Triphase slurry bed reactor for preparing liquid fuel with synthetic gas

A slurry bed reactor and liquid fuel technology, which is used in liquid hydrocarbon mixture recovery, petroleum industry and other directions, can solve the problems of difficult operation, high manufacturing cost, catalyst wear, etc., and achieves simple internal components, low manufacturing cost, and difficulty in manufacturing. inactive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

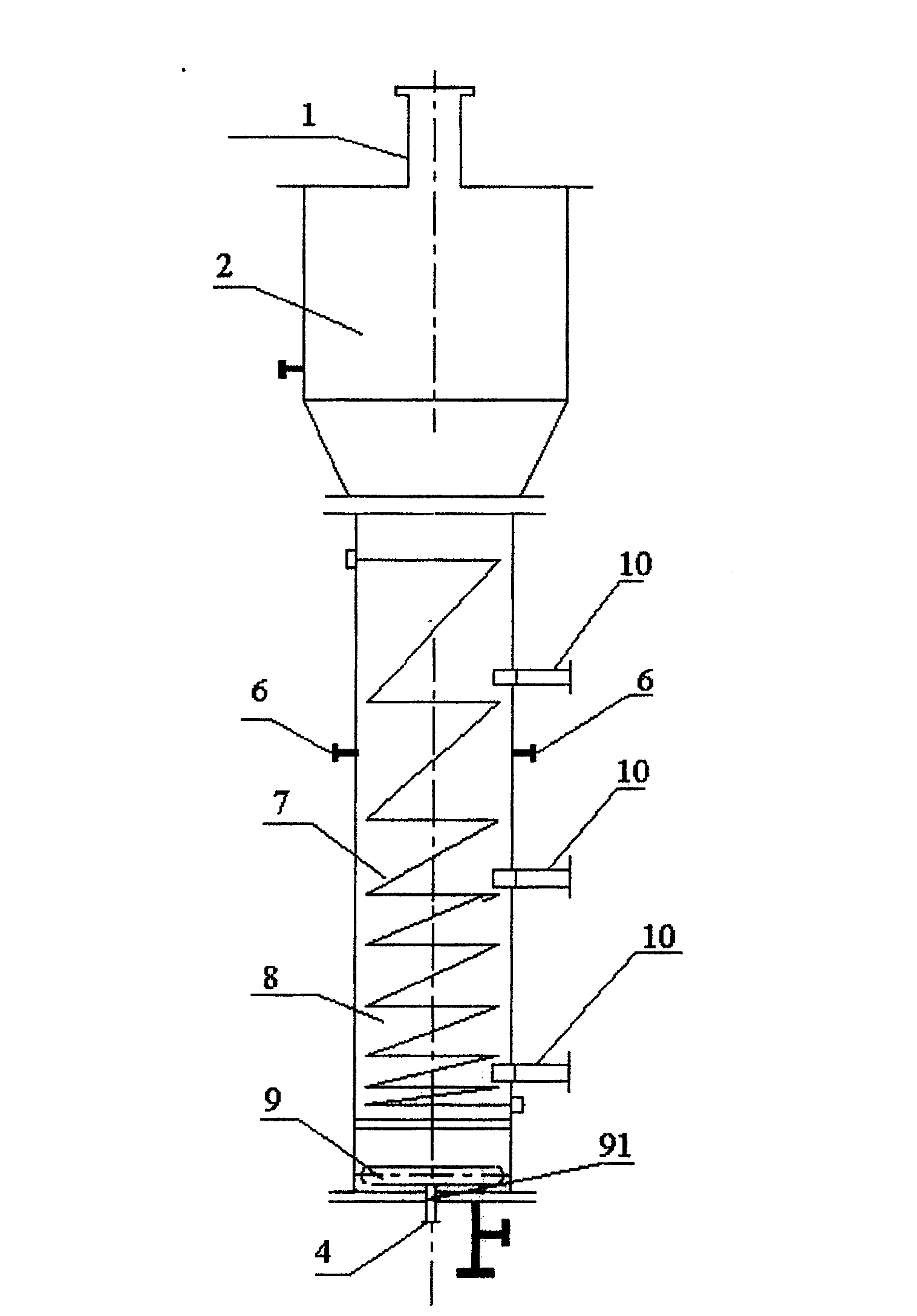

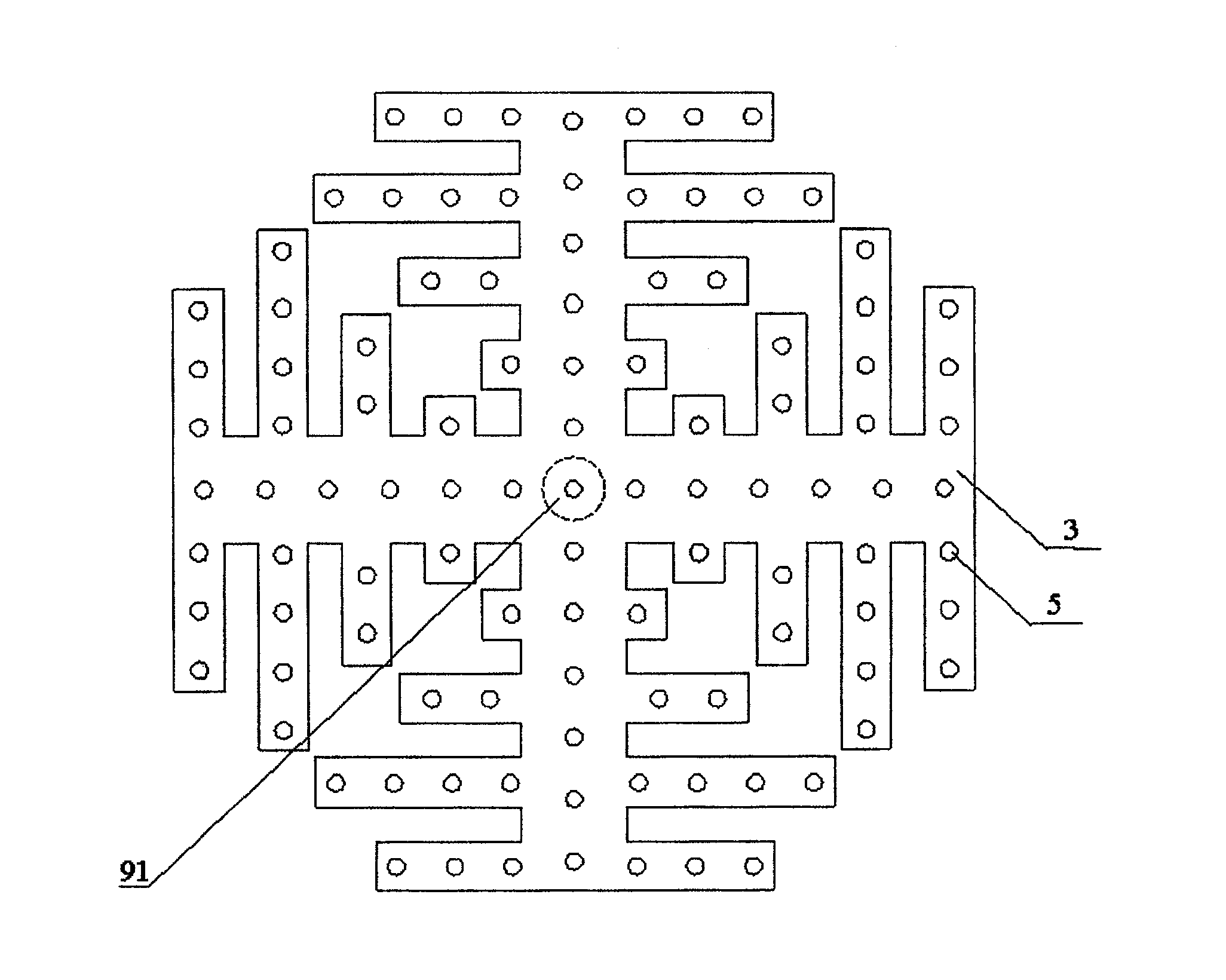

[0039] use figure 1 The three-phase slurry bed reactor and figure 2 gas distributor.

[0040] Among them: the diameter of the reaction part of the reactor is 1.45 meters, the height is 22 meters, the diameter of the separation part is 1.8 meters, and the height is 6 meters. degree angle, the diameter of the small hole is 1.0mm, y=1.2x, where x is the equivalent length of the reactor along the axial direction, and y is the equivalent heat transfer density of the heat exchanger along the axial direction;

[0041] Using synthesis gas as raw material, the one-step method can produce 30,000 tons of alcohol ether fuel per year. The average gas holdup of the reactor is 0.189, the mass of the catalyst is 12.38 tons, and the mass of the inert liquid-phase heat carrier is 23 tons. In the synthesis gas, the content of CO is 28%, H2 is 68%, and CO2 is 3% (volume). When the temperature is 250°C and the pressure is 5.0Mpa, the conversion rate of CO is 0.6667, and the annual output of dim...

Embodiment 2

[0045] use figure 1 The three-phase slurry bed reactor and figure 2 gas distributor.

[0046] in:

[0047] The diameter of the reaction part of the reactor is 3.25 meters, and the height is 23 meters. The diameter of the separation part is 3.9 meters, and the height is 7 meters. , the hole diameter is 1mm, y=2.5x, where x is the equivalent length of the reactor along the axial direction, and y is the equivalent heat transfer density of the heat exchanger along the axial direction;

[0048] Using synthesis gas as raw material, the one-step method can produce 300,000 tons of alcohol ether fuel per year. The average gas holdup of the reactor is 0.189, the mass of catalyst is 120 tons, and the mass of inert liquid-phase heat carrier is 230 tons. The CO content in the syngas is 28%, the H 2 68%, CO 2 When the temperature is 250°C and the pressure is 5.0Mpa, the conversion rate of CO is 0.67, the annual output of dimethyl ether is 280,000 tons, and the annual output of methano...

Embodiment 3

[0052] use figure 1 The three-phase slurry bed reactor and figure 2 gas distributor.

[0053]Among them: the diameter of the reaction part of the reactor is 1.45 meters, the height is 22 meters, the diameter of the separation part is 1.8 meters, and the height is 6 meters. degree angle, the diameter of the small hole is 1mm, y=2.0x, where x is the equivalent length of the reactor along the axial direction, and y is the equivalent heat transfer density of the heat exchanger along the axial direction;

[0054] Using syngas as raw material, F-T synthesis produces 30,000 tons of heavy hydrocarbon fuels per year, and the H in the syngas 2 / CO is 2.0, when the temperature is 220°C and the pressure is 2.5Mpa, the CO conversion rate reaches 84.88%, the selectivity of hydrocarbons, CH4 and CO2 are 99.63%, 5.47% and 0.37%, respectively, and the selectivity of heavy hydrocarbons is 88.16%.

[0055] Catalyst adopts self-made F-T synthesis catalyst, and the preparation method is as fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com