Method for preparing thin film type photon lattice structure GaN base LED

A technology of light emitting diodes and photonic lattices, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as small tolerances, and achieve the effect of reducing requirements and improving light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

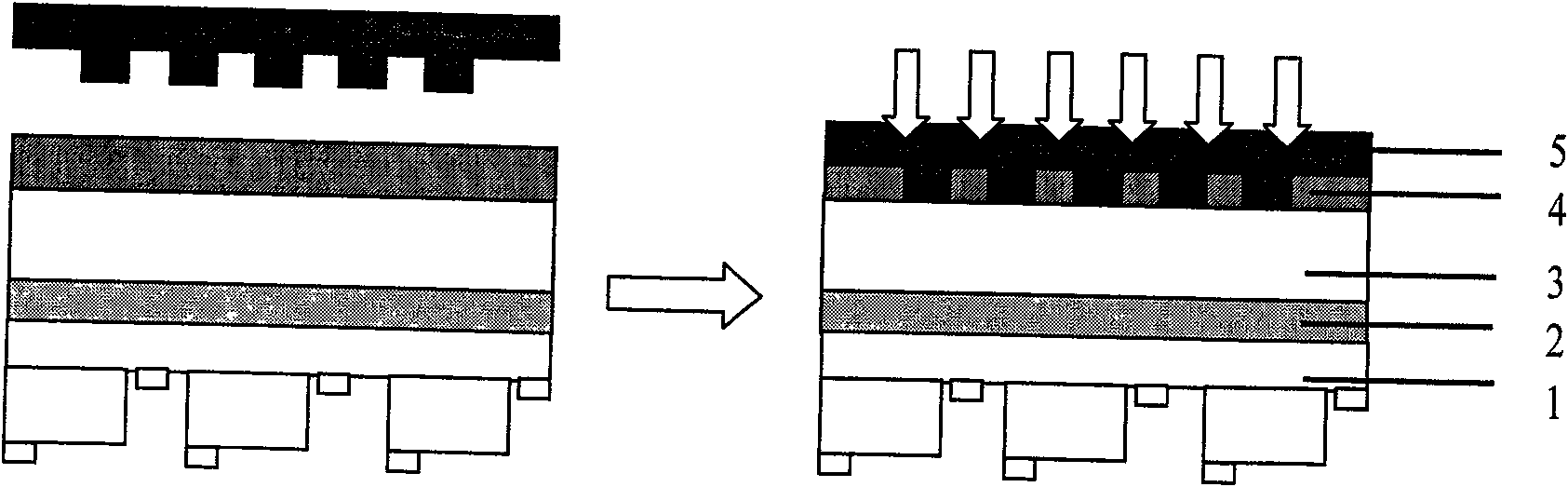

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0030] 1. Preparation of GaN-based light-emitting diode (LED) chips

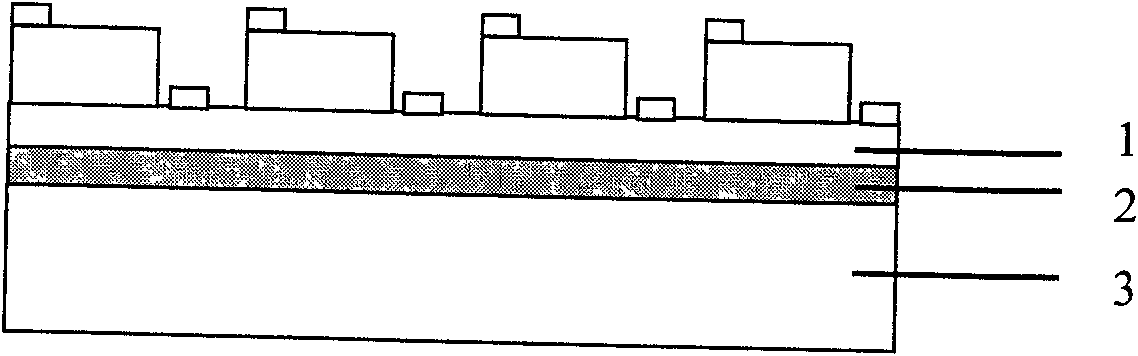

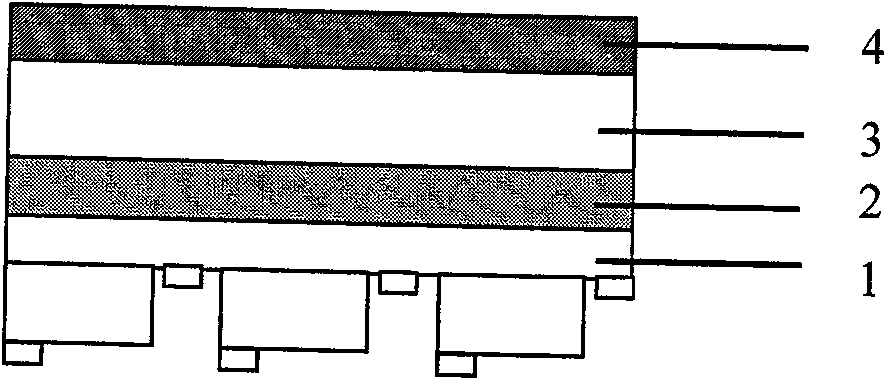

[0031] GaN-based LED materials including non-doped GaN layers are grown on sapphire substrates by epitaxial technology, such as figure 1 shown. That is, a layer of non-doped GaN is grown on the sapphire substrate with a thickness of 0.1-2 μm. Then grow an n-type GaN layer, multiple quantum wells, and a p-type GaN layer on the non-doped GaN layer, and prepare GaN-based light-emitting diodes (LEDs) by photolithography, dry etching, and metal deposition to form a sapphire substrate. on GaN-based chips.

[0032] Wherein, the stacking sequence of the n-type GaN layer, the multiple quantum wells and the p-type GaN layer determines whether the prepared light-emitting diode is a front-chip type or a flip-chip type.

[0033] The sapphire substrate can be polished or unpolished, wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com