Organic-inorganic polysulfide lithium cell positive pole material, producing method thereof, lithium cell positive pole, and lithium cell

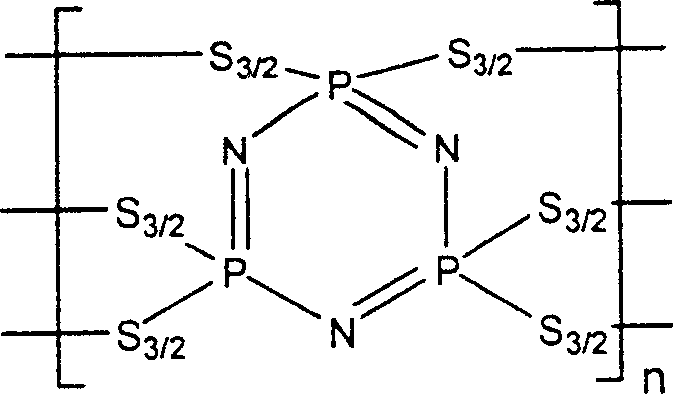

A polysulfide, cathode material technology, applied in battery electrodes, lithium storage batteries, electrode manufacturing, etc., can solve the problems of unsatisfactory electronic conductivity, low degree of effective energy utilization, and inability to be practically applied, and achieves high utilization. The effect of large specific capacity and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Will 80 copies [(NPS 3 ) 3 ] n product, 10 parts of acetylene black and 10 parts of polyethylene oxide (M w =2*10 5 ) was stirred in deionized water for 8 hours to obtain a homogeneously mixed positive electrode slurry, which was coated on a current collector aluminum foil (thickness 20 μm), and vacuum-dried at 60° C. for 24 hours to obtain a positive electrode for lithium batteries.

Embodiment 2

[0053] Will 70 parts [(NPS 3 ) 4 ] n product, 15 parts of acetylene black and 15 parts of polyethylene oxide (M w =2*10 5 ) was stirred in deionized water for 4 hours to obtain a homogeneously mixed positive electrode slurry, which was coated on a current collector aluminum foil (thickness 20 μm), and vacuum-dried at 65° C. for 20 hours to obtain a positive electrode for lithium batteries.

Embodiment 3

[0055] Will 90 parts [NPS 3 ] n product, 5 parts of acetylene black and 5 parts of polyethylene oxide (M w =2*10 5 ) was stirred in deionized water for 10 hours to obtain a homogeneously mixed positive electrode slurry, which was coated on a current collector aluminum foil (thickness 20 μm), and vacuum-dried at 80° C. for 30 hours to obtain a positive electrode for lithium batteries.

[0056] 156 g of LiCF in an argon glove box 3 SO 3 Added to the mixed solvent of DME (500mL) and DG (500mL), the LiCF 3 SO 3 After complete dissolution, the electrolyte solution required for testing the battery is obtained.

[0057] The above battery positive electrode, electrolyte solution, metal lithium (thickness 100 μm) and Celgard2400 separator were assembled in an argon glove box to form a battery for use. The test experiment of the above battery is as follows:

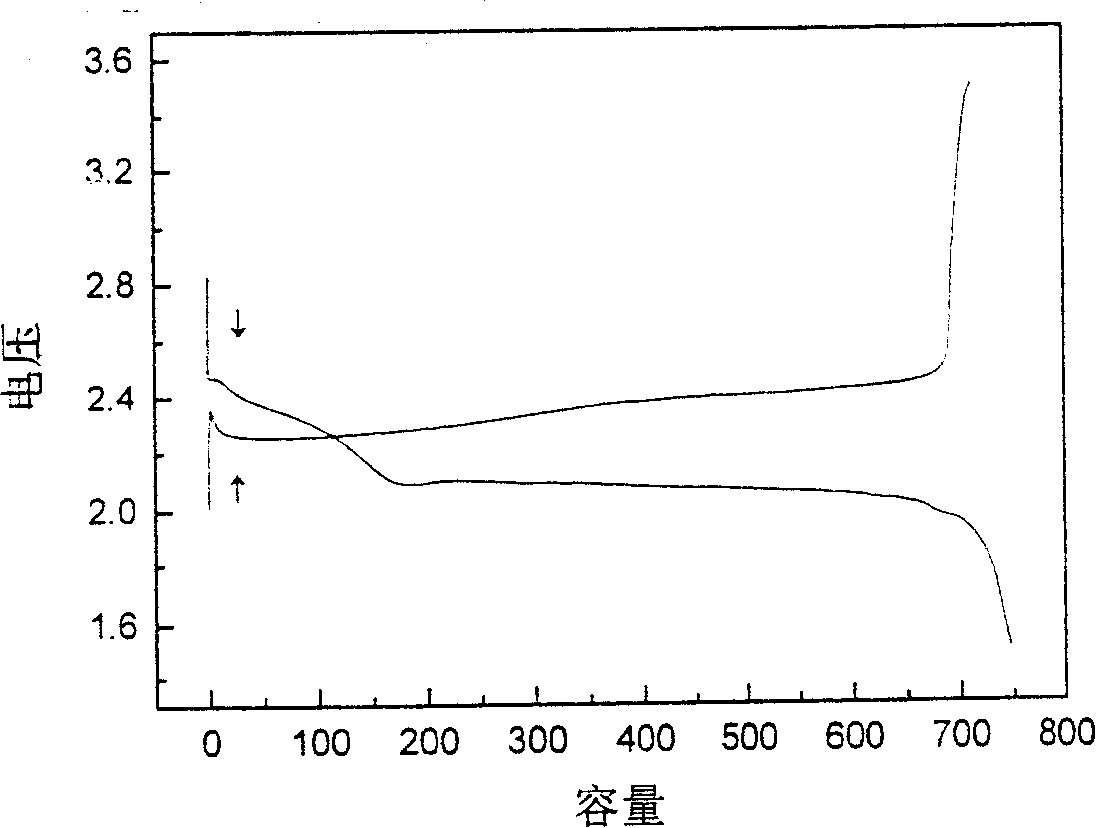

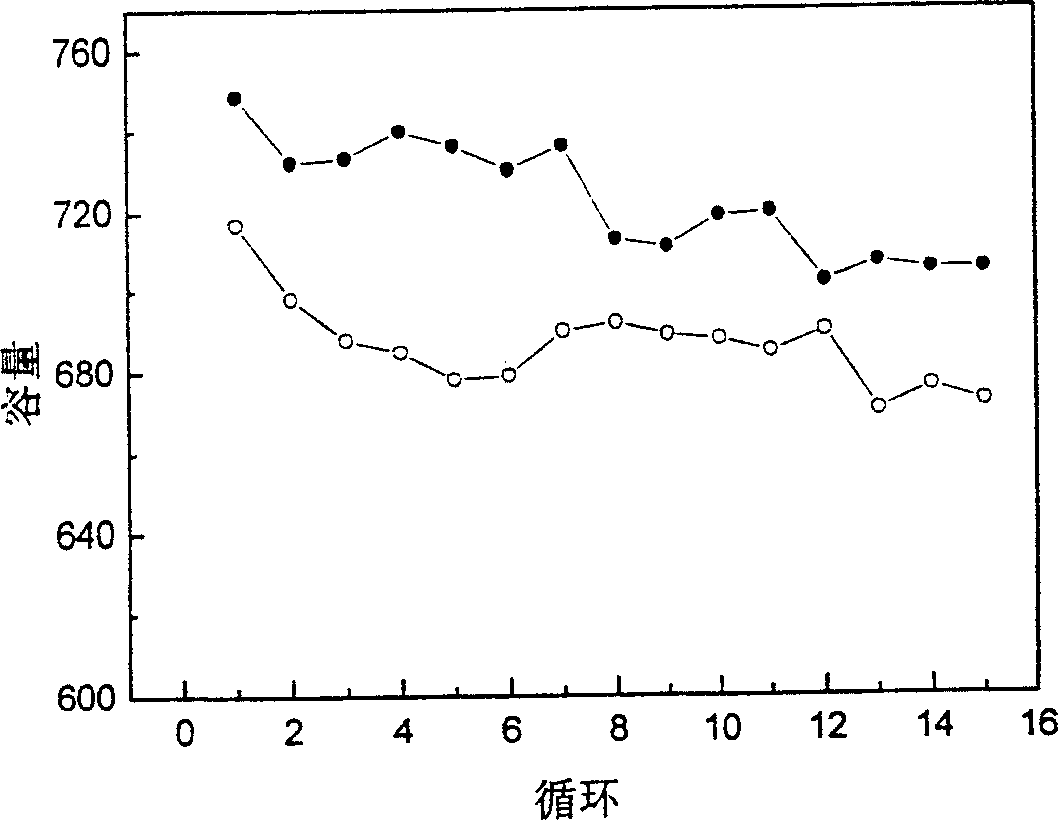

[0058] Carry out charge and discharge test with the battery in embodiment 1, charge and discharge current 25mA·g -1 , vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com