Hydrogen oxygen hydrocarbon mixed gas generator

A technology of mixed gas and generator, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of self-treatment of electrolytic impurities in the electrolyte, insufficient drying of gas, reduction of service life and working efficiency of electrolytic cells, etc., and achieve the elimination of internal The effect of reducing explosion hazard, reducing flame burning speed, improving service life and working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

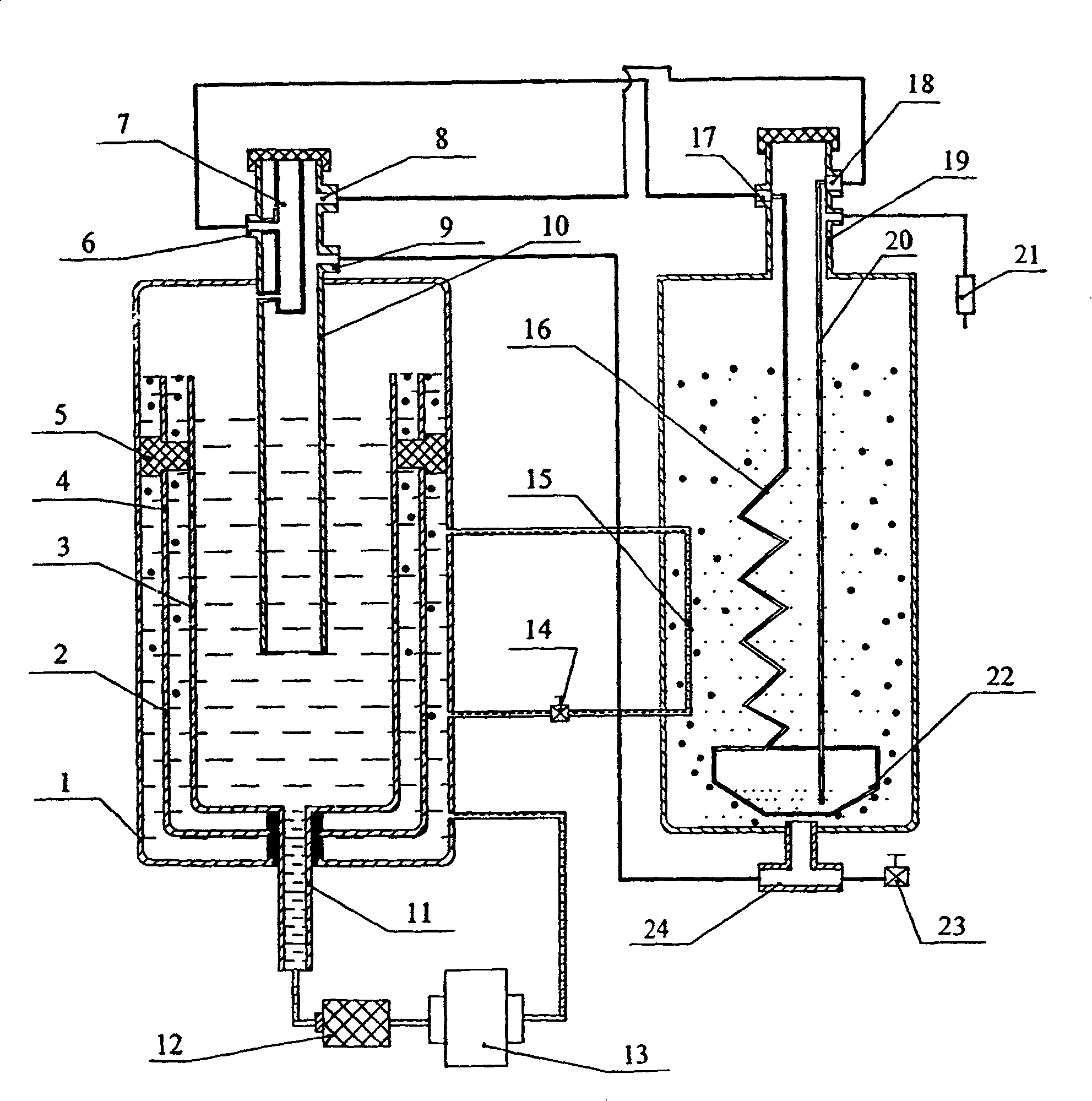

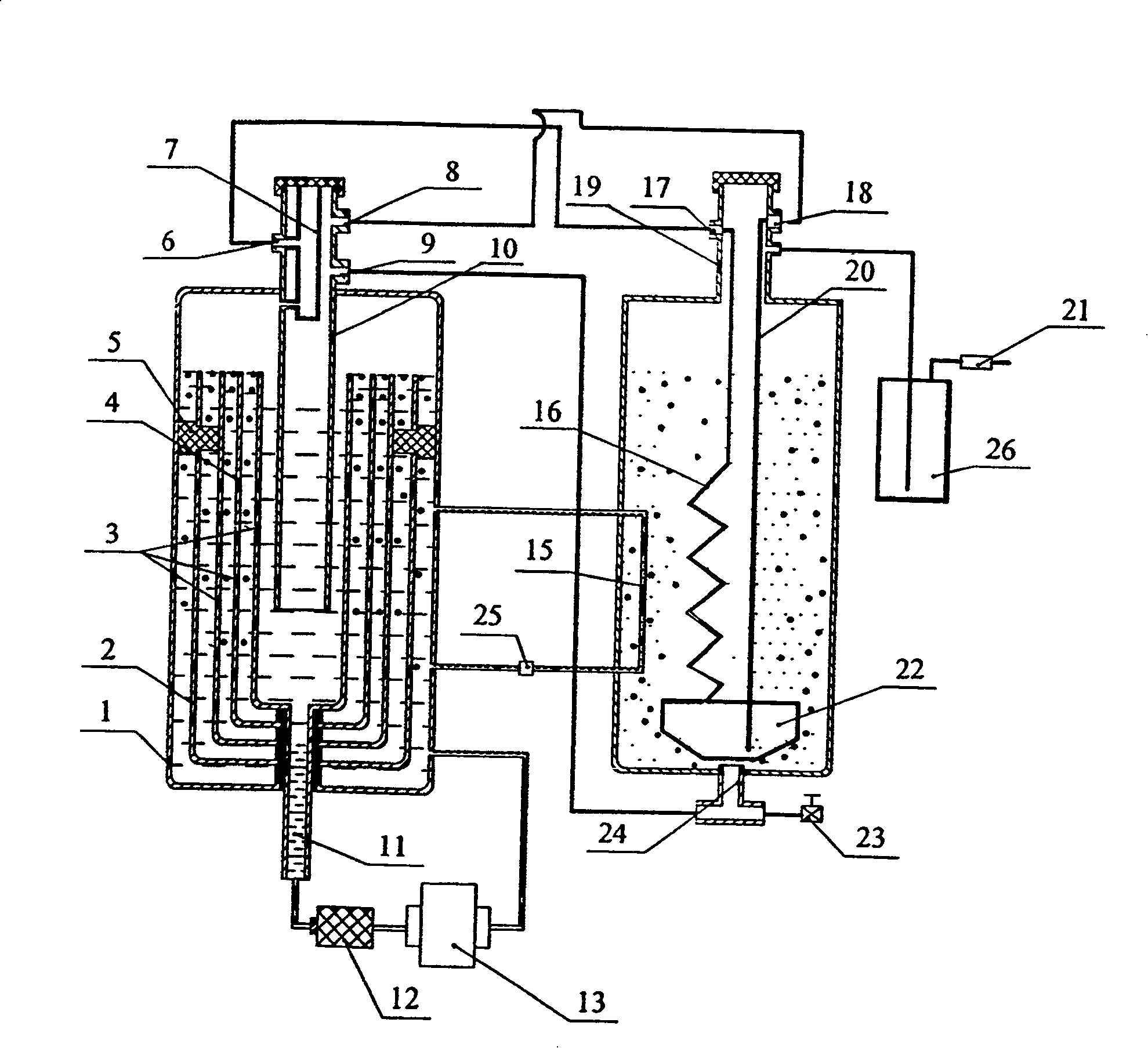

[0014] see Figure 1-Figure 2 , Hydrogen-oxygen-hydrocarbon mixed gas generator is composed of electrolyzer and evaporator, and the two are connected through pipelines. The electrolytic cell is composed of an electrolytic tank, a steam-water separator 7, a conductive pumping composite pipe 11, a filter 12, and a circulating pump 13. The electrolytic tank is made of multi-layer concentric cylinder sets to form a closed cylinder, including an outer cylinder 1, a middle cylinder 2 and an inner cylinder 3. The number of layers of the inner cylinder can be the single-layer structure of the embodiment 1, or it can be the embodiment The 3-layer structure of 2 is supported by isolation columns 5 between the layers, so that the distance between the side walls of the cylinder is kept to prevent short circuits. Except for the cylinder, there are liquid holes on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com