Carbon steel double-roller thin-belt continuous metal cast process

A twin-roll thin strip continuous casting and carbon steel technology, applied in metal rolling and other directions, can solve the problem of limited effect of heat flow density, and achieve the effects of improving productivity, improving heat transfer and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

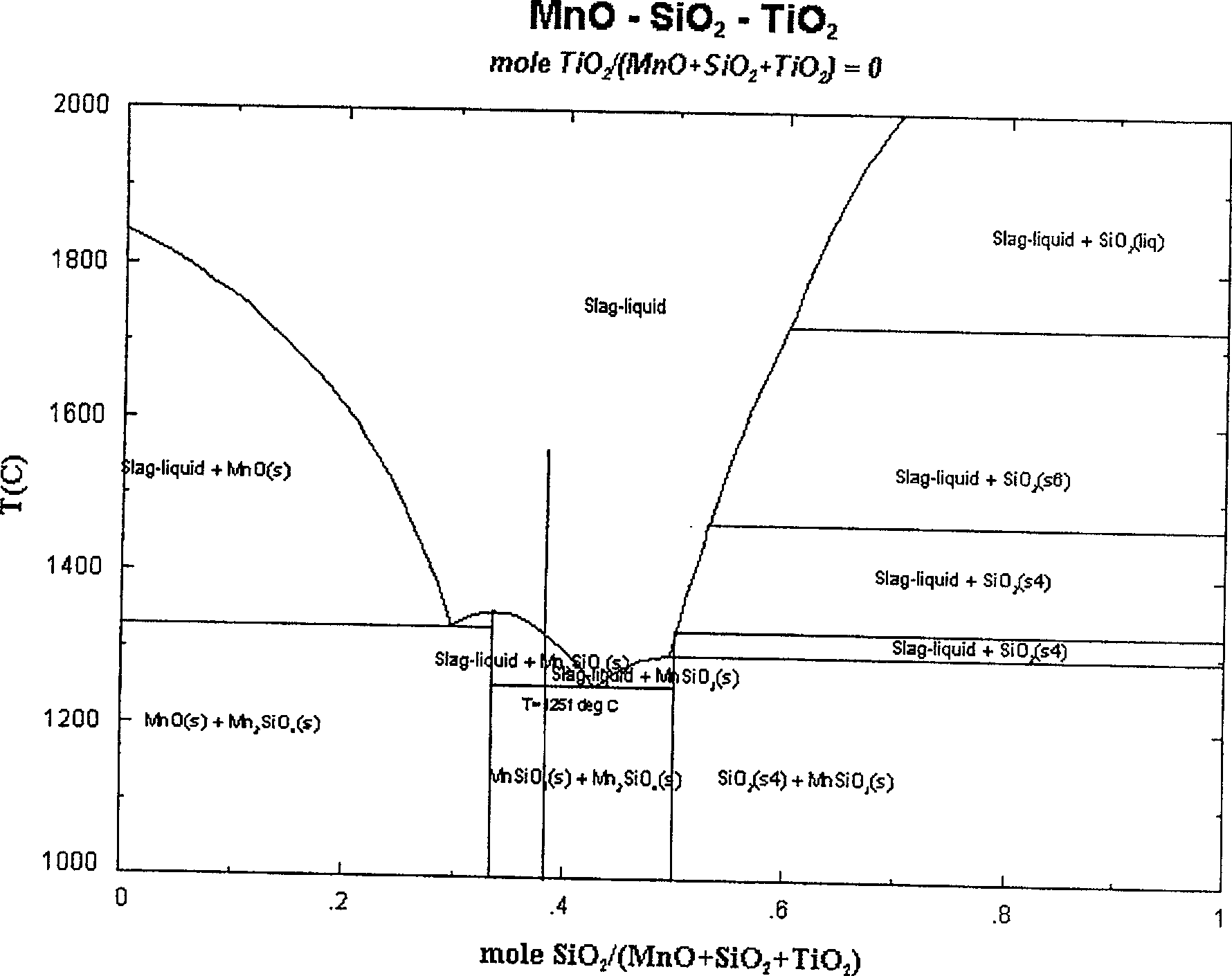

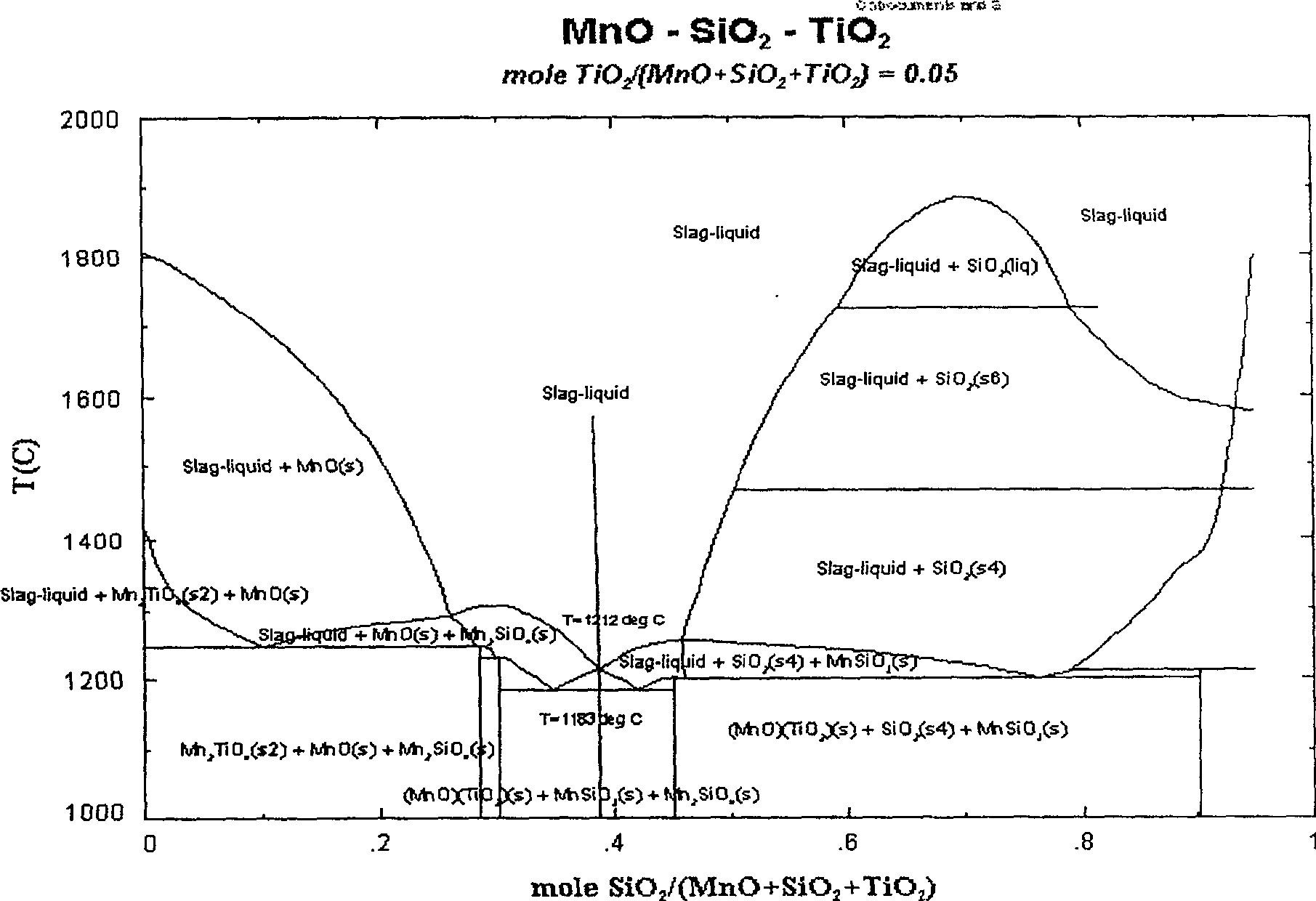

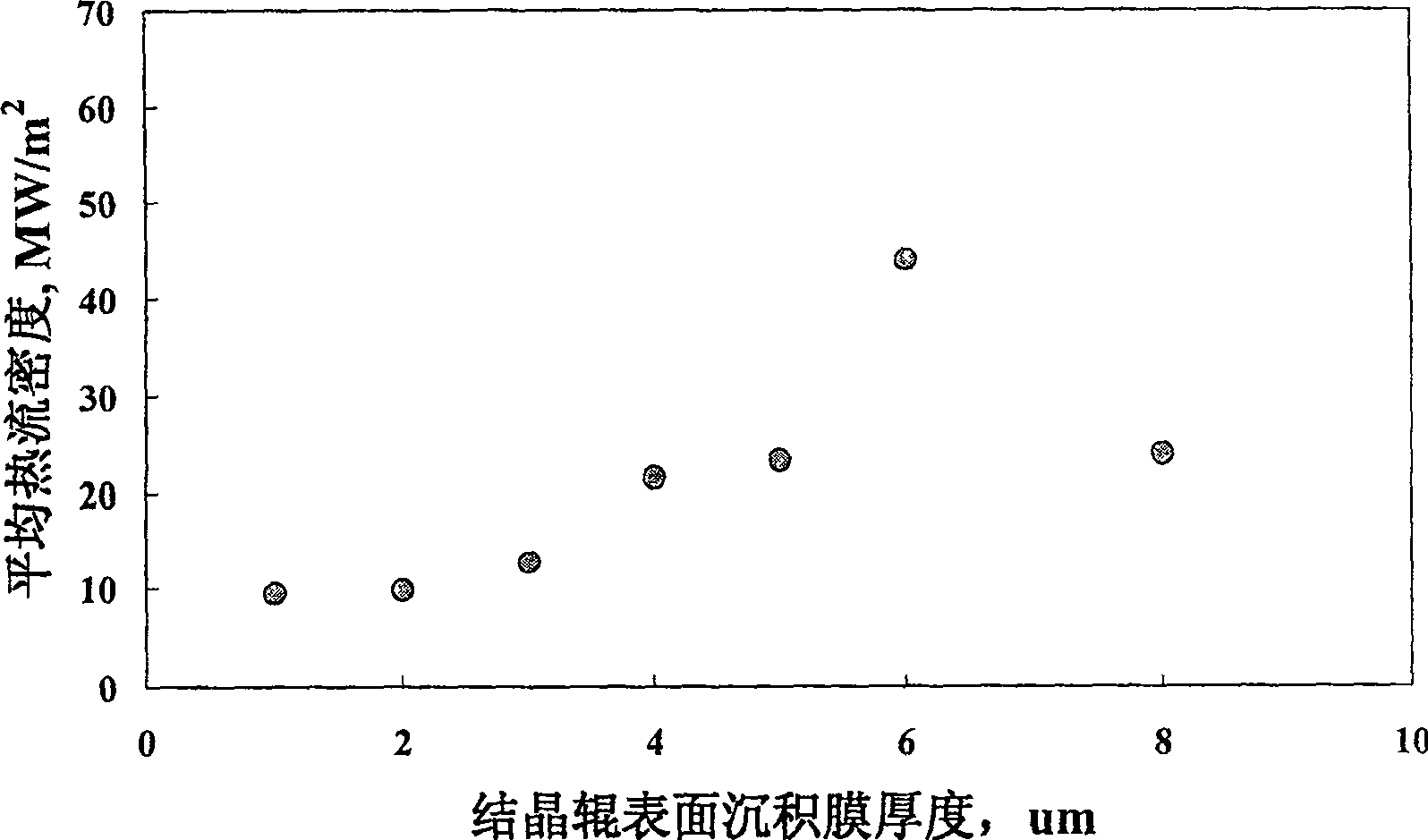

[0045] Adding titanium 0.04% Ti to the ordinary carbon steel composition, in the argon or argon-hydrogen mixed gas, the composition of the crystallization roller surface deposit is a mixed oxide of silicon oxide, manganese oxide and titanium oxide, and the morphology of the oxide See Figure 4 . When the gas is argon, the oxygen partial pressure is 10 -2 ~10 -4 Within the range, the average heat flux at this time is 8MW / m 2 , when the gas is Ar-10%H 2 , the partial pressure of oxygen can reach 10 -22 atm, the average heat flux reaches 12MW / m 2 .

Embodiment 2

[0047] Adding titanium 0.1% Ti to the ordinary carbon steel composition, in the argon or argon-hydrogen mixed gas, the composition of the deposit on the surface of the crystallization roller is a mixed oxide of silicon oxide, manganese oxide and titanium oxide, when the gas is argon , when the oxygen partial pressure is 10 -2 ~10 -4 Within the range, the average heat flux at this time is 10MW / m 2 , when the gas is Ar-5%H 2 , the partial pressure of oxygen can reach 10 -14 atm, the average heat flux reaches 14MW / m 2 .

[0048] The heat flux is increased, and for the same process parameters of the same steel grade, the heat transfer coefficient is increased, the heat transfer coefficient is increased, and the casting speed can be increased, thus improving the productivity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com