Temperature observation circuit

A technology for monitoring circuits and circuits, applied in thermometers, electrical components, measuring devices, etc., can solve the problems that integrated circuits cannot be fully cooled, do not have temperature hysteresis characteristics, and increase production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

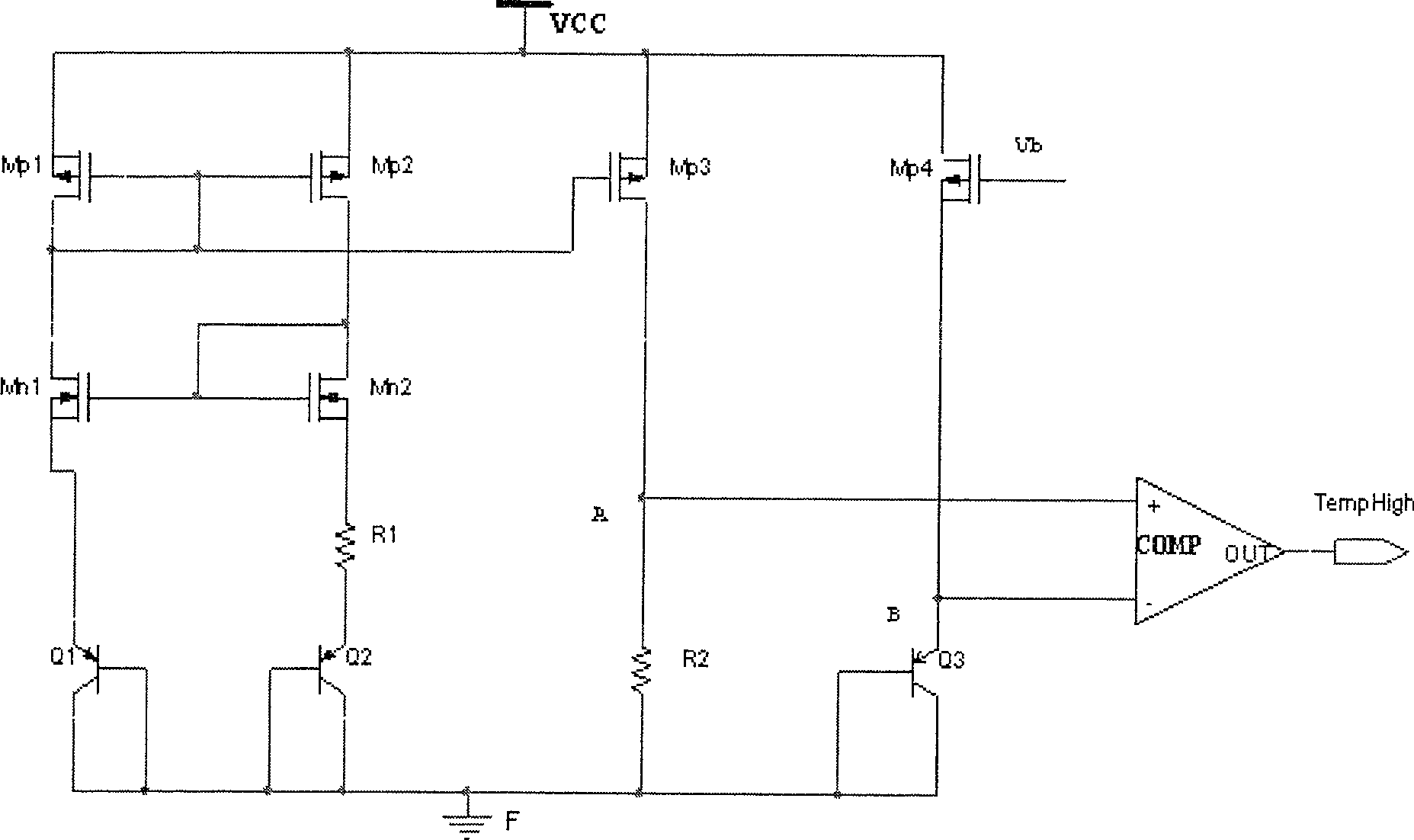

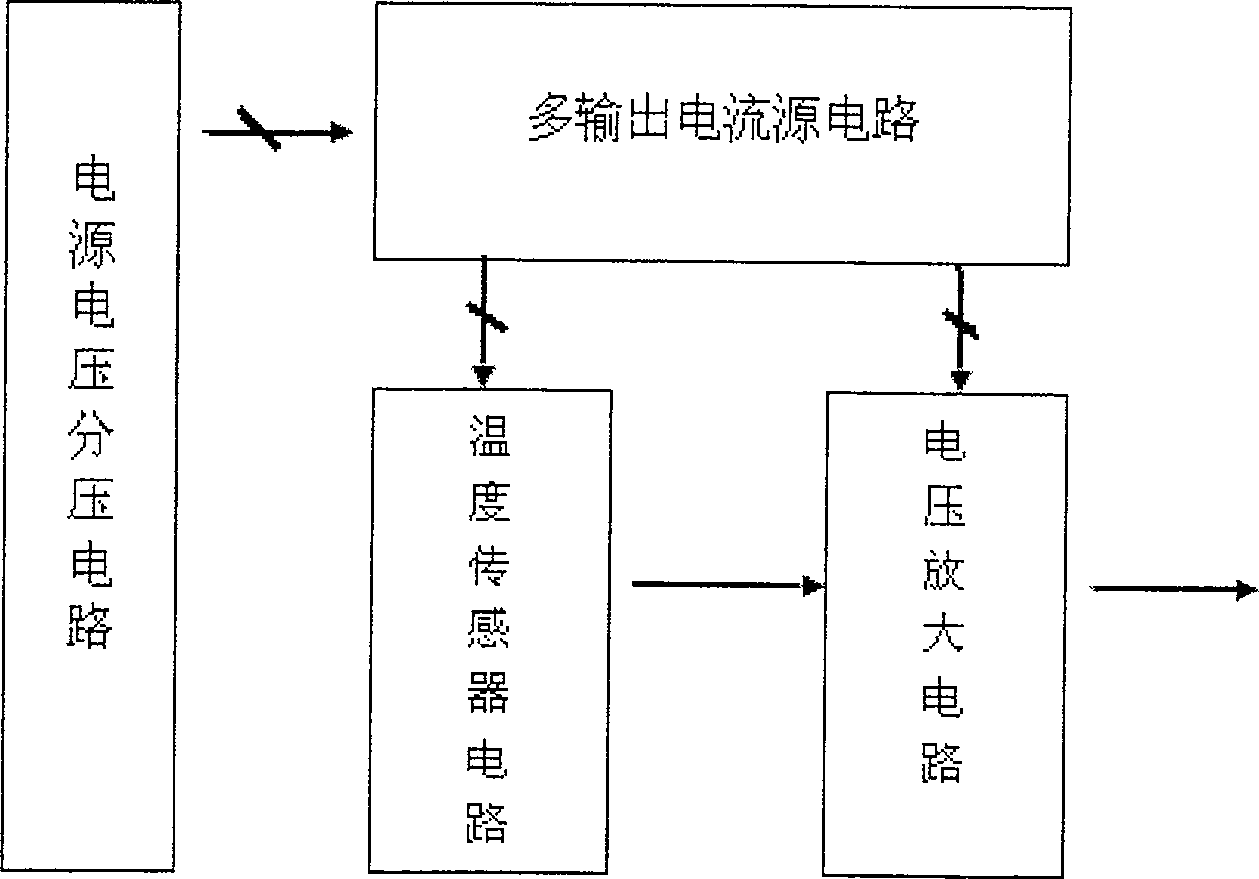

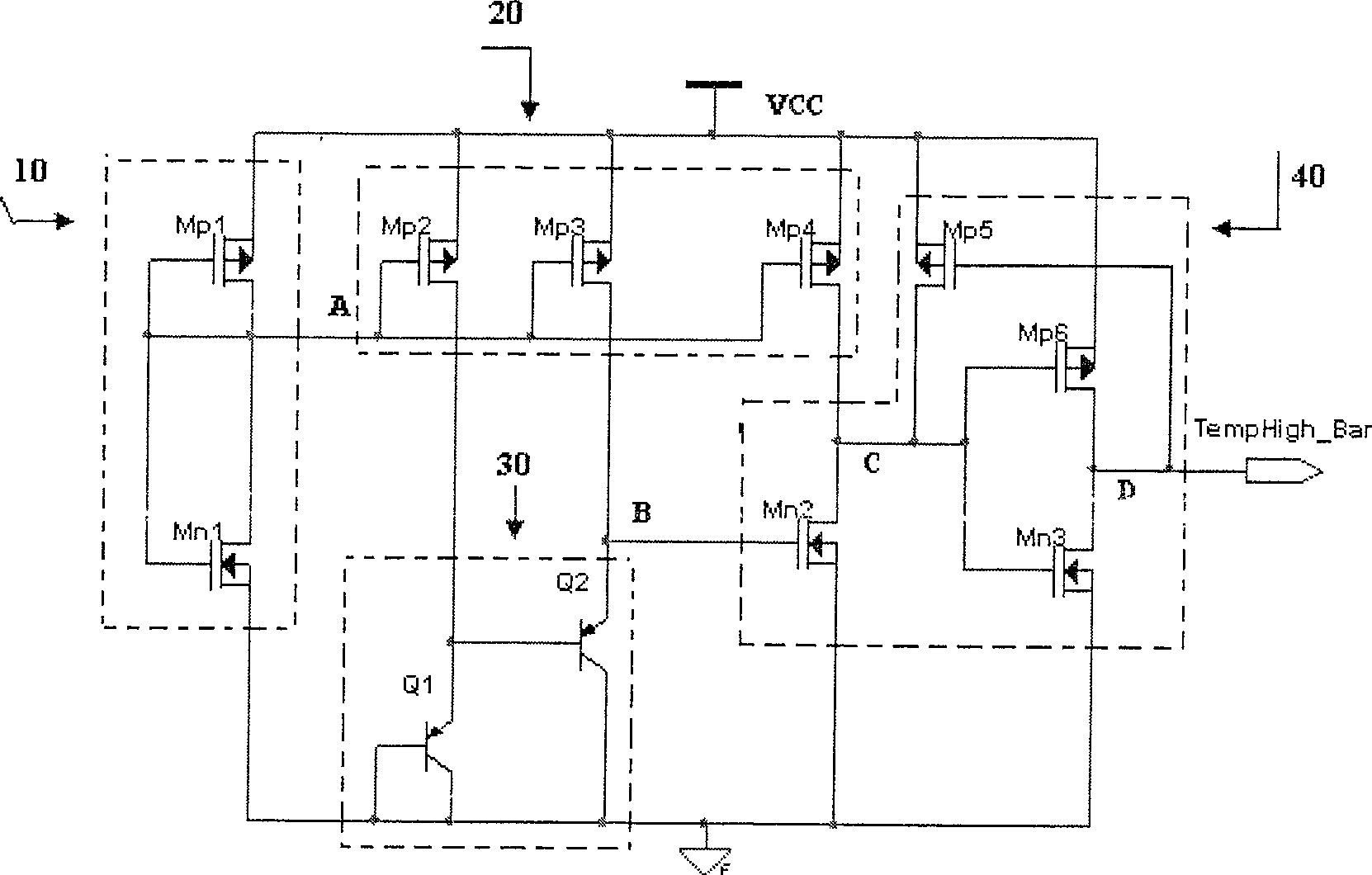

[0017] An implementation example circuit of the temperature monitoring circuit of the present invention is as image 3 As shown, it includes a power supply voltage divider circuit 10, a multi-output current source circuit 20, a temperature sensor circuit 30, and a voltage amplifying circuit 40 composed of a common source amplifier stage and an inverter amplifier stage.

[0018] The power supply voltage divider circuit 10 is: the source of the PMOS transistor Mp1 as an active resistor is connected to the power supply, the gate and the drain are short-circuited, and connected to point A, and the source of the NMOS transistor Mn1 as an active resistor Grounded, the gate and the drain are short-circuited, and also connected to point A, which is the output end of the power supply voltage divider circuit.

[0019] The multi-output current source circuit 20 includes PMOS transistors Mp2, Mp3, and Mp4 whose sources are connected to the power supply and whose gates are connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com