Method and equipment for reducing vehicle energy consumption

A vehicle and energy consumption technology, applied in control devices, vehicle components, transmission control, etc., can solve problems such as low output torque of internal combustion engines, low vehicle driving efficiency, and endangering crankshaft safety, achieving high power performance and economic performance. Improves practicality and prolongs life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

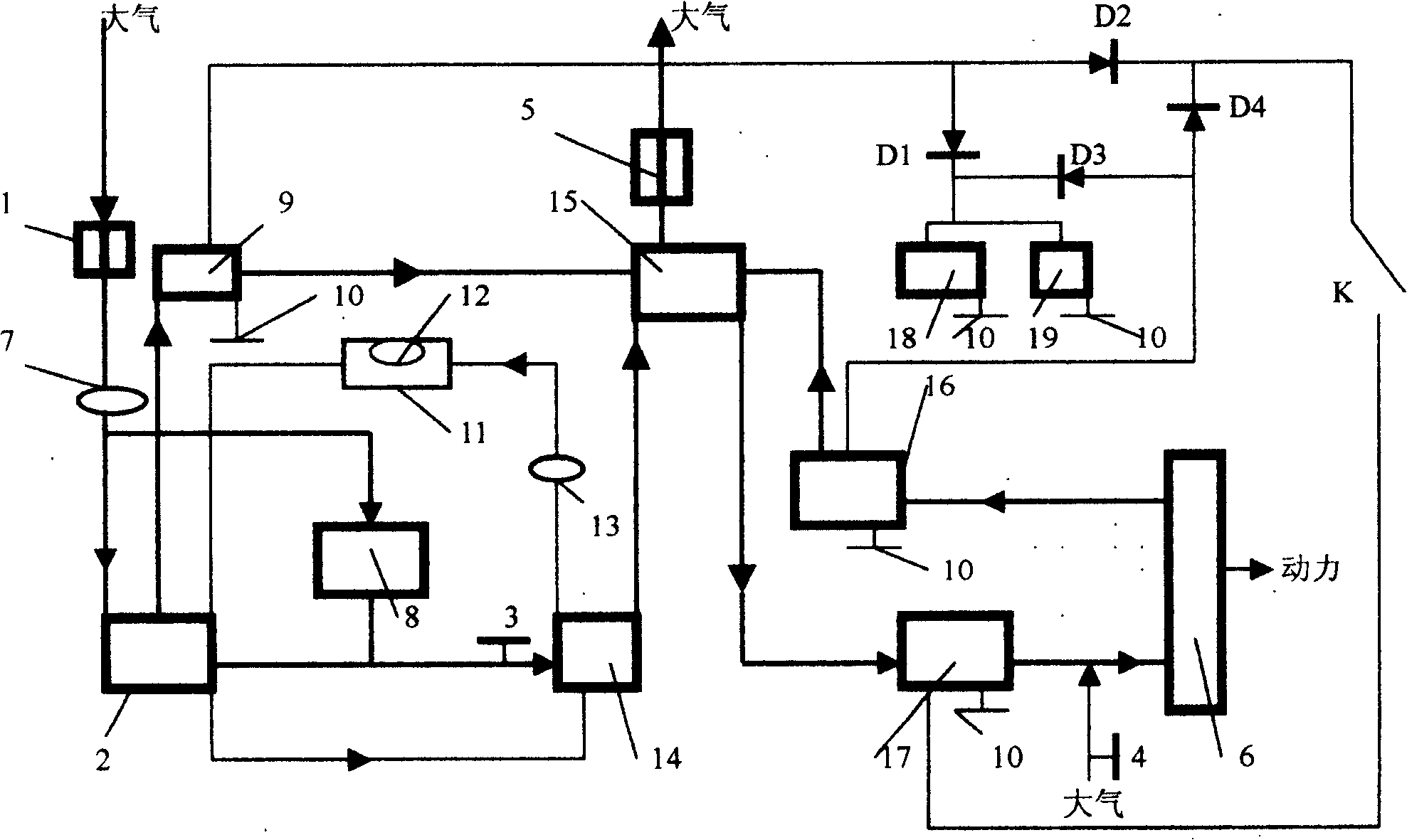

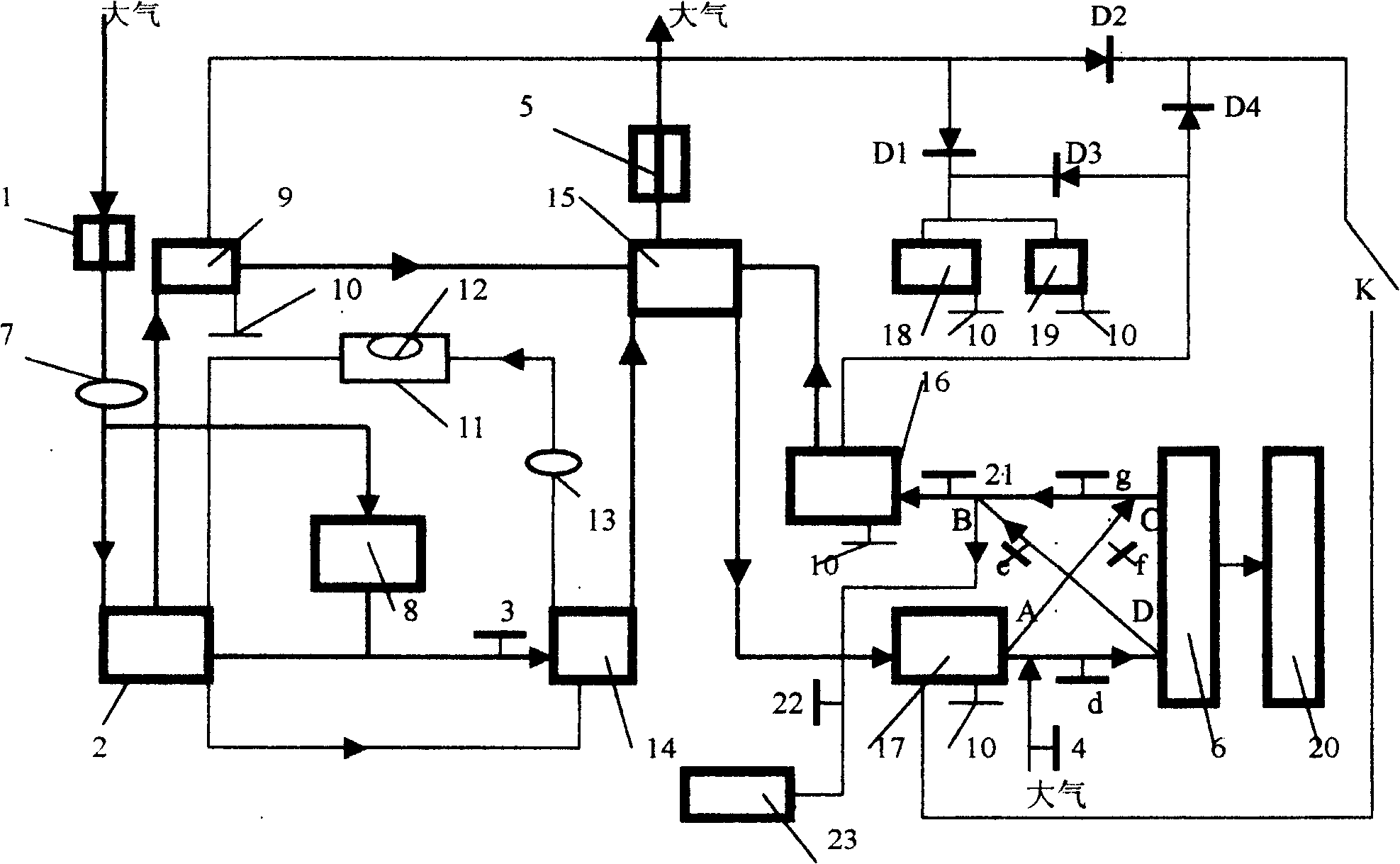

[0045] Because the embodiment when using electric air compressor and canned compressed air as prime mover is similar to the embodiment when using internal combustion engine type air compression as prime mover, below in conjunction with accompanying drawing, take internal combustion engine type air compressor 2 as prime mover as example The present invention is further described.

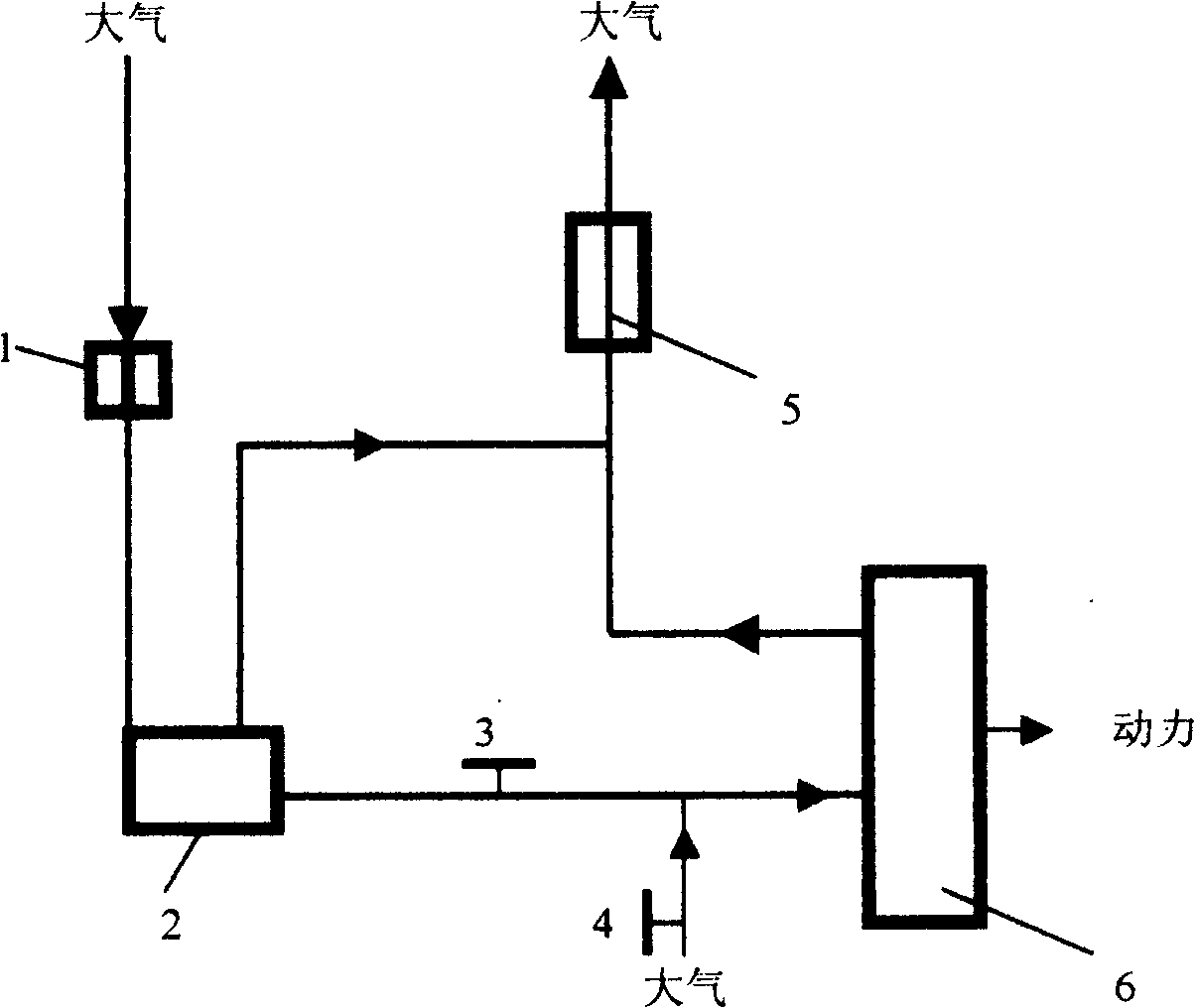

[0046] figure 1 , is a kind of original driven engine power plant, comprises by air compressor 2 and its air filter 1, valve (3,4), pipeline, muffler 5, two process engine 6, and air compressor passes its output air valve 3. The pipeline is connected to the intake manifold of a secondary process engine 6 that converts the internal energy of compressed air into mechanical energy. The exhaust gas of the internal combustion engine of the secondary process engine 6 and the air compressor enters the atmosphere through the muffler 5 and is set at the output gas valve 3 to The valve 4 between the cylinders...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com