Method for extracting metallic gallium from aluminium oxide production procedure

A production process and metal extraction technology, applied in the field of metal gallium extraction, can solve problems such as the stability of the production process affecting the life cycle of the resin, the complex operation process, the unbalanced resin, etc., and achieve the effect of high degree of automation, easy process and short process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

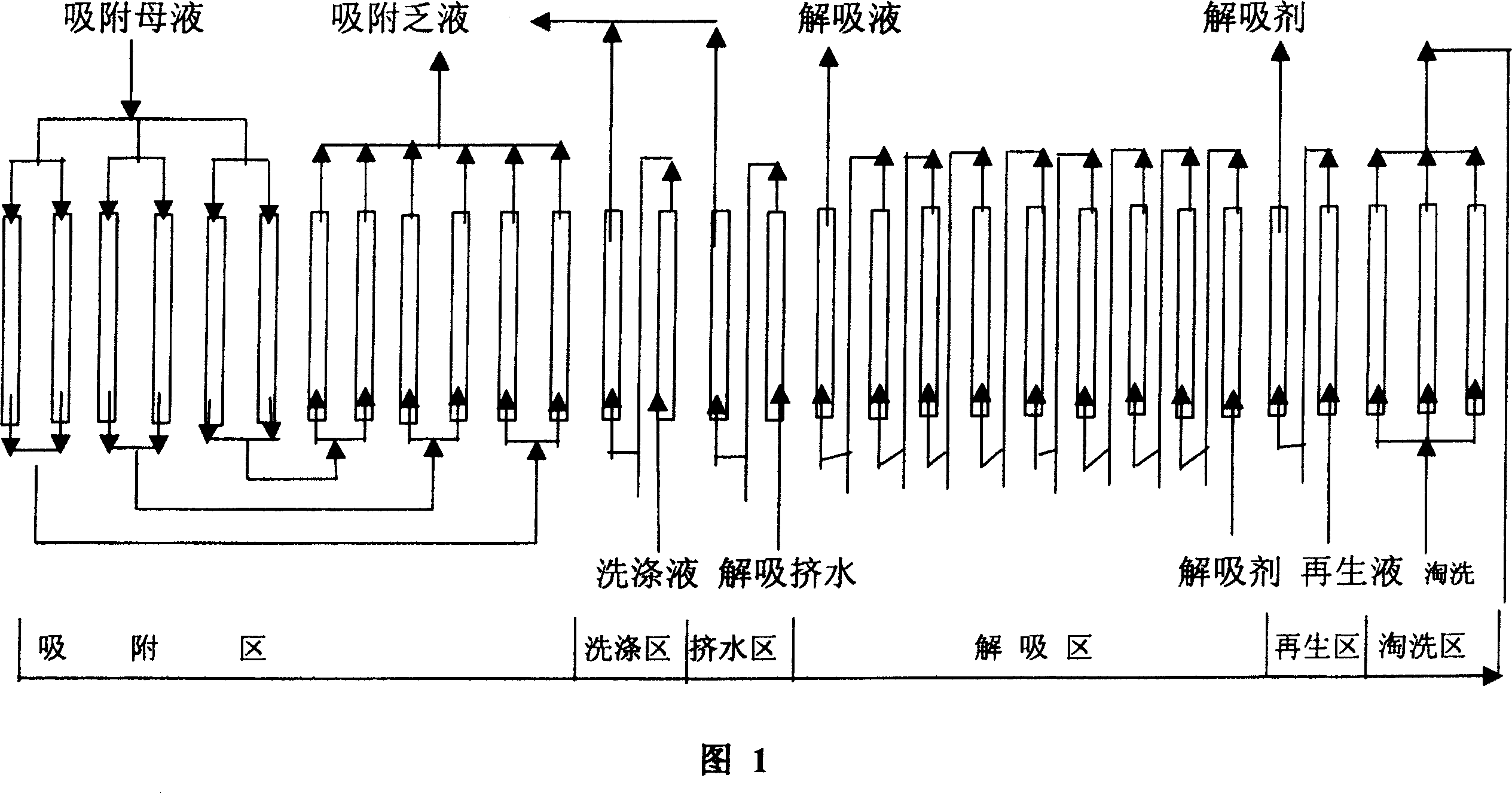

[0021] As shown in the figure, the method for extracting gallium metal from the alumina production process described in the present invention is carried out by using ISEP ion separation technology, and the adsorption gallium chelating resin is used for adsorption. There are 30 resin exchange columns in the ISEP system, and each column is loaded with 1.7 tons of resin.

[0022] (1) Adsorption with 12 columns, using two-stage serial series forward and countercurrent adsorption, adsorption time 20 hours, flow rate 25 cubic meters per hour, and the difference in gallium concentration before and after adsorption is 56 mg / L.

[0023] (2) Wash 2 columns, wash the resin countercurrently with 0.8N aqueous sodium hydroxide solution for 3 hours, flow rate 2 cubic / hour.

[0024] (3) Desorption Squeeze water and desorption 11 columns, use the aqueous solution of 2N sodium hydroxide and 0.7N sodium sulfide to desorb in series countercurrent, the time is 20 hours, and the flow rate is 2 cubi...

Embodiment 2

[0027] As shown in the figure, the method for extracting gallium metal from the alumina production process described in the present invention is carried out by using ISEP ion separation technology, and the adsorption gallium chelating resin is used for adsorption. There are 30 resin exchange columns in the ISEP system, and each column is loaded with 1.7 tons of resin.

[0028] (1) Adsorption with 12 columns, using two-stage series-connected forward and countercurrent adsorption, the adsorption time is 22 hours, the flow rate is 23 cubic meters per hour, and the concentration difference of gallium before and after adsorption is 54 mg / L.

[0029] (2) Wash 2 columns, wash the resin countercurrently with 0.5 aqueous sodium hydroxide solution for 3 hours, flow 2 cubic / hour.

[0030] (3) Desorption Squeeze water and desorption 11 columns, use 3N sodium hydroxide and L.0 N sodium sulfide aqueous solution for serial countercurrent desorption, time 20 hours, flow rate 2.4 cubic / hour. ...

Embodiment 3

[0033] As shown in the figure, the method for extracting gallium metal from the alumina production process described in the present invention is carried out by using ISEP ion separation technology, and the adsorption gallium chelating resin is used for adsorption. There are 30 resin exchange columns in the ISEP system, and each column is loaded with 1.7 tons of resin.

[0034] (1) Adsorption of 12 columns, using two-stage serial sequential and countercurrent adsorption, the adsorption time is 25 hours, the flow rate is 20 cubic meters per hour, and the concentration difference of gallium before and after adsorption is 55 mg / L.

[0035] (2) Wash the 2 columns, wash the resin countercurrently with 0.7N aqueous sodium hydroxide solution for 2 hours, and flow 3 cubic meters per hour.

[0036] (3) Desorption Squeeze water and desorption 11 columns, use the aqueous solution of 2N sodium hydroxide and 0.8N sodium sulfide to desorb in series countercurrent, the time is 22 hours, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com