Method for synthesizing molecular screen membrane from in-site aging-microwave heat

A microwave heating and molecular sieve technology, which is applied in the synthesis and application of molecular sieve membranes, can solve problems such as limited applications, and achieve the effects of wide application, high repeatability, and excellent alcohol/water pervaporation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1A

[0033] The preparation of embodiment 1A type molecular sieve membrane

[0034] The base membrane used in the synthesis of molecular sieve membranes is porous Al 2 o 3 The basement membrane has a pore size of 0.1-0.3um and a porosity of 30%. The basement membrane is sheet-shaped with a diameter of 25mm and a thickness of 2mm. Before use, the base film is smoothed with spun paper, ultrasonically washed in distilled water, and then dried for later use. The dried base film can be directly used for synthesis without pre-coating seed crystals.

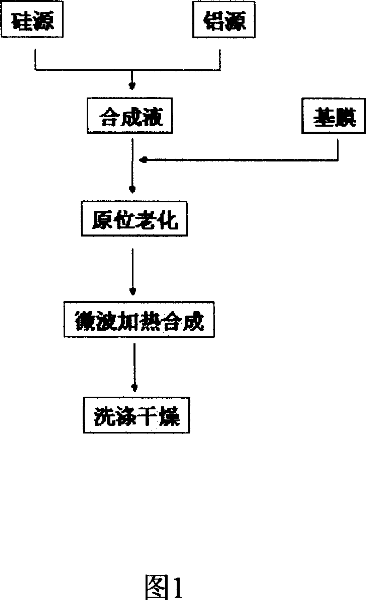

[0035] The schematic diagram of the preparation process is shown in Figure 1.

[0036] The synthesis solution for synthesizing molecular sieve membranes is configured as follows:

[0037] Solution (1): Dissolve 100.0 grams of NaOH in 398 ml of deionized water, then add 2.5 grams of metal aluminum foil, and dissolve to obtain solution (1);

[0038] Solution (2): 82.3 grams of NaOH was dissolved in 398ml of deionized water, and then 46.3m...

Embodiment 2

[0041] The preparation of embodiment 2A type molecular sieve membrane

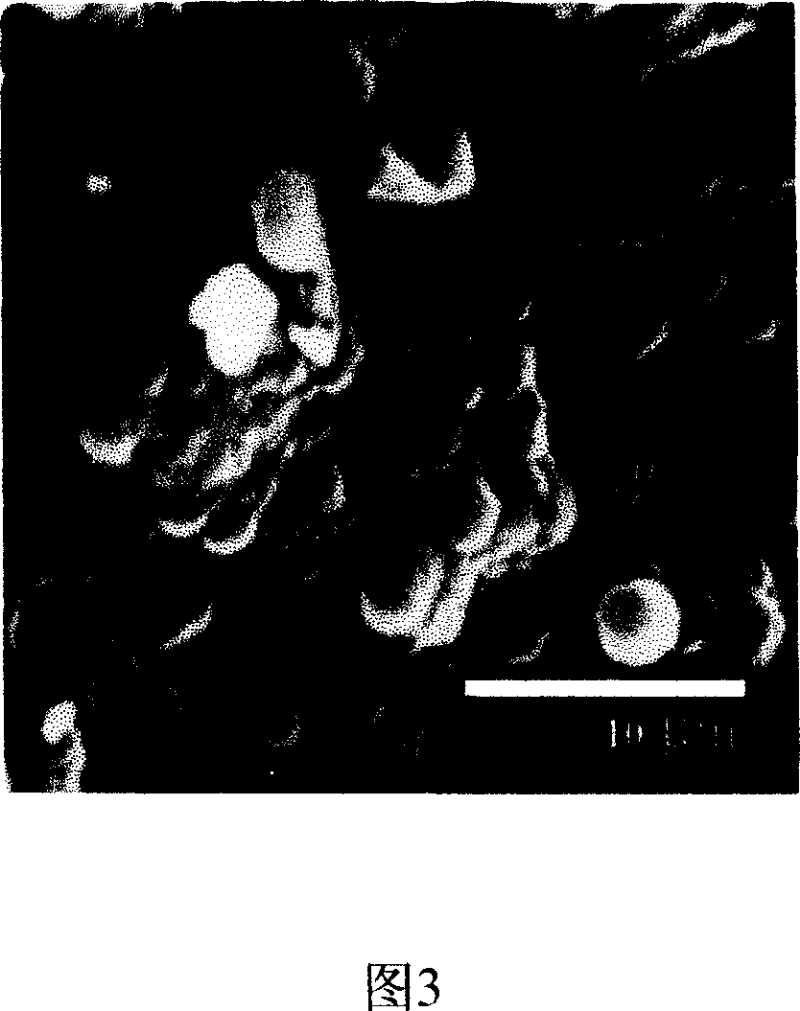

[0042] The same operation as in Example 1 was performed, except that the basement membrane used was tubular, with an inner diameter of 10 mm, an outer diameter of 14 mm, and a length of 40 cm. Both ends of the unseeded membrane tube are blocked with polytetrafluoroethylene plugs (to prevent the inside of the membrane tube from contacting the synthesis solution), and then vertically placed in a polytetrafluoroethylene synthesis kettle to synthesize on the outer surface of the membrane tube. From the scanning electron microscope photos, it can be seen that the surface morphology of the synthesized molecular sieve membrane is similar to that of the molecular sieve membrane synthesized by using the sheet-like basement membrane as a carrier in Example 1 (as shown in FIG. 4 ).

Embodiment 3

[0043] The preparation of embodiment 3A type molecular sieve membrane

[0044] The same operation as in Example 2, except that the outer wall of the film tube without seed crystals is wrapped with a polytetrafluoroethylene tape (to prevent the outer wall of the film tube from contacting the synthetic solution), then vertically placed in the polytetrafluoroethylene synthesis kettle, and the The inner surface of the tube is synthesized. The pervaporation separation performance of the synthesized molecular sieve membrane is close to that of the molecular sieve membrane synthesized outside the tube. This example shows that this method can be conveniently synthesized in the pores of the carrier, so it can be applied to multi-channel carriers and hollow fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com