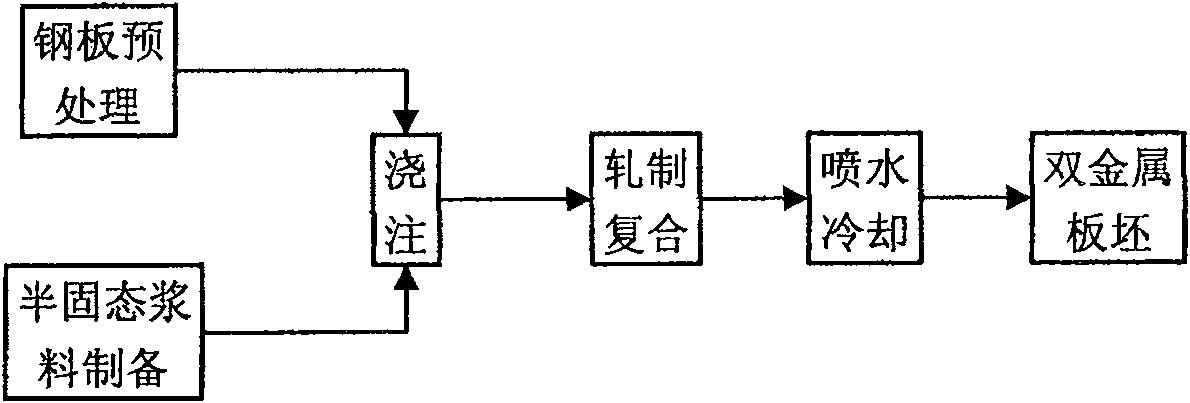

Composite technique for rolling semi-solid state copper-lead bearing alloy/steel bi-metal

A copper-lead bearing, rolling composite technology, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve problems such as poor adhesion, lead segregation, looseness, etc., to eliminate looseness, solve lead segregation, improve The effect of interfacial bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] The grade of copper-lead bearing alloy selected is CuPb22Sn, and its main component weight percentage content is 22.0% Pb, 1.0% Sn, and the rest is Cu. The steel plate is an ordinary low-carbon steel plate with a carbon content of 0.2%, and the size of the steel plate is 150mm in length / 100mm in width / 5mm in thickness. The specific process for preparing bimetallic slabs is as follows:

[0026] 1) steel plate pretreatment

[0027] First, polish the surface of the steel plate with a wire brush to remove surface dirt. After polishing, soak the steel plate in 10% NaOH solution at 80°C for 5 minutes to remove grease, shake it when taking it out, and then use hot water at 60°C to remove residual alkali. Then put it into 10% HCl solution for derusting for 8 minutes, and the surface of the steel plate is bright silvery white. After rinsing the remaining acid solution on the surface of the steel plate with clean water, put the steel plate in 90°C borax aqueous solution (20% c...

example 2

[0036] The selected copper-lead bearing alloy and the composition and size of the steel plate are the same as the example 1, and the concrete process for preparing the bimetallic slab is as follows:

[0037]1) The process is the same as in Example 1, but the preheating temperature of the steel plate is 500°C.

[0038] 2) The process is the same as Example 1, but the temperature of the prepared semi-solid copper-lead bearing alloy slurry is 970°C.

[0039] 3) After the steel plate is preheated to 500°C, it is taken out from the box-type resistance furnace, and the prepared copper-lead alloy semi-solid slurry is poured on the steel plate, and the thickness of the copper-lead alloy layer is 8mm. The semi-solid copper-lead alloy and solid steel plate are sent to the rolling mill for rolling and compounding. The rolling speed is 30mm / s. After rolling, the thickness of the steel plate remains basically unchanged, and the thickness of the copper-lead alloy layer is 4mm.

[0040] 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com