Method for preparing propylene by catalytic cracking olefin with four carbon or above

A technology of catalytic cracking and olefins, which is applied in the production of bulk chemicals, hydrocarbon cracking to produce hydrocarbons, organic chemistry, etc. It can solve the problems of poor catalyst stability and achieve the effect of improving stability, good carbon deposition resistance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

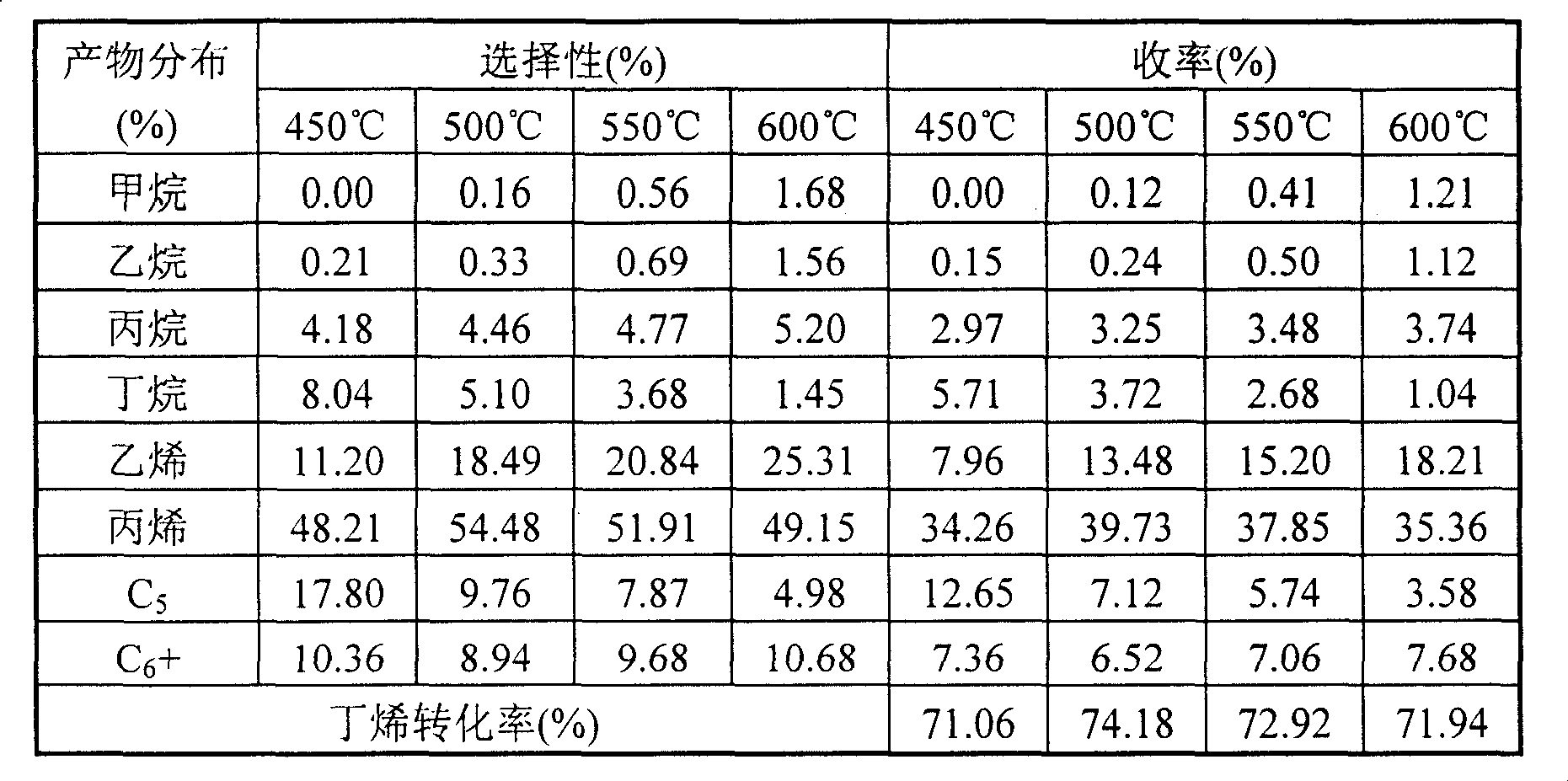

[0023] Molecular sieve silicon aluminum ratio has a significant impact on the stability of the catalyst. ZSM-5 molecular sieves with three silicon-aluminum ratios of A, B, and C were synthesized according to the ratio and crystallization conditions in Table 1.

[0024] Table 1

[0025] Molecular sieve Proportion Crystallization conditions SiO 2 / Al 2 o 3 The molar ratio of A 40SiO 2 :Al 2 o 3 :30TPABr:26OH -1 : 7600H 2 o 140℃,24h 40 B 80SiO 2 : Al 2 o 3 : 30TPABr : 80NaCl : 26OH -1 : 7600H 2 o 140℃,48h 80 C 160SiO 2 : Al 2 o 3 : 30TPABr : 80NaCl : 26OH -1 : 7600H 2 o 140℃,60h 160

[0026] 5 grams of ZSM-5 molecular sieve A was calcined at 600° C. for 10 hours in an air atmosphere. Then placed in 200 ml, 5% wt NH 4 NO 3 In the solution, exchange at a temperature of 85-90°C for 2 hours, and repeat 3 times. After the exchange, the hydrogen-type ZSM-5 molecular sieve w...

Embodiment 4~5

[0028] C used in the experiment 4 The raw material comes from the raffinate mixed carbon four in the ethylene plant. The raw material composition is shown in Table 2.

[0029] Table 2 Composition of mixed carbon four in ethylene plant raffinate

[0030] project Raw material composition (weight%) Isobutane 1.81 n-butane 5.05 Propylene 0.12 Acetylene 0.08 Anti-butene 11.25 Butene-1 32.07 Isobutylene 43.39 Butene 6.20 C 4 above 0.04

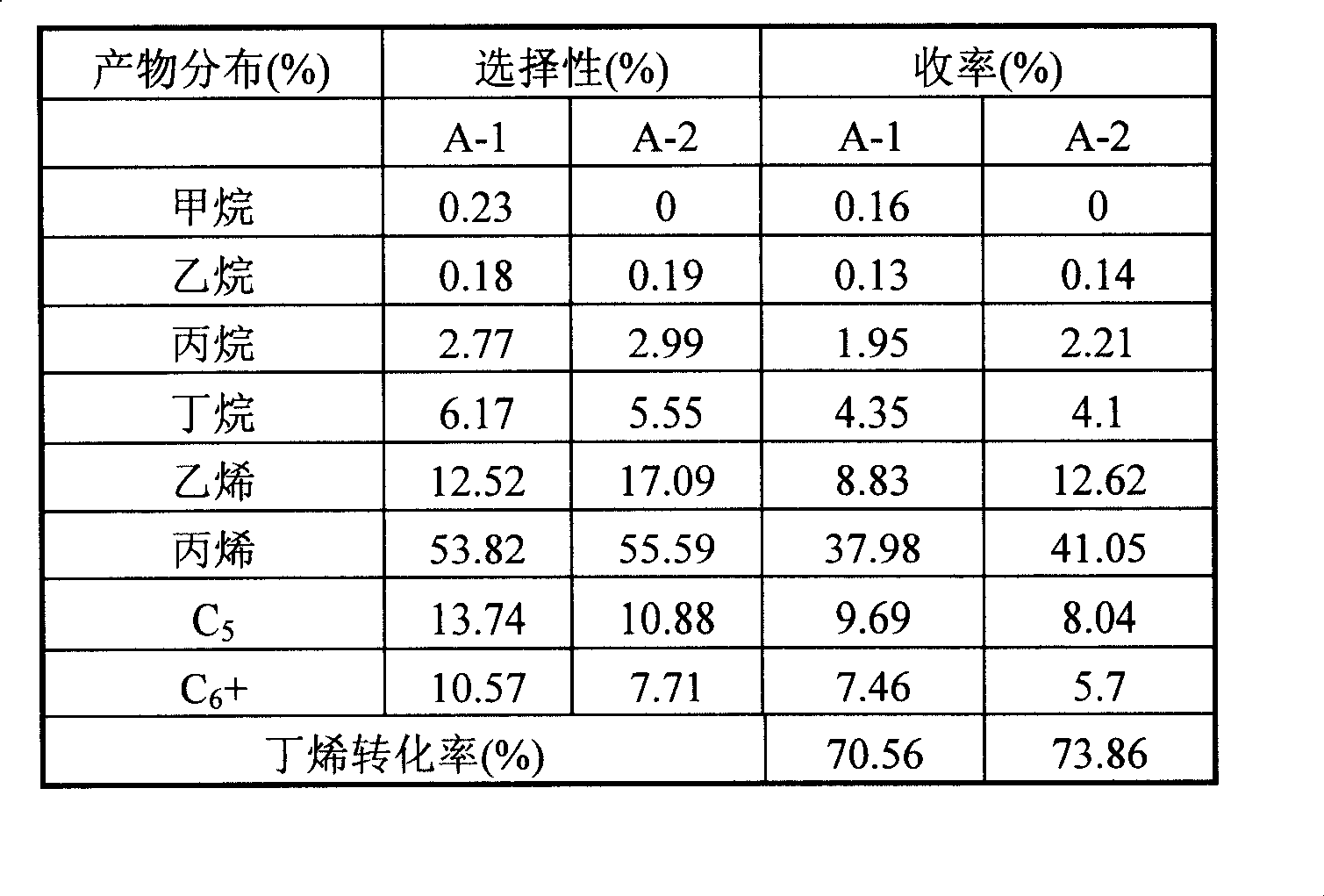

[0031] Take 2 grams of catalyst A-1, activate the catalyst at 500°C under a nitrogen atmosphere for 2 hours before the reaction, and then use the raffinate mixed carbon four as raw material, at 500°C, the weight space velocity is 3 hours -1 The reaction is carried out under certain conditions. During the reaction, water is added to the raw material as a diluent gas, and the water / olefin weight ratio is 1.5. Take another 2 grams of A-1 catalyst, pre-reaction at 500 ° C, space v...

Embodiment 7~9

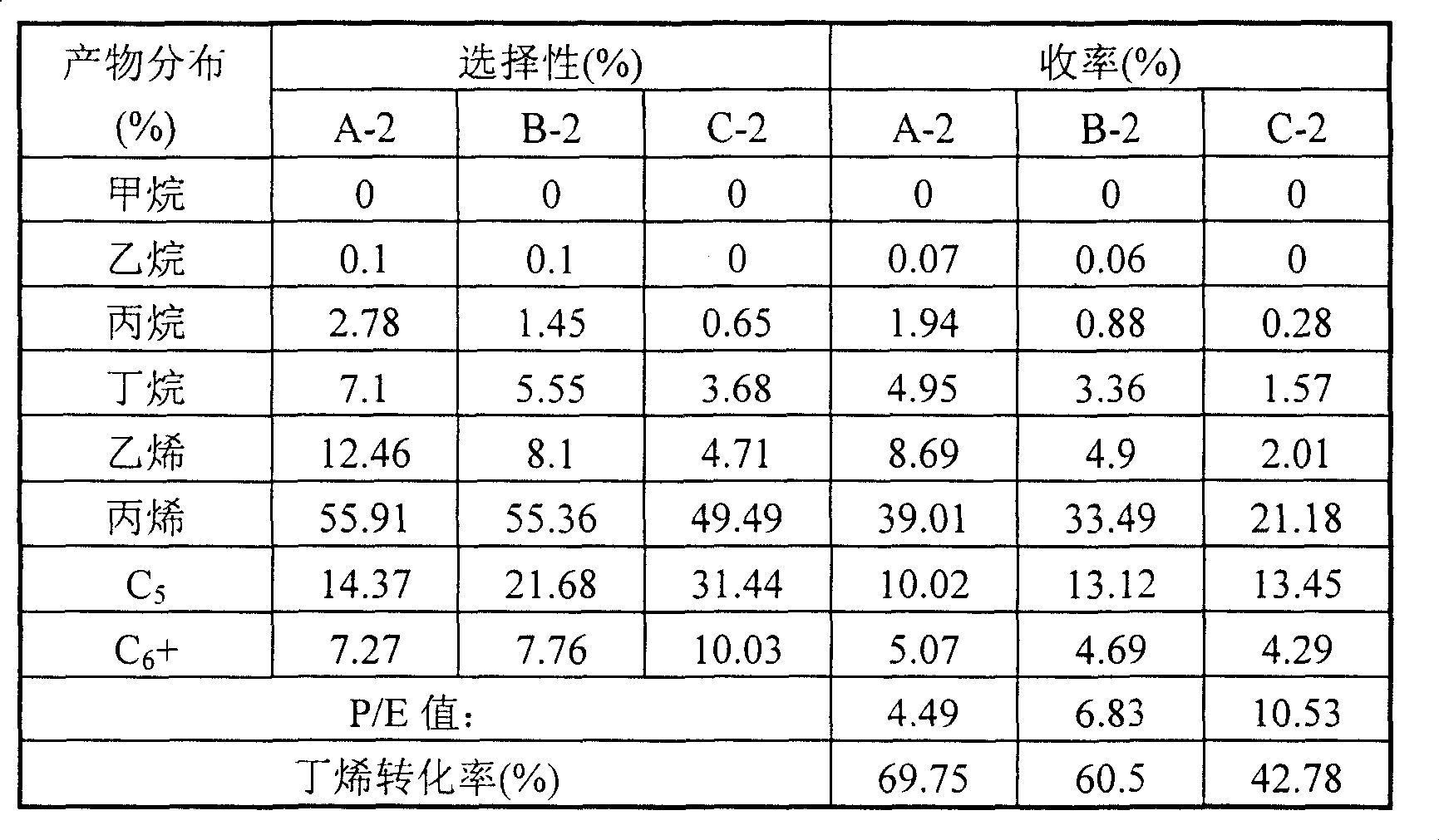

[0035] Take 2 grams of A-1, B-1, and C-1 catalysts respectively, and pre-react at 500°C with a space velocity of 3.0 hours before the reaction -1 Under the water vapor atmosphere, after processing for 24 hours, A-2, B-2, and C-2 catalysts were prepared. Before the reaction, the catalyst was activated at 500°C under a nitrogen atmosphere for 2 hours, and then the residual mixed carbon four was used as raw material at 500°C with a weight space velocity of 3 hours -1 The reaction is carried out under certain conditions. During the reaction, water is added to the raw material as a diluent gas, and the water / olefin weight ratio is 1.5. The initial butene conversions of A-2, B-2, and C-2 after steam treatment were all greater than 75%. After a reaction time of 500 hours, the performance of the catalysts was compared.

[0036] Table 2 Effect of silicon-aluminum ratio on catalyst stability

[0037]

[0038]It can be clearly seen from Table 2 that after the same t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com