Process for producing bata-mannanase fermented by pseudo honey agaric and application thereof

A technology of mannanase and Pseudo Armillaria is applied in the directions of microorganism-based methods, biochemical equipment and methods, enzymes, etc., and achieves broad application prospects and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

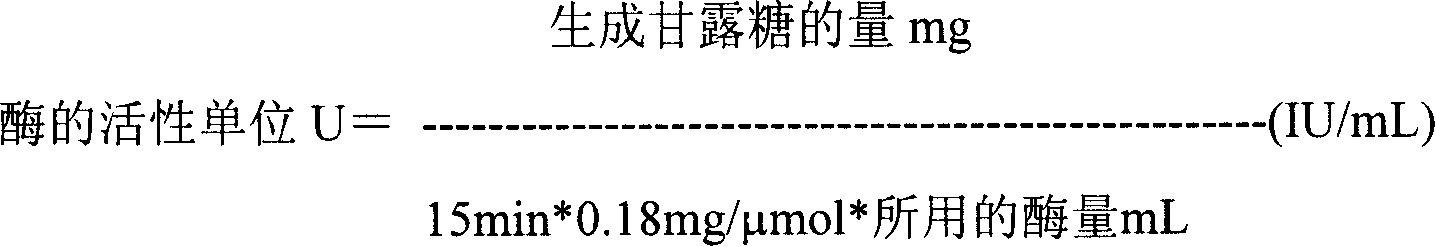

Method used

Image

Examples

Embodiment 1

[0022] Armillariella tabescens AS5.92 CGMCC. The Pseudoarmillaria can secrete β-mannanase, β-mannanase has good heat resistance, the working temperature range is 30-75°C, and the optimum reaction temperature is 60°C; the reaction pH is 3-8, and the optimum pH is 5 .5~6.0. The method for fermenting and producing β-mannanase by Armillaria pseudoarmilla comprises the following steps:

[0023] (1) Qualitative detection of β-mannanase produced by Armillaria armillaria by transparent hydrolysis circle method

[0024] The slant bacteria were inoculated in the solid medium containing 0.1% Quliben blue, and the formula of the plate medium for producing transparent hydrolysis circle was calculated by mass percentage: 25% of potato juice, 1% of peptone, 2% of konjac powder, KH 2 PO 4 0.3%, MgSO 4 0.15%, vitamin B 1 0.01%. After static culture at 26.5°C for 8 days, a transparent hydrolysis circle can be seen around the bacteria.

[0025] (2) After the Pseudoarmillaria cultured on t...

Embodiment 2

[0033] The method for fermenting and producing β-mannanase by Armillaria pseudoarmilla comprises the following steps:

[0034] (1) Qualitative detection of β-mannanase produced by Armillaria armillaria by transparent hydrolysis circle method

[0035] The slant bacteria were inoculated in the solid medium containing 0.5% Quliben blue, and the formula of the plate medium for producing transparent hydrolysis circle was calculated by mass percentage: 10% of potato juice, 0.5% of peptone, 3% of konjac powder, KH 2 PO 4 0.5%, MgSO 4 0.1%, vitamin B 1 0.02%. After static culture at 26.5°C for 5 days, a transparent hydrolysis circle can be seen around the bacteria.

[0036] (2) After the Pseudoarmillaria cultured on the slant is subjected to primary liquid culture, secondary liquid culture, and tertiary liquid culture, it can be fermented to produce β-mannanase.

[0037] 1) Inclined surface culture: The formula of the medium is: 10% potato juice, 0.5% peptone, 3% konjac powder, K...

Embodiment 3

[0041] The method for fermenting and producing β-mannanase by Armillaria pseudoarmilla comprises the following steps:

[0042] (1) Qualitative detection of β-mannanase produced by Armillaria armillaria by transparent hydrolysis circle method

[0043] The slant bacteria were inoculated in the solid medium containing 0.3% Quliben blue, and the formula of the plate medium for producing a transparent hydrolysis circle was calculated by mass percentage: 40% of potato juice, 2% of peptone, 0.5% of konjac powder, KH 2 PO 4 0.1%, MgSO 4 0.5%, vitamin B 1 0.05%. After static culture at 26.5°C for 15 days, a transparent hydrolysis circle can be seen around the bacteria.

[0044] (2) After the Pseudoarmillaria cultured on the slant is subjected to primary liquid culture, secondary liquid culture, and tertiary liquid culture, it can be fermented to produce β-mannanase.

[0045] 1) Incline culture: The formula of the culture medium is: 40% of potato juice, 2% of peptone, 0.5% of konja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com