Polyvinildene difluoride copolymer gel state electrolyte film and its preparation technology

A technology of polyvinylidene fluoride and electrolyte membrane, which is applied to secondary battery parts and other directions, can solve problems such as unstable thermodynamic performance, increased battery internal resistance, troublesome production control, etc., and achieves favorable ion migration and qualified packaging The effect of increasing the rate and improving the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

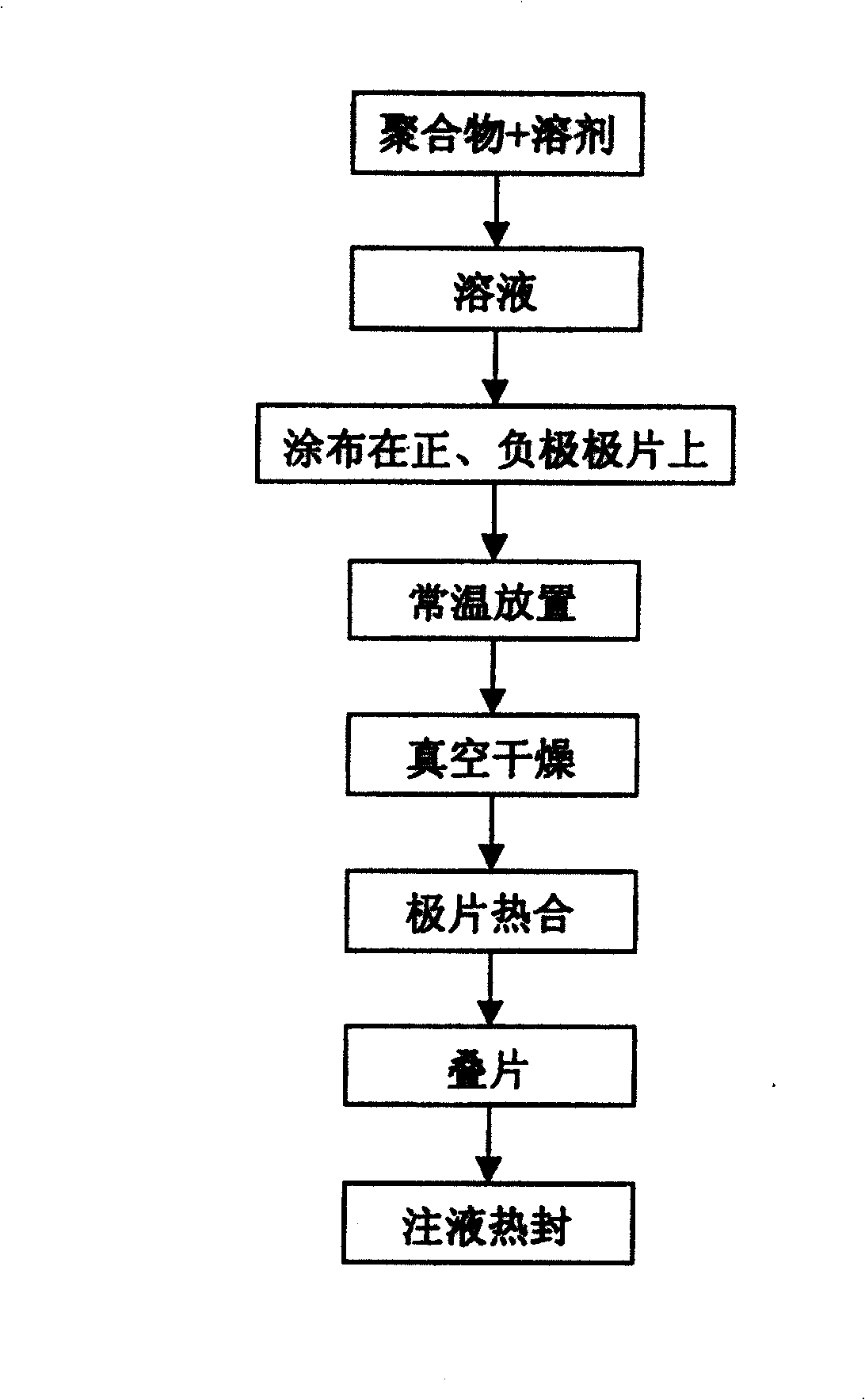

Image

Examples

Embodiment 1

[0063] Take 1 kg of polyvinylidene fluoride copolymer and 7 kg of mixed solvent of acetone and butanol (including 6 kg of acetone and 1 kg of butanol), mix them, heat to about 50°C and keep stirring to completely dissolve the polyvinylidene fluoride copolymer In a solvent, prepare a polyvinylidene fluoride copolymer solution, apply the solution on each positive pole piece and negative pole piece respectively to form a thin film, leave it at room temperature for 24 hours, let the solvent volatilize naturally, and initially form a polyvinylidene fluoride copolymer on the electrode pole piece. Gel-state film layer of vinyl fluoride copolymer. Then place the above-mentioned film-forming electrode pole piece in a vacuum drying oven and dry it at 65-70°C for 24 hours to allow the solvent to evaporate further and form a stable polyvinylidene fluoride copolymer gel-state film layer on the electrode pole piece. Then, the film-forming electrode pole pieces are rolled and heat-sealed to ...

Embodiment 2

[0065] Mix 1 kg of polyvinylidene fluoride copolymer with 6 kg of mixed solvent of acetone and butanol (including 5 kg of acetone and 1 kg of butanol), heat to about 50°C and keep stirring to completely dissolve the polyvinylidene fluoride copolymer In a solvent, prepare a polyvinylidene fluoride copolymer solution, apply the solution on each positive pole piece and negative pole piece respectively to form a thin film, place it at room temperature for 20 hours, let the solvent evaporate naturally, and initially form a polyvinylidene fluoride copolymer on the electrode pole piece. Gel-state film layer of vinyl fluoride copolymer. Then place the above-mentioned film-forming electrode pole piece in a vacuum drying oven and dry at 60-70° C. for 20 hours to allow the solvent to evaporate further to form a stable polyvinylidene fluoride copolymer gel film layer on the electrode pole piece. Then, the film-forming electrode pole pieces are rolled and heat-sealed to make the polyvinyli...

Embodiment 3

[0067] Mix 1 kg of polyvinylidene fluoride copolymer with 8 kg of mixed solvent of acetone and butanol (including 6.5 kg of acetone and 1.5 kg of butanol), heat to about 50°C and keep stirring to completely dissolve the polyvinylidene fluoride copolymer In a solvent, prepare a polyvinylidene fluoride copolymer solution, apply the solution on each positive pole piece and negative pole piece respectively to form a thin film, leave it at room temperature for 30 hours, let the solvent volatilize naturally, and initially form a polyvinylidene fluoride copolymer on the electrode pole piece. Gel-state film layer of vinyl fluoride copolymer. Then place the above-mentioned film-forming electrode pole piece in a vacuum drying oven and dry at 70-80°C for 30 hours to allow the solvent to evaporate further and form a stable polyvinylidene fluoride copolymer gel-state film layer on the electrode pole piece. Then, the film-forming electrode pole pieces are rolled and heat-sealed to make the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com