Pebble-imitated ecological concrete precast member and preparation method thereof

A technology of ecological concrete and prefabricated parts, applied in the direction of clay preparation equipment, mixing operation control, chemical instruments and methods, etc., can solve the problems of unsatisfactory ammonia nitrogen pollution and other problems, improve waste utilization rate, improve landscape functions, and contribute to Recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Raw material preparation (in this embodiment, each raw material is prepared with 10KG as a standard): 100KG of Portland cement of grade 42.5, 700KG of granular slag with a single grain diameter of 10-20mm, dodecylbenzenesulfonic acid 20KG of sodium, 30KG of silicon powder, 100KG of zeolite powder (produced by Jinxin Zeolite Powder Factory in Ninghai County, Zhejiang Province) with a single particle diameter of ≤2mm, 10KG of water reducing agent (water reducing rate>20%), 15KG of iron oxide, and appropriate amount of water.

[0026] Preparation process: Prepare the above raw materials in proportion, stir them evenly to form a mixture; apply a release agent on the inner wall of the pebble prefabricated mold; press the mixture into a prefabricated mold, or place the mixture in a prefabricated mold and vibrate to form; stand still Remove the mold after 0.5 hours and cure for 24 hours. In this embodiment, the port diameter of the hemispherical mold cavity of the prefabricate...

Embodiment 2

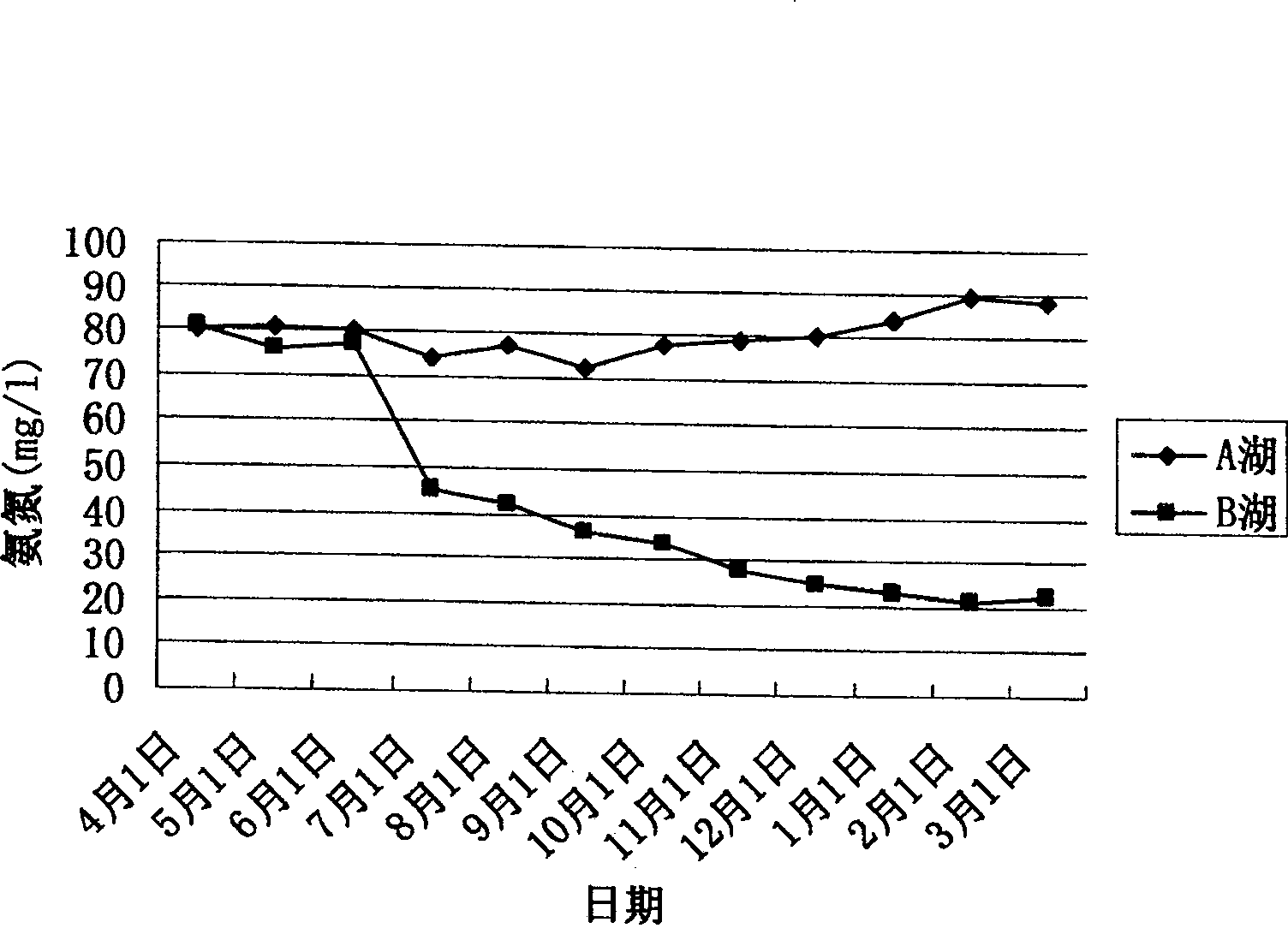

[0028] Select two 100m buildings of almost the same size, A and B, in the community 2 The left and right artificial lakes have an average depth of 1.5m. Lake A is built with traditional mortared rubble, with an inner throw of 5m 3 Ordinary pebbles; the bottom of Lake B is built with traditional mortar and flakes, and the inner throw is 5m 3 Imitation pebble ecological concrete prefabricated part (obtained by embodiment 1). Eutrophic water was injected into the two lakes at the same time on April 1, 2005, and the initial ammonia nitrogen concentration in the raw water was about 80mg / l. And from May 1, 2005 to March 1, 2006, the water quality test was carried out, and the test results were as follows: figure 1 . It can be seen from the figure that the concentration of ammonia nitrogen in the water of Lake B is significantly lower than that of Lake A. After 7 months, the concentration of ammonia nitrogen drops and remains between 20 and 30 mg / l; Iron oxide is added to make t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com