Binding neodybium iron boron magnet surface cathode electrophoresis production technology

A cathodic electrophoresis and production process technology, applied in electrophoresis plating, magnetic objects, permanent magnet manufacturing, etc., can solve the problems of poor coating adhesion, low production efficiency, small size, etc., and achieve good anti-rust performance and anti-rust. The effect of high performance and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

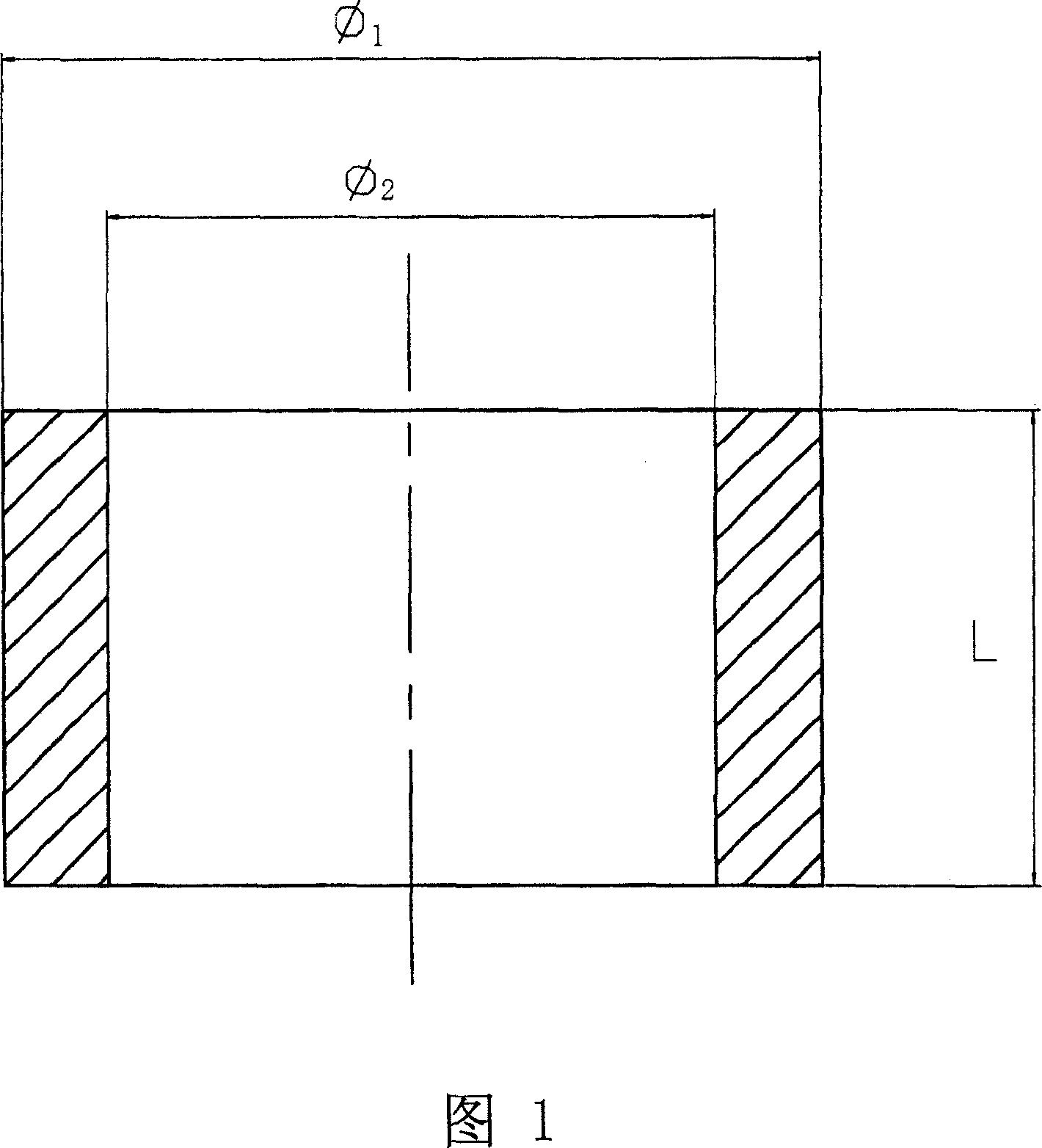

[0024] As shown in Figure 1, a bonded neodymium iron boron magnetic ring, the specification is Ф 1 10.2×Ф 2 7.8×L9, put 100 pieces of bonded neodymium iron boron magnetic rings into a large wave liquid cleaning machine for pretreatment to remove magnetic powder and other impurities on the surface of the magnet, and then rinse them with tap water and pure water in two stages.

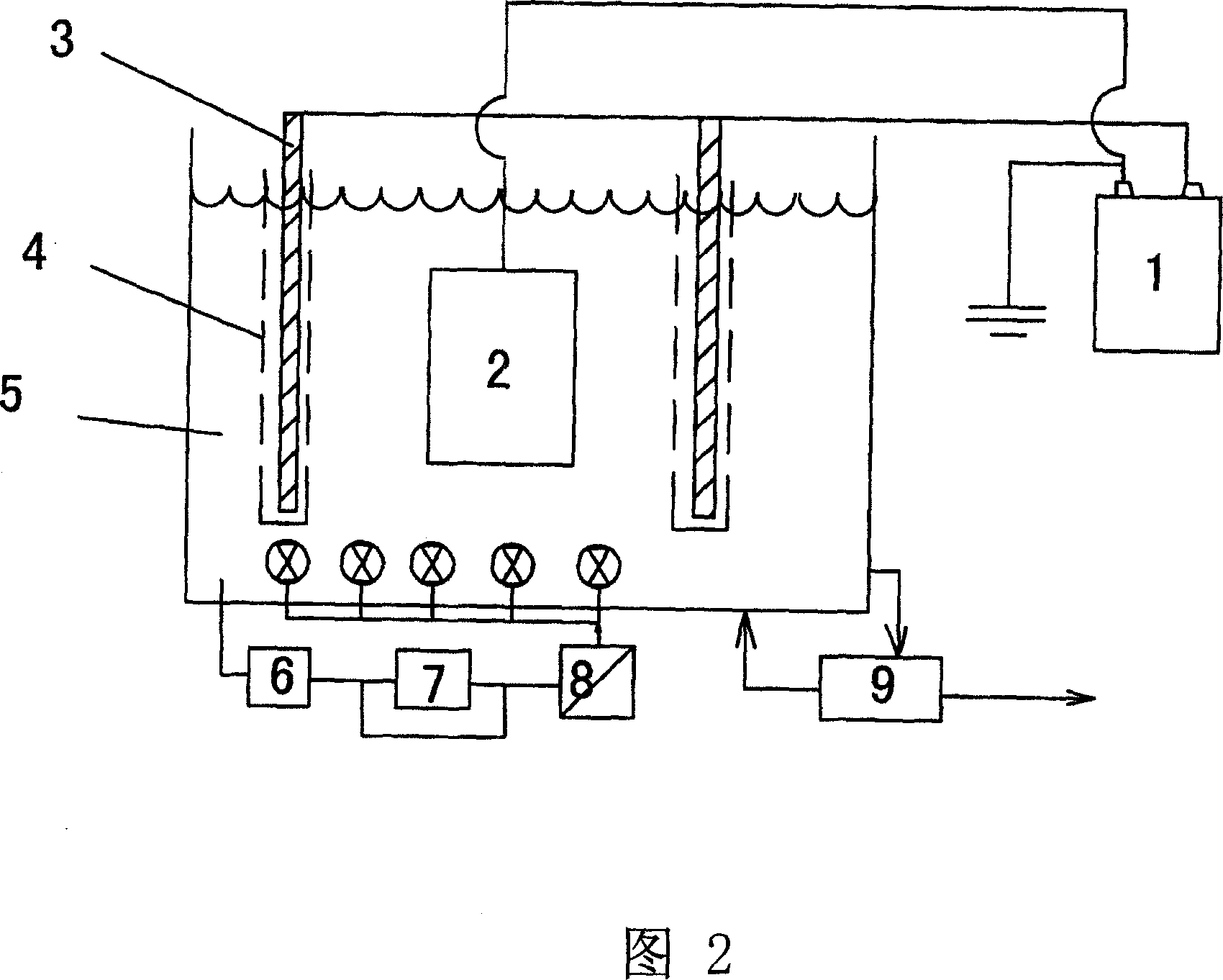

[0025] The pre-processed magnetic ring is used as a cathode, and is coated in a cathode electrophoresis tank to form an electrophoretic layer. As shown in Figure 2, the figure includes the power source 1, the object to be coated (magnetic ring cathode) 2, the anode plate 3, the diaphragm 4, the paint solution 5, the pump 6, the filter 7, the heat exchanger 8, and the ultrafiltration device 9. 60 kg of electrophoresis solution is prepared, 30 kg of cathodic electrophoresis paint (concentration of 36% by weight) is added to 30 kg of deionized water, and cyclic stirring is performed. The electrophoresis tank is...

Embodiment 2

[0040] As shown in Figure 1, a bonded neodymium iron boron magnetic ring with the same specifications as Example 1. The magnet surface pretreatment is carried out by a large wave liquid cleaning machine. The pretreatment liquid is composed of rust preventive liquid and deionized water. The treatment time For 10 minutes. Using alkaline water as the degreasing agent, the concentration of the alkaline water is 0.1-0.8% by weight, and the magnet is treated in a degreasing tank for 10 minutes at a temperature of 25°C.

[0041] The pre-processed magnetic ring is used as a cathode, and is coated in a cathode electrophoresis tank to form an electrophoretic layer. As shown in Figure 2, the figure includes an anode plate 1, a diaphragm 2, a paint solution 3, a magnetic ring cathode 4, a pump 5, a filter 6, a heat exchanger 7, an ultrafiltration device 8, and a power source 9. 60 kg of electrophoresis solution is prepared, 30 kg of cathodic electrophoresis paint (concentration of 36% by weig...

Embodiment 3

[0047] As shown in Figure 1, a bonded neodymium iron boron magnetic ring with the same specifications as the first embodiment. The pretreatment of the magnet surface is carried out by an ultrasonic device. The pretreatment liquid is composed of anti-rust liquid and deionized water. The treatment time is 40 minutes. Using alkaline water as the degreasing agent, the concentration of the alkaline water is 0.8% by weight, and the magnet is treated in a degreasing tank for 40 minutes at a temperature of 10°C.

[0048] The pre-processed magnetic ring is used as a cathode, and is coated in a cathode electrophoresis tank to form an electrophoretic layer. As shown in Figure 2, the figure includes an anode plate 1, a diaphragm 2, a paint solution 3, a magnetic ring cathode 4, a pump 5, a filter 6, a heat exchanger 7, an ultrafiltration device 8, and a power source 9. 60 kg of electrophoresis solution is prepared, 30 kg of cathodic electrophoresis paint (concentration of 36% by weight) is ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com