Welding process for high damping copper alloy and steel

A welding process, copper alloy technology, applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems of no patent literature, etc., and achieve the effect of good fluidity, high metal strength, and excellent mechanical properties of the weld seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take the CuMn50 alloy of the gear web of the marine power system, and the material of the ring gear and the hub is 40CrNiMoA as an example:

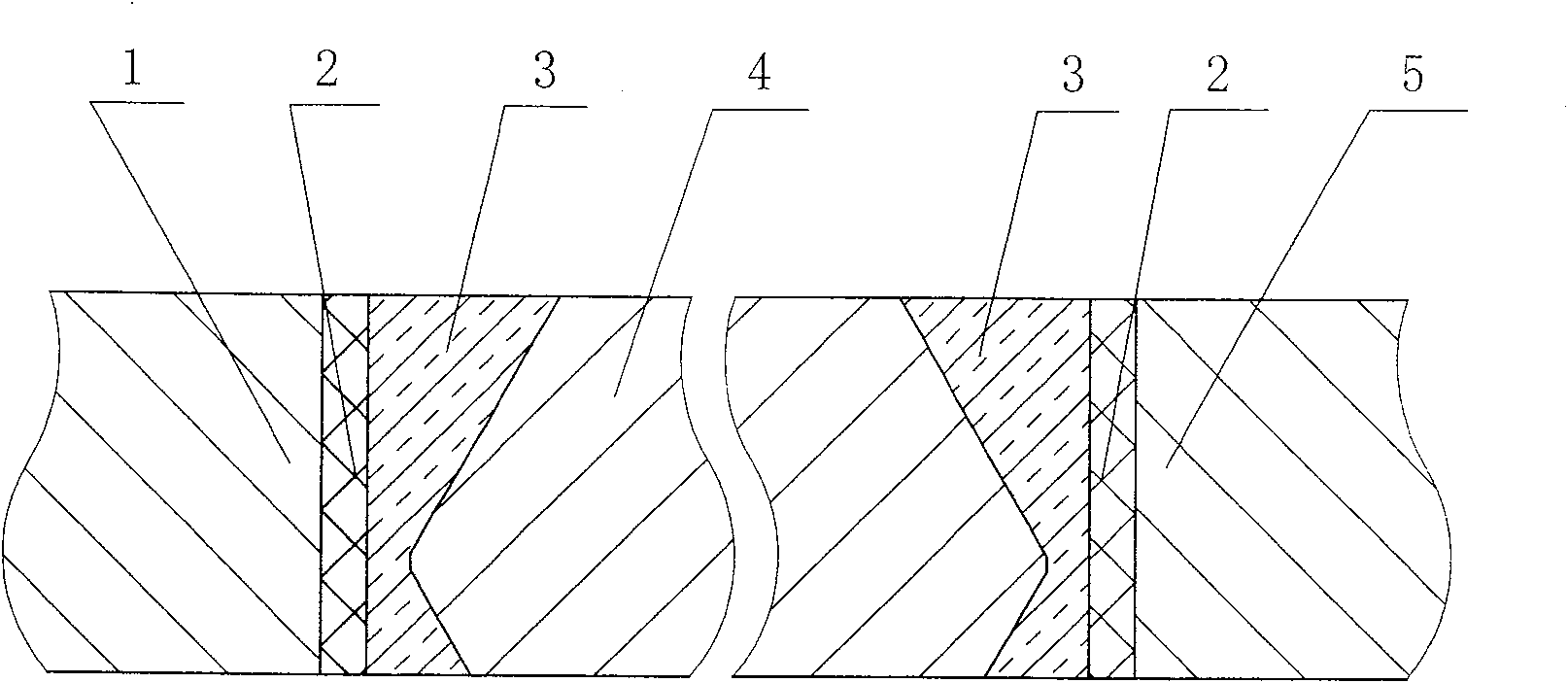

[0027] The spoke plate is made of CuMn50 alloy, which mainly uses its high damping characteristics to reduce the noise of gears in the traditional system. figure 1 K-shaped groove, that is, to process the K-shaped groove on the connecting surface of the spoke plate, the ring gear and the hub. The grease, water and other impurities on the surface within 30mm on both sides of the groove, as well as the oxide film on the metal surface must be carefully checked. Clean until a metallic sheen is revealed.

[0028] Using cerium tungsten electrode, DC manual tungsten argon arc welding, the purity of protective argon is ≥99.99%.

[0029] ERNi-1 surfacing welding is used on the connection surface of the gear (ring gear, wheel hub) structural steel, φ2.5mm welding wire, surfacing welding thickness 3mm, welding interlayer temperature ≤ 50 ℃...

Embodiment 2

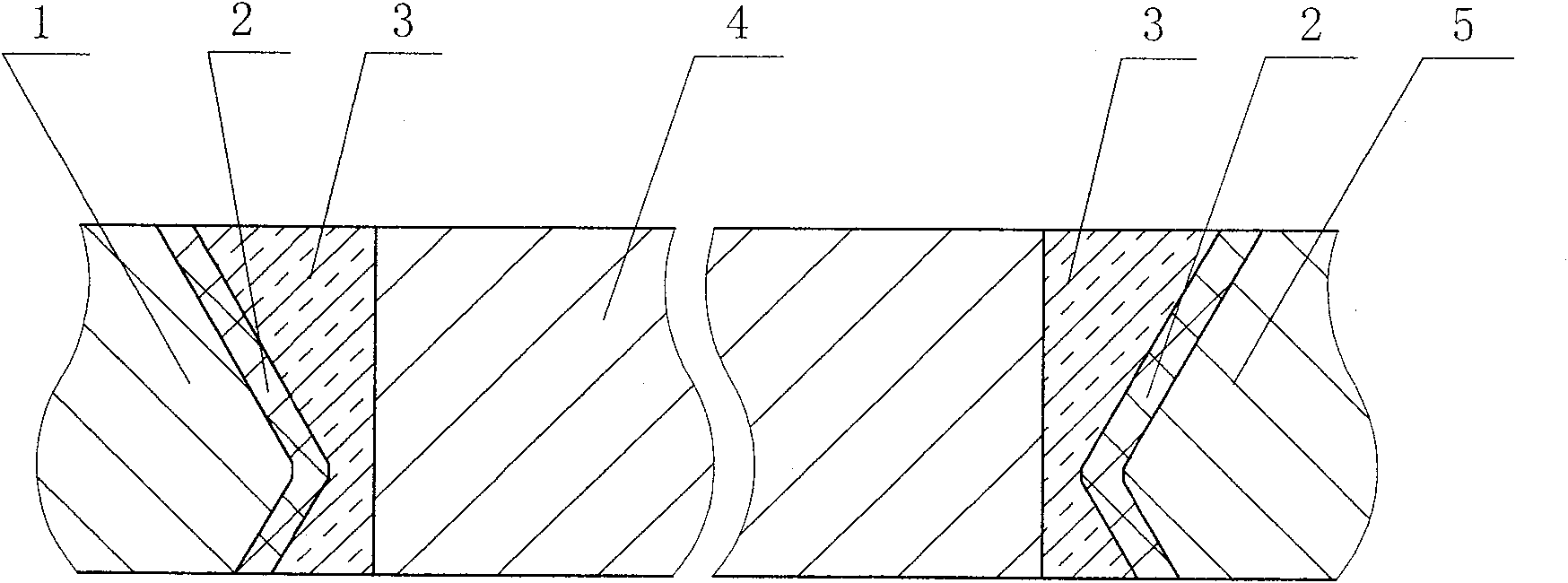

[0036] CuMn50 alloy is used for the gear web, and the groove type is as follows figure 2 As shown, the ring gear and hub are made of alloy steel 30CrMoA as an example:

[0037] Using the same welding process as described in Example 1, 25mm thick CuMn50 and 30CrMoA welded joint performance: normal temperature tensile strength (R m / MPa)460~500; impact energy (A Kv / J) 100~110; cold bending angle (d=4a) 65°~80°. Weld fatigue life 10 7 Under the conditions, the stress is greater than 100MPa. All meet the target requirements.

Embodiment 3

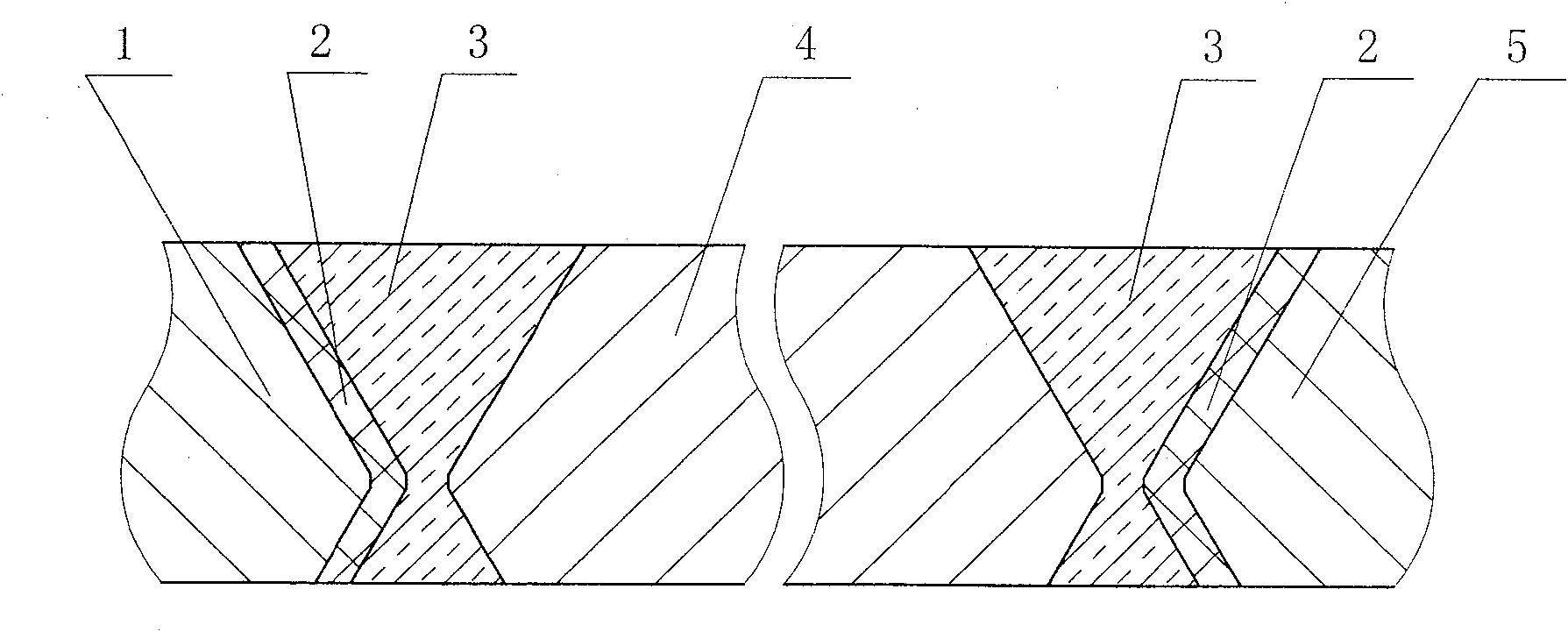

[0039] CuMn50 alloy is used for the gear web, and the groove type is as follows image 3 As shown, the ring gear and hub are made of alloy steel 20CrMnMo as an example:

[0040] Using the same welding process as described in Example 1, 25mm thick CuMn50 and 20CrMnMo welded joint performance: normal temperature tensile strength (R m / MPa)460~500; impact energy (A Kv / J) 90~110; cold bending angle (d=4a) 60°~80°. All met the required indicators.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com