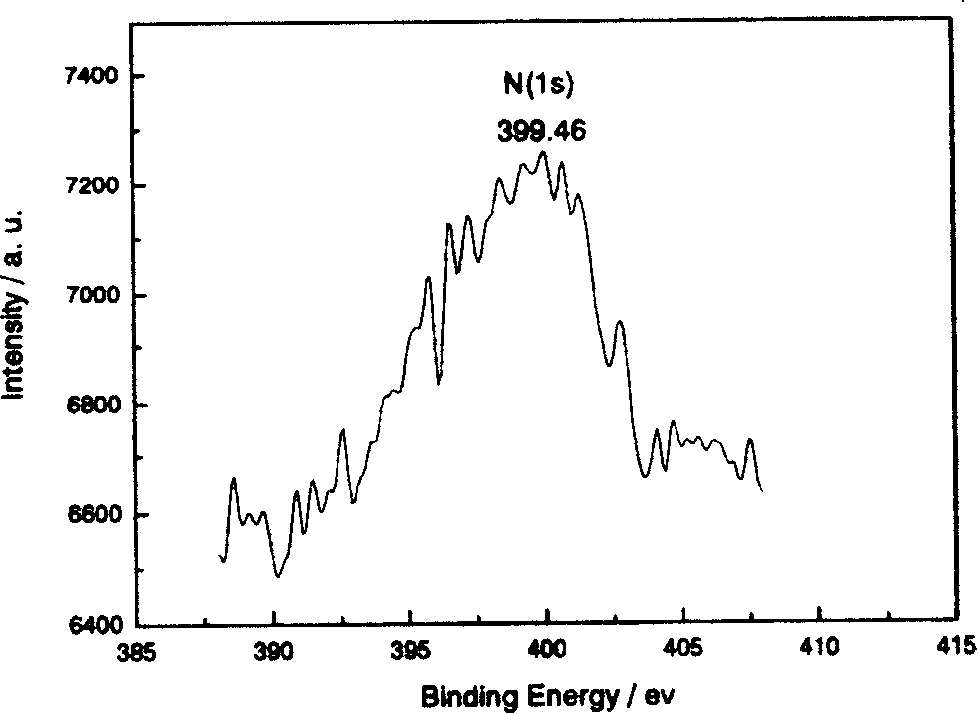

Method for preparing carbon nano-tube/poly L-cysteine composite modified glassy carbon electrode

A technology of cysteine and glassy carbon electrodes, which is applied in the direction of material electrochemical variables, can solve the problems of cumbersome electrode preparation methods, expensive electrode modification materials, and limited current peak resolution, and achieve a firm electrode modification layer and low cost , little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] For the pretreatment of bare glassy carbon electrodes, use 0.3μm and 0.05μm ultrafine Al 2 O 3 The suspension was polished on silk, then ultrasonically cleaned in double distilled water for five minutes, and finally dried with high-purity nitrogen for use.

[0014] Purification of carbon nanotubes, placing 10 mg of multi-walled carbon nanotubes (MWNCTs) in 40 mL of concentrated HNO 3 Stir and reflux for 12 hours and let it stand. When the carbon nanotubes have settled completely, the supernatant liquid is decanted, and the carbon nanotube precipitation is washed with secondary water several times until the supernatant liquid shows a neutral pH. The carbon nanotube precipitation was vacuum dried for 24h.

[0015] Preparation of carbon nanotube modified electrode. Add 1 mg of multi-walled carbon nanotubes after acidification to 10 mL of N,N-dimethylformamide (DMF), and ultrasonically disperse for 30 minutes to obtain a uniform black solution (concentration of 0.1 mg). ·ML -1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com