Paper-making effluent purifying treatment process

A technology for pulping and papermaking and purification treatment, which is applied in anaerobic digestion treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. problems, to achieve the effect of reducing energy demand, stable operation and saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

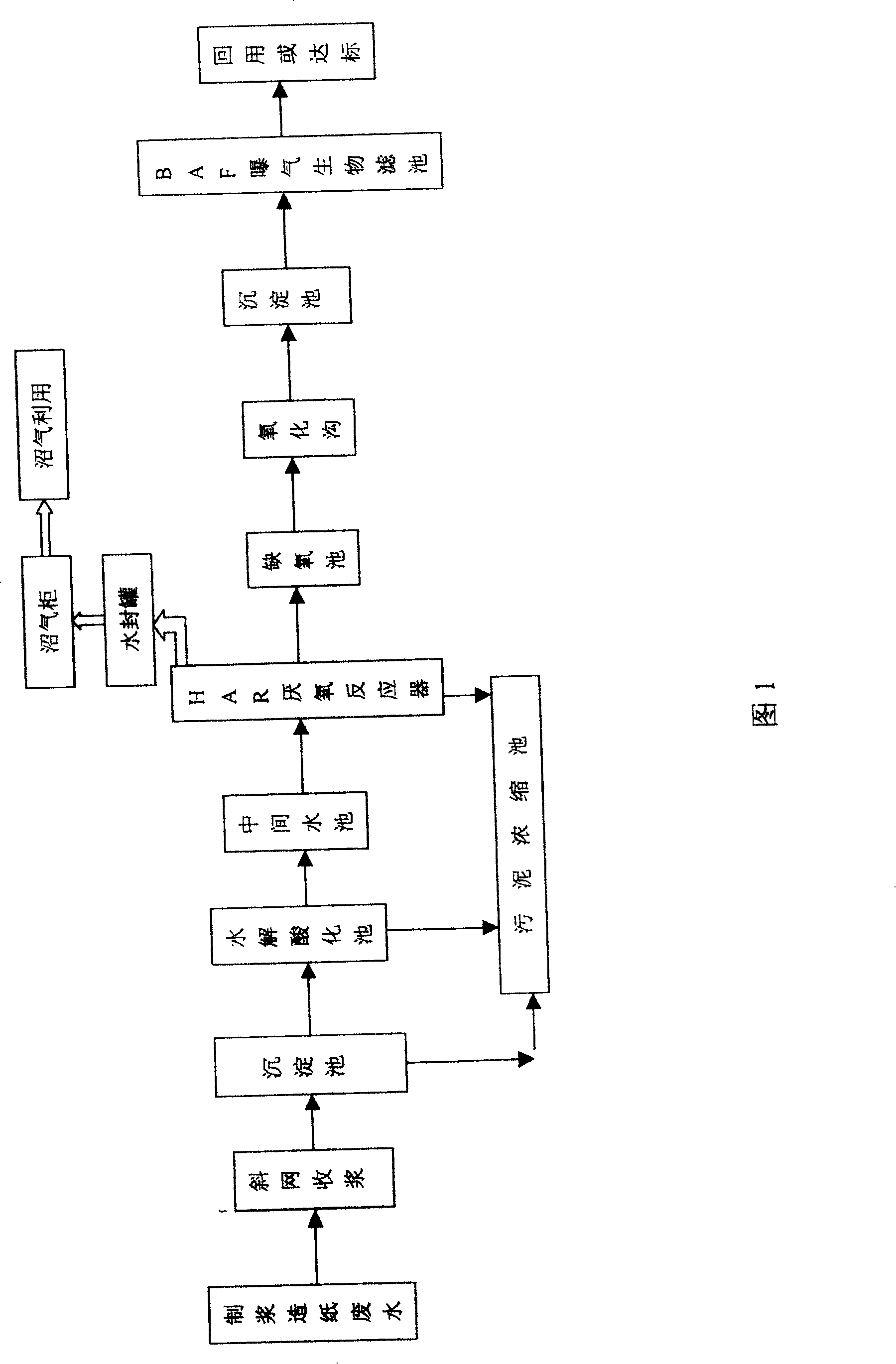

[0027] The present invention is illustrated below in conjunction with accompanying drawing.

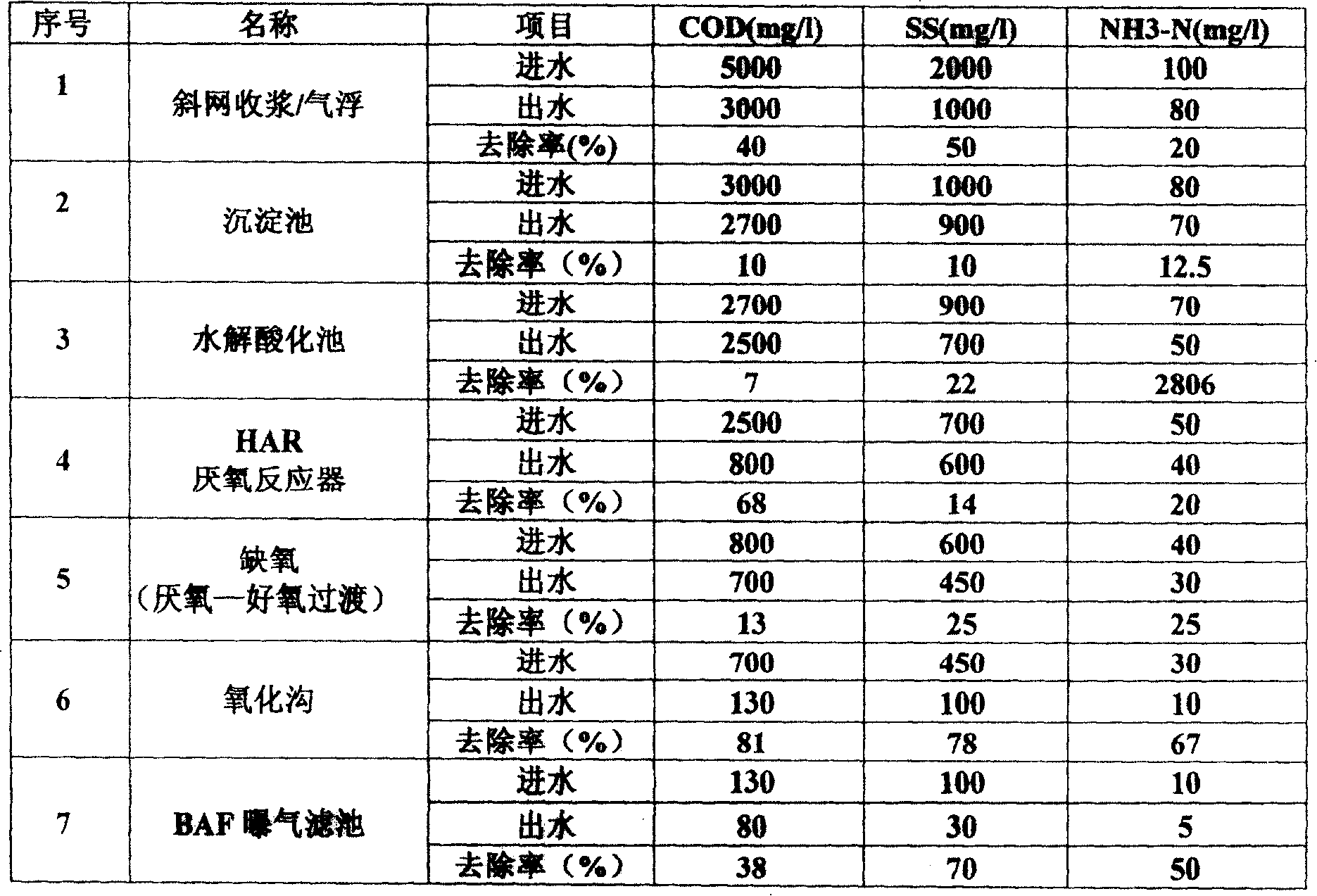

[0028]The mixed wastewater from pulping and papermaking passes through the grid to remove large pieces of mechanical impurities, collects the pulp and recovers fine fibers through the inclined screen with an aperture of 90 mesh, and then enters the air flotation device, passes through the flocculant (polyaluminum chloride with a mass concentration of 10% or It is treated with 0.1% polyacrylamide) to remove tiny suspended matter, and then enters the sedimentation tank, and adjusts the water quality to PH=6~9 through water volume, and COD4 and CO 2 , so that the water quality is purified, the operating condition is that the volume load is 3.0-5.0kgCOD / (m 3 .d), using normal temperature anaerobic digestion, the total residence time is 24-30h, and the average sludge concentration (MLVSS) is 30-40g / L. The effluent from the anaerobic reactor enters the anoxic tank, and the dissolved oxygen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com