High-polymer modified pitch, its water-proof roll material and use thereof

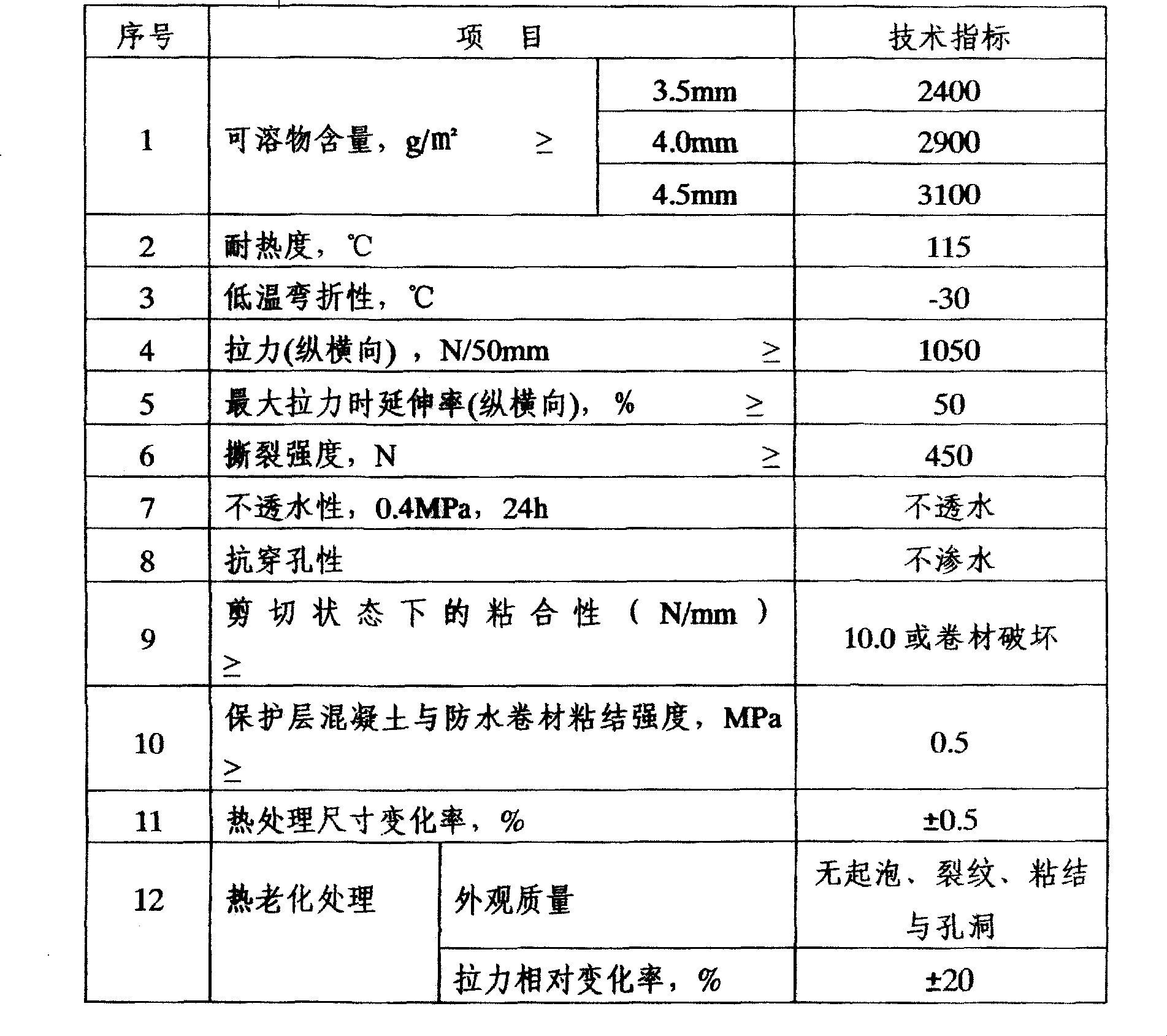

A technology of polymer modification and waterproof membrane, which is applied in the direction of roofing, building structure and building insulation material using flexible materials. It can achieve the effect of wide plastic range and service temperature range, high tensile strength and excellent water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The polymer modified asphalt of this embodiment is composed of the following components: 510kg base asphalt, 70kg blending oil, 140kg SBS, 90kg APAO, 40kg IPP (polypropylene), 150kg stone powder (200 mesh).

[0055] The base bitumen is selected from the 90# bitumen processed by Qinhuangdao imported from Venezuela’s Aoli crude oil. SBS is selected from Yanshan Petrochemical 4402, and APAO (melting index 0.3g / 10min) is selected from Liaoyang Liaohua Qida Chemical Co., Ltd., IPP Yanshan Petrochemical Polypropylene 9020 is selected, and the blended oil is Liaohe Vacuum Third-line Oil (density 0.94g / ml).

[0056] The preparation process of polymer modified asphalt is as follows:

[0057] 1) First add 510kg base pitch and 70kg blending oil, and heat up to 180℃;

[0058] 2) Then add 140kg SBS to it;

[0059] 3) Raise the temperature to within 185°C, swell for 1 hour, then start the colloid mill for grinding for 2 hours, until no small particles are visible to the naked eye;

[006...

Embodiment 2

[0068] Basically the same as Example 1, except that the polymer modified asphalt is composed of the following components: 450kg base asphalt (140# asphalt), 80kg blending oil, 130kg SBS, 70kg APAO (melting index 1.0g / 10min), 70kg polymer Ethylene, 200kg dolomite powder (300 mesh).

[0069] The preparation process of polymer modified asphalt is as follows:

[0070] 1) First add 450kg base asphalt and 80kg blending oil, and heat up to 170℃;

[0071] 2) Then add 130kg SBS to it;

[0072] 3) Raise the temperature to within 180℃, swell for 2h, then start the colloid mill to grind for 3h, until there are no small particles visible to the naked eye;

[0073] 4) Add 70kg APAO and 70kg polyethylene, control the temperature at 190℃, and stir and mix for 3h;

[0074] 5) Finally, add 200kg of dolomite powder and stir at high speed for 50 minutes;

[0075] 6) Test, put into storage tank and prepare for production on line after passing the test.

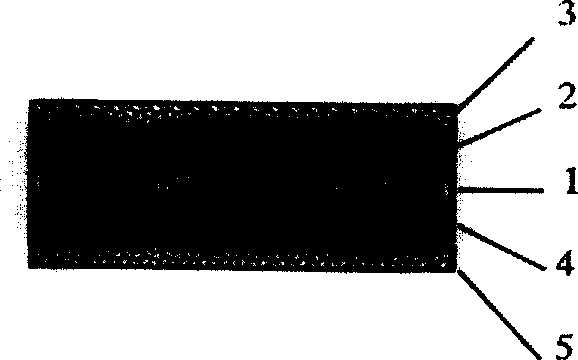

[0076] The structure of the waterproof membrane...

Embodiment 3

[0079] Basically the same as Example 1, except that the polymer modified asphalt is composed of the following components: 550kg base asphalt (100# asphalt), 40kg blending oil, 120kg SBS, 90kg APAO (melting index 0.6g / 10min), 20kg polymer Styrene, 180kg light calcium powder (150 mesh).

[0080] The preparation process of polymer modified asphalt is as follows:

[0081] 1) First add 550kg base asphalt and 40kg blending oil, and heat up to 175℃;

[0082] 2) Then add 120kg SBS to it;

[0083] 3) Raise the temperature to within 185°C, swell for 1 hour, then start the colloid mill for grinding for 2 hours, until no small particles are visible to the naked eye;

[0084] 4) Add 90kg APAO and 20kg polystyrene, control the temperature at 195°C, stir and mix for 2h;

[0085] 5) Finally, add 180kg light calcium powder and stir at high speed for 60min;

[0086] 6) Test, put into storage tank and prepare for production on line after passing the test.

[0087] Polymer modified asphalt is made in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com