Palm root carbon preparing process and its biomembrane reaction apparatus

A preparation process and palm root technology are applied in the field of granular fillers and biofilm reaction devices, which can solve the problems of unfavorable microbial growth and reproduction, low mechanical strength, poor economic benefits, etc., and achieve good sewage purification effect, high mechanical strength, and degradation speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

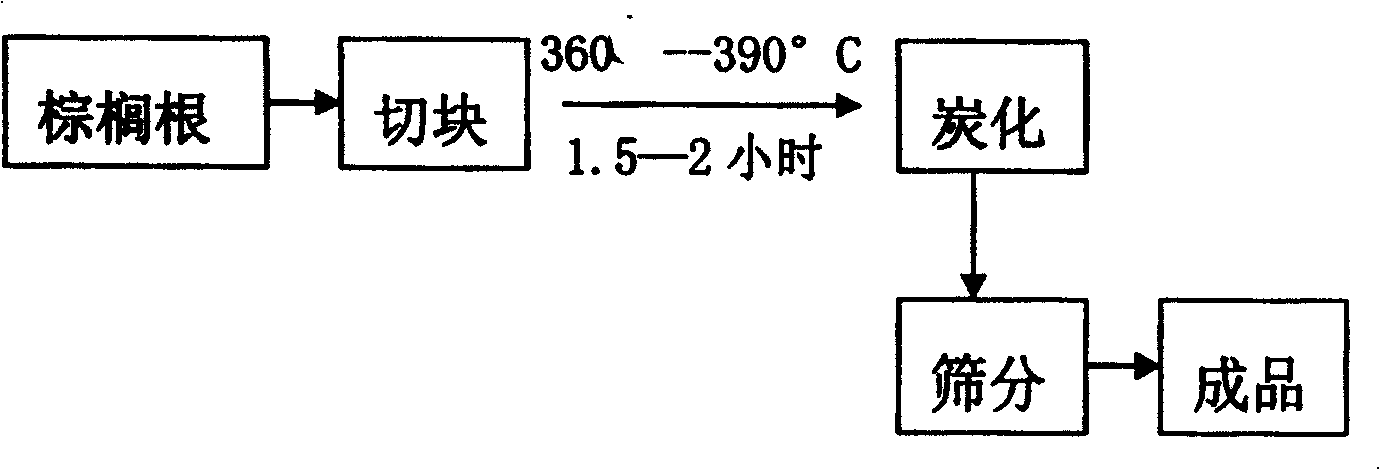

[0018] The preparation technology of palm root charcoal of the present invention is as figure 1 shown. Including dicing, carbonization, screening:

[0019] (1) cutting into pieces; the palm root is broken and screened to obtain coarse particles with a particle diameter of 1.0-1.5cm;

[0020] (2) Carbonization: the coarse particles are heated and dry-distilled under the condition of air isolation for degassing treatment, the carbonization temperature is 360--390°C, and the carbonization time is 1.5-2 hours;

[0021] (3) Sieving: Sieving with a sieve to obtain irregular dark brown particles.

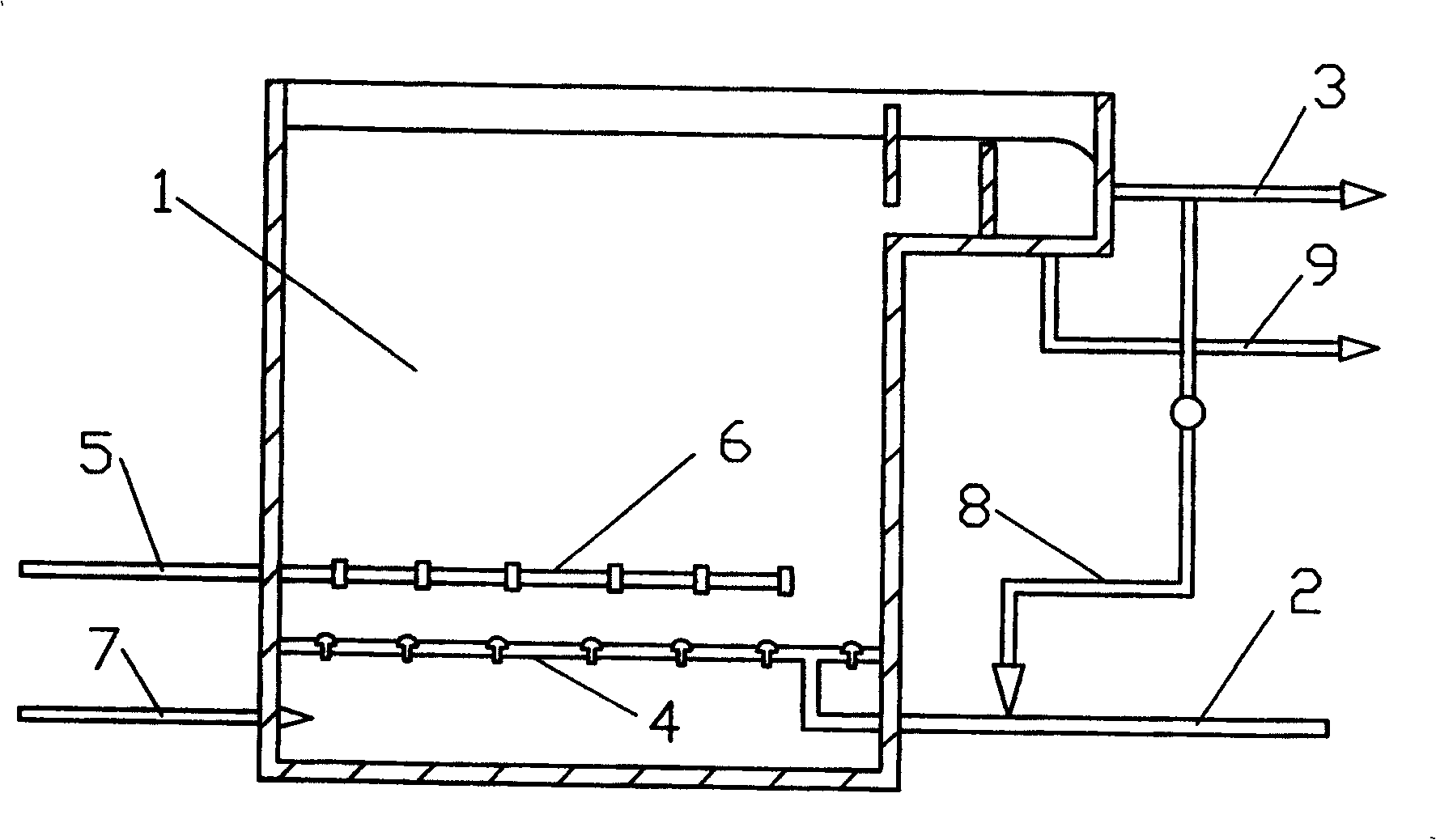

[0022] Palm root charcoal biofilm reaction device of the present invention such as figure 2 shown. The device consists of a palm root charcoal biofilter 1, a water distribution pipe 4 and an air distributor 6. The palm root charcoal biofilter 1 is filled with palm root charcoal granules, and then added with nutrient solution to provide sufficient dissolved oxygen and suitable water t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com