Amorphous perfluorinated polymers

A perfluorinated, polymer technology, which is applied in the direction of originals for photomechanical processing, photographic process for patterned surfaces, photosensitive materials for photomechanical equipment, etc., and can solve the problem of unrecorded polymer transmittance values question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Embodiment 1 (comparative example)

[0085] A copolymer of TFE / TTD=20 / 80 was prepared using an AISI 316 reactor and at a temperature of 75°C.

[0086] After evacuating with an oil pump, 2,790 ml of demineralized water was added to a 5 liter AISI 316 autoclave equipped with a stirrer at 650 rpm, followed by mixing the following materials to obtain a 6.67 g / l water microemulsion:

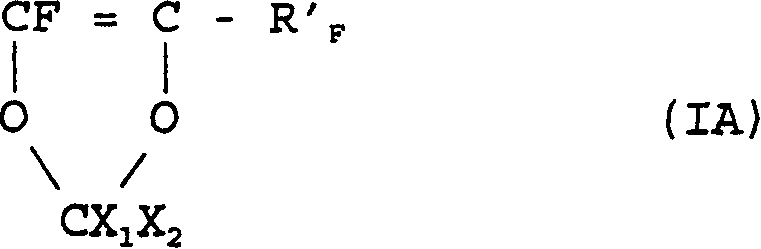

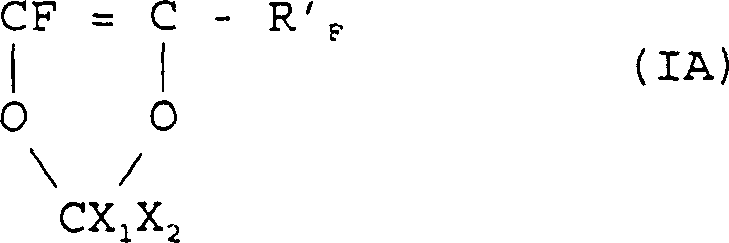

[0087] 7.5ml of perfluoropolyoxyalkylene with acid end groups, the general formula of this perfluoropolyoxyalkylene is:

[0088] CF 2 ClO(CF 2 -CF(CF 3 )O) n (CF 2 O) m CF 2 COOH

[0089] Wherein n / m=10, the average molecular weight is 600;

[0090] -30% volume NH 3 7.5ml of aqueous solution;

[0091] -15ml demineralized water;

[0092] - 4.5ml of Galden with the following general structure D02:

[0093] CF 3 O(CF 2 -CF(CF 3 )O) n (CF 2 O) m CF 3

[0094] Where n / m=20, the average molecular weight is 450.

[0095] The autoclave was heated to 75° C. and 33.3 (g / l water)...

Embodiment 1A

[0097] Embodiment 1A (comparative example)

[0098] The ionic labile groups of the copolymer obtained from Example 1 were fluorinated (comparative).

[0099] Dissolving the perfluorinated solvent Galden obtained by embodiment 1 (comparative example) The 420g 5%wt copolymer solution of D100 (perfluoropolyether having a boiling point of 100°C) was added to a 300ml photochemical glass reactor equipped with a mechanical stirrer and a mercury vapor-immersed ultraviolet lamp (Hanau TQ150 ). Inject nitrogen gas into the solution for 1 hour until oxygen is completely eliminated, and then input a nitrogen / fluorine mixture with a volume ratio of 1:1 at a temperature of 25°C under ultraviolet irradiation for 30 hours. After the reaction is completed, remove it by reducing pressure. Residual fluorine and solvents.

[0100] After 13 hours of fluorination, 1 mmol / kg of residual COOH end groups and 1.4 mmol / kg of COF end groups formed by the reaction were still found by infrared spectr...

Embodiment 2

[0105] Preparation of Copolymer of TFE / TTD=3 / 97(mol)

[0106] After evacuating with an oil pump, in a 1-liter autoclave equipped with magnetic stirring, add 350 ml of demineralized water and 15 ml of microemulsion obtained by mixing the following materials:

[0107] - 1.486 ml of perfluoropolyoxyalkylenes having acid end groups of the general formula:

[0108] CF 2 ClO(CF 2 -CF(CF 3 )O) n (CF 2 O) m CF 2 COOH

[0109] Wherein n / m=l0, average molecular weight is 600;

[0110] - 1.486ml of 30% volume NH 3 aqueous solution

[0111] - 2.973ml of demineralized water;

[0112] -9.054ml of Galden with the following general structure D02:

[0113] CF 3 O(CF 2 -CF(CF 3 )O) n (CF 2 O) m CF 3

[0114] Where n / m=20, the average molecular weight is 450;

[0115] 174g of TTD was added. 0.72 g of gaseous tetrafluoroethylene (TFE) at 0.03 MPa was charged to the reactor. Then 0.1 g of ammonium persulfate was added. The autoclave was heated to 50°C. After 12 hours t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com