Control apparatus and method for pulse water-feeding SBR deep denitrogenation process and course

A process control and deep denitrification technology, applied in the field of SBR biological treatment process, can solve the problems of poor denitrification effect, complicated operation and high carbon source operating cost, and achieve the effect of saving cost, good denitrification effect and reducing reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

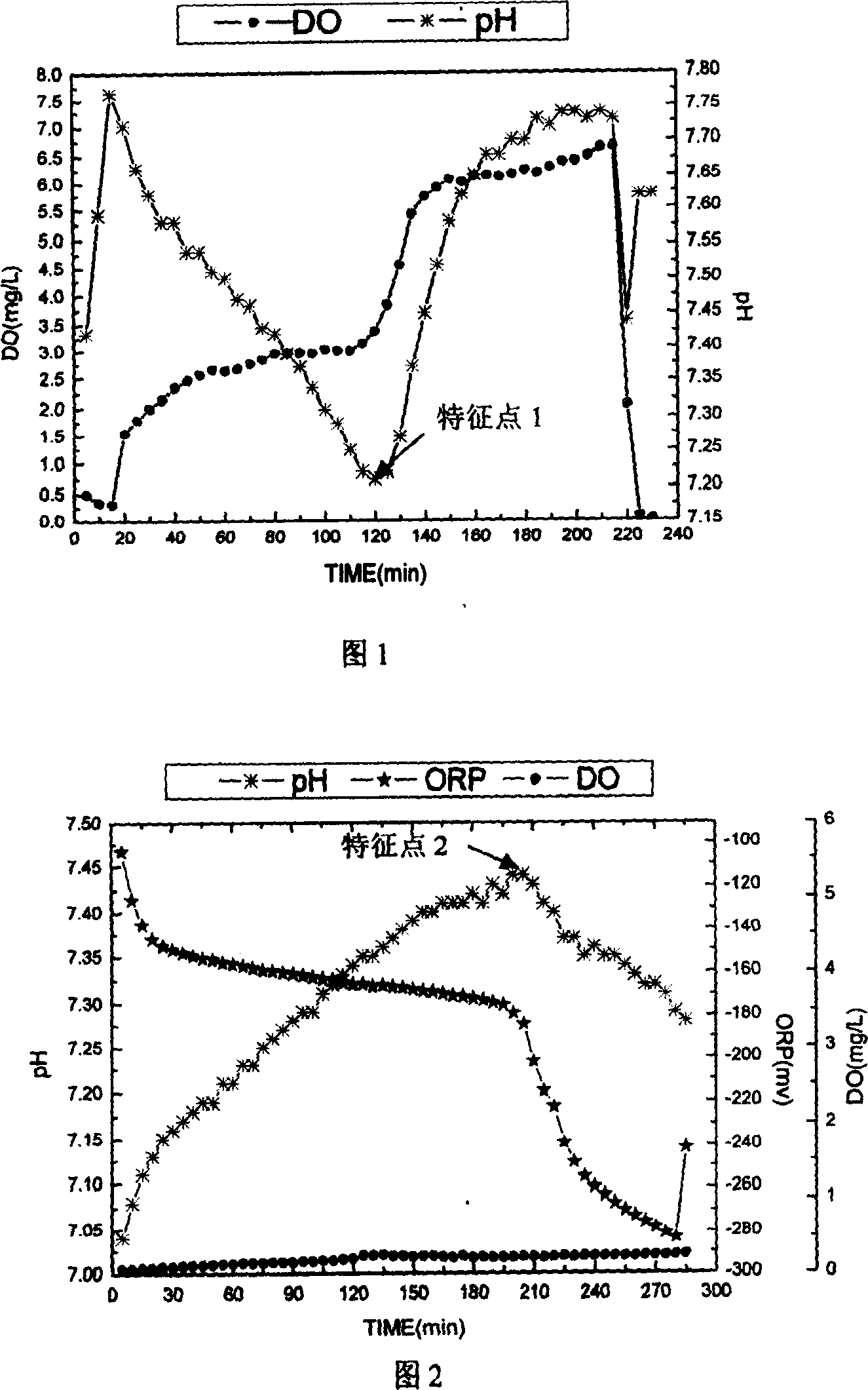

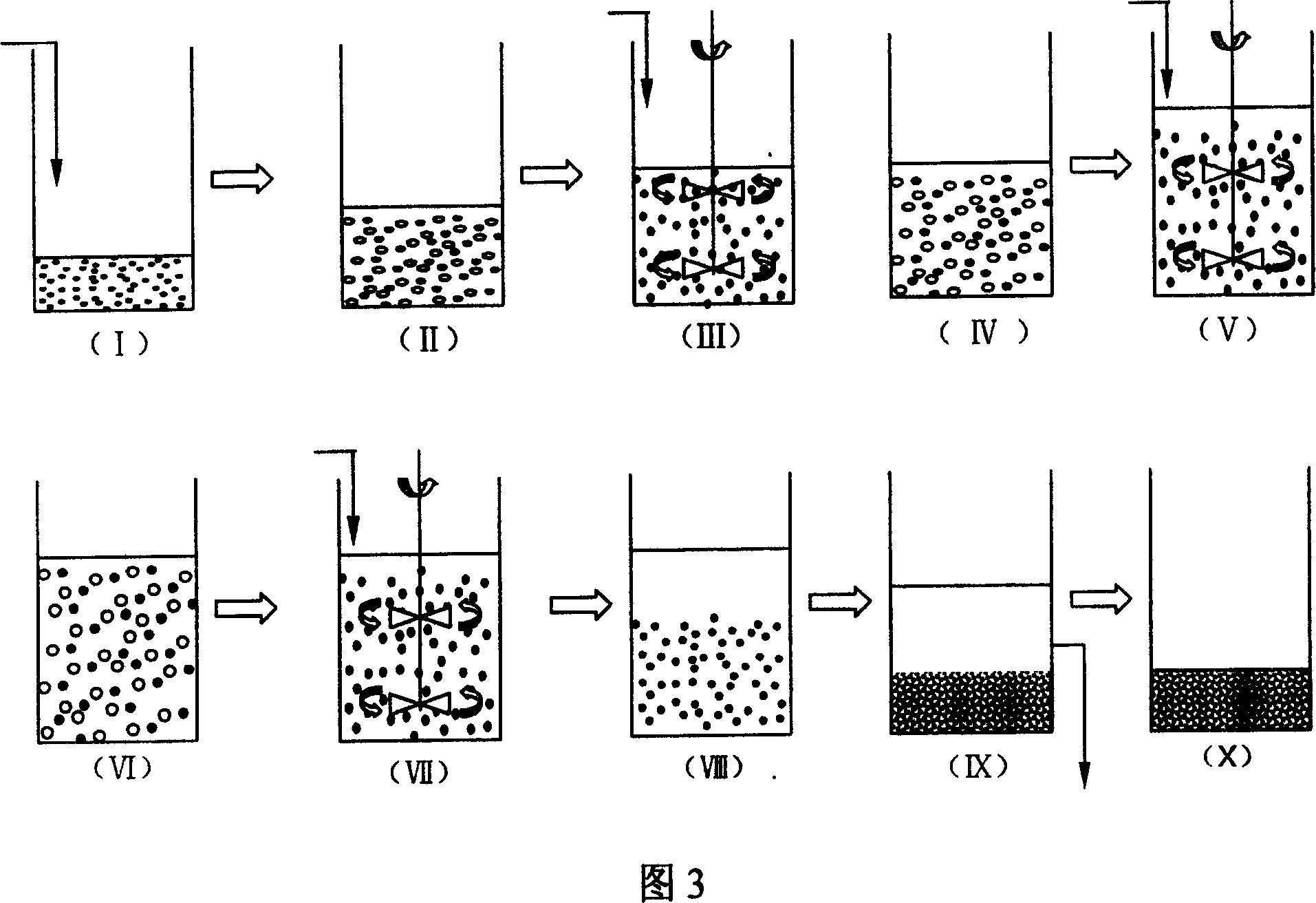

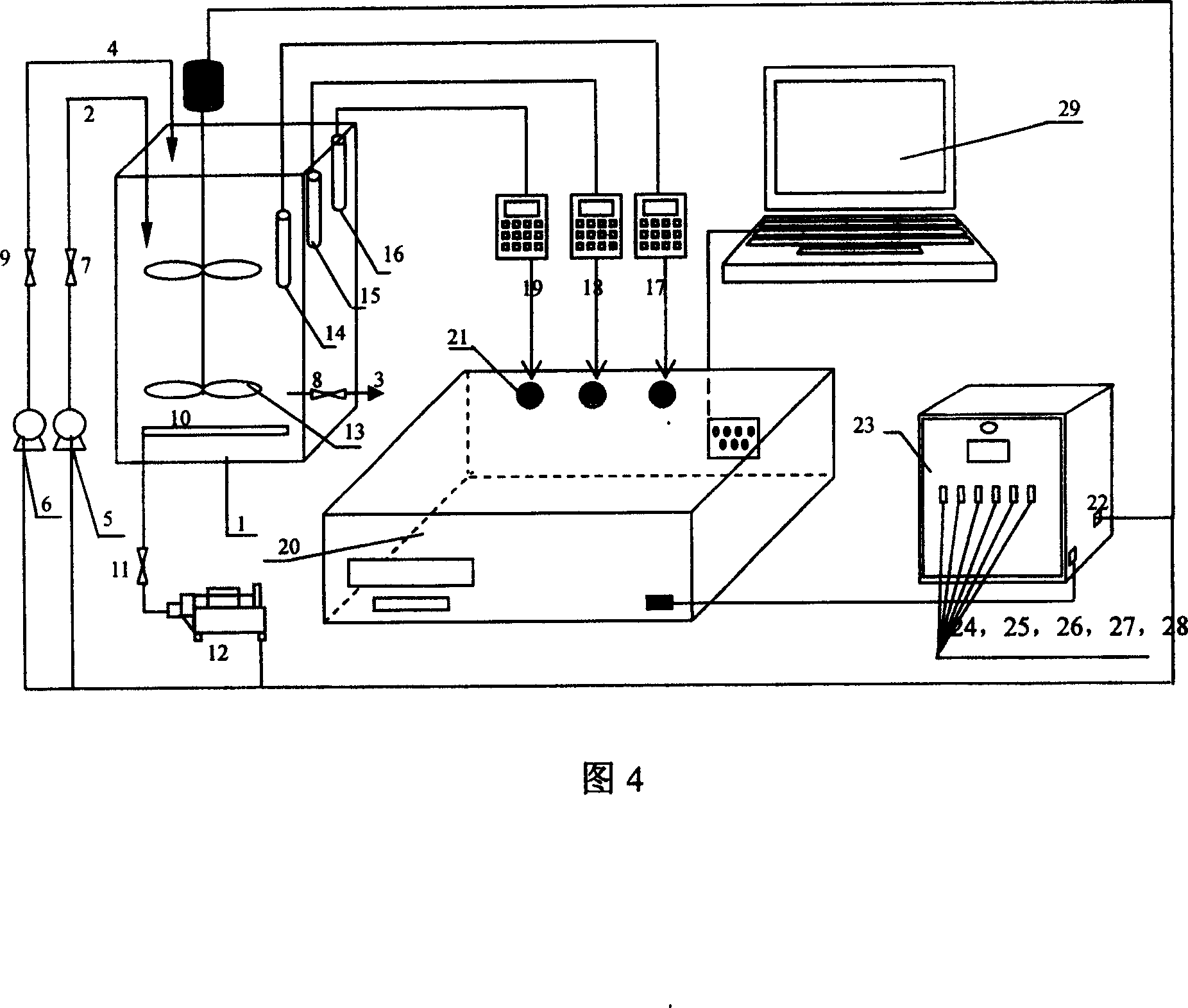

[0045] In conjunction with embodiment, as Fig. 3, shown in Fig. 5, the running operation procedure of technique of the present invention:

[0046] The actual domestic sewage discharged from a family area of a university was used as the experimental object (pH=6.5~7.8, COD=260~350mg / L, TN=75~80mg / L). The selected SBR reactor has an effective volume of 15L and is divided into three water intakes, each water intake is about 4L. The COD concentration of the mixed liquid in the reactor is maintained at 200-300mg / L, and the NH 4 + -N concentration is 55~60mg / L, the initial sludge concentration in the reactor is 3.5~4.0g / L, and the aeration rate is constant at 0.6m 3 / h, the mud age is maintained at about 15d, and the reaction temperature is 25°C. The external carbon source is 95% ethanol. The specific process is as follows:

[0047] 1 water inlet application pulse water inlet SBR biological denitrification process device provided by the present invention, first open the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com