Analyzer for mixed gas containing O2, N2 and H2

An analysis device and gas switching technology, which is applied in the field of analysis devices, can solve problems such as cumbersome operation, large errors, and complex data processing, and achieve good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

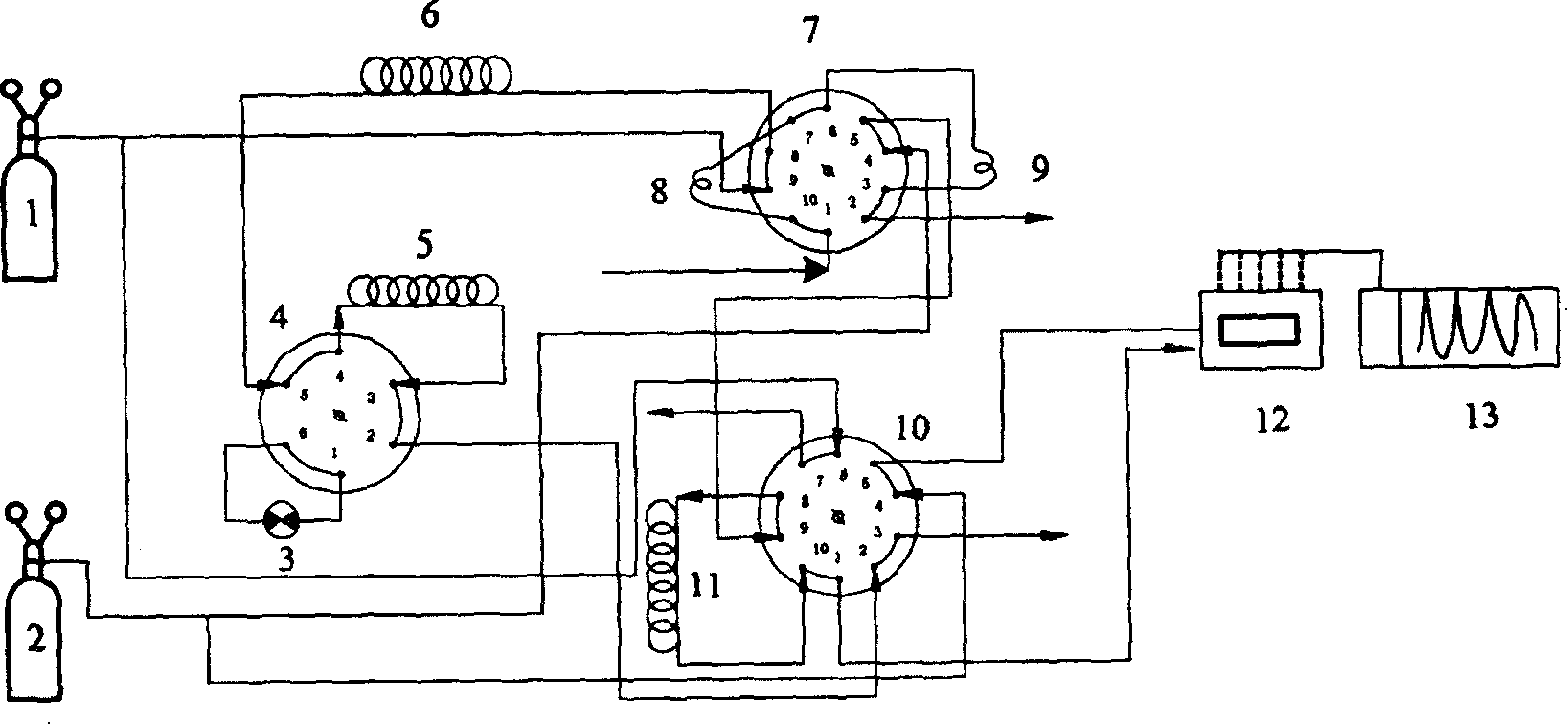

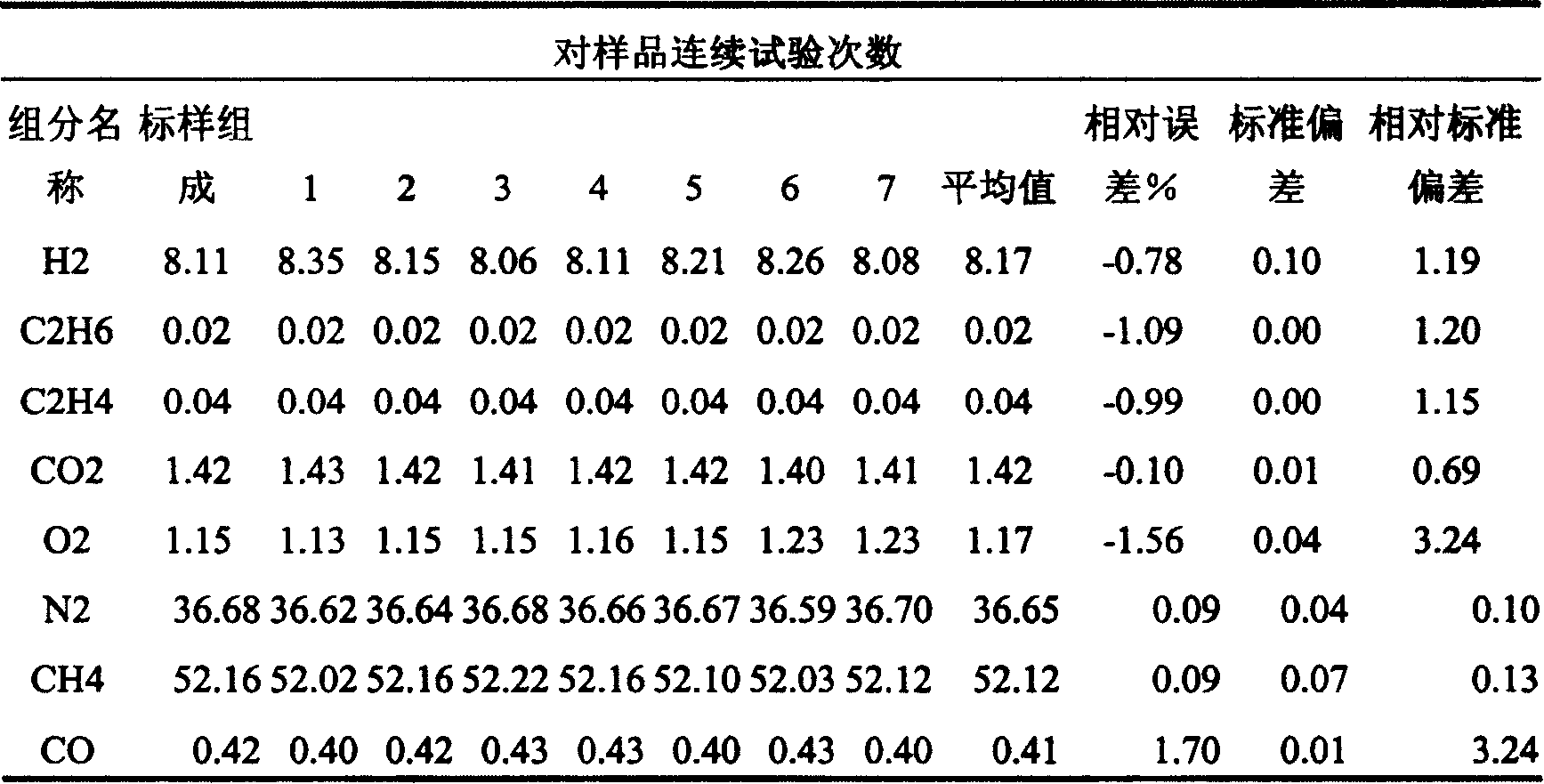

[0024] Analytical instrument: HP-6890, American Agilent Company, equipped with a six-way valve, two ten-way valves, and a TCD detector. Data processing was carried out by HP 2070A chromatographic workstation.

[0025] Chromatographic column: the second chromatographic column is a Porapak N packed column, the third chromatographic column is a 13-x molecule sieve column; the first chromatographic column is a 613-x molecule sieve packed column;

[0026] Chromatographic conditions: temperature program: furnace temperature 50°C, stay for 3 minutes, then rise to 80°C at a rate of 5°C / min and stay for 5.5 minutes; TCD detector, temperature 250°C, carrier gas starts to be nitrogen as carrier gas (for measuring Hydrogen), after 0.7 minutes, hydrogen was used as carrier gas; the column flow rate was 18 ml / min.

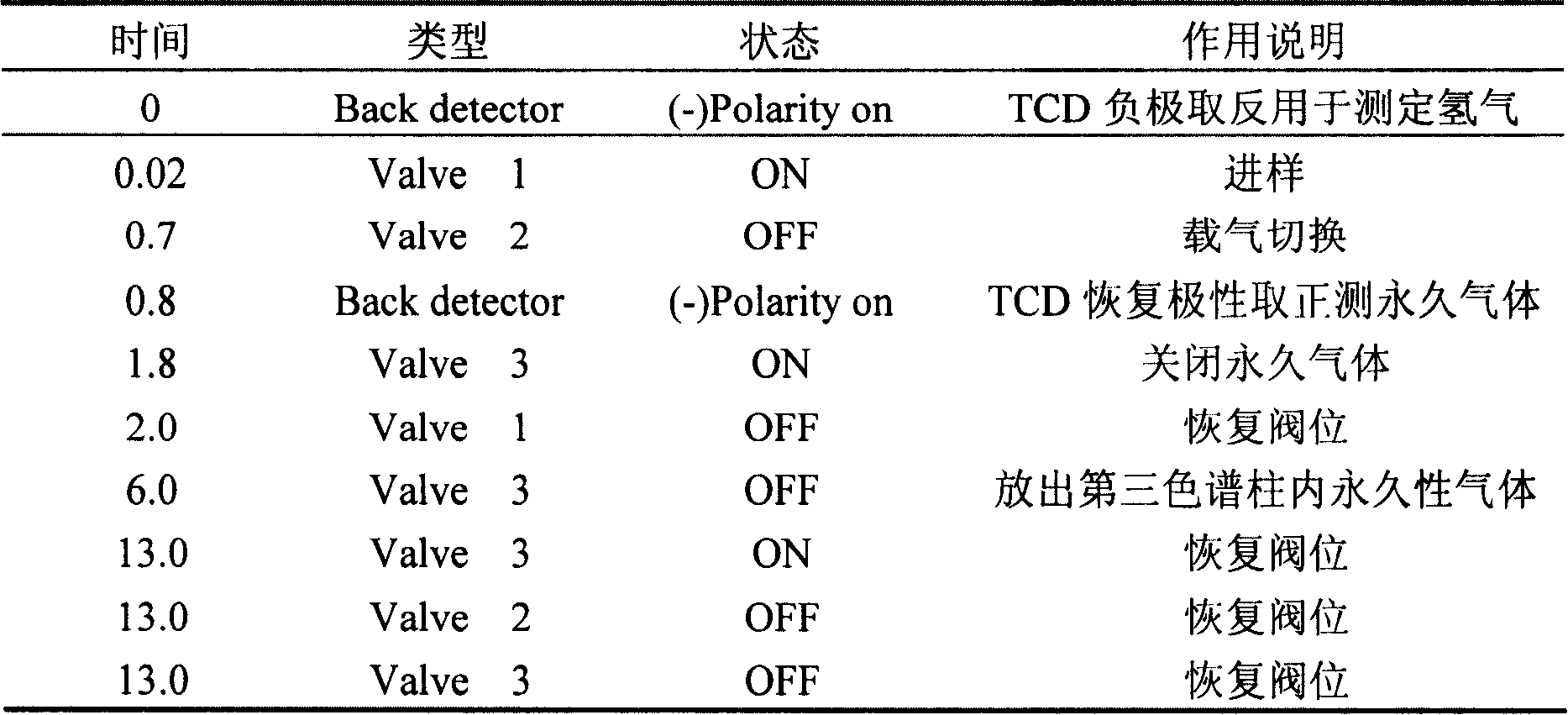

[0027] See Table 1 for the running time control program.

[0028] Table 1 Mixed gas analysis running time control switching table

[0029]

[0030] Valve 1 refers to the inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com