Method for processing high temperature condensed water by integration technique of membrane

A high-temperature condensate, membrane integration technology, applied in adsorption water/sewage treatment, permeation/dialysis water/sewage treatment, etc., can solve the problems of unstable treatment effect, frequent replacement of adsorbent materials, etc., to achieve stable and reliable effluent quality, beneficial to Long-term stable operation, reduced equipment investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

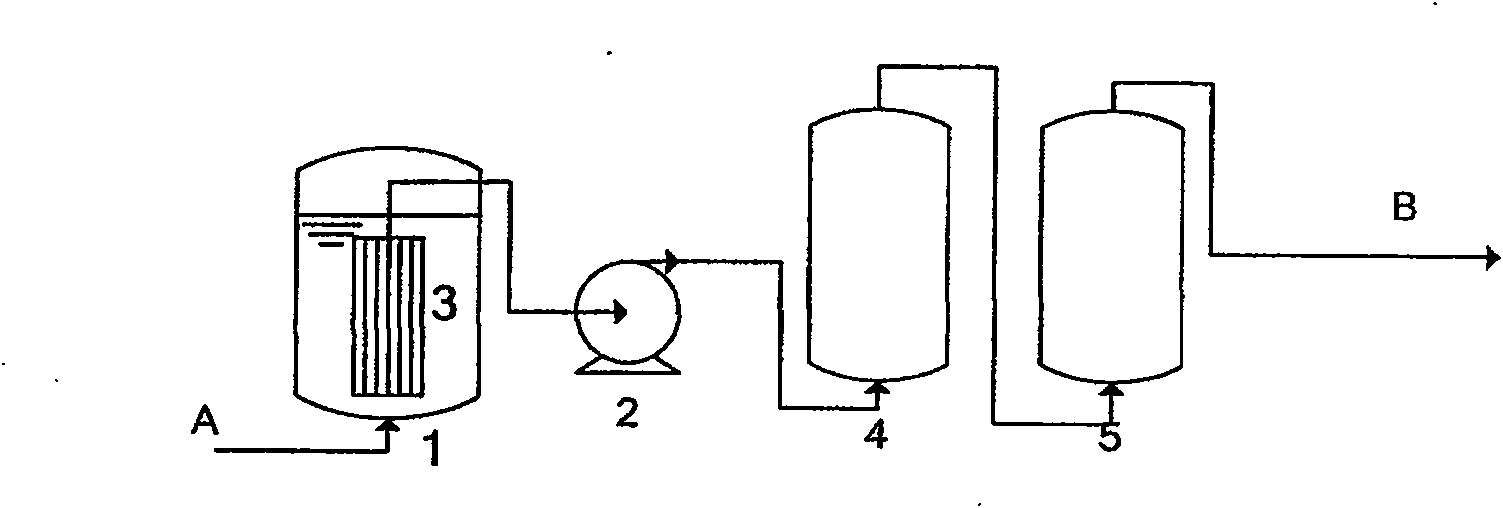

[0032] Embodiment 1 (flow process is as figure 1 )

[0033] 50L steam condensate A at 65°C is passed into the condensate treatment system, and the water quality of the steam condensate is shown in Table 1.

[0034] Membrane filtration unit 3 adopts a modified polyethersulfone hollow fiber microfiltration membrane with a pore size of 0.8 μm and a membrane area of 8 m 2 . Use as attached figure 1In the dead-end filtration method shown, the membrane filtration unit 3 is a modified polyethersulfone hollow fiber microfiltration membrane, which is placed in the high-temperature condensate storage tank 1 and powered by the suction pump 2 connected to the permeation side of the membrane. The operating pressure is 0.02MPa, under this condition, the stable flux through the microfiltration membrane is 0.5m 3 / 11, the water quality of membrane filtrate is shown in Table 1.

[0035] The membrane permeated water of the membrane filtration unit 3 is sucked out by the pump 2 and sent t...

Embodiment 2

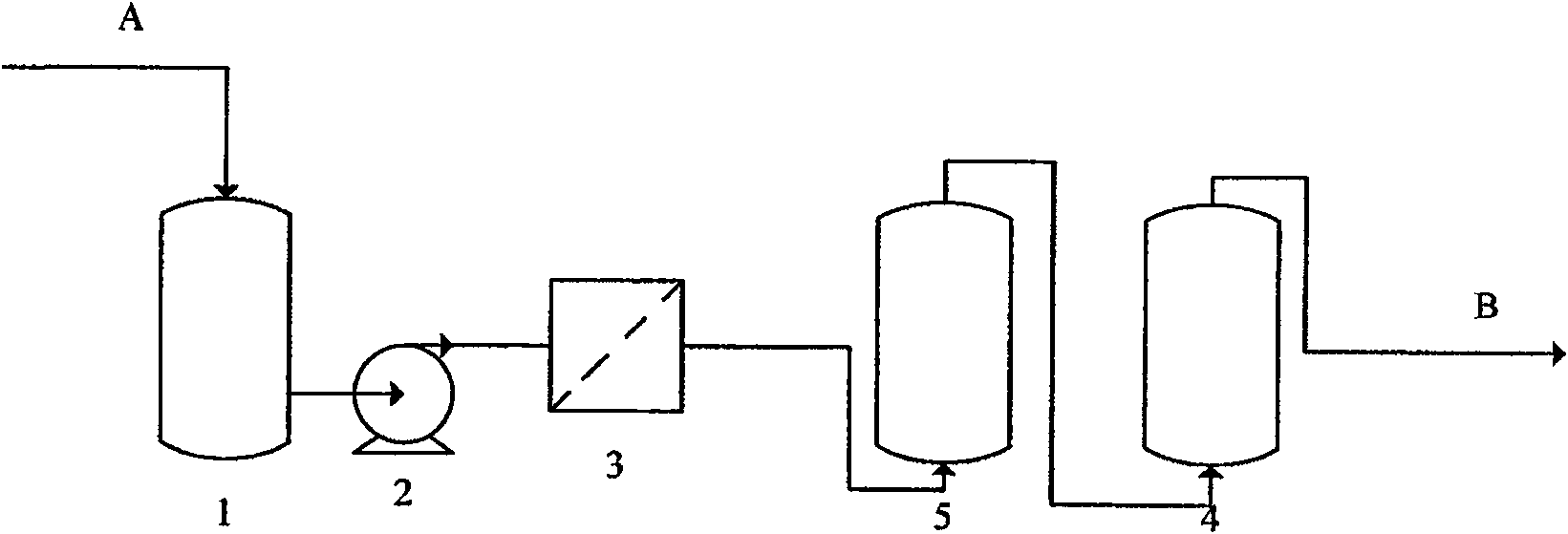

[0039] Embodiment 2 (flow process is as figure 2 )

[0040] Pass 50L steam condensate A at 80°C into the condensate treatment system. The water quality of the steam condensate is shown in Table 1.

[0041] Membrane filtration unit 3 uses a 19-channel tubular ceramic microfiltration membrane with a pore size of 200nm and a membrane area of 0.5m 2 . Use as attached figure 2 In the dead-end filtration method shown, the membrane filtration unit 3 is a multi-channel tubular microfiltration membrane made of zirconia material, which communicates with the high-temperature condensate storage tank 1, and is driven by a centrifugal pump connected between the high-temperature condensate storage tank and the membrane inlet. 2 to provide power, the operating pressure is 1.2MPa, under this condition the average flux of the microfiltration membrane is 1.7m 3 / h, when the membrane flux drops to 0.5m 3 / h, backwash the permeation side of the ceramic membrane with compressed air for 10s...

Embodiment 3

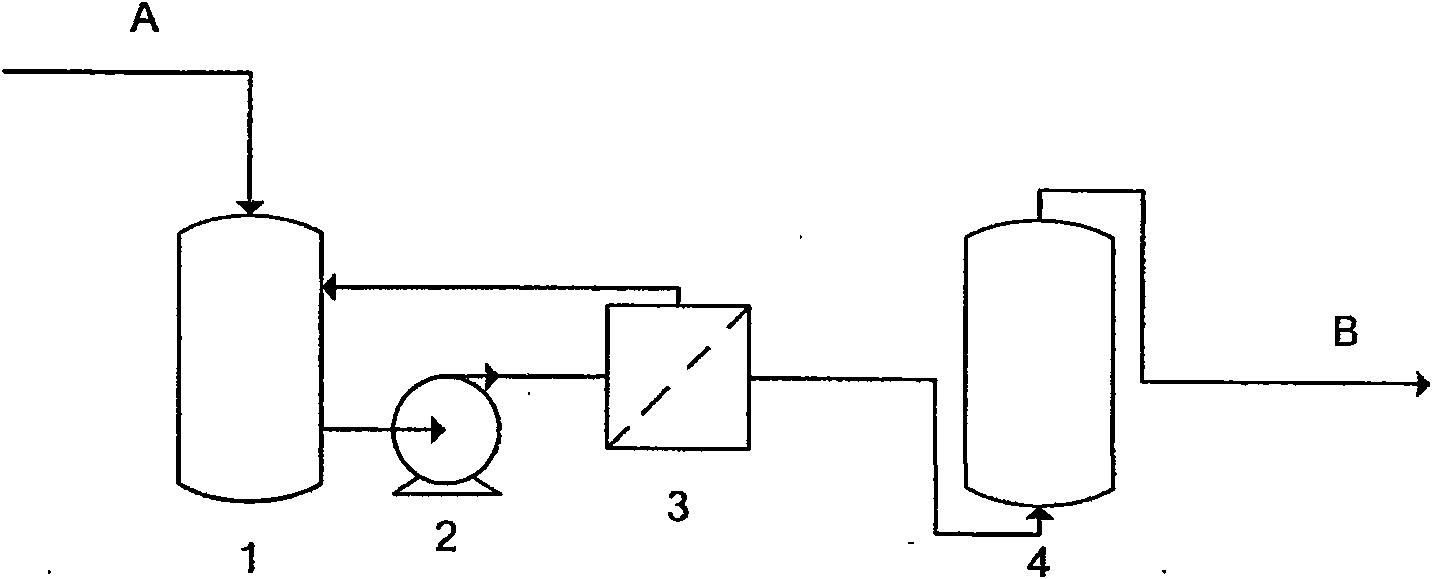

[0046] Embodiment 3 (flow process is as image 3 )

[0047] Pass 50L steam condensate A at 95°C into the condensate treatment system. The water quality of the steam condensate is shown in Table 3.

[0048] Membrane filtration unit 3 adopts a 19-channel tubular ceramic ultrafiltration membrane with a pore size of 20nm and a membrane area of 3m 2 . Use as attached image 3 In the cross-flow filtration method shown, the membrane filtration unit 3 is a multi-channel tubular ultrafiltration membrane made of alumina, which communicates with the high-temperature condensate storage tank 1, and is connected by a centrifugal filter connected between the high-temperature condensate storage tank and the membrane inlet. The pump 2 provides power, the operating pressure is 0.35MPa, the high-temperature condensed water in the liquid storage tank 1 is sent to one side of the ultrafiltration membrane of the membrane filtration treatment unit 3 through the pump 2, and the permeate penetrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Membrane area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com