Enhancing SNCR-aided combustion with oxygen addition

An oxygen and combustion zone technology, applied in gas fuel burners, combustion chambers, burners, etc., can solve problems such as reducing boiler thermal efficiency and energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

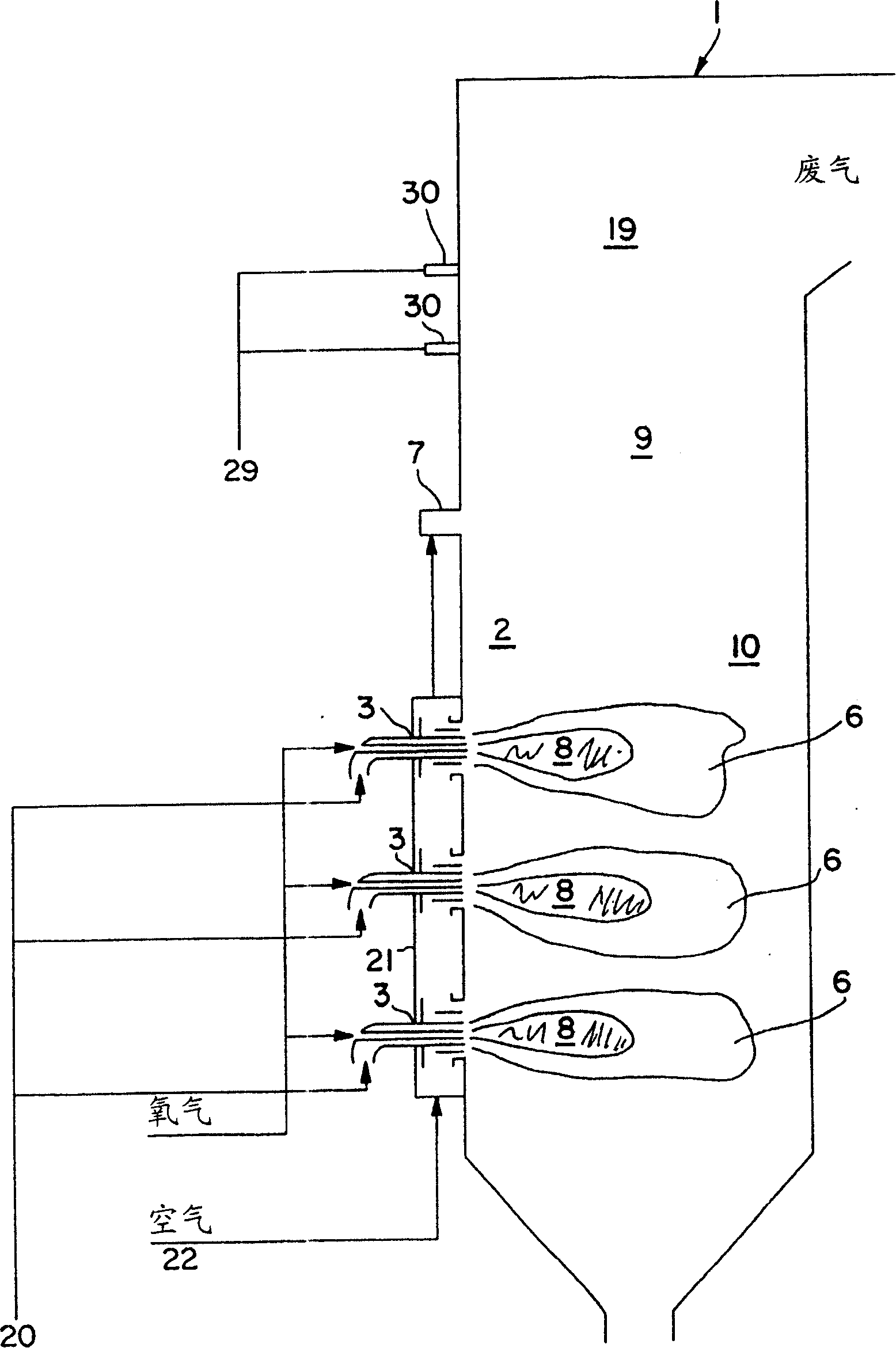

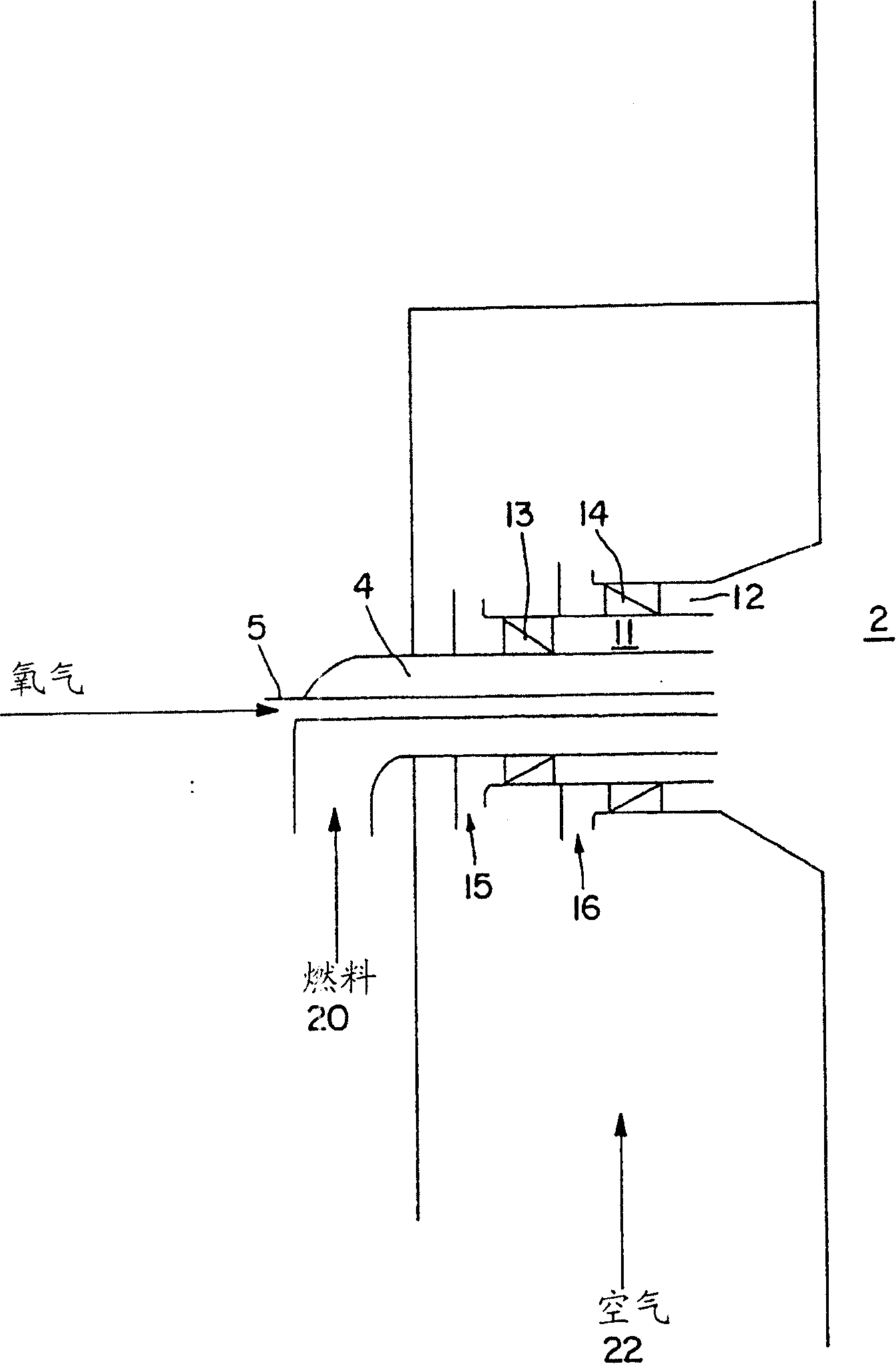

Method used

Image

Examples

Embodiment 1

[0065] Table 1 illustrates the NO obtained by using SNCR with and without oxygen X reduction. In this example, it is assumed that oxygen reduced NO X 30% of baseline, NO reduced by SNCR X It is also 30% of the baseline, and the injection molar ratio of ammonia to nitrogen oxide is 1. It is further assumed that due to the decrease in gas temperature, when combined with oxygen, NO reduced by SNCR at the same injection ratio X The percentage is increased to 40%.

[0066] Table 1. With and without O 2 , Using SNCR to reduce NO X Example of

[0067] Combination method only SNCR

[0068] NO X (1b / MMBtu) Baseline 0.4 0.4

[0069] NO after O2 injection X (1b / MMBtu) 0.28

[0070] NO after adopting SNCR X (1b / MMBtu) 0.168

[0071] 0.28

[0072] SNCR's NO X Reduction% 40 30

[0073] NH3 consumption (1b / MMBtu) 0.108

[0074] 0.148

[0075] The above example shows the NO obtained by SNCR alone or oxygen injection alone X Reduction from 0.4 1b / MMBtu to 0.28 1b / MMBtu. Wh...

Embodiment 2

[0077] The invention is described in detail in the following examples simulated by a boiler computer model.

[0078] Based on the heat input, in Examples 1, 1a, 1b and 1c, bituminous coal from the Pittsburgh#8 (Pit#8) coal seam was used to feed a 220MW tangentially fired boiler. Examples 2, 2a, 2b, and 2c used Powder River from Wyoming Low-grade sub-bituminous coal from Basin (PRB). Table 2 summarizes the characteristics of coal.

[0079] Table 2

[0080] Industrial analysis (%, wet)

[0081] Pit#8 PRB

[0082] Moisture 5.2 28.7

[0083] V.M 38.1 32.0

[0084] F.C 48.1 33.7

[0085] Ash content 8.6 5.6

[0086] Total 100 100

[0087] Elemental analysis (%, dry)

[0088] C 74.0 68.30

[0089] H 5.1 4.91

[0090] N 1.6 1.00

[0091] O 7.9 17.25

[0092] S 2.3 0.70

[0093] ASH 9.1 7.84

[0094] Total 100 100

[0095] HHV(btu / 1b, wet) 12540 8650

[0096] Table 3 summarizes the operating characteristics of the boilers in the followin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com