Dual-hydrolysis fast treatment method of organic solid waste matter

A technology for organic solids and wastes, applied in the preparation of organic fertilizers, the treatment of biological organic parts, organic fertilizers, etc., can solve the problems of large dryers, long hydrolysis reaction time, large water content, etc. Investment, organic nutrient content and optimization, the effect of high organic nutrient content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

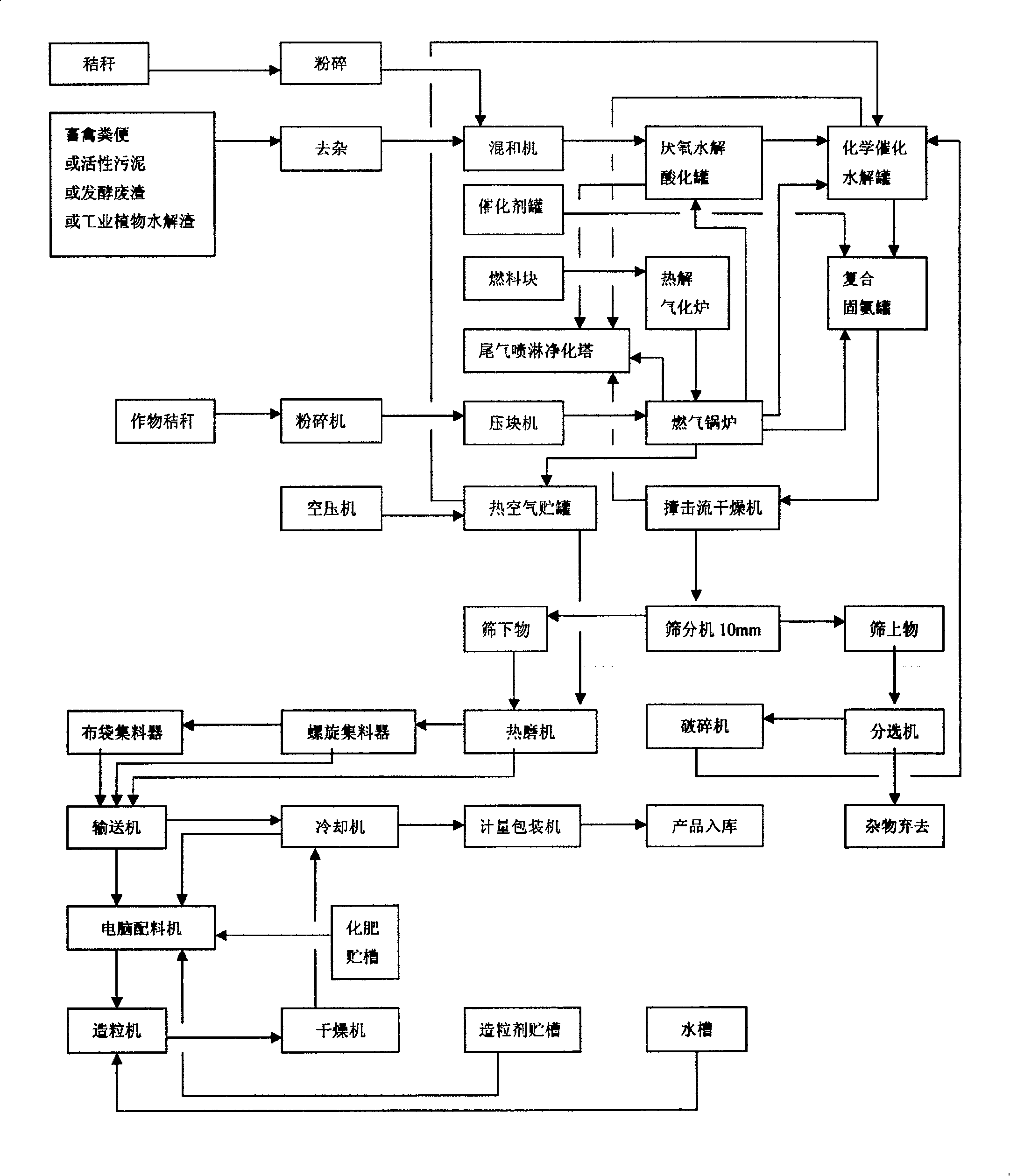

[0010] Below in conjunction with accompanying drawing and production process flow citing embodiment further illustrate the present invention.

[0011]In this embodiment, livestock and poultry manure, crop straw, leaves, branches, humus, organic domestic garbage, activated sludge from sewage treatment plants, industrial fermentation waste residue, and industrial plant hydrolysis residue can be used. If crop straw is used, it needs to be crushed first. One or more than two of the above-mentioned materials are crushed and screened to remove impurities, mixed in a mixer, and then fed into an anaerobic hydrolysis acidification tank. If thermo-anaerobic fermentation is selected, the control temperature is 60°C, and the fermentation time is 4 hours; if high-temperature anaerobic fermentation is selected, the temperature is controlled at 85°C, the fermentation time is 2 hours, and the carbon-nitrogen ratio is controlled at 1:5. After a large amount of organic acid is produced, the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com