Catalyst for simultaneously removing nitrogen oxide and CO in automobile exhaust

A technology of automobile exhaust and nitrogen oxides, which is applied in the field of pollution control and can solve the problem of high catalyst cost and achieve the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Using cerium nitrate as raw material, carrier CeO 2 Three methods were used to prepare:

[0025] (1)Ce(NO 3 ) 3 · 6H 2 O was calcined in a muffle furnace at 600 °C for 4 hours, and the obtained sample was named CeO 2 (1). (2) Preparation of cerium oxide by ammonia precipitation: take a certain amount of Ce(NO 3 ) 3 · 6H 2 O is made into a 0.05M solution and added to a 500ml round-bottomed flask, and at room temperature, in the constantly stirring solution, dropwise adding ammoniacal liquor with a concentration of 26 to 28wt.% to PH=10, reacted at room temperature for 10 hours, filtered, Wash until pH2 (2).

[0026] (3) Preparation of cerium oxide by uniform precipitation method: we use different molar concentration ratios of Ce(NO 3 ) 3 · 6H 2 O and urea aqueous solution as raw materials to prepare CeO 2 (where Ce(NO 3 ) 3 · 6H 2 O solution is selected as 0.05M), and finally optimizes its molar concentration ratio to be the best when it is 1:6. The p...

Embodiment 2

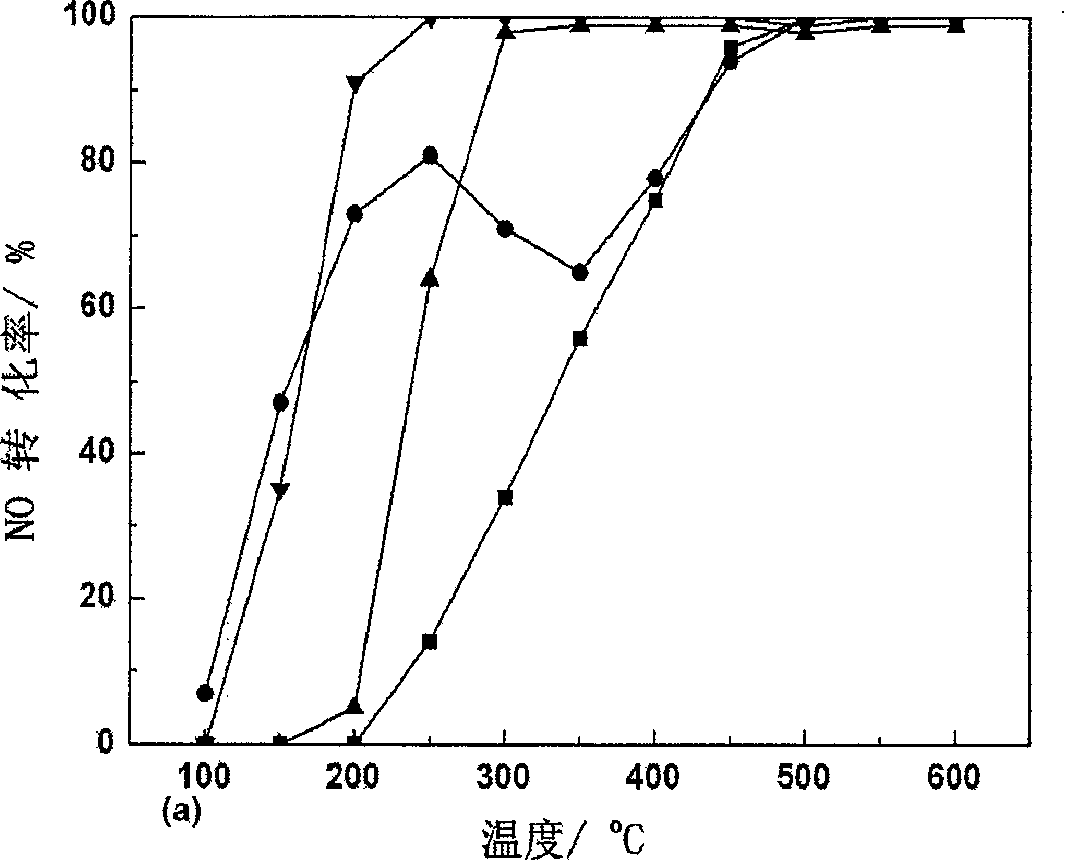

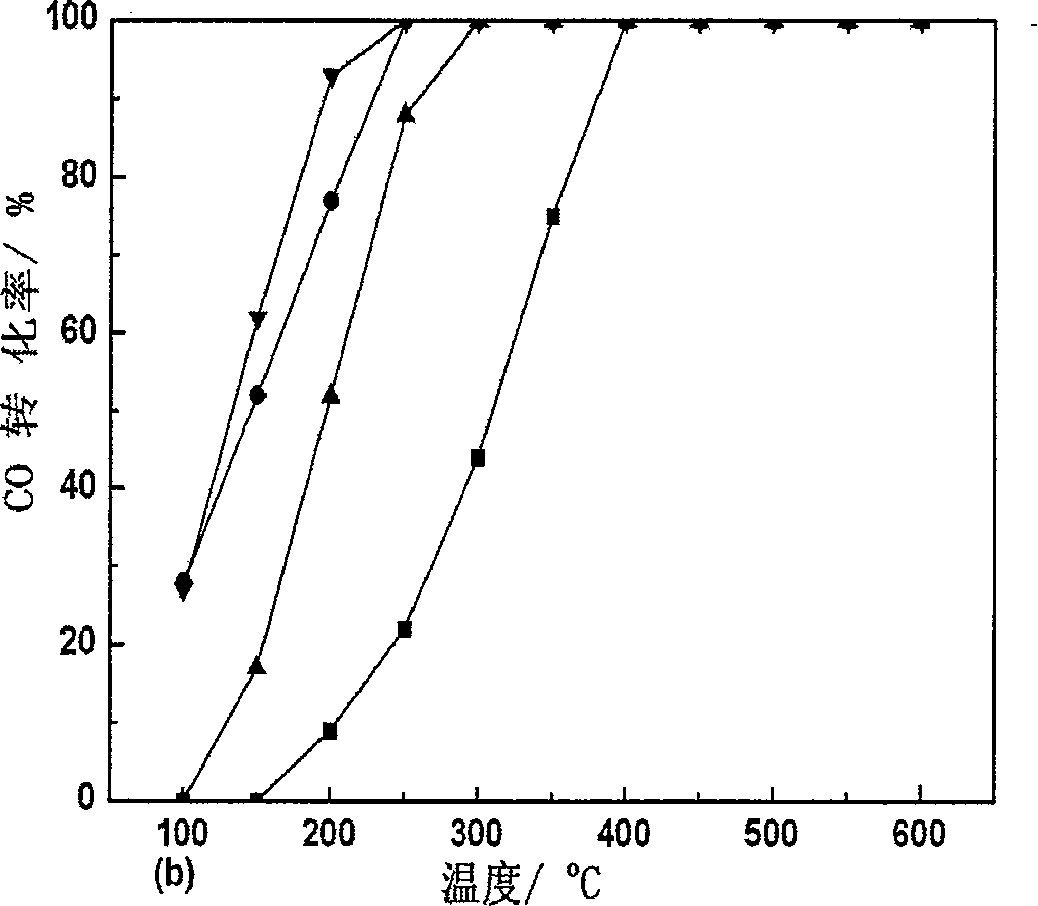

[0032] In Example 1 4wt%Ag / CeO 2 On the basis of introducing 0.4wt% Co in the same way, the resulting 4%Ag-0.4%Co / CeO 2 Catalyst activity vs. 4%Ag / CeO 2 and 0.4% Co / CeO 2 Catalyst activity comparison results are shown in the attached figure 1 And attached figure 2 (reaction conditions such as example 1).

Embodiment 3

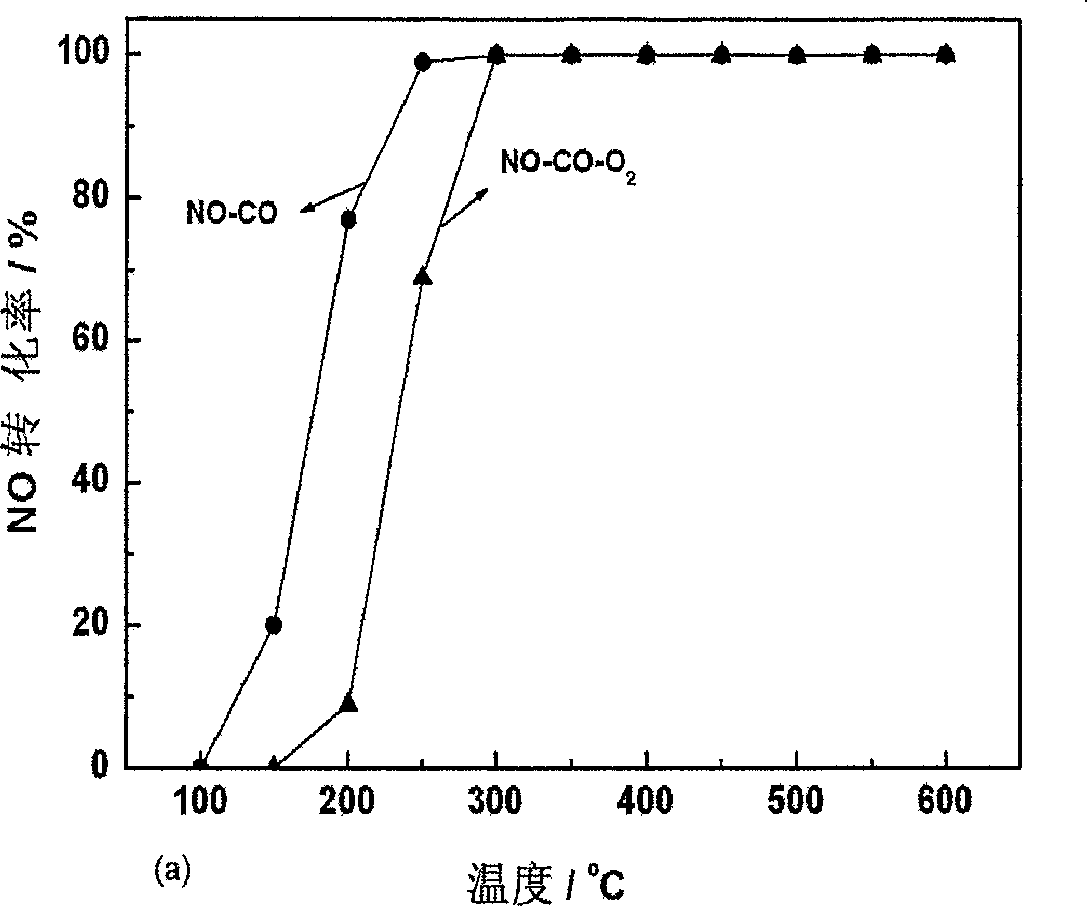

[0034] Get the 4%Ag-0.4%Co / CeO prepared in example 2 2 Catalyst 100mg is loaded into a miniature fixed-bed reactor under normal pressure. Pretreatment in He flow at 500°C for 1 hour, and then lower the temperature to below 100°C. Respectively feed reaction gas 2500ppm NO+2500ppm CO+He and oxygen-containing reaction gas 2500ppm NO+5000ppm O 2 +12500ppm CO+He, flow rate 75ml / min, activity comparison results are shown in the attachment image 3 And attached Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com