Preparation of gallium nitride based epitaxial film

A gallium nitride-based, epitaxial film technology, applied in the fields of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., can solve problems such as high requirements for lasers and laser lift-off systems, and limited speed of laser lift-off processing , to achieve the effect of fast low-power laser peeling, reducing the probability of spot repetition, and spot enlargement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

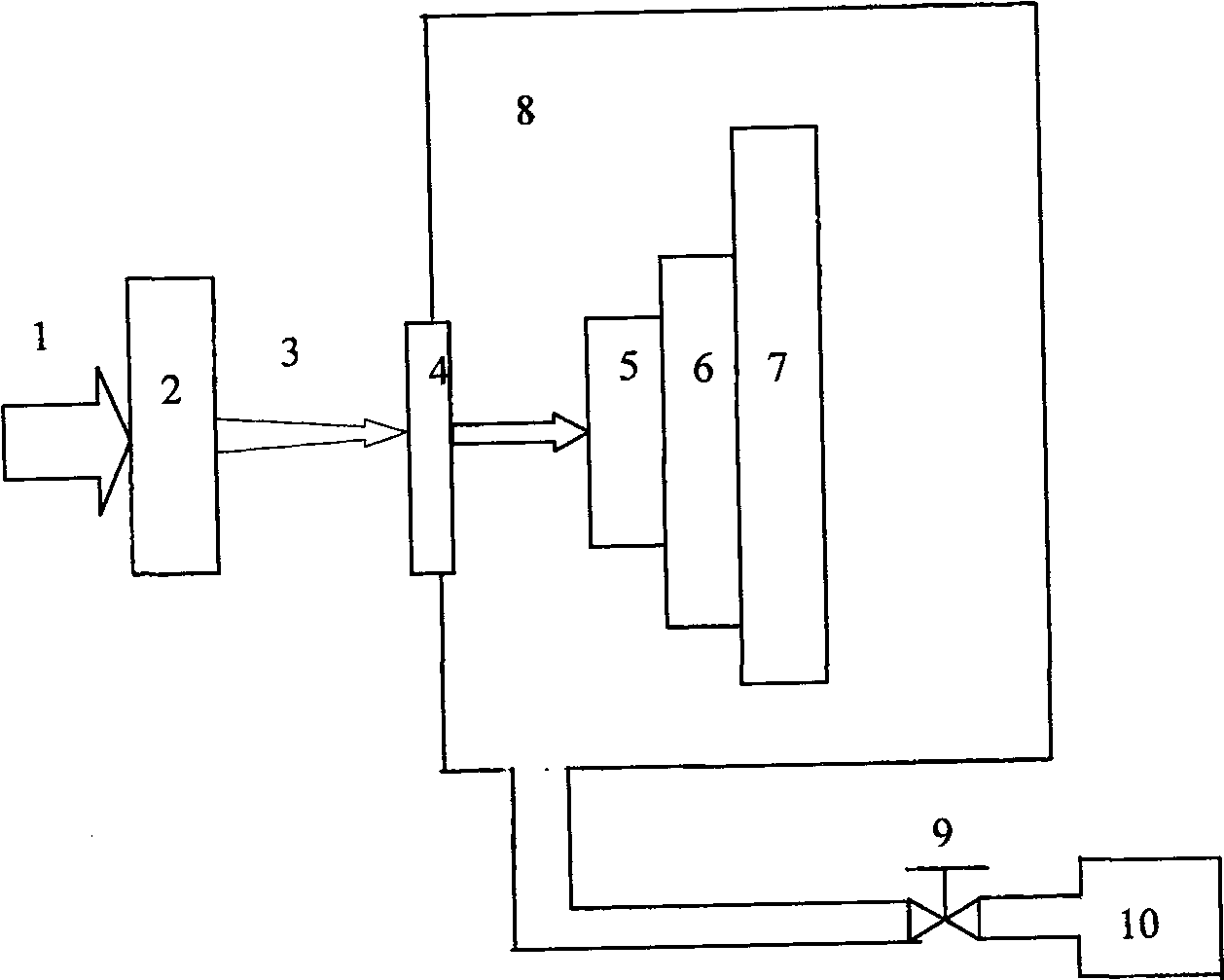

[0037] Such as figure 1 The fully enclosed low-vacuum laser lift-off system is shown, and the specific scheme includes the following steps:

[0038] 1. The GaN epitaxial film is grown on the sapphire substrate by metal-organic vapor phase epitaxy.

[0039]2. Glue the P side of the gallium nitride-based epitaxial film grown on the sapphire substrate to the Si sheet, glass or copper sheet with epoxy resin, and place it in a vacuum chamber to remove the bubbles in the epoxy resin to ensure that the GaN-based epitaxial film Uniform void-free contact with the support substrate.

[0040] 3. Fix the gallium nitride-based epitaxial film sample 5 grown on the sapphire substrate adhered to the support substrate on the object glass 6, put the sample 5 and the electric platform 7 into the vacuum chamber 8, and open the valve 9. Use the mechanical pump 10 to evacuate the vacuum chamber 8 to 4-5 Pa.

[0041] 4. Adjust the output energy density of the excimer laser to 400mJ / cm 2 , the pu...

Embodiment 2

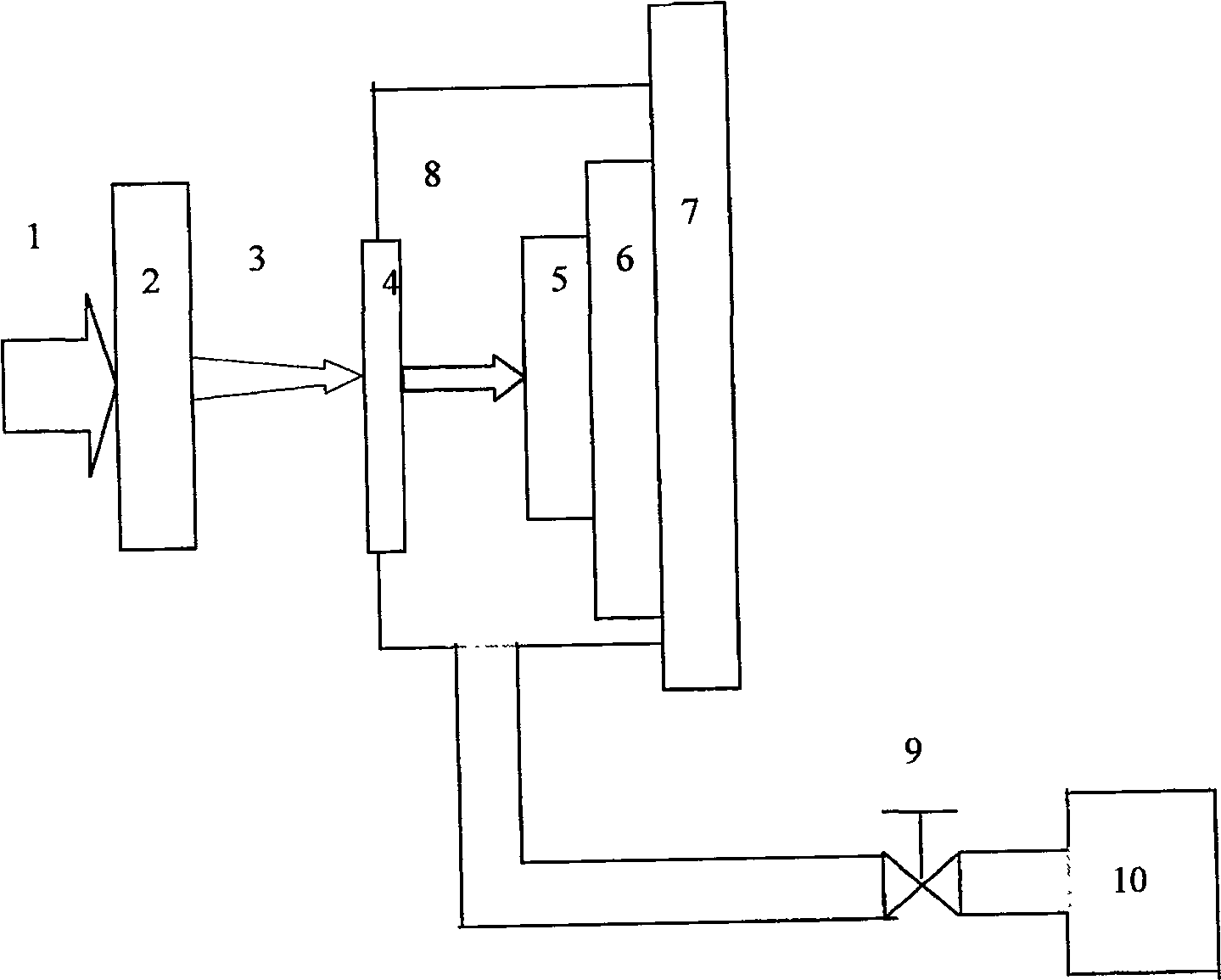

[0046] Such as figure 2 As shown, a semi-closed low-vacuum laser lift-off system is used, and the specific scheme includes the following steps:

[0047] 1. A GaN epitaxial film is grown on a sapphire substrate by metal organic vapor phase epitaxy (MOCVD).

[0048] 2. The P side of the gallium nitride-based epitaxial film grown on the sapphire substrate is glued to the Si sheet, glass or copper sheet with epoxy resin, and placed in a vacuum chamber to remove the air bubbles in the epoxy resin to ensure that the GaN-based epitaxial film is in good contact with the epitaxial film. Uniform void-free contact to the support substrate.

[0049] 3. Fix the gallium nitride-based epitaxial film sample 5 grown on the sapphire substrate adhered to the support substrate on the object glass 6, and fix the rear end of the vacuum chamber 8 on the electric platform 7.

[0050] 4. Open the valve 9, and use the mechanical pump 10 to evacuate the vacuum chamber 8 to 4-5 Pa.

[0051] 5. Adjust...

Embodiment 3

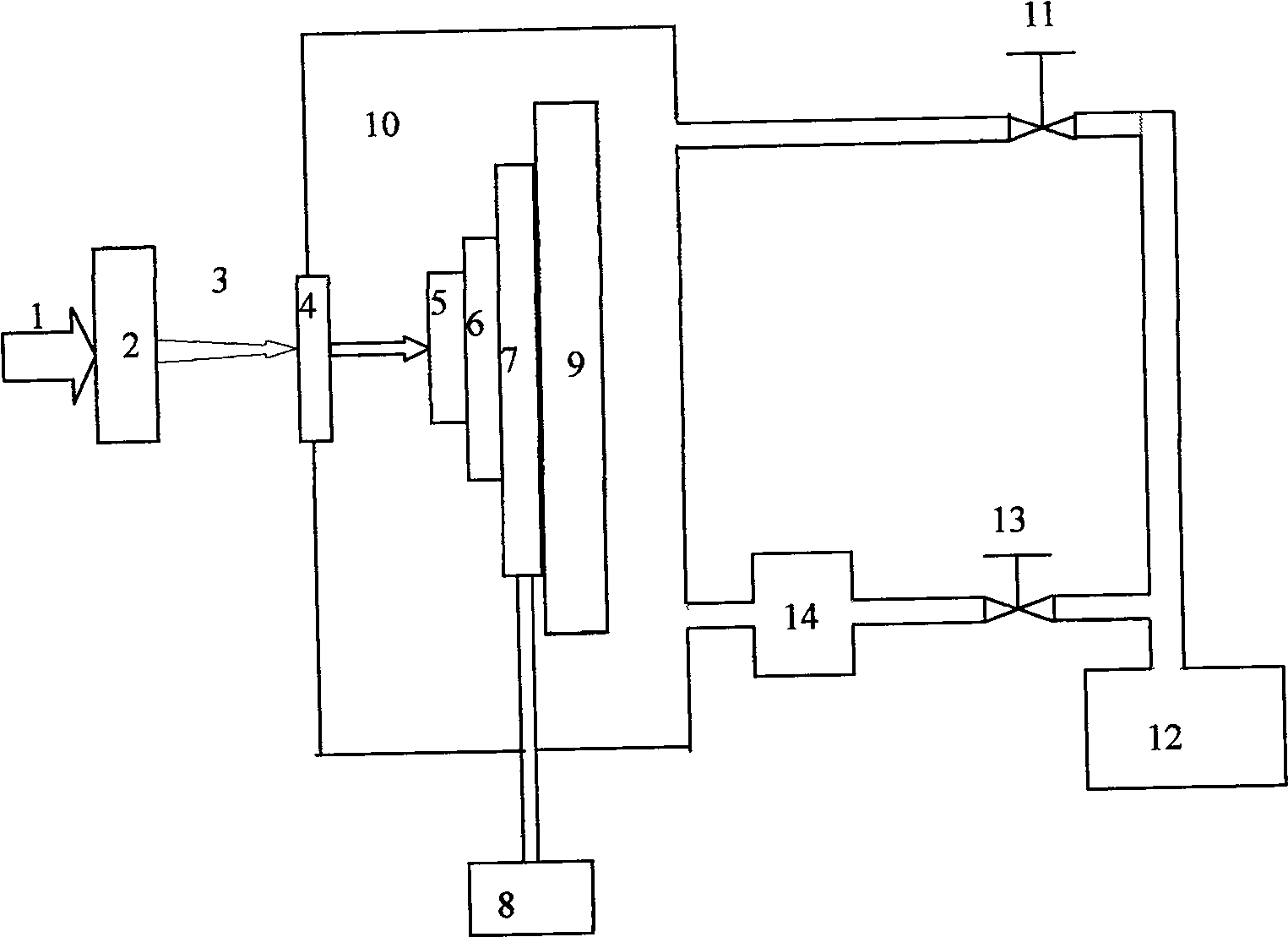

[0056] Such as image 3 The fully enclosed high-vacuum laser lift-off system is shown, and the specific scheme includes the following steps:

[0057] 1. A GaN epitaxial film is grown on a sapphire substrate by metal organic vapor phase epitaxy (MOCVD).

[0058] 2. The P side of the gallium nitride-based epitaxial film grown on the sapphire substrate is glued to the Si sheet, glass or copper sheet with epoxy resin, and placed in a vacuum chamber to remove the air bubbles in the epoxy resin to ensure that the GaN-based epitaxial film is in good contact with the epitaxial film. Uniform void-free contact to the support substrate.

[0059] 3. Fix the gallium nitride-based epitaxial film sample 5 grown on the sapphire substrate adhered to the support substrate on the object glass 6, and use the heating device 7 to heat the sample 5, and the heating temperature is 400 ° C. The power is 8. Put the sample, heating device and motorized platform 9 into the vacuum chamber 10 together. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com