Process for treating sewage and sewage and mud mixed liquid

A treatment method and mixed liquid technology, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of heavy membrane pollution and complicated preparation process, and achieve simple and convenient preparation process A large amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

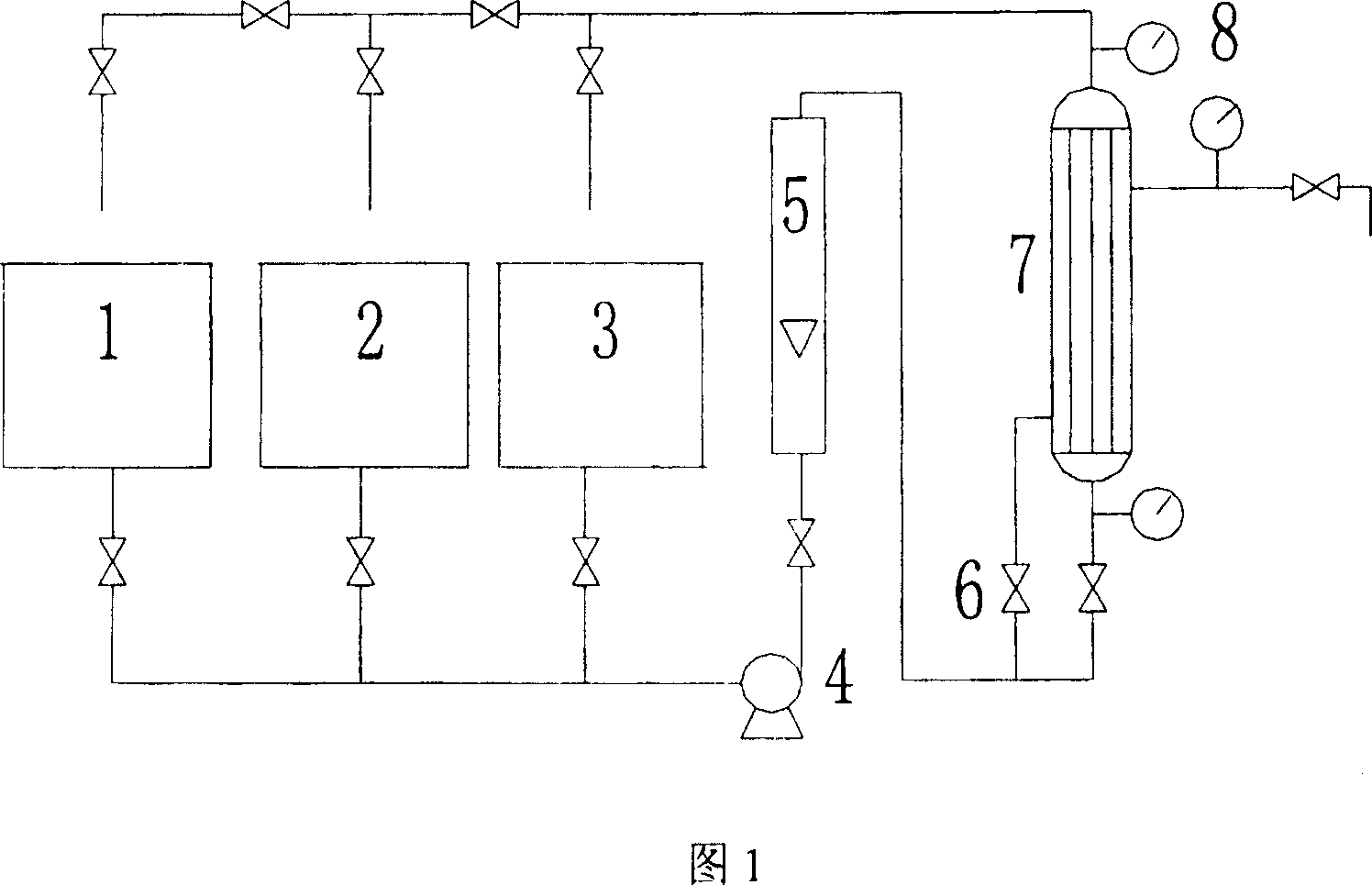

Embodiment 1

[0025] There are secondary effluents from urban sewage treatment plants. The sewage contains suspended solids, colloidal substances, and dissolved organic matter. The water quality indicators are: COD: 120-150mg / L; Turbidity: 50-100NTU; pH: 7-8 .Introduction of sewage into the cesspool. First, the particle suspension is prepared, the suspended particles are kaolin with an average diameter of 1 μm, and the concentration of the suspended particles is 0.3 g / 1. Make the suspension flow through the membrane module in cross-flow, the cross-flow velocity is 0.5m / s, the transmembrane pressure difference is 0.2Mpa, and run for 10min to uniformly coat a layer of thin film with separation performance on the carrier membrane tube. Sewage is sent to the membrane module with a centrifugal pump, the cross-flow velocity is 1m / s, and the transmembrane pressure difference is 0.2Mpa. After being treated by the membrane module, the effluent COD: 50~60mg / L, turbidity: 0.1NTU. After long-term ope...

Embodiment 2

[0027] There is landfill leachate, which contains a large amount of humus, suspended matter, colloidal substances and dissolved organic matter, etc., and its water quality characteristic indicators are: COD: 500-800mg / L; SS: 190g / L; Turbidity: 200NTU; pH: 6.5-6.8. Direct landfill leachate into sewage ponds. The particle suspension is prepared, the suspended particles are wollastonite with an average diameter of 1 μm, and the concentration of the suspended particles is 0.3 g / l. According to the operation method and conditions of Example 1, a layer of film with separation performance is evenly coated on the carrier film tube. Use a centrifugal pump to send the landfill leachate into the membrane module, the cross-flow velocity is 1m / s, and the transmembrane pressure difference is 0.2Mpa. After being treated by the membrane module, the effluent COD: 150~190mg / L, turbidity: 0.1NTU. After long-term operation, when the filtrate flux drops greatly, the membrane module needs to be ...

Embodiment 3

[0029] There is a mixture of domestic sewage and sludge, in which the concentration of sludge is 4g / 1. The sewage and sludge mixture is introduced into the sewage tank. The particle suspension is prepared, the suspended particles are diatomite with an average diameter of 1 μm, and the concentration of the suspended particles is 0.3 g / l. According to the operation method and conditions of Example 1, a layer of film with separation performance is uniformly coated on the carrier film tube. A centrifugal pump is used to send the mixed solution of domestic sewage and sludge into the membrane module, the cross-flow velocity is 2m / s, and the transmembrane pressure difference is 0.2Mpa. After being treated by the membrane module, the turbidity of the effluent: 0.1NTU. After long-term operation, when the filtrate flux drops greatly, the membrane module needs to be cleaned. The method is: make the tap water cross-flow at a speed of 5m / s to flush the membrane tube, the particle coating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com