Method for preparing catalyst for converting mercaptan in gasoline

A catalyst and gasoline technology, which is applied in the field of catalyst preparation, can solve the problems of no disclosed catalyst preparation method, easy loss of catalyst active components, affecting the start-up progress of the device, etc., and achieves the effects of saving start-up time, low cost and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

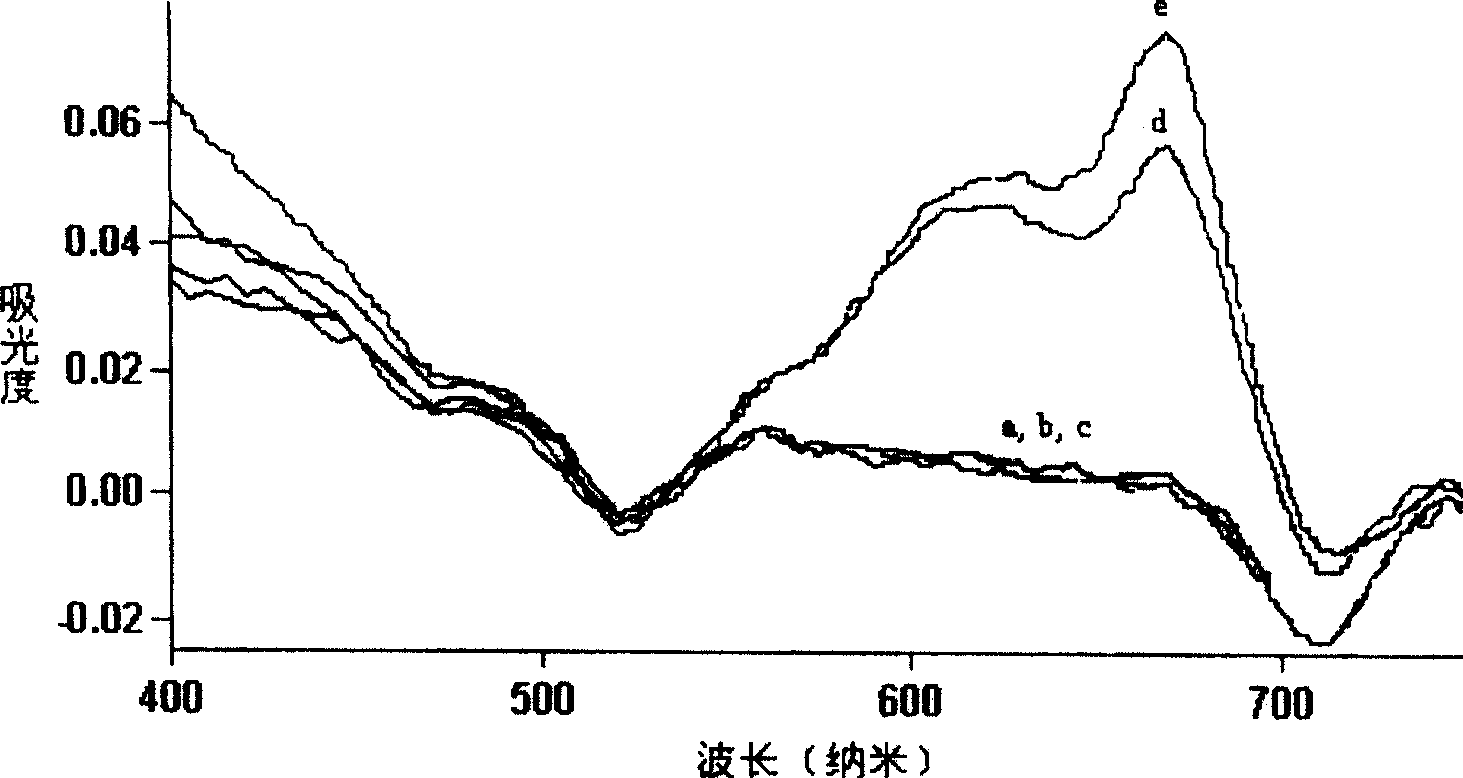

Image

Examples

Embodiment 1

[0013] The method of the present embodiment has the following steps:

[0014] ①Activation of the carrier: The activated carbon was placed at 200°C for 18 hours to obtain an activated carrier;

[0015] 2. dissolving the active component in a solvent: dissolving the active component of 0.5 gram of quaternary ammonium alkalized cobalt phthalocyanine catalyst in a mixed solvent composed of 15 wt% ammonia and fatty alcohol in a ratio of 1:1;

[0016] ③ Impregnation of the carrier: Take 100 grams of activated carbon activated in step ①, add it to 150 ml of the solution obtained in step ② and immerse for 36 hours to obtain a mixed material;

[0017] ④ Filtration and drying: filter out the carrier from the mixture obtained in step ③, dry the carrier at 90° C. for 6 hours, and reuse the solvent.

[0018] ⑤ secondary impregnation of the carrier: continue to immerse the dried carrier in step ④ in a 10wt% NaOH solution for 24 hours to obtain a mixed material;

[0019] ⑥ Filtration and d...

Embodiment 2

[0021] The method of the present embodiment has the following steps:

[0022] ①Activation of the carrier: the activated carbon was placed at 180°C for 8 hours to obtain an activated carrier;

[0023] ② Dissolving the active component in a solvent: 1.0 g of quaternary ammonium alkalized cobalt phthalocyanine catalyst active component was dissolved in N,N-dimethylformamide;

[0024] ③ Impregnation of the carrier: Take 100 grams of activated carbon activated in step ①, add it to 100 ml of the solution obtained in step ② and immerse for 48 hours to obtain a mixed material;

[0025] ④ Filtration and drying: Filter out the carrier from the mixture obtained in step ③, dry the carrier at 160° C. for 5 hours, and reuse the solvent.

[0026] ⑤ secondary impregnation of the carrier: continue to immerse the dried carrier in step ④ in a 5wt% NaOH solution for 18 hours to obtain a mixed material;

[0027] ⑥ Filtration and drying: filter out the carrier from the mixed material obtained in ...

Embodiment 3

[0029] The method of the present embodiment has the following steps:

[0030] ①Activation of the carrier: the α-Al 2 o 3 Placed at 220°C for 10 hours to obtain an activated carrier;

[0031] ② dissolving the active component in the solvent: dissolving 0.15 g of the active component of the polyphthalocyanine cobalt catalyst in a mixed solvent compounded by aliphatic amine and N,N-dimethylformamide at a ratio of 1:6;

[0032] ③ Impregnation of the carrier: take the activated a-Al in step ① 2 o 3 50 grams, added to 150 milliliters of the solution obtained in step ② and soaked for 6 hours to obtain a mixed material;

[0033] ④ Filtration and drying: filter out the carrier from the mixture obtained in step ③, dry the carrier at 140° C. for 7 hours, and reuse the solvent.

[0034] ⑤ secondary impregnation of the carrier: continue to immerse the dried carrier in step ④ in 15wt% ammonia solution for 16 hours to obtain a mixed material;

[0035] ⑥ Filtration and drying: filter ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com