Preparation method of ammonium poly-vanadate

A technology of ammonium polyvanadate and calcium vanadate, applied in chemical instruments and methods, vanadium compounds, inorganic chemistry, etc., can solve the problem that potassium and sodium content cannot be controlled correspondingly, the amount of ammonium carbonate added is large, and the production cost is high. problems, to achieve good economic and social benefits, reduce ammonia concentration, and improve the effect of vanadium grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

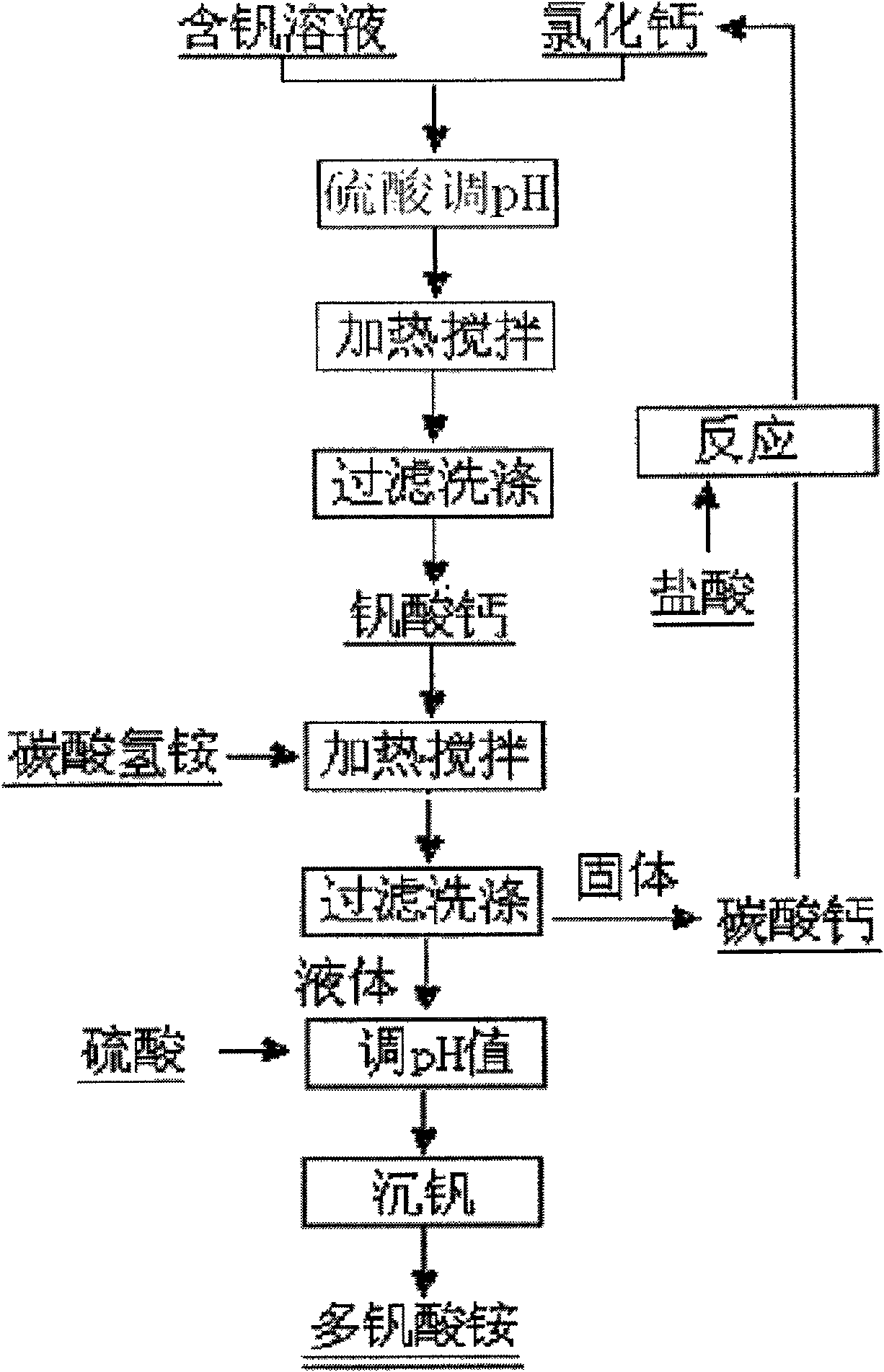

Method used

Image

Examples

Embodiment 1

[0024] Embodiment one prepares ammonium polyvanadate with the inventive method

[0025] Take 1400ml of a solution with a vanadium concentration of 33.1g / L, add 188ml of a 500g / L calcium chloride solution; under stirring conditions, add milk of lime to adjust the pH of the solution to 9.46; heat to boiling for 40min. Obtain calcium vanadate 153.1g, calcium vanadate TV is 29.83%; Precipitation calcium vanadate supernatant liquid volume is 1120ml, TV is 0.408g / L; Calcium vanadate washing solution volume is 267ml, TV is 0.128g / L; Vanadium The precipitation rate was 98.94%.

[0026] Take 100 g of this calcium vanadate containing 29.83% vanadium, add it into 1000 ml of a solution containing 5% ammonium bicarbonate, stir and heat to boiling, and react for 30 minutes. After the reaction is completed, filter, wash the precipitated vanadium with water, combine the filtrate and washing water, the volume is 1440mL, the TV content is 20.25g / L, and the vanadium leaching rate is 97.77%. Af...

Embodiment 2

[0027] Embodiment two prepares ammonium polyvanadate with the inventive method

[0028] Take 1000ml of a solution with a vanadium concentration of 51.82g / L, add 210ml of a 500g / L calcium chloride solution; under stirring conditions, add milk of lime to adjust the pH of the solution to 9.26; heat to boiling, and react for 30min. Obtain calcium vanadate 185.2g, calcium vanadate TV is 27.62%; Precipitation calcium vanadate supernatant volume is 990ml, TV is 0.58g / L; Calcium vanadate washing solution volume is 210ml, TV is 0.054g / L; Vanadium The precipitation rate was 98.87%.

[0029] Take 100 g of this calcium vanadate containing 27.62% vanadium, add it to 350 mL of a solution containing 15% ammonium bicarbonate, stir and heat to boiling, and react for 30 minutes. After the reaction is completed, filter, wash the precipitated vanadium with water, combine the solution and washing water, the volume is 825mL, the TV content is 32.82g / L, and the vanadium leaching rate is 98.03%. Af...

Embodiment 3

[0030] Embodiment three uses the inventive method to prepare ammonium polyvanadate

[0031] Take 1000ml of a solution with a vanadium concentration of 35.6g / L, add 200ml of a 500g / L calcium nitrate solution; under stirring conditions, add milk of lime to adjust the pH of the solution to 9.1; heat to boiling, and react for 30min. 107.98 g of calcium vanadate was obtained, and the TV of calcium vanadate was 32.45%. After the precipitated calcium vanadate supernatant was combined with washing water, the volume was 1550 ml, the TV was 0.36 g / L, and the vanadium precipitation rate was 98.43%.

[0032] Take 100g of this calcium vanadate containing 32.45% vanadium, add it into 350mL solution containing 15% ammonium bicarbonate, stir and heat to 85°C, and react for 60min. After the reaction is completed, filter, wash the precipitated vanadium with a small amount of water, combine the solution and washing water, the volume is 886mL, the TV content is 36.2g / L, and the vanadium leaching ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com