Oriented production of acetic acid in sludge anaerobic fermentation by methane-bacterium specific inhibitor

A technology for sludge anaerobic fermentation and methanogens, which is applied in the field of sludge recycling, can solve the problems of increased greenhouse gas, large investment in purification and storage, and waste of energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] The sludge in the natural state was used for fermentation (the sludge was not pretreated and not inoculated with seed sludge). The sludge was taken from the residual sludge of the secondary sedimentation tank of a domestic sewage treatment plant in Wuxi for research, and the experiment was carried out with a shaker flask under experimental conditions. , the liquid volume of the shake bottle is 300mL, BES is added at the beginning of fermentation, and the dosage concentration is 50mmol / L. Compared with the anaerobic fermentation of sludge under natural conditions, the concentration of acetic acid in the fermentation broth can be increased by at least 3 times (from 0.3g / L to 1.2g / L) after adding BES (concentration is 50mmol / L).

Embodiment 2

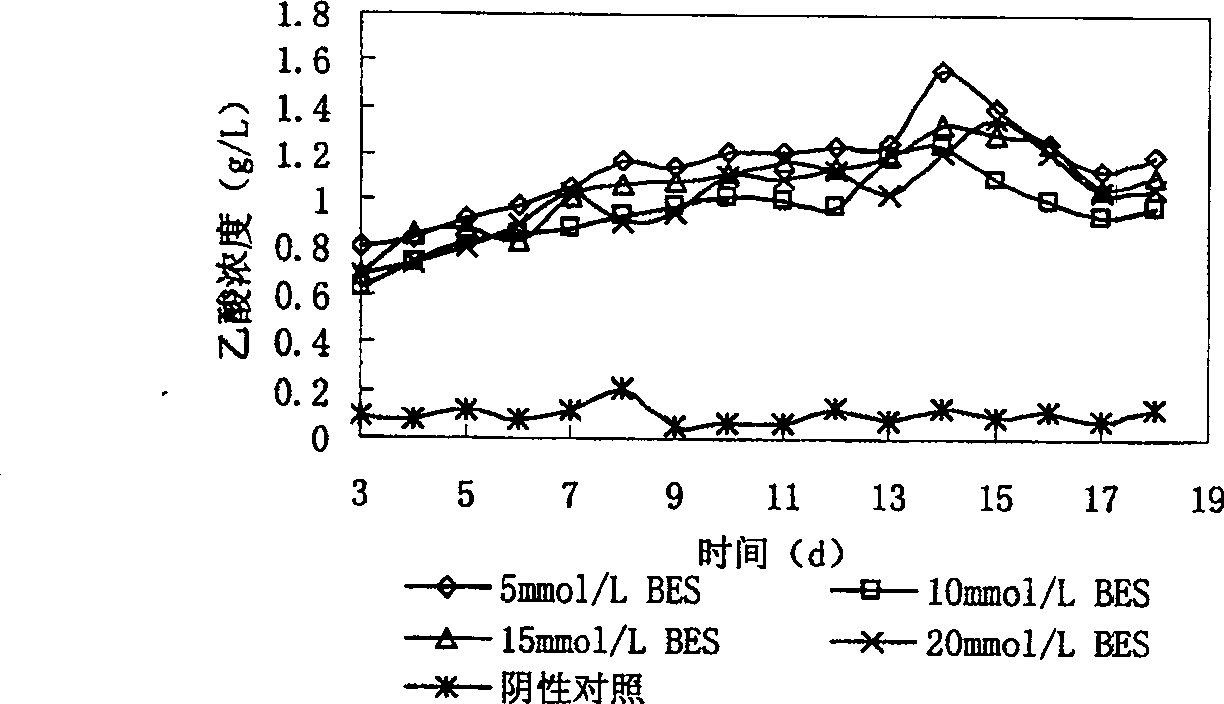

[0014] The source of sludge and experimental conditions are the same as in Example 1. The sludge is first pretreated with hot alkali (pH 12, 120°C, 30min). Mixed for anaerobic fermentation, after shake flask fermentation, such as figure 1 As shown, the concentration of BES added is 5-20mmol / L, the fermentation time is 13-20d, and the concentration of acetic acid is above 1.2g / L. The optimum concentration of BES was 5mmol / L, and the highest concentration of acetic acid was 1.56g / L after 14 days of fermentation.

Embodiment 3

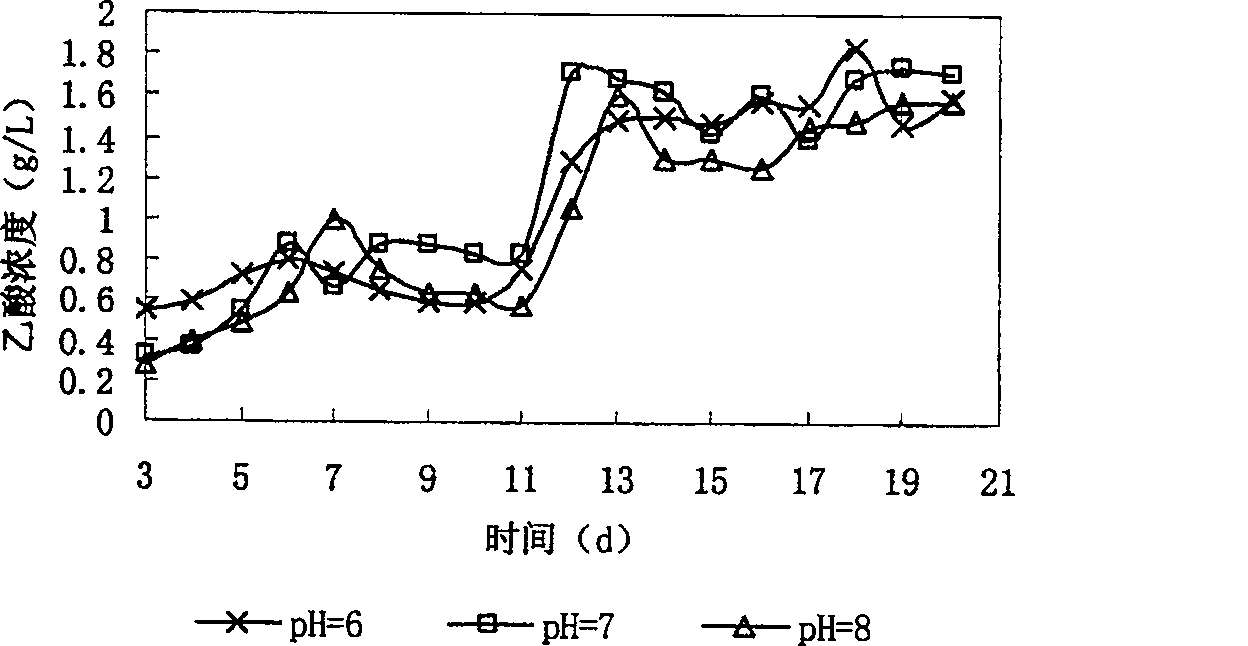

[0016] Also for the pretreated sludge, under the condition that the concentration of BES added is fixed at 5mmol / L, different initial pHs (6, 7, 8) are preset, such as figure 2 It was shown that when the initial pH was 6, the maximum cumulative concentration of acetic acid in the fermentation broth reached 1.84g / L at 18 days of fermentation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com