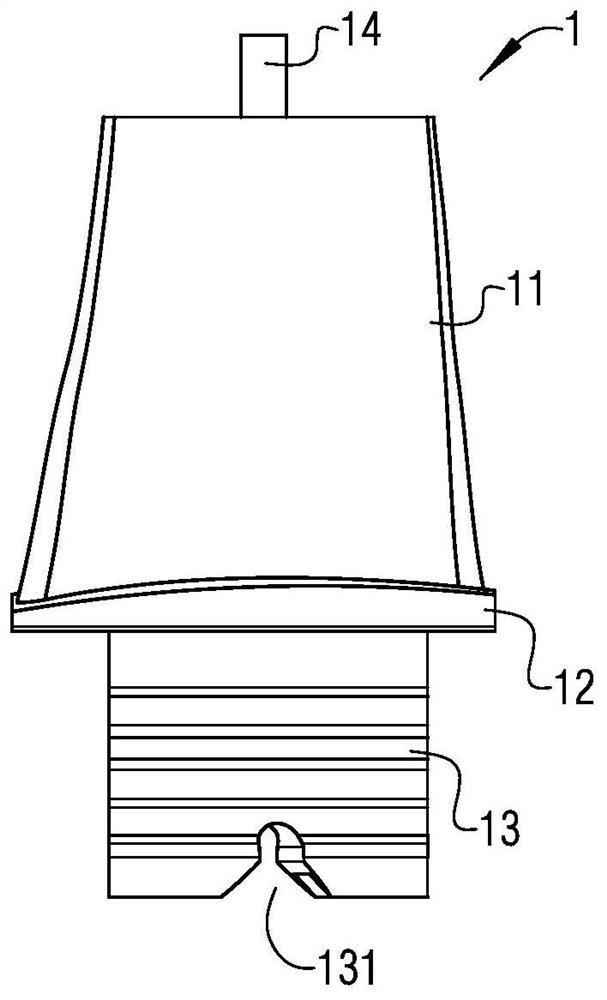

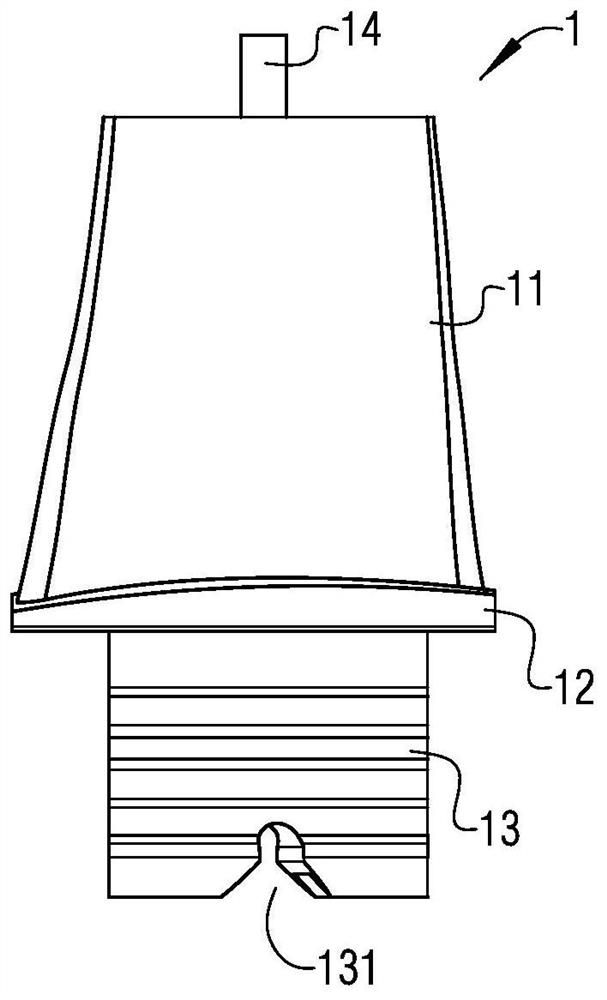

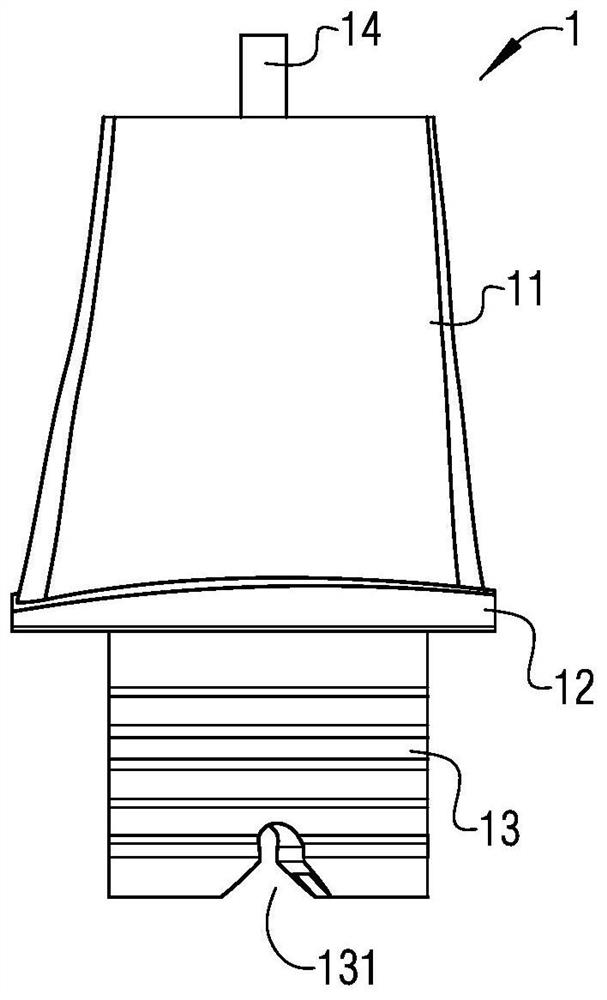

Impeller auxiliary measuring base manufacturing method

ActiveCN109458900AShorten the measurement periodReduce manufacturing costFoundry mouldsFoundry coresImpellerAlloy

The invention discloses an impeller auxiliary measuring base manufacturing method. The method comprises the steps that A, a piece of casting equipment is provided, and an impeller is fixed; B, low-melting-point alloy casting is conducted in a casting cavity, and the integrally casting of a positioning plate and a rectangular block is conducted; C, a piece of melting shaping equipment is provided to allow the alloy covering a lock piece groove formed in the top of a tenon tooth to be melted, so that the lock piece groove is allowed to be exposed from the rectangular block, and the preparation of the rectangular block is completed. The method has the advantages that a standardized base is prepared so that the measuring working period of the impeller can be greatly shortened, and the production cost and maintaining cost can be reduced.

Owner:CHINA HANGFA SOUTH IND CO LTD

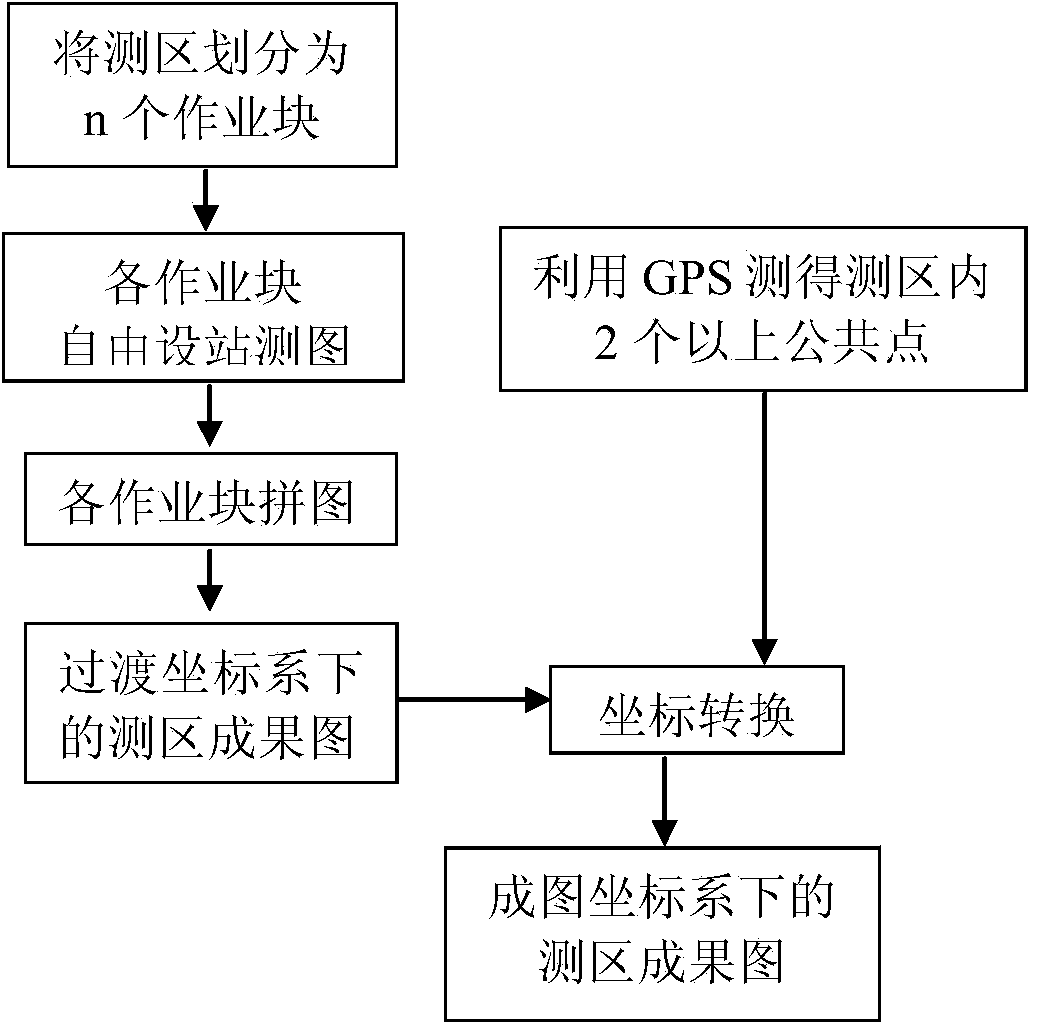

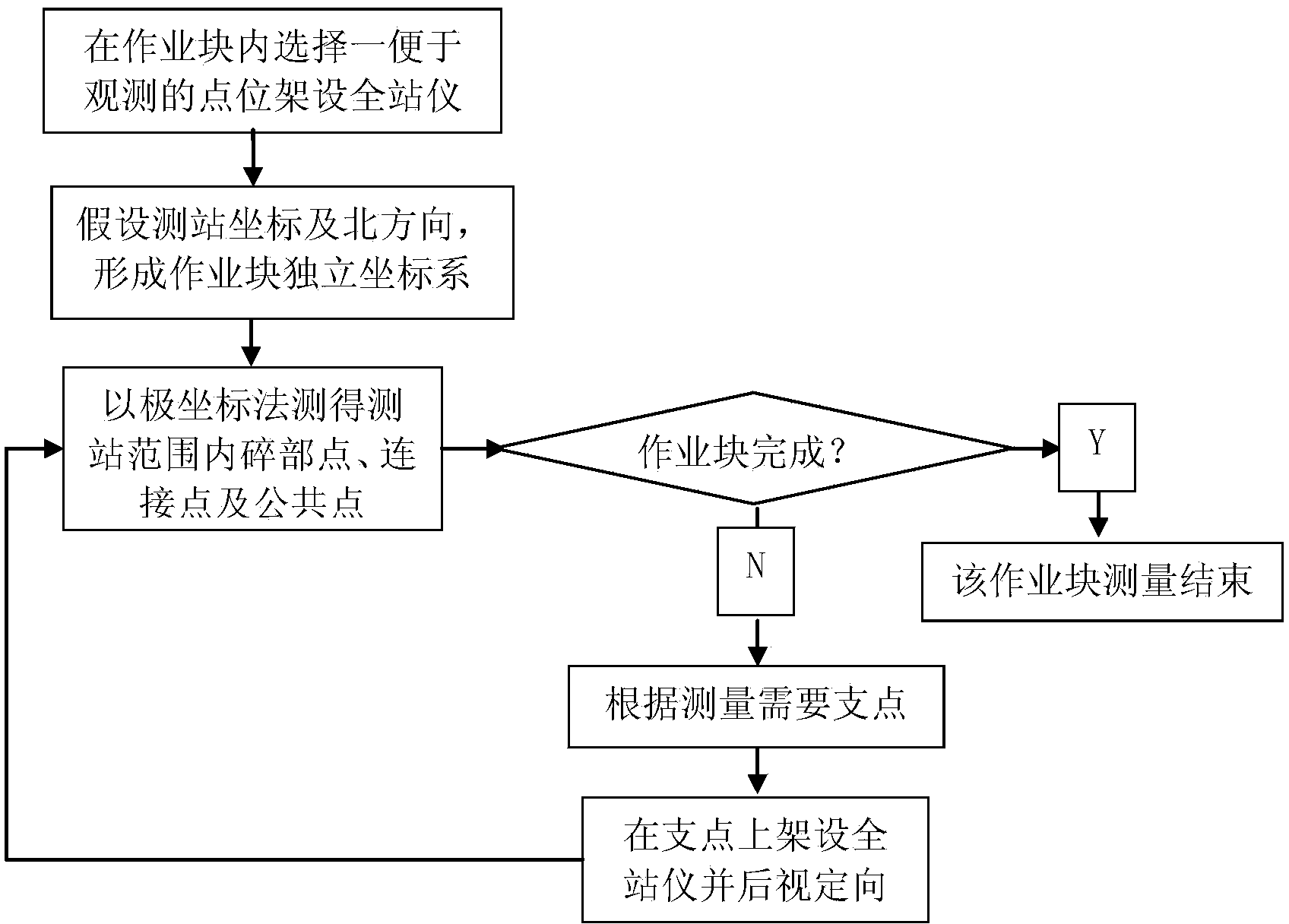

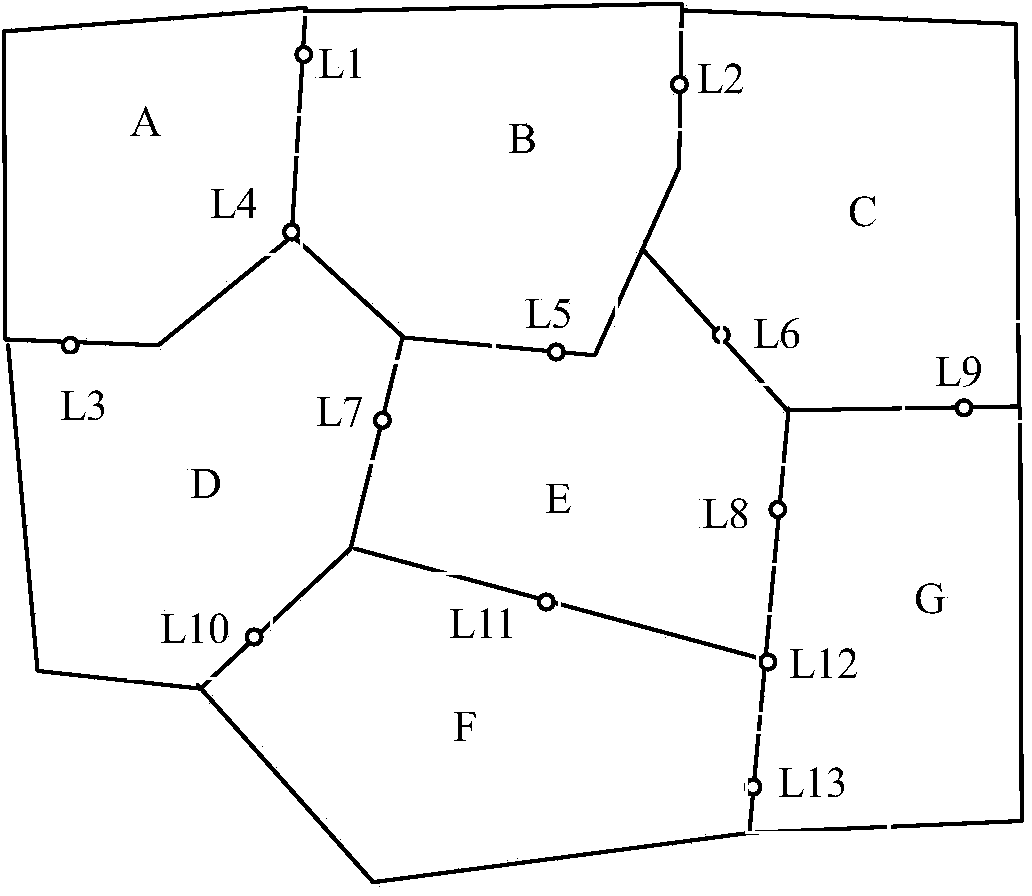

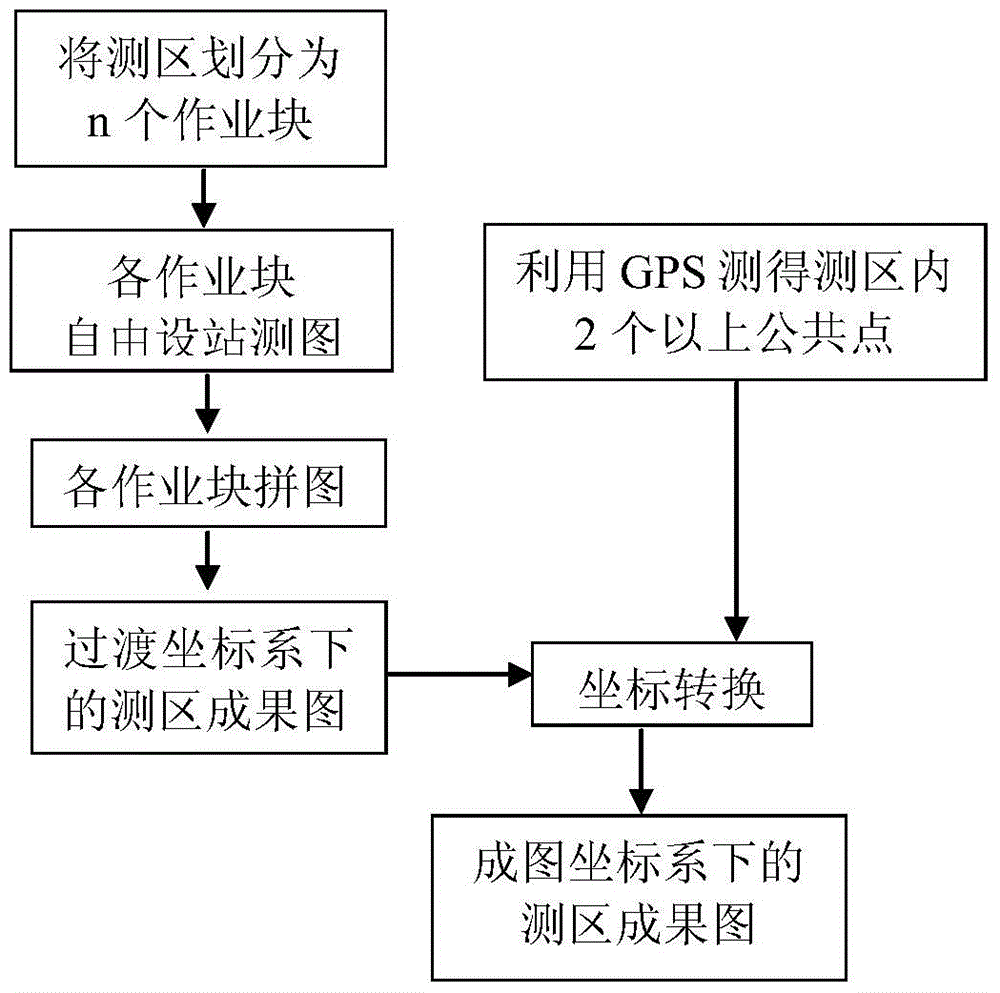

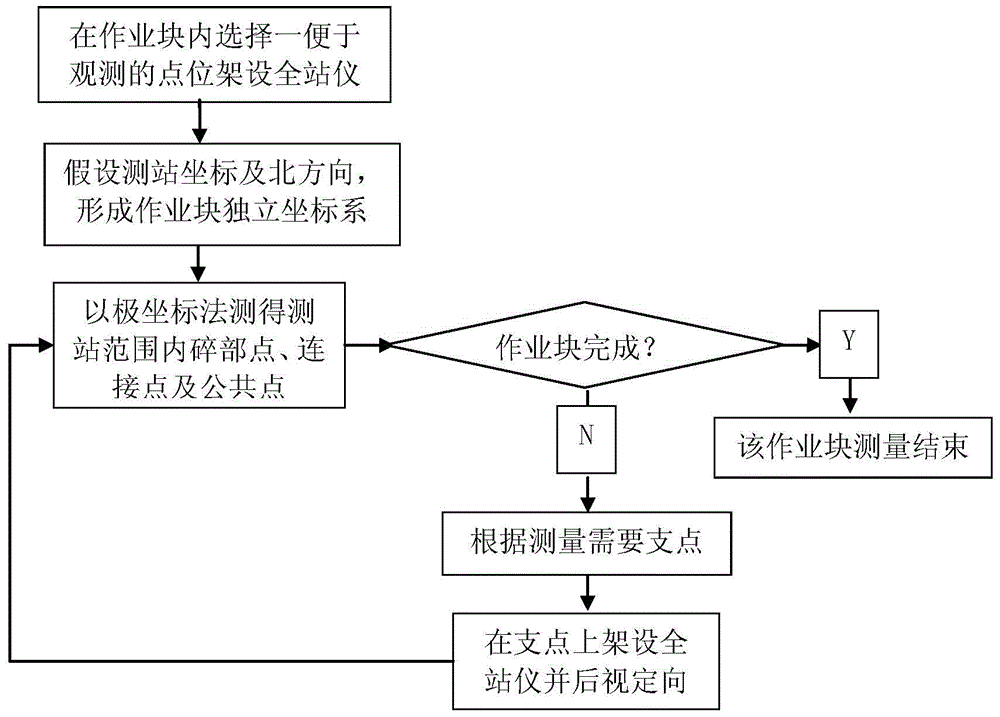

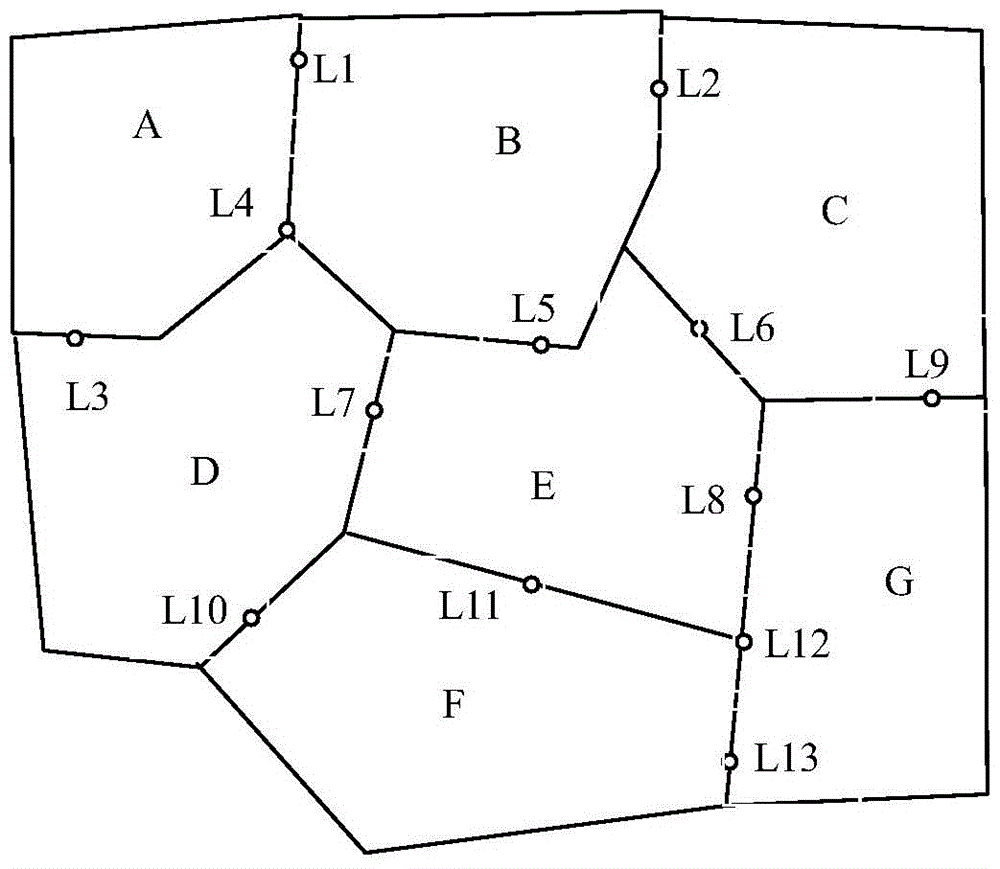

Mapping method employing assembly of multiple job blocks based on free station establishment

ActiveCN104316036ARelieve measurement pressureEasy to observeSurveying instrumentsComputer scienceJoin point

The invention discloses a mapping method employing assembly of multiple job blocks based on free station establishment. The mapping method includes the following steps: the coordinates of two or more common points in a finished map coordinate system are measured in a whole mapping area through the GPS (global position system) technology; the whole mapping area is divided into n job blocks, and a connecting point is arranged between every two adjacent job blocks; a job block result map under an independent coordinate system is obtained for each job block through the free station establishment method; all the job block result maps are jointed through the connecting points, so as to obtain a mapping area result map under a transitional coordinate system; a mapping area result map under the finished map coordinate system is obtained through the common points and coordinate transformation. The method has the advantages of few necessary GPS points, avoidance of the mapping control measurement process, as well as short mapping period, and is particularly suitable for mapping in towns, mountainous areas and other areas with intervisibility difficulties.

Owner:SOUTHEAST UNIV

Construction method of spiral steel pipe pile in photovoltaic power station

ActiveCN106193034BGuaranteed positioning accuracyEnsure personal safetyBulkheads/pilesGps measurementRotation function

The invention relates to the field of construction of photovoltaic power stations, and discloses a photovoltaic power station spiral steel pipe pile construction method. The construction method uses a total station for calibrating and adjusting pile positions on main axles after using GPS measuring equipment for quickly measuring and setting the pile positions, so that the positioning precision of the pile positions is guaranteed; a domestic general outdoor down-hole drill is refitted, so that the cost is low, the performance is reliable, and the safety is high; the propelling and rotating functions of the drill are used; and a self-made driving shaft is added at the front end of a revolving speed reducing box output shaft of the drill, so that a drill output shaft and a spiral steel pipe pile can be connected and disassembled more conveniently, the drilling construction requirements of the spiral steel pipe pile are satisfied, and the construction efficiency, reliability, safety and economy are greatly improved. The method is suitable for flat floors or mountains with slopes of not higher than 30 degrees, and is suitable for construction of the spiral steel pipe pile under the condition that the thickness of a remolded place soil layer is not smaller than a designed drilling depth.

Owner:SEPCO ELECTRIC POWER CONSTR CORP

Manufacturing method for pedestal used for blade measuring

ActiveCN109465606AShorten the measurement periodReduce manufacturing costWork periodElectric heating

The invention discloses a manufacturing method for a pedestal used for blade measuring, and the pedestal is a rectangular block which is cast from a low-melting-point alloy, and surrounds tenon teeth.The manufacturing method comprises the following steps: step A, providing casting equipment and fixing blades; step B, pouring the low-melting-point alloy into the casting cavity, and taking out theblades with the rectangular block when the low-melting-point alloy is quickly condensed; and step C, providing cutting equipment, utilizing an electric heating wire to cut an alloy part which coats alocking sheet slot, thereby accomplishing manufacturing of the rectangular block. According to the manufacturing method for the pedestal used for blade measuring provided by the invention, the standard pedestal is manufactured, so that the measuring work-period of the blades can be greatly shortened; and meanwhile, production cost and maintenance cost can be reduced.

Owner:CHINA HANGFA SOUTH IND CO LTD

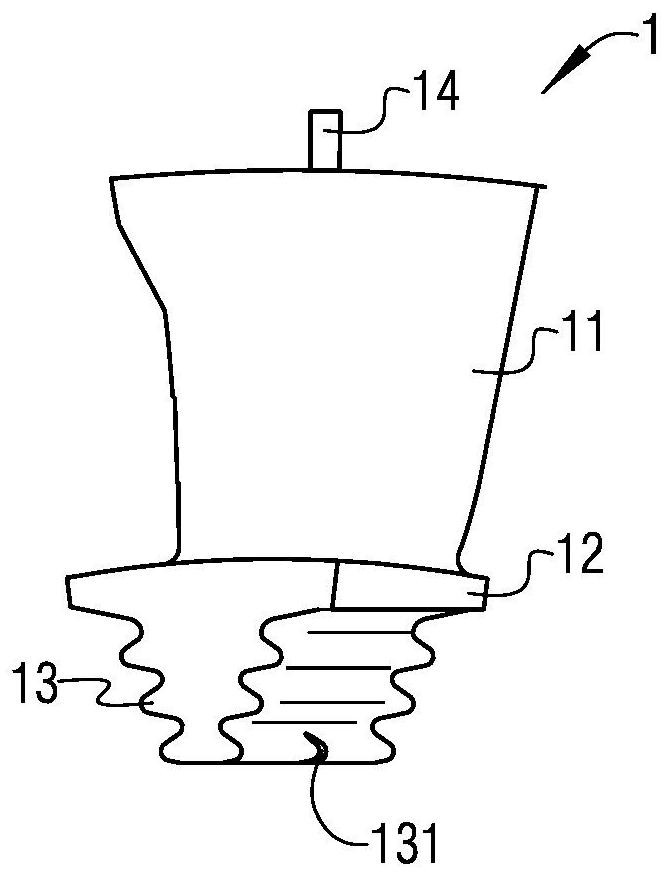

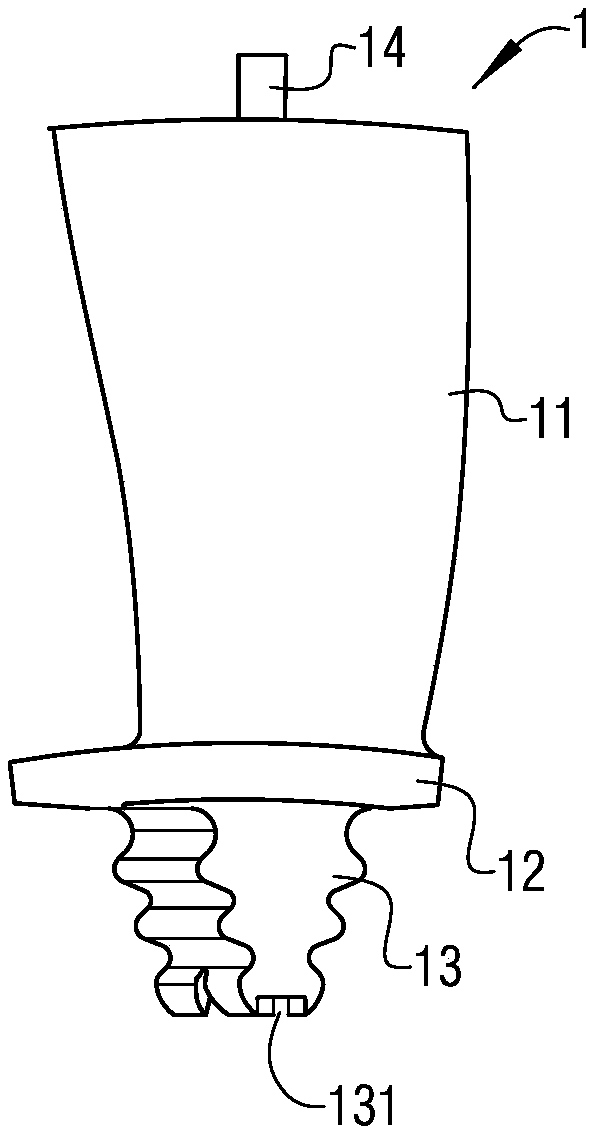

A turbine blade base preparation device

ActiveCN109397141BShorten the measurement periodReduce manufacturing costWork holdersTurbine bladeMechanical engineering

The invention discloses a turbine blade base preparation device. The device comprises a casting facility used for casting a blank of a rectangular block and a dissolving and shaping facility used forshaping the blank of the rectangular block. According to the turbine blade base preparation device, a standardized base is prepared, so that the measurement period of a blade can be greatly shortened,and meanwhile, the production cost and the maintenance cost can be reduced.

Owner:CHINA HANGFA SOUTH IND CO LTD

A kind of preparation method of turbine blade base

ActiveCN109530626BShorten the measurement periodReduce manufacturing costPreparing sample for investigationFoundry mouldsTurbine bladeEngineering

The invention discloses a preparation method of a base of turbine blades. The preparation method of the base of the turbine blades comprises the following steps that A, casting equipment is provided,the casting equipment comprises a casting base, a fixed positioning block and a movable positioning block, so that a movable clamping part and a fixed clamping part form clamping and fixing of tenon teeth; B, pouring is carried out on a low-melting-point alloy; C, dissolution shaping equipment is provided, the dissolution shaping equipment comprises a shaping base, the shaping base is provided with a hot oil cavity, an alloy part covering a locking piece groove and under the first horizontal plane is immersed into the hot oil of the hot oil cavity, so that the locking piece groove can be exposed from a rectangular block; and the preparation of the rectangular block is completed. The invention provides the preparation method of the base of the turbine blades, the standard base is prepared,the measuring period of the turbine blades can be greatly shortened, and meanwhile the production cost and the maintenance cost can be reduced.

Owner:CHINA HANGFA SOUTH IND CO LTD

Method for manufacturing blade casting measurement block

ActiveCN109465405AShorten the measurement periodReduce manufacturing costPreparing sample for investigationFoundry mouldsDissolutionAlloy

The invention discloses a method for manufacturing the blade casting measurement block. The method for manufacturing the blade casting measurement block comprises the following steps of A, providing acasting device, and fixing the blade; B, pouring a low-melting-point alloy in a casting cavity; and C, providing a dissolution shaping device, wherein the dissolution shaping device comprises a shaping base, the shaping base is provided with a working cavity, at least one hot oil nozzle pointing to the upper part in the working cavity is arranged on the side wall of the working cavity, so that the hot oil nozzle sprays hot oil with the temperature not lower than 180 DEG C to a rectangular block, and after the alloy to be covered with a lock sheet groove area is melted by hot oil, the preparation of the rectangular block is completed. According to the method for manufacturing the blade casting measuring block, the standardized measuring blocks are prepared in batches, so that the measurement period of the blade can be greatly shortened, meanwhile, the production cost and the maintenance cost can be reduced.

Owner:CHINA HANGFA SOUTH IND CO LTD

A manufacturing method of a turbine blade positioning base

ActiveCN109483172BShorten the measurement periodReduce manufacturing costWork holdersTurbine bladeStructural engineering

The invention discloses a turbine blade positioning base manufacturing method. The turbine blade positioning base manufacturing method comprises the following steps: (A) casting equipment is provided;the casting equipment comprises a casting base, a fixed positioning block and a movable positioning block; and a movable clamping part and a fixed clamping part fixedly clamp tenon teeth; (B) low-melting-point alloys are cast; and (C) alloy removing equipment is provided, and comprises a shaping base; the shaping base is provided with a rectangular working groove; horizontal oil spraying heads with the same heights are arranged on two opposite side walls in the working groove; and the horizontal oil spraying heads spray hot oil with a temperature of not lower than 180 DEG C to the connectingplace between two strip cavities until alloy blocks wrapped on top teeth of tenon heads under the strip cavities fall to finish preparation of rectangular blocks. In the turbine blade positioning basemanufacturing method, through preparation of standard positioning bases, the blade measuring period can be greatly shortened.

Owner:CHINA HANGFA SOUTH IND CO LTD

A manufacturing device for blade casting measuring block

ActiveCN109405699BShorten the measurement periodReduce manufacturing costMechanical measuring arrangementsManufactured apparatusMechanical engineering

A blade casting measuring block manufacturing apparatus comprises a casting device for casting a blank of a rectangular block and a dissolution shaping device for shaping the blank of the rectangularblock. The blade casting measuring block manufacturing apparatus can greatly shorten the measuring period of the blade by manufacturing the standardized measuring blocks in batches, and can reduce theproduction cost and the maintenance cost.

Owner:CHINA HANGFA SOUTH IND CO LTD

A multi-job block-assembled mapping method based on free station setup

ActiveCN104316036BRelieve measurement pressureEasy to observeSurveying instrumentsBase freeComputer science

The invention discloses a mapping method employing assembly of multiple job blocks based on free station establishment. The mapping method includes the following steps: the coordinates of two or more common points in a finished map coordinate system are measured in a whole mapping area through the GPS (global position system) technology; the whole mapping area is divided into n job blocks, and a connecting point is arranged between every two adjacent job blocks; a job block result map under an independent coordinate system is obtained for each job block through the free station establishment method; all the job block result maps are jointed through the connecting points, so as to obtain a mapping area result map under a transitional coordinate system; a mapping area result map under the finished map coordinate system is obtained through the common points and coordinate transformation. The method has the advantages of few necessary GPS points, avoidance of the mapping control measurement process, as well as short mapping period, and is particularly suitable for mapping in towns, mountainous areas and other areas with intervisibility difficulties.

Owner:SOUTHEAST UNIV

Method for manufacturing integrated pedestal for blade measurement

ActiveCN109434396AShorten the measurement periodReduce production and maintenance costsLocking plateMelting point

A method for manufacturing an integrated pedestal for blade measurement comprises the steps that step A, a casting cavity is built, and a blade is vertically lifted above the casting cavity; step B, alow melting point alloy is cast into the casting cavity built in the step A, and a rectangular-block blank is formed; and step C, the rectangular-block blank manufactured in the step B is subjected to local heat treatment, an alloy structure covering a locking plate groove is removed by melting, so that the locking plate groove is completely exposed. A rectangular block is manufactured. Through the method for manufacturing the integrated pedestal for blade measurement, by providing the standardized pedestal for blades, the blade measurement period is greatly shortened, and the production costand maintenance cost are effectively reduced.

Owner:CHINA HANGFA SOUTH IND CO LTD

Method for manufacturing blade casting measuring block

ActiveCN109465405BShorten the measurement periodReduce manufacturing costPreparing sample for investigationFoundry mouldsAlloyMaterials science

The invention discloses a method for manufacturing the blade casting measurement block. The method for manufacturing the blade casting measurement block comprises the following steps of A, providing acasting device, and fixing the blade; B, pouring a low-melting-point alloy in a casting cavity; and C, providing a dissolution shaping device, wherein the dissolution shaping device comprises a shaping base, the shaping base is provided with a working cavity, at least one hot oil nozzle pointing to the upper part in the working cavity is arranged on the side wall of the working cavity, so that the hot oil nozzle sprays hot oil with the temperature not lower than 180 DEG C to a rectangular block, and after the alloy to be covered with a lock sheet groove area is melted by hot oil, the preparation of the rectangular block is completed. According to the method for manufacturing the blade casting measuring block, the standardized measuring blocks are prepared in batches, so that the measurement period of the blade can be greatly shortened, meanwhile, the production cost and the maintenance cost can be reduced.

Owner:CHINA HANGFA SOUTH IND CO LTD

A preparation method of blade measuring base

ActiveCN109317936BShorten the measurement periodReduce manufacturing costOther manufacturing equipments/toolsStructural engineeringAlloy

A method for preparing a blade measuring base, which includes the following steps, step A, providing a casting device, the casting device includes a casting base, a fixed positioning block and a movable positioning block, step B, pouring a low melting point alloy, and waiting for the low melting point alloy to cool solidified, remove the leaves. In step C, a cutting device is provided, and the alloy part covering the groove of the lock piece at the bottom of the mortise teeth is cut with a heating wire, and the preparation of the rectangular block is completed. The preparation method of the blade measurement base provided by the present invention can greatly shorten the measurement period of the blade by preparing a standardized base, and can reduce production costs and maintenance costs at the same time.

Owner:CHINA HANGFA SOUTH IND CO LTD

Blade casting measuring block manufacturing apparatus

ActiveCN109405699AShorten the measurement periodReduce manufacturing costMechanical measuring arrangementsManufactured apparatusDissolution

A blade casting measuring block manufacturing apparatus comprises a casting device for casting a blank of a rectangular block and a dissolution shaping device for shaping the blank of the rectangularblock. The blade casting measuring block manufacturing apparatus can greatly shorten the measuring period of the blade by manufacturing the standardized measuring blocks in batches, and can reduce theproduction cost and the maintenance cost.

Owner:CHINA HANGFA SOUTH IND CO LTD

A preparation device for blade measuring base

ActiveCN109317980BShorten the measurement periodReduce manufacturing costOther manufacturing equipments/toolsStructural engineeringMechanical engineering

A blade measurement base preparation device, which includes a casting device for casting the blank of the rectangular block and a cutting device for shaping the blank of the rectangular block, the casting device includes a casting base, A fixed positioning block and a movable positioning block, the fixed positioning block is fixedly connected to the casting base, the movable positioning block is slidably connected to the casting base, and the fixed positioning block is provided with a half The fixed clamping part of the profile consistent with the circular arc surface, the movable positioning block is provided with the movable clamping part of the profile consistent with the semi-circular surface of the standard roller bar, the cutting equipment includes a cutting base and a cutting frame, the cutting frame is movably connected with the cutting base. The blade measurement base preparation device provided by the present invention can greatly shorten the blade measurement period and reduce production and maintenance costs by preparing a standardized base.

Owner:CHINA HANGFA SOUTH IND CO LTD

An integrated base for blade measurement

ActiveCN109443146BShorten the measurement periodReduce manufacturing costMechanical measuring arrangementsAlloyMechanical engineering

An integrated base for blade measurement is disclosed, the integrated base is a rectangular block which is formed by casting a low-melting-point alloy and surrounds a tenon tooth, the integrated basecomprises a first side vertical surface, a second side vertical surface, a third side vertical surface and a fourth side vertical surface which are connected in sequence, the first side vertical surface and / or the third side vertical surface are / is parallel to the x axis of the blade theoretical reference coordinate system, the second side vertical surface and / or the fourth side vertical surfaceare / is parallel to the y axis of the theoretical reference coordinate system, the rectangular block further comprises a first horizontal plane perpendicular to the z axis of the theoretical referencecoordinate system, and by the integrated base, the measurement period of blades is greatly shortened, and the production cost and the maintenance cost are effectively reduced.

Owner:CHINA HANGFA SOUTH IND CO LTD

A method for manufacturing a blade auxiliary measuring base

ActiveCN109458900BShorten the measurement periodReduce manufacturing costFoundry mouldsFoundry coresImpellerAlloy

The invention discloses an impeller auxiliary measuring base manufacturing method. The method comprises the steps that A, a piece of casting equipment is provided, and an impeller is fixed; B, low-melting-point alloy casting is conducted in a casting cavity, and the integrally casting of a positioning plate and a rectangular block is conducted; C, a piece of melting shaping equipment is provided to allow the alloy covering a lock piece groove formed in the top of a tenon tooth to be melted, so that the lock piece groove is allowed to be exposed from the rectangular block, and the preparation of the rectangular block is completed. The method has the advantages that a standardized base is prepared so that the measuring working period of the impeller can be greatly shortened, and the production cost and maintaining cost can be reduced.

Owner:CHINA HANGFA SOUTH IND CO LTD

Preparation device for blade base of aero-engine

ActiveCN109332654AShorten the measurement periodReduce manufacturing costMeasurement devicesAviationMaterials science

The invention discloses a preparation device for a blade base of an aero-engine. The preparation device comprises casting equipment for casting a blank of a rectangular block and dissolving shaping equipment for shaping the blank of the rectangular block; the casting equipment comprises a casting base, a positioning template and a casting cavity; the casting base is connected with a first liftingarm which is liftable; the first lifting arm is rotationally connected with a first technological boss fixing device through a bearing; the dissolving shaping equipment comprises a shaping base 51; the shaping base is connected with a second lifting arm which is liftable; the second lifting arm is provided with a second technological boss fixing device; a hot oil cavity is formed in the shaping base and is arranged below the second lifting arm; and hot oil with the temperature not lower than 180 DEG C is injected into the hot oil cavity. By the aid of the preparation device for the blade baseof the aero-engine, the standard base is prepared, so that the blade measuring working period can be greatly shortened, and meanwhile, the production cost and the maintenance cost can be reduced.

Owner:CHINA HANGFA SOUTH IND CO LTD

Turbine blade base preparation device

ActiveCN109397141AShorten the measurement periodReduce manufacturing costWork holdersTurbine bladeEmbedded system

The invention discloses a turbine blade base preparation device. The device comprises a casting facility used for casting a blank of a rectangular block and a dissolving and shaping facility used forshaping the blank of the rectangular block. According to the turbine blade base preparation device, a standardized base is prepared, so that the measurement period of a blade can be greatly shortened,and meanwhile, the production cost and the maintenance cost can be reduced.

Owner:CHINA HANGFA SOUTH IND CO LTD

An aero-engine blade base preparation device

ActiveCN109332654BShorten the measurement periodReduce manufacturing costMechanical measuring arrangementsAviationStructural engineering

The invention discloses a preparation device for a blade base of an aero-engine. The preparation device comprises casting equipment for casting a blank of a rectangular block and dissolving shaping equipment for shaping the blank of the rectangular block; the casting equipment comprises a casting base, a positioning template and a casting cavity; the casting base is connected with a first liftingarm which is liftable; the first lifting arm is rotationally connected with a first technological boss fixing device through a bearing; the dissolving shaping equipment comprises a shaping base 51; the shaping base is connected with a second lifting arm which is liftable; the second lifting arm is provided with a second technological boss fixing device; a hot oil cavity is formed in the shaping base and is arranged below the second lifting arm; and hot oil with the temperature not lower than 180 DEG C is injected into the hot oil cavity. By the aid of the preparation device for the blade baseof the aero-engine, the standard base is prepared, so that the blade measuring working period can be greatly shortened, and meanwhile, the production cost and the maintenance cost can be reduced.

Owner:CHINA HANGFA SOUTH IND CO LTD

A kind of preparation method of aero-engine blade base

ActiveCN109622923BShorten the measurement periodReduce manufacturing costMechanical measuring arrangementsStructural engineeringAlloy

Owner:CHINA HANGFA SOUTH IND CO LTD

A method of manufacturing a blade positioning base

ActiveCN109332653BShorten the measurement periodReduce manufacturing costMechanical measuring arrangementsStructural engineeringAlloy coating

The invention discloses a manufacturing method of a blade positioning base. The method comprises the following steps that step A, casting equipment is provided to fixing a blade; step B, a low-melting-point alloy is poured in a casting cavity, a hollow square positioning frame and a rectangular block are cast into a whole; step C, dissolving shaping equipment is provided, an alloy coating a locking piece groove at the top of a tenon tooth is dissolved, thus the locking piece groove is exposed out of the rectangular block, and the rectangular block is prepared. With the method, the standard base is prepared, so that the blade measuring working period can be greatly shortened, and meanwhile, the production cost and the maintenance cost can be reduced.

Owner:CHINA HANGFA SOUTH IND CO LTD

A method of manufacturing an integrated base for blade measurement

A method for manufacturing an integrated pedestal for blade measurement comprises the steps that step A, a casting cavity is built, and a blade is vertically lifted above the casting cavity; step B, alow melting point alloy is cast into the casting cavity built in the step A, and a rectangular-block blank is formed; and step C, the rectangular-block blank manufactured in the step B is subjected to local heat treatment, an alloy structure covering a locking plate groove is removed by melting, so that the locking plate groove is completely exposed. A rectangular block is manufactured. Through the method for manufacturing the integrated pedestal for blade measurement, by providing the standardized pedestal for blades, the blade measurement period is greatly shortened, and the production costand maintenance cost are effectively reduced.

Owner:CHINA HANGFA SOUTH IND CO LTD

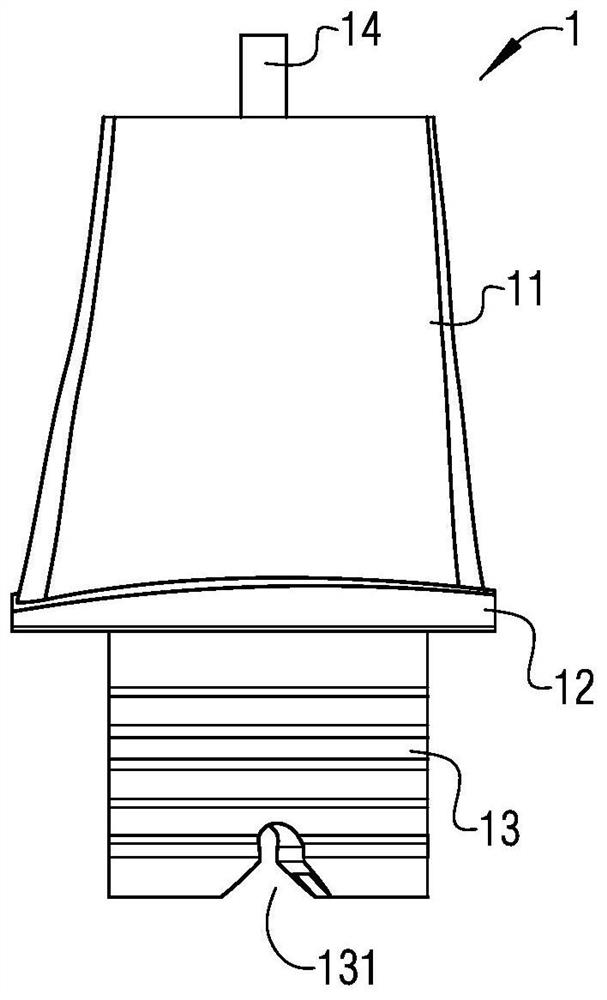

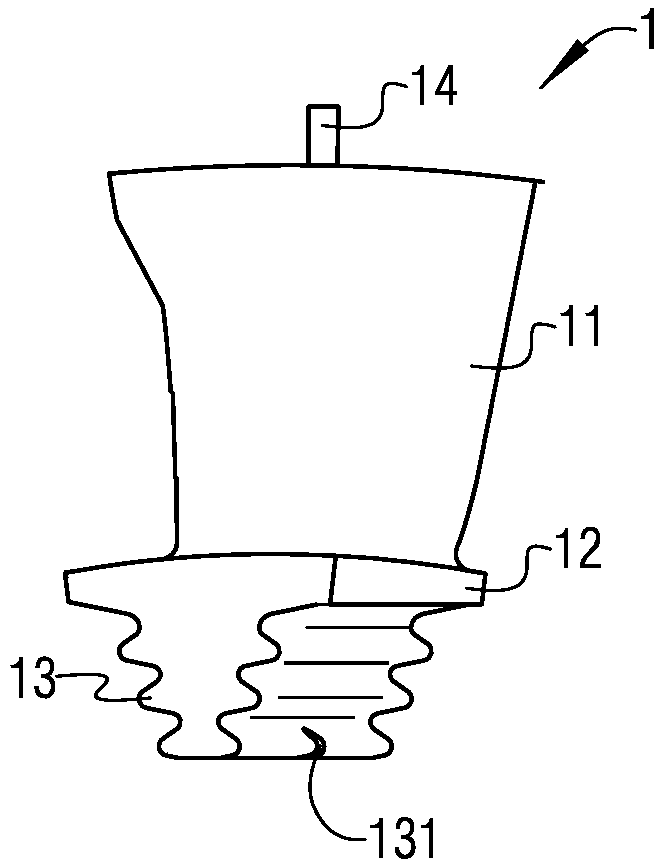

A blade positioning base manufacturing device

ActiveCN109332652BShorten the measurement periodReduce manufacturing costMechanical measuring arrangementsStructural engineeringMechanical engineering

The invention discloses a blade positioning base manufacturing device. The blade positioning base manufacturing device comprises casting equipment for casting blanks of rectangular blocks, and dissolution shaping equipment for shaping the blanks of the rectangular blocks. The casting equipment comprises a casting base, a positioning sample plate, and a casting cavity; the casting cavity is formedby the casting base ad a movable side wall movably connected with the casting base; a first reserved groove is formed in the T-shaped surface, on the side wall of the casting base, of a first liftingarm; the movable side wall is provided with a second reserved groove corresponding to the first reserved groove; and through the first reserved groove and the second reserved groove, a mouth-shaped positioning frame is provided. Through preparation of the standard base, the blade positioning base manufacturing device can greatly shorten the blade measuring period, and meanwhile, can reduce the production cost and the maintenance cost.

Owner:CHINA HANGFA SOUTH IND CO LTD

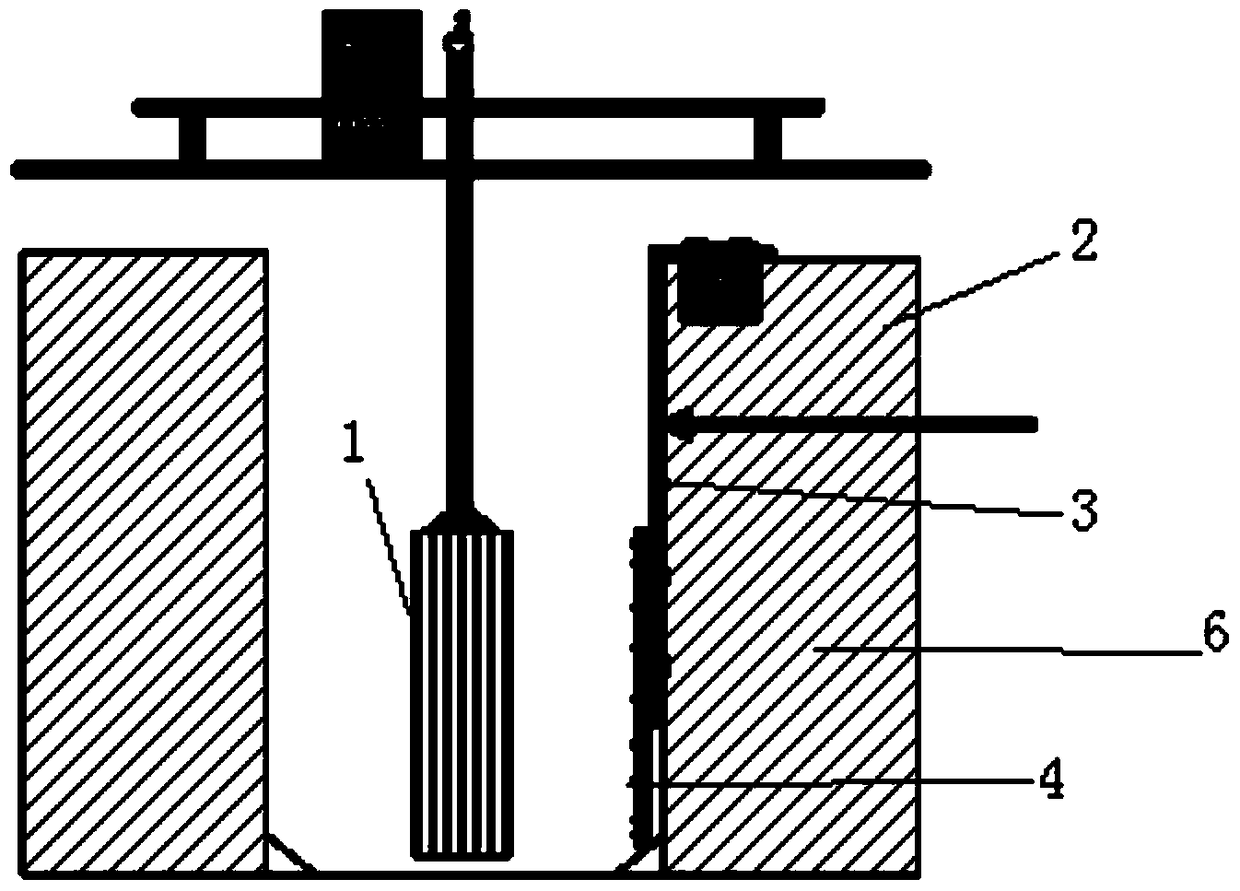

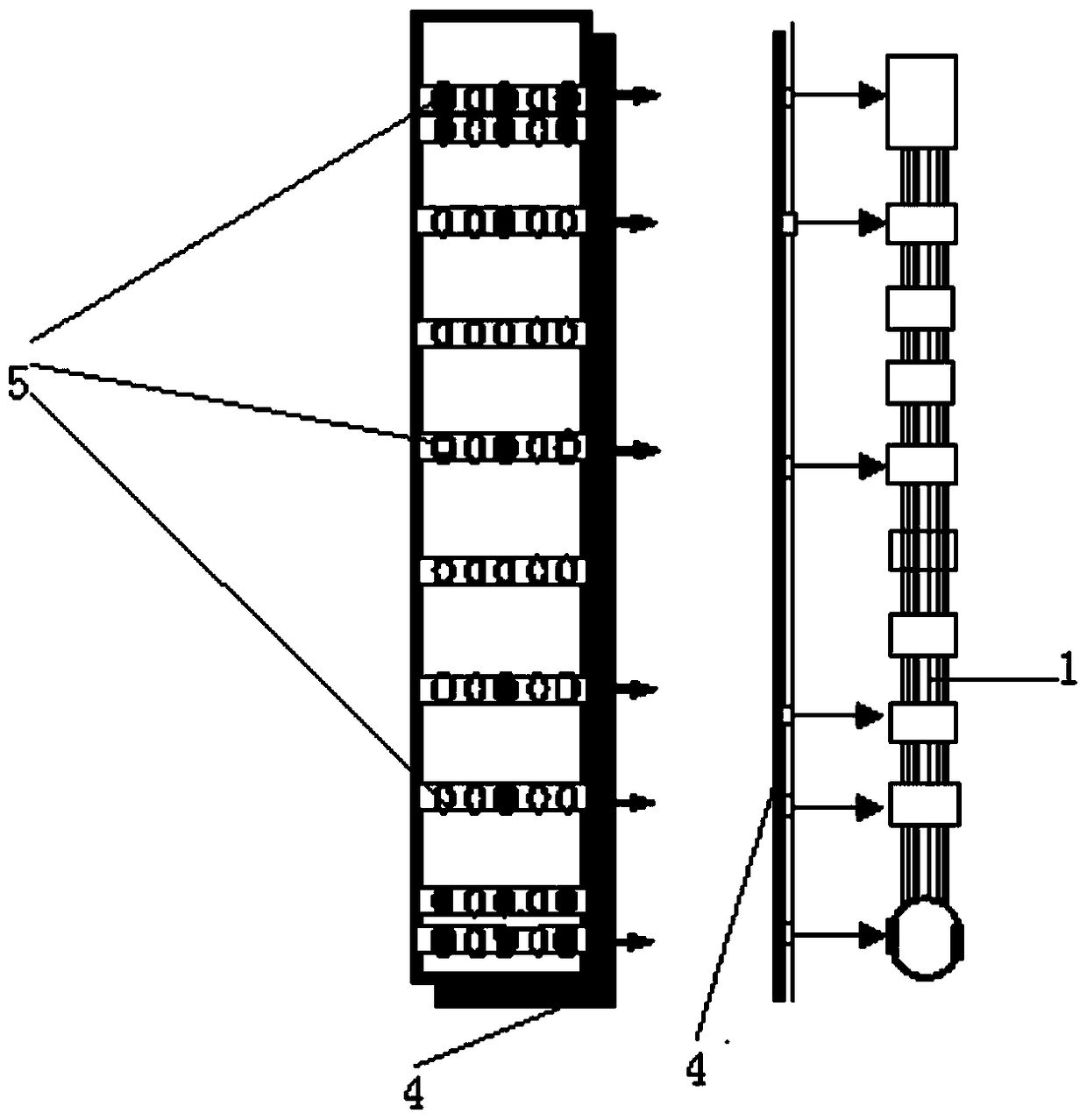

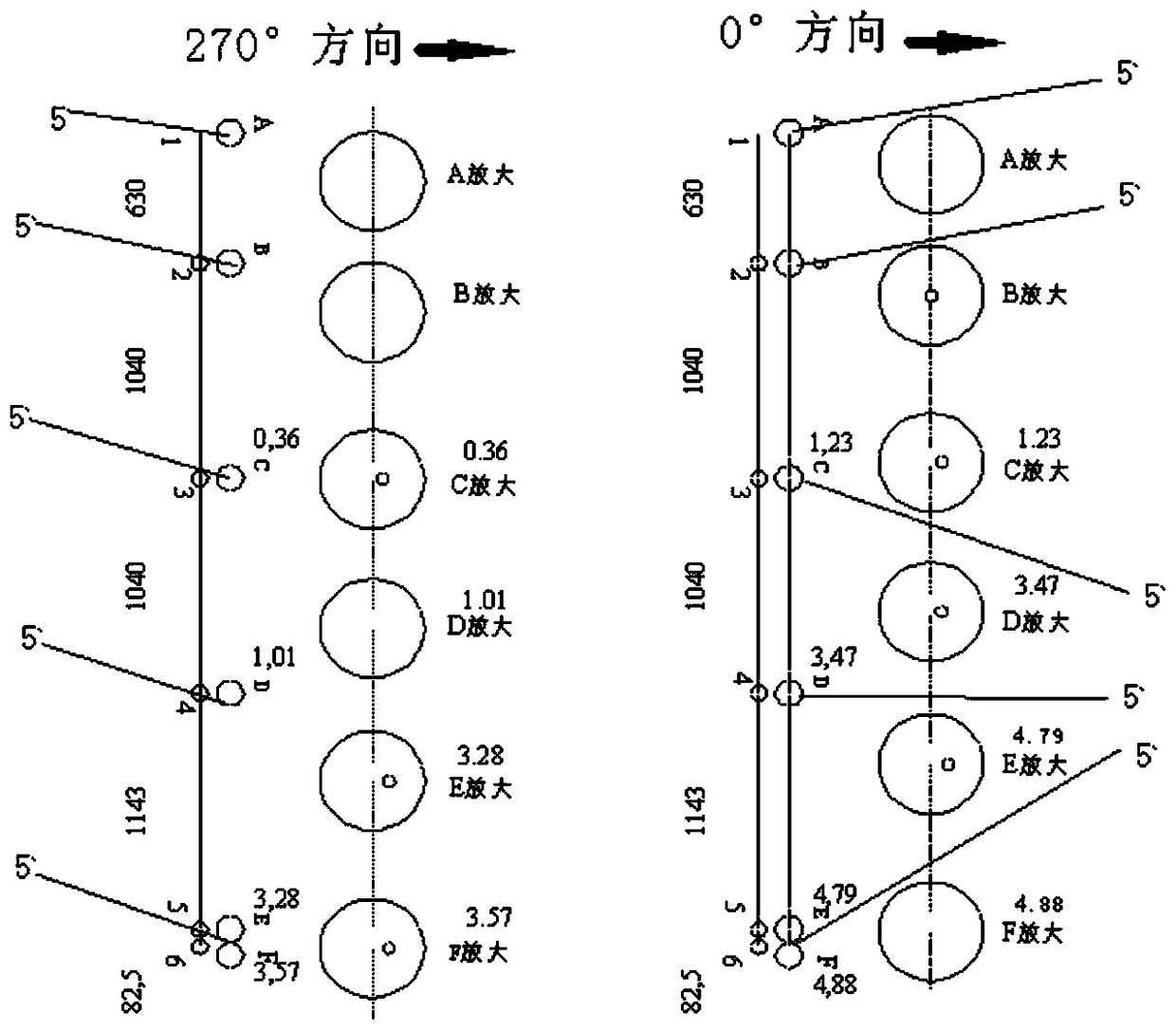

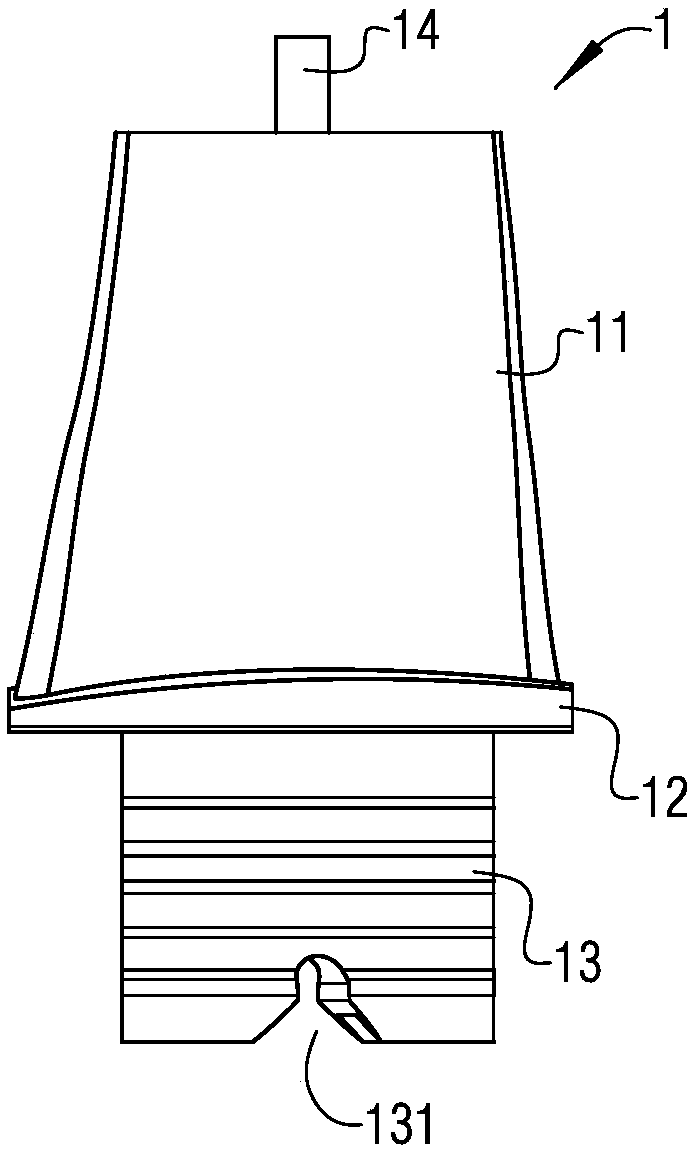

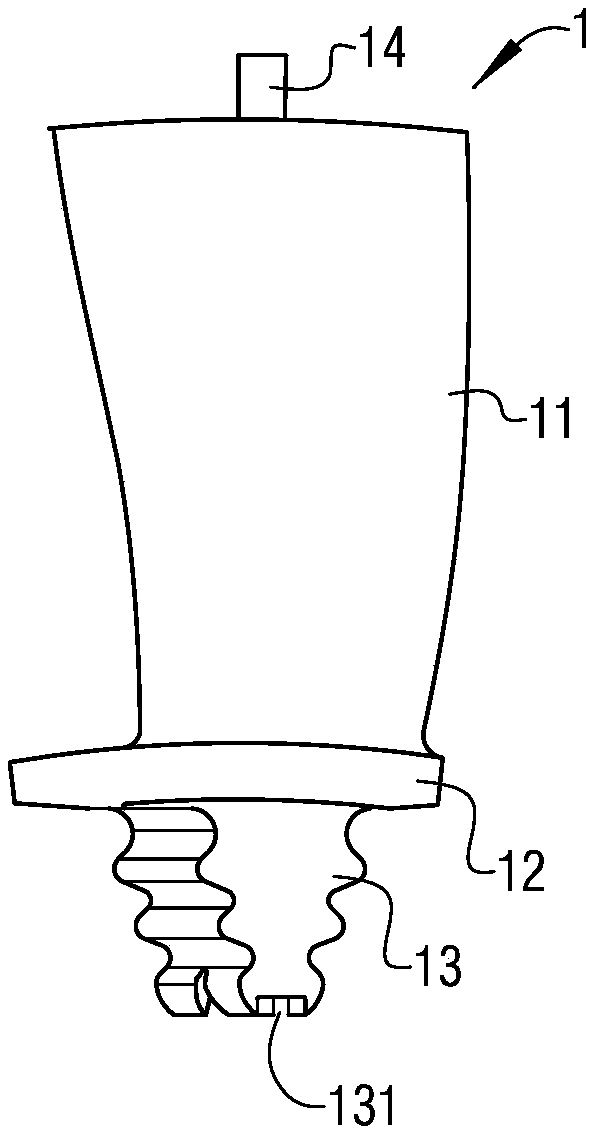

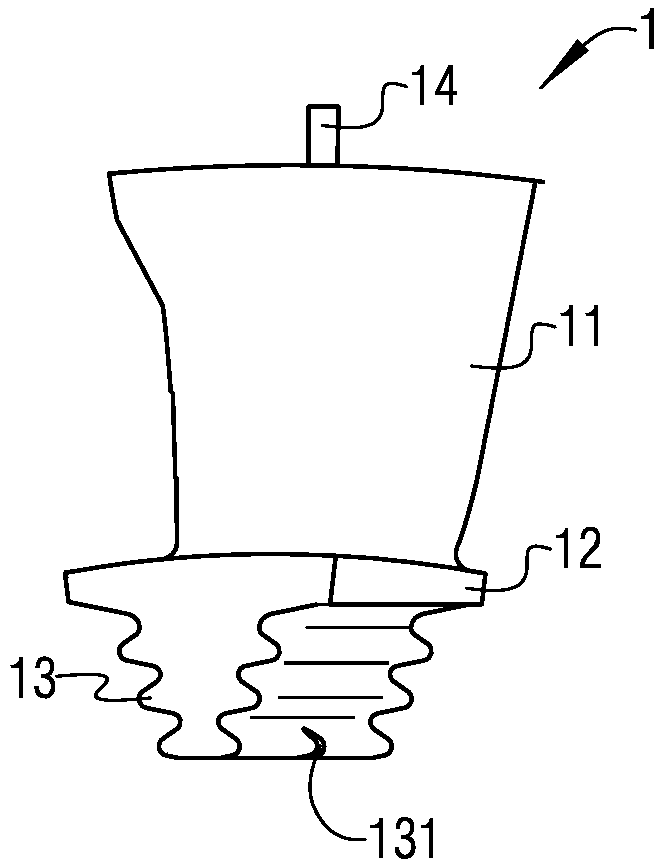

Device and method for measuring deformation of fuel assembly

ActiveCN104751918BContinuous acquisitionShorten the measurement periodNuclear energy generationUsing subsonic/sonic/ultrasonic vibration meansMeasurement deviceEngineering

The invention belongs to the field of shape deformation analyzing and ultrasonic ranging of fuel assemblies in a nuclear power plant, in particular to a deformation measurement device and a deformation measurement system for fuel assemblies. The device comprises a fuel assembly, an upper supporting fixing clamp plate, an extending supporting frame, a probe tray carriage, spent fuel pool gate channels and a plurality of probes; the upper supporting fixing clamp plate and the extending supporting frame integrally form a perpendicular supporting frame, the upper supporting fixing clamp plate is fixed on the upper part of one spent fuel pool gate channel, the extending supporting frame is fixed on the inner side of the spent fuel pool gate channel, the probe tray carriage is arranged on the extending supporting frame and can slide vertically along the extending supporting frame, the plurality of probes are fixed on the probe tray carriage, and the fuel assembly is located between the two spend fuel pool gate channels. According to the deformation measurement device, in a high-radiation environment, the self deformation of the fuel assembly can be measured in a mode of noncontact with the assembly by adopting an ultrasonic method.

Owner:CHINA NUCLEAR POWER OPERATION TECH +1

Preparation method of aeroengine blade base

ActiveCN109622923AShorten the measurement periodReduce manufacturing costMechanical measuring arrangementsDissolutionAlloy

The invention discloses a preparation method of an aeroengine blade base. The preparation method of the aeroengine blade base comprises the following steps that step A, a casting device is provided, wherein the casting device includes a casting base, a positioning template and a casting cavity, and a blade is fixed; step B, a low-melting-point alloy is poured in a casting cavity, and the arrangedblade is taken out when the low-melting-point alloy is cooled and solidified; and step C, a dissolution shaping device is provided, the dissolution shaping device includes a shaping base, and a hot oil cavity is formed in the shaping base, so that the alloy part, wrapping and covering lock piece grooves at the top of a tenon tooth, under the first horizontal plane is immersed in hot oil of the hotoil cavity, and the preparation of a rectangular block is completed. According to the preparation method of the aeroengine blade base, by preparing a standardized base, the measuring time of the blade can be shortened greatly, and meanwhile, the production cost and maintenance cost can be reduced.

Owner:CHINA HANGFA SOUTH IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com