Laser material processing machine tool

A machine tool and laser system technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., to achieve the effect of large working space, flexible transmission, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

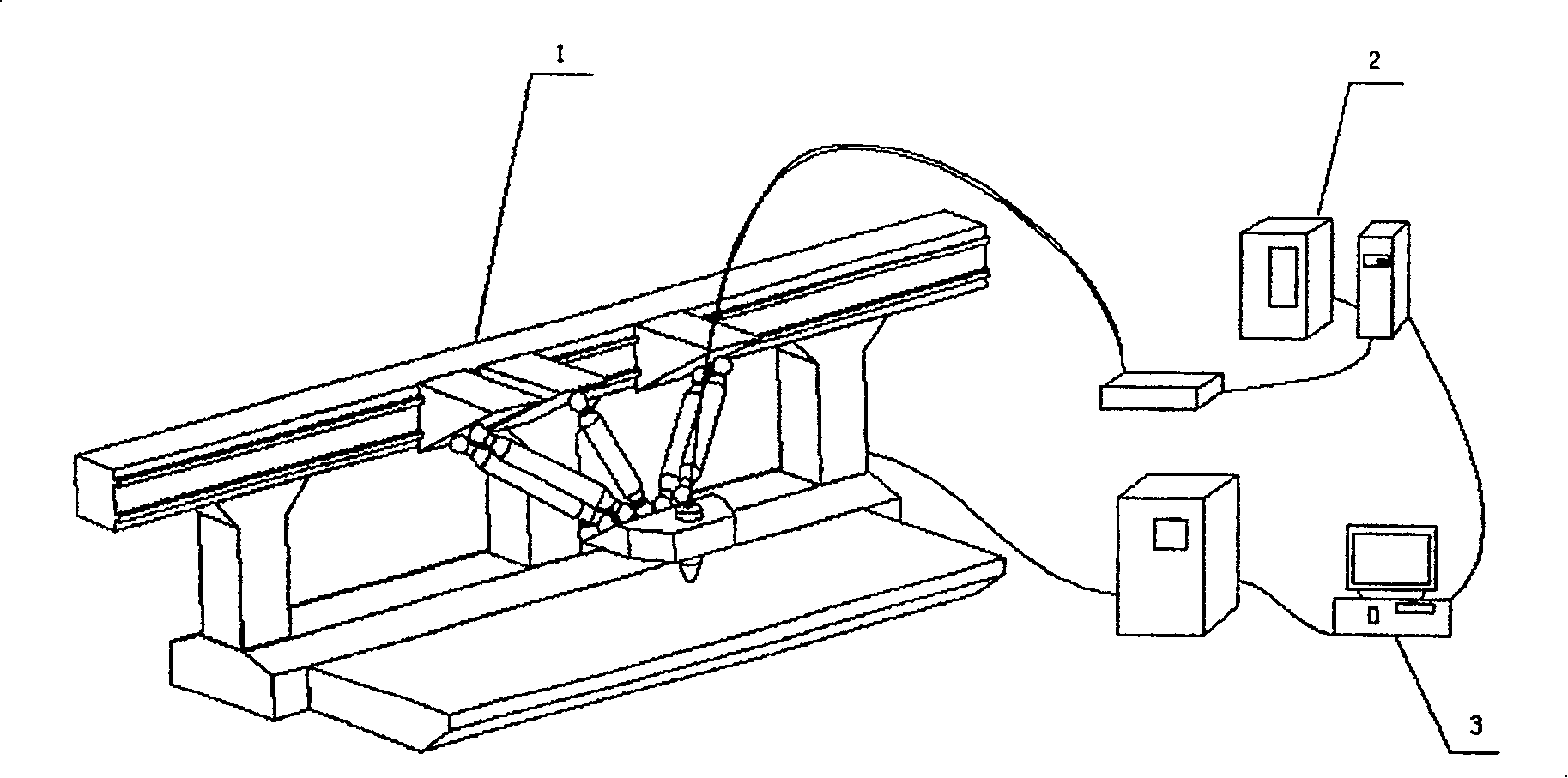

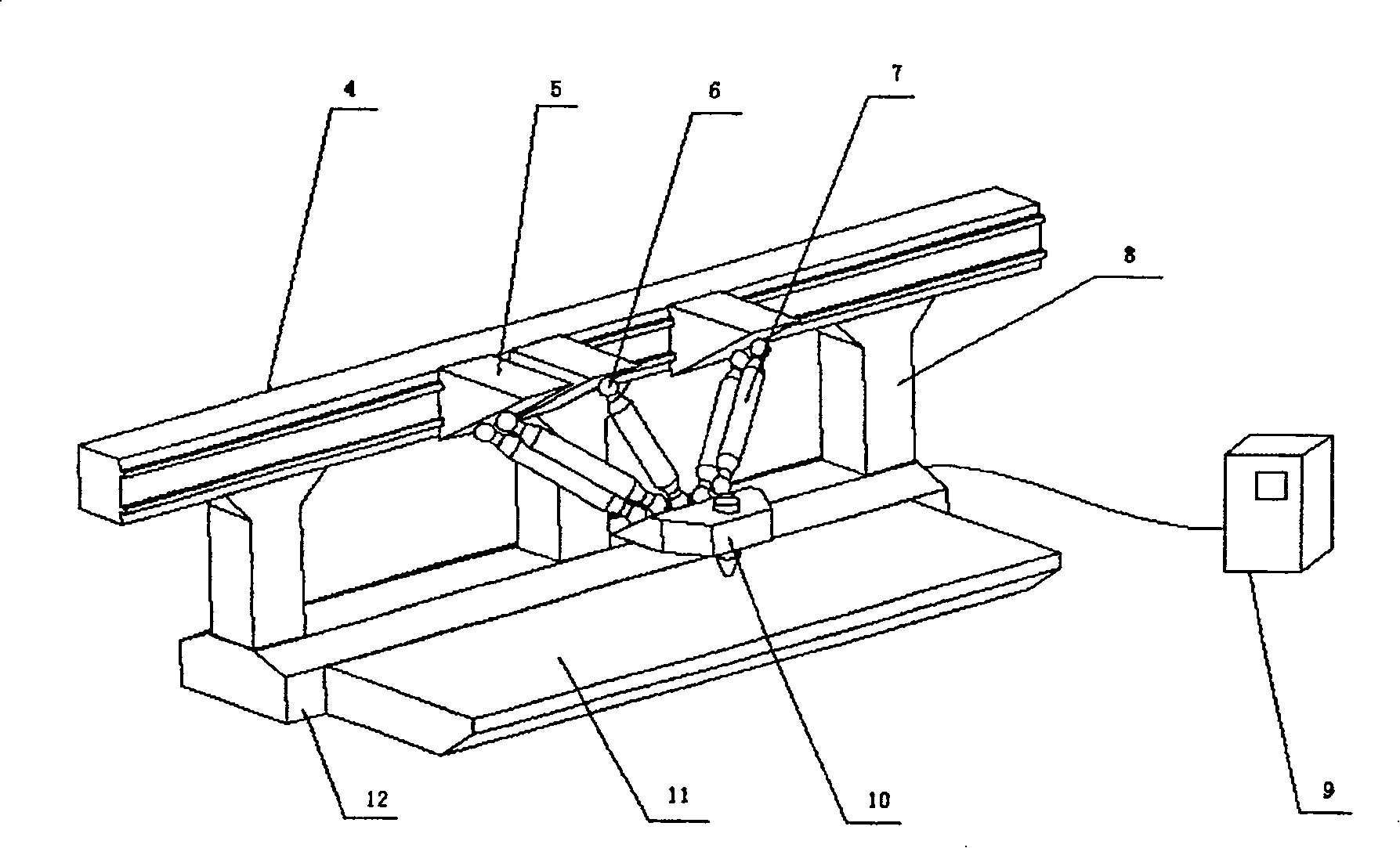

[0015] Laser processing machine tool of the present invention such as figure 1 As shown, it is mainly composed of a parallel machine tool 1, a laser system 2 and a control system. The control system is a control computer 3, one end of the communication line is connected to the parallel machine tool control cabinet 9, and the other end is connected to the laser system power supply and the controller 16.

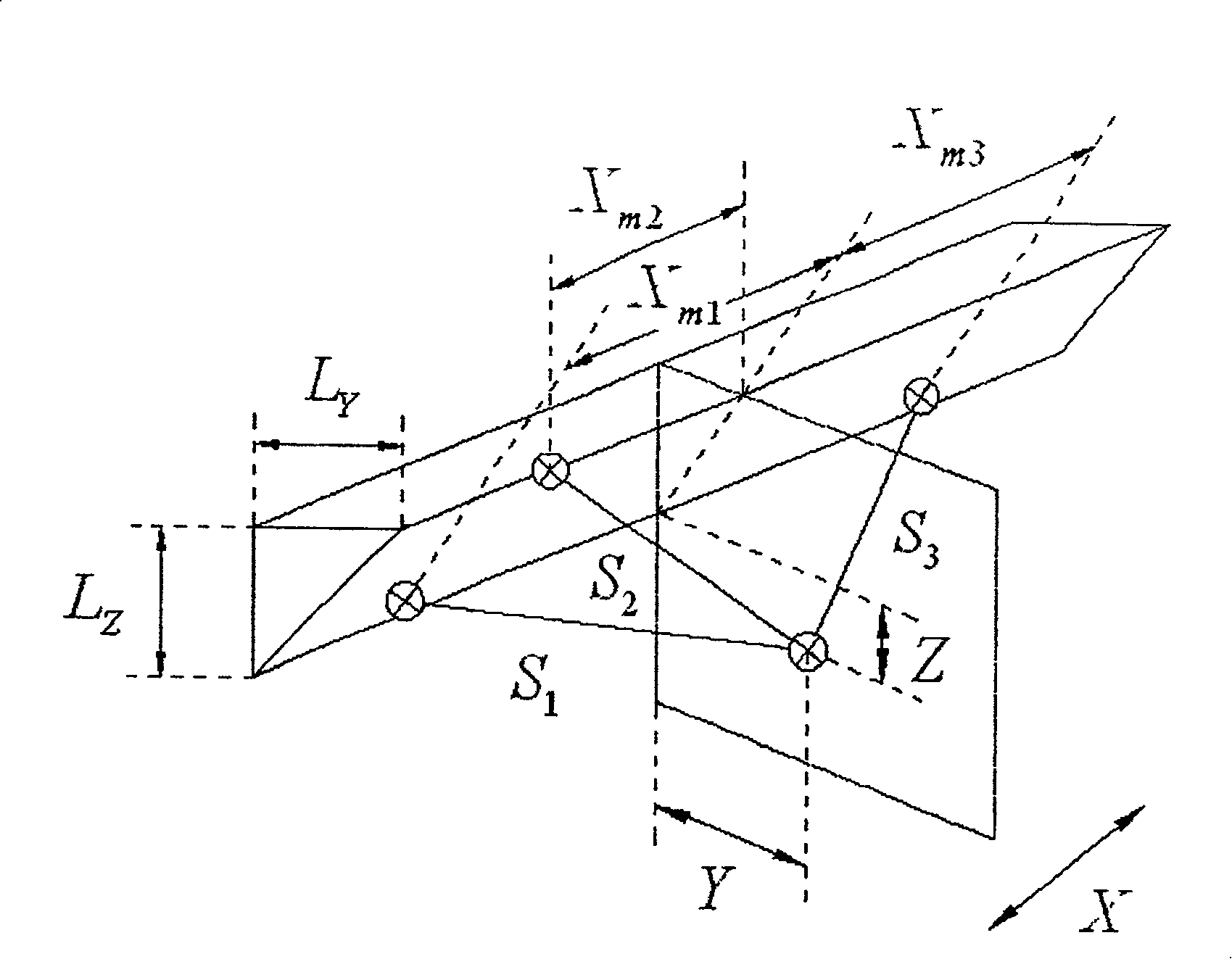

[0016] Its working principle is that the control computer 3 sends a control command, one end is sent to the parallel machine tool control cabinet 9, and the other end is sent to the power supply and controller 16 of the laser system. The parallel machine tool control cabinet 7 analyzes and processes the control commands sent by the control computer 3, and generates CNC commands to control the parallel connection through contour modeling→G code generation→G code format conversion→interpolation→coordinate transformation→kinematic transformation→servo control. The drive slider 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com