Method for determining concentration of heavy metal ion

A heavy metal ion and concentration technology, which is applied in the direction of chemical reaction of materials for analysis, chemiluminescence/bioluminescence, etc., can solve the problems of complex synthesis routes of polymers, large quenching constants, and high difficulty of synthesis, and achieve excellent solubility , Low production equipment requirements, good linear correlation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

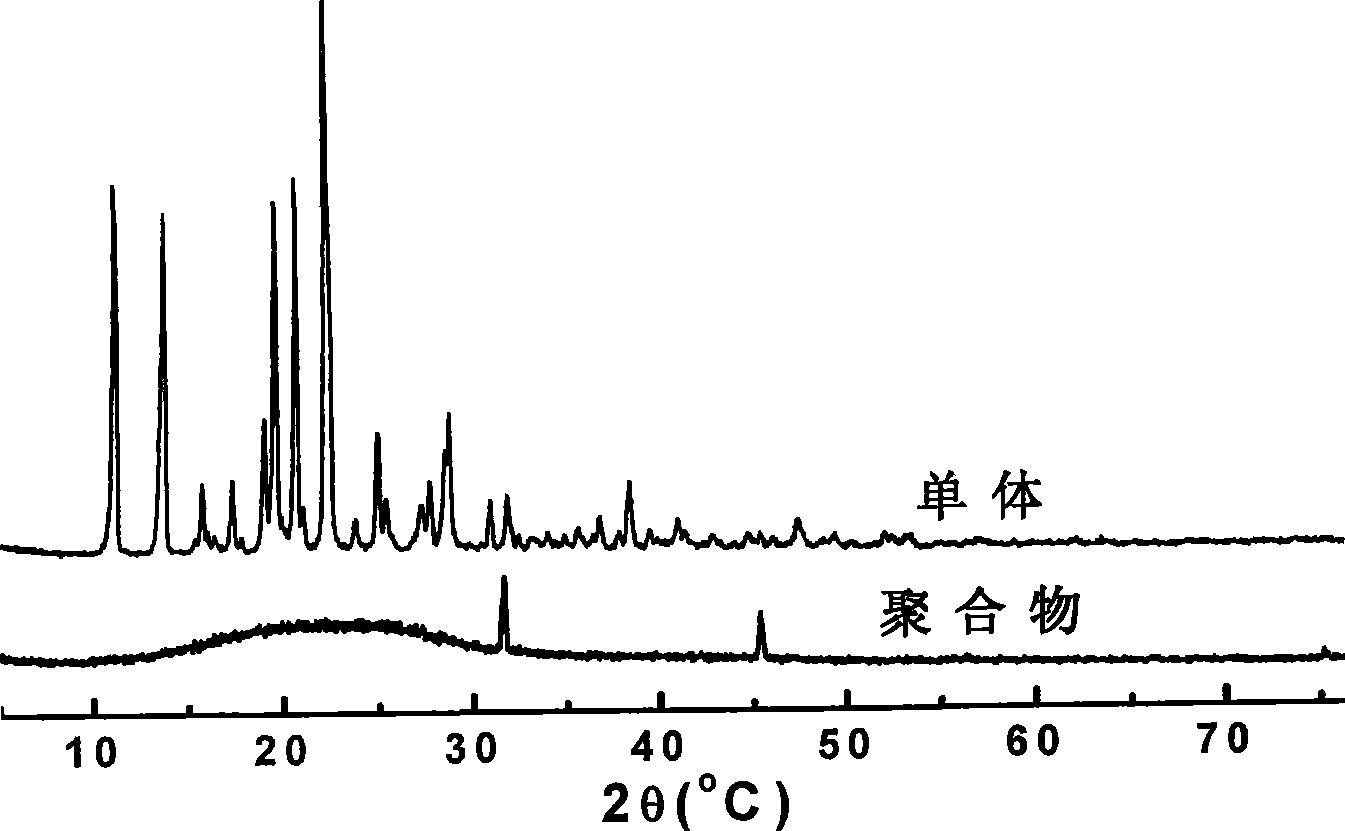

[0039] The following examples will illustrate that the poly(7-sulfonic acid-1-naphthylamine) of the present invention is in an aqueous solution system, adopts hydrogen peroxide / ferrous sulfate redox system to initiate polymerization, and realizes according to the chemical oxidation polymerization reaction path .

[0040] Accurately measure 6mL of water into a 50mL beaker, and then add 2mL of NaOH solution with a concentration of 1mol / L. Accurately weigh 446.5 mg (2 mmol) of 7-sulfonic acid-1-naphthylamine, and transfer it into the above aqueous alkali solution. Stir the blended system with a magnetic stirrer for 18 minutes to completely dissolve the monomer in the aqueous alkali solution, and then add 1 mL (0.05 mmol) of FeSO with a concentration of 50 mmol / L to the beaker. 4 Add 1ml (10mmol) hydrogen peroxide to the solution within about 5 minutes, at this time, the color of the solution changes from light gray to dark brown. The beaker was sealed and the reaction was conti...

Embodiment 2~7

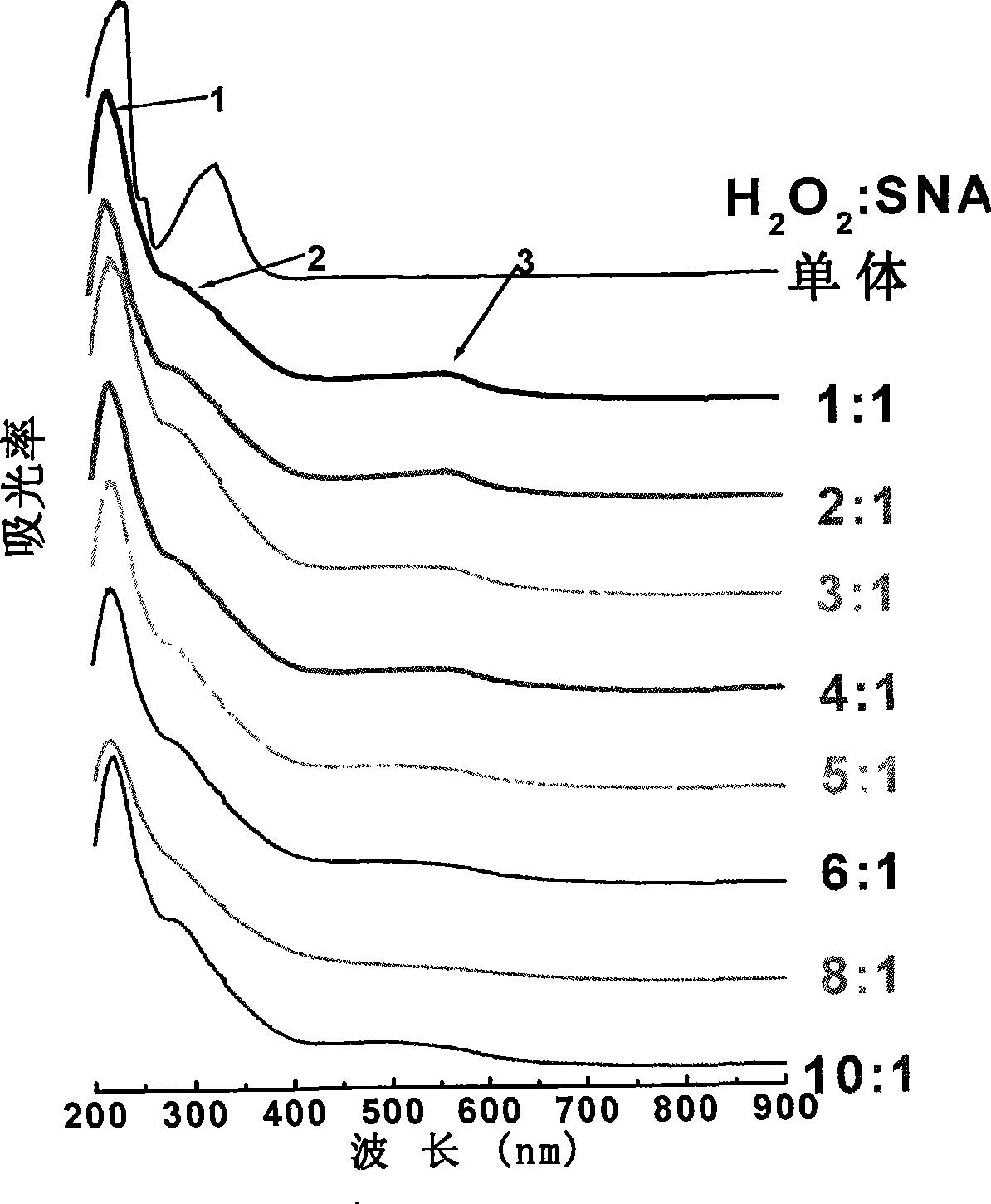

[0042] The following examples will illustrate the influence of different oxygen single ratios on the polymerization yield in the present invention.

[0043] Repeat Example 1, change the amount of oxidant hydrogen peroxide added, so that the oxygen ratio is 1:1, 2:1, 3:1, 4:1, 8:1, 10:1. A black solid powder was obtained with yields of 15.8%, 21.7%, 23.7%, 25.3%, 87.6%, and 59.5%, respectively. The conductivity measured by tablet method is 2.12×10 -6 S / cm, 2.12×10 -6 S / cm, 2.20×10 -6 S / cm, 2.19×10 -6 S / cm, 1.25×10 -6 S / cm, 0.65×10 -6 S / cm.

Embodiment 8~10

[0045] The following examples illustrate the effect of reaction time on polymer yield in the present invention.

[0046] Example 1 was repeated, and the reaction time was changed so that the reaction time was 6h, 12h, and 28h respectively, and black solid powder was obtained with yields of 44.3%, 52.5%, and 81.4%, respectively. The conductivity measured by tablet method was 1.36×10 -6 S / cm, 1.45×10 -6 S / cm, 2.12×10 -6 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com