Production of pivalic acid

A technology of pivalic acid and pressure is applied in the field of preparing pivalic acid by a synthetic method, which can solve the problems of high cost, high cost of pivalic acid, influence on market competitiveness, etc. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

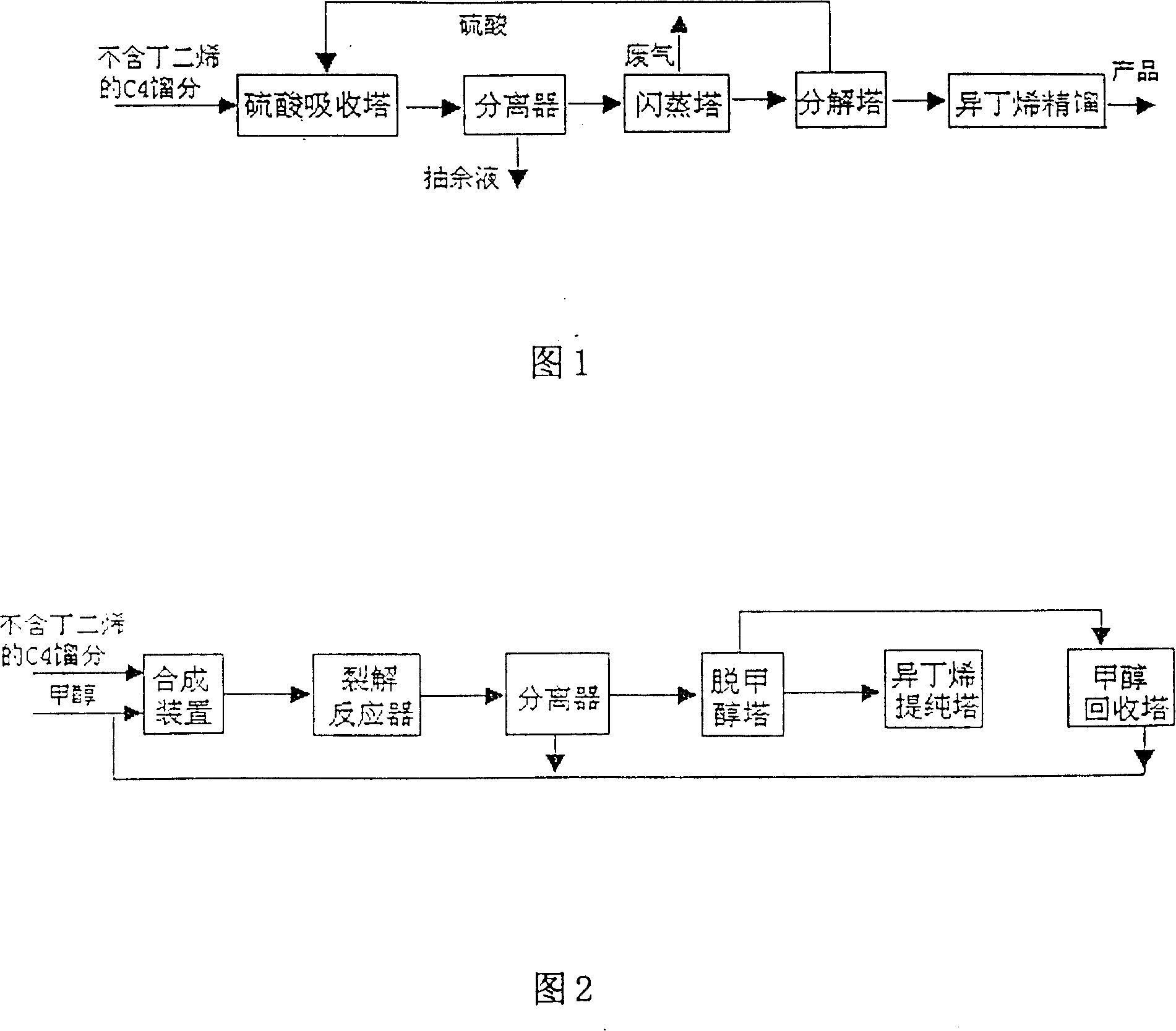

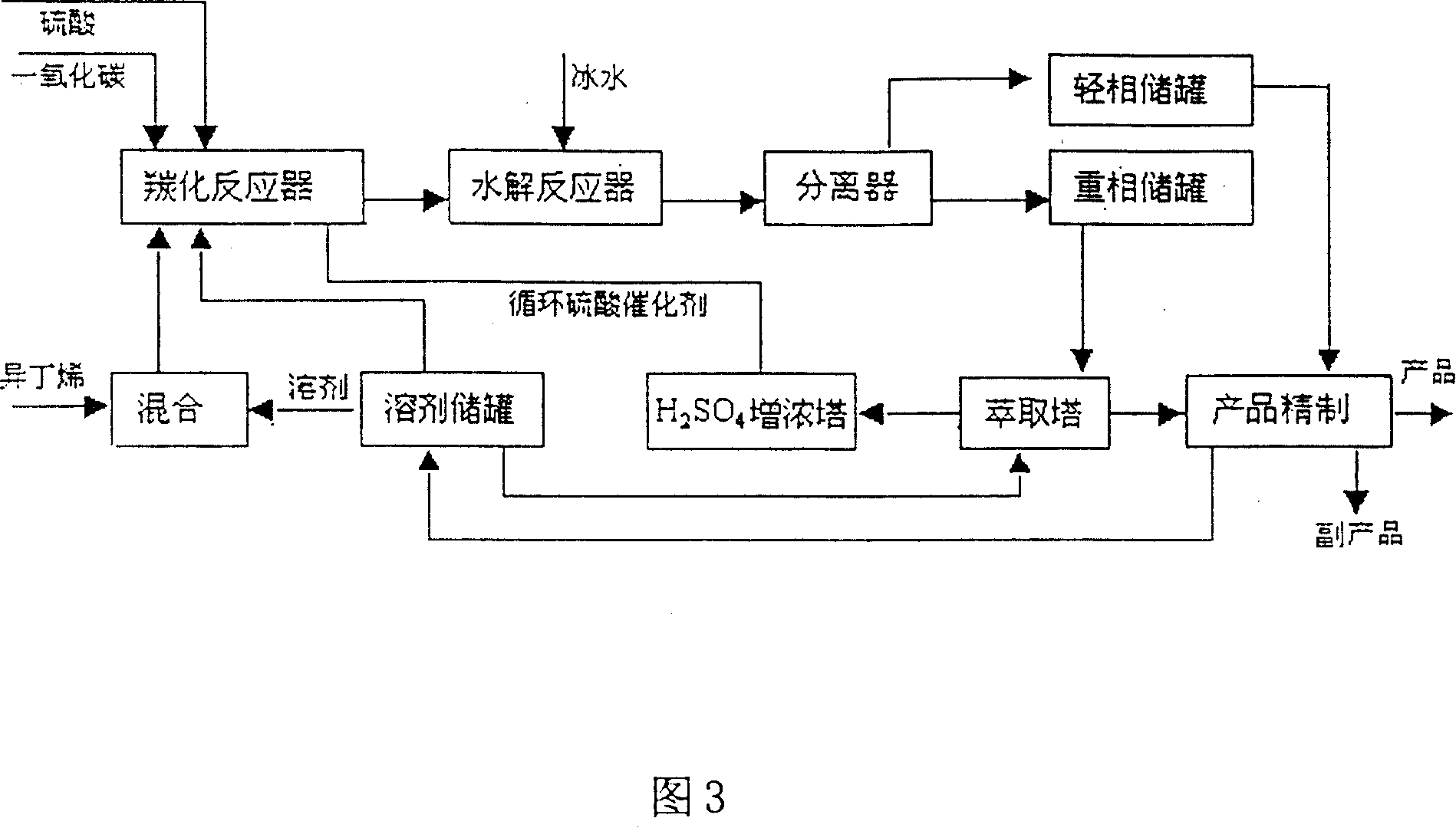

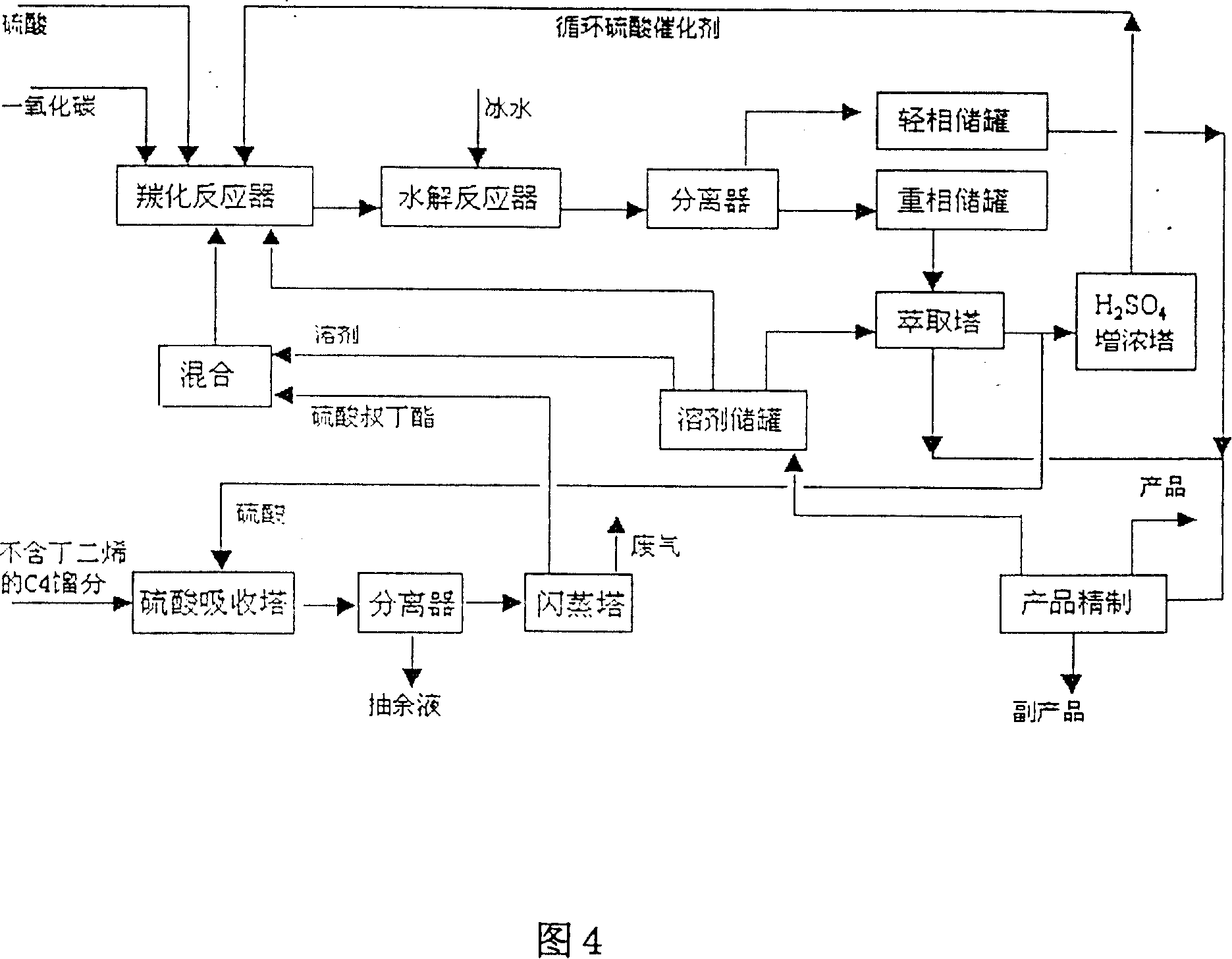

[0031] With 1.65 tons of butadiene-free carbon four cuts (isobutene 45%, isobutane 3%, 1-butene 25%, n-butane 11%, trans-2-butene 9%, cis-2-butene 7 % and 1,3-butadiene <0.5%) and 2.7 tons of 50% sulfuric acid as raw materials, the reaction temperature is 15-40 ° C and the pressure is 0.12-0.45Mpa, respectively enter the sulfuric acid absorption tower for esterification. The reaction mixture (tert-butyl sulfate, tert-butanol and raffinate containing isobutylene) enters the separator for separation, and the lower layer mixture (tert-butyl sulfate, tert-butanol) enters the flash column for flashing to remove A small amount of hydrocarbons, the mixture obtained (the total content of tert-butyl sulfate and tert-butanol is more than 99% after analysis), enters the mixer and mixes with chloroform from the solvent storage tank, and the mixed solution enters the carbonylation reactor , add 4.3 tons of 85% sulfuric acid in the carbonylation reactor simultaneously, carry out carbonylati...

example 2

[0033] With 1.65 tons of butadiene-free carbon four cuts (isobutene 45%, isobutane 3%, 1-butene 25%, n-butane 11%, trans-2-butene 9%, cis-2-butene 7 % and 1,3-butadiene <0.5%) and 3.0 tons of 50% sulfuric acid as raw materials, the reaction temperature is 15-40°C and the pressure is 0.12-0.45Mpa, respectively enter the sulfuric acid absorption tower for esterification. The reaction mixture (tert-butyl sulfate, tert-butanol and raffinate containing isobutylene) enters the separator for separation, and the lower layer mixture (tert-butyl sulfate, tert-butanol) enters the flash column for flashing to remove A trace amount of hydrocarbons, the mixture obtained (the total content of tert-butyl sulfate and tert-butanol reaches more than 99% after analysis) enters the mixer and mixes with the chloroform from the solvent storage tank, and the mixed solution enters the carbonylation reactor, Add 4.3 tons of 85% sulfuric acid in the carbonylation reactor simultaneously, carry out carbon...

example 3

[0035]With 1.65 tons of butadiene-free carbon four cuts (isobutene 45%, isobutane 3%, 1-butene 25%, n-butane 11%, trans-2-butene 9%, cis-2-butene 7 % and 1,3-butadiene <0.5%) and 2.7 tons of 50% sulfuric acid as raw materials, the reaction temperature is 10-15°C and the pressure is 0.1-0.12Mpa, respectively enter the sulfuric acid absorption tower for esterification. The reaction mixture (tert-butyl sulfate, tert-butanol and raffinate containing isobutylene) enters the separator for separation, and the lower layer mixture (tert-butyl sulfate, tert-butanol) enters the flash column for flashing to remove A trace amount of hydrocarbons, the mixture obtained (the total content of tert-butyl sulfate and tert-butanol reaches more than 99% after analysis) enters the mixer and mixes with the chloroform from the solvent storage tank, and the mixed solution enters the carbonylation reactor, Add 4.3 tons of 85% sulfuric acid in the carbonylation reactor simultaneously, carry out carbonyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com