Improved temperature gradient method for BaY2F8 monocrystal growing and device therefor

A temperature gradient method and single crystal technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of low growth rate, supercooled components, small size, etc., and achieve easy automatic control and convenient growth process , the effect of good crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

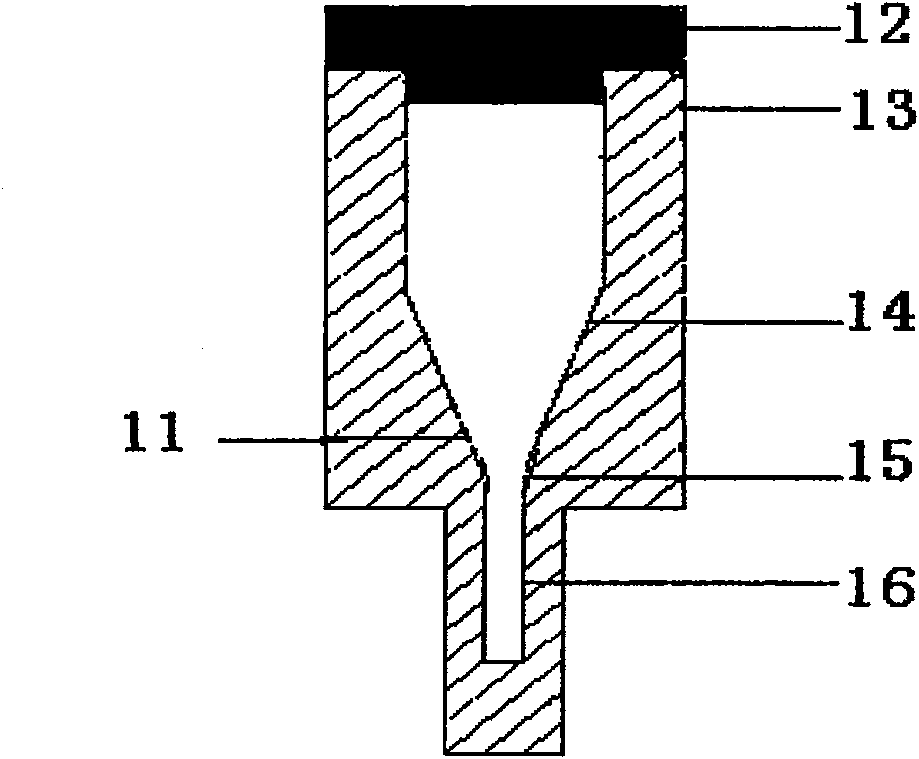

[0021] Embodiment 1, the unique design of small cone angle crucible

[0022] Crucible design such as figure 1 shown. The bottom of the crucible is a seeding capillary with a diameter of 2 mm. A capillary with such a scale diameter is conducive to the selection of a single growth direction in the spontaneous crystallization process of the crystal. If the diameter is too small, the generated surface tension will make it difficult for the melt to enter the capillary. In this example, the length of the seeding capillary is 30mm. The middle part of the crucible (the shoulder part) is an inverted conical shape, and its characteristic is that the apex angle of the cone is a small angle, about 29°. This is different from other crystals (such as CaF 2 , NaF and other crystals) The cone angle of the shoulder part of the crucible used in the temperature gradient method growth. Relevant theoretical calculations show that the angle of the apex angle of the cone designed here complies ...

Embodiment 2

[0027] Embodiment 2, temperature gradient and test

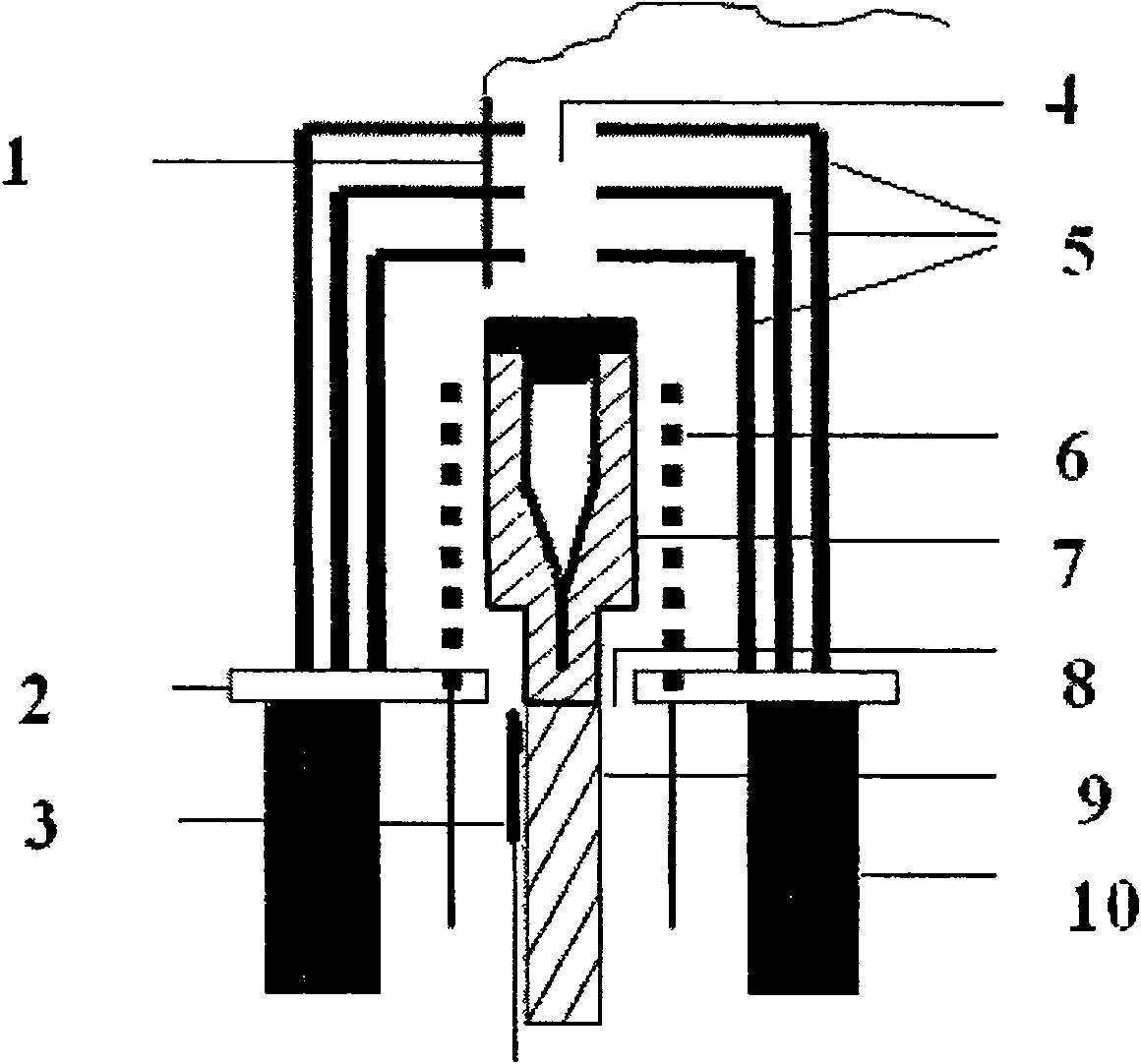

[0028] The appropriate temperature gradient is the temperature gradient method to grow BaY 2 f 8 One of the key elements of the crystal. Figure 2 It is a schematic structural diagram of a single crystal growth device in the method of the present invention. Vacuum tungsten rod resistance heating is used, the crucible is placed in the middle of the heating element, and the heating element is surrounded by multi-layer concentric molybdenum-skinned drums for heat preservation. The base is made of stainless steel, and a ring-shaped alumina ceramic plate is placed above the base. There is a gap of not less than 2cm between the ring-shaped ceramic plate and the crucible holder.

[0029] The top opening of the molybdenum skin insulation barrel and the center of the alumina ceramic plate leave a gap, which is one of the characteristics of the present invention, and its purpose is to help form a larger and longer distance axial t...

Embodiment 3

[0030] Embodiment 3, doping Er 3+ The heavy metal fluoride BaY 2 f 8 Temperature Gradient Growth of Single Crystal

[0031] 1, raw materials will be high-purity BaF 2 , YF 3 Weigh according to the molar ratio of 1:2, and add 2mol.% of ErF 3 , grind and mix evenly in an agate mortar, and dry for later use.

[0032] 2. Furnace loading Put the prepared raw materials into a graphite crucible with a small cone angle.

[0033] 3. Vacuumize the furnace until the air pressure in the furnace is lower than 5×10 -3 Pa, filled with high-purity argon as a protective gas.

[0034] 4. The melting material is heated up to 1200°C and kept at this temperature for 2 hours to ensure that the raw materials are completely melted and mixed evenly.

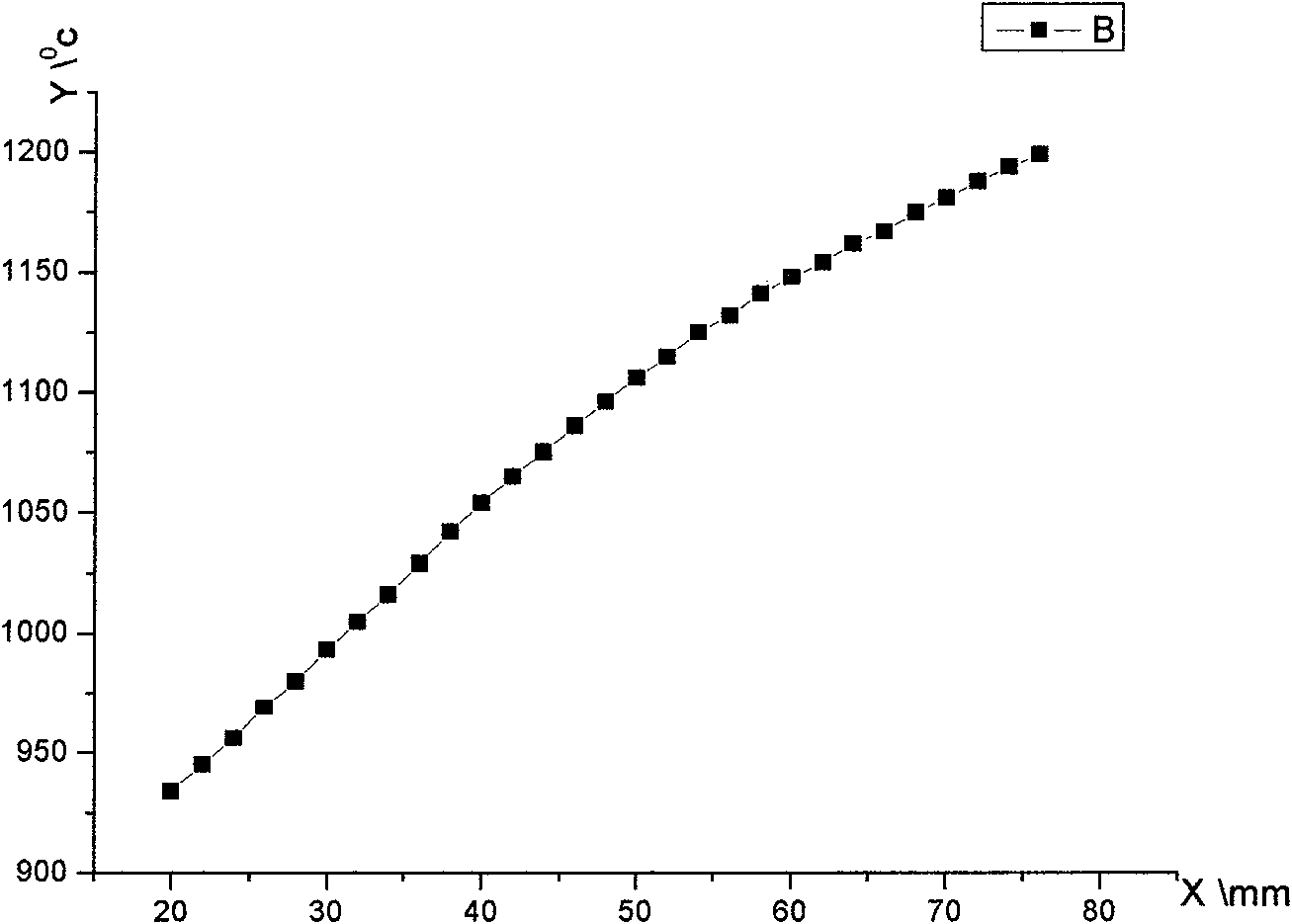

[0035]5. Cool down Use the FP93 automatic temperature controller produced by SHIMADEN, and uniformly cool down at a rate of 4°C / hour to grow crystals. Since the pre-adjusted temperature gradient in the furnace is 8° C. / mm, the actual crystal gro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com